Ceramic grouting forming method and mold thereof

A technology of grouting molding and molding methods, which is applied in the direction of ceramic molding machines, die-casting molds, mold auxiliary parts, etc., can solve problems such as high cost, easy hollowing, and difficult pressure control, and achieve uniform density, prevent delamination or Cracking, stress cracking reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

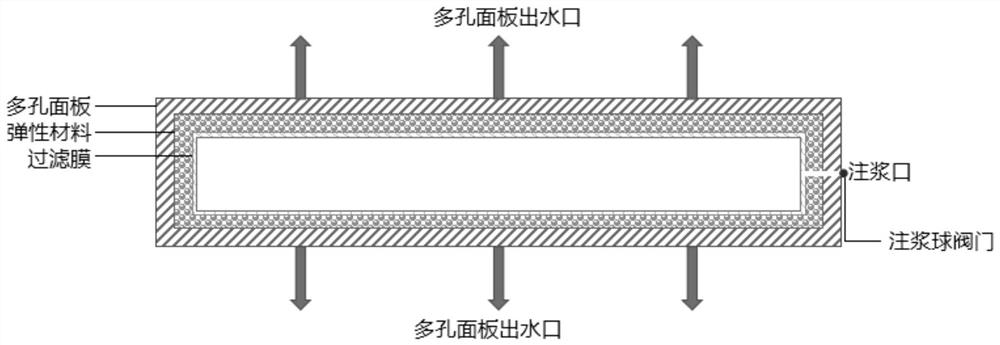

[0024] A 4mm thick EVA foam material layer and a PTFE filter membrane layer with a pore size of 1.2 μm are sequentially laid on the inner surface of the porous panel. The 25% compressive stress of the EVA foam material layer is 45-55kPa. Inject the alumina ceramic slurry into the mold at a pressure of 0.1 MPa from the grouting port. After the pressurized grouting is completed, keep the pressure at 0.1 MPa for 4 hours. After the pressure is maintained, close the grouting valve and dry under normal temperature and pressure. After 8 days, the green body was demoulded to obtain the green body, which was then sintered at 1650°C after placing the green body to a constant weight.

Embodiment 2

[0026] On the inner surface of the porous panel, a 12mm thick EVA foam material layer and a polypropylene filter membrane layer with a pore size of 0.5 μm are sequentially laid. The 25% compressive stress of the EVA foam material layer is 45-55kPa. Inject the alumina ceramic slurry into the mold at a pressure of 0.5 MPa. After the pressurized grouting is completed, keep the pressure at 0.5 MPa for 12 hours. After the pressure is maintained, close the grouting valve and dry it at room temperature and pressure for 3 days. , Demoulding to get the green body, place the green body to constant weight and then sinter at 1650°C.

Embodiment 3

[0028] On the inner surface of the porous panel, an 8mm thick plastic-rubber composite material layer and a polyethersulfone filter membrane layer with a pore size of 0.8 μm are sequentially laid. The 25% compressive stress of the plastic-rubber composite material layer is 30-50kPa. After closing the mold Inject the alumina ceramic slurry into the mold at a pressure of 0.1MPa through the grouting port. After the pressure grouting is completed, keep the pressure at 0.1MPa for 4 hours. After the pressure keeping, close the grouting valve and place it under normal temperature and pressure. Dry for 8 days, demould to obtain the green body, place the green body to constant weight, and then sinter at 1650°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com