Water-based sound-absorbing heat-insulating fireproof coating and preparation method thereof

A fire retardant coating, water-based technology, applied in the field of indoor coatings, can solve the problems of affecting the sound insulation effect, poor sound insulation effect, easy volatilization of solvents, etc., to achieve the effect of good reflection, firm bonding, and no fear of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

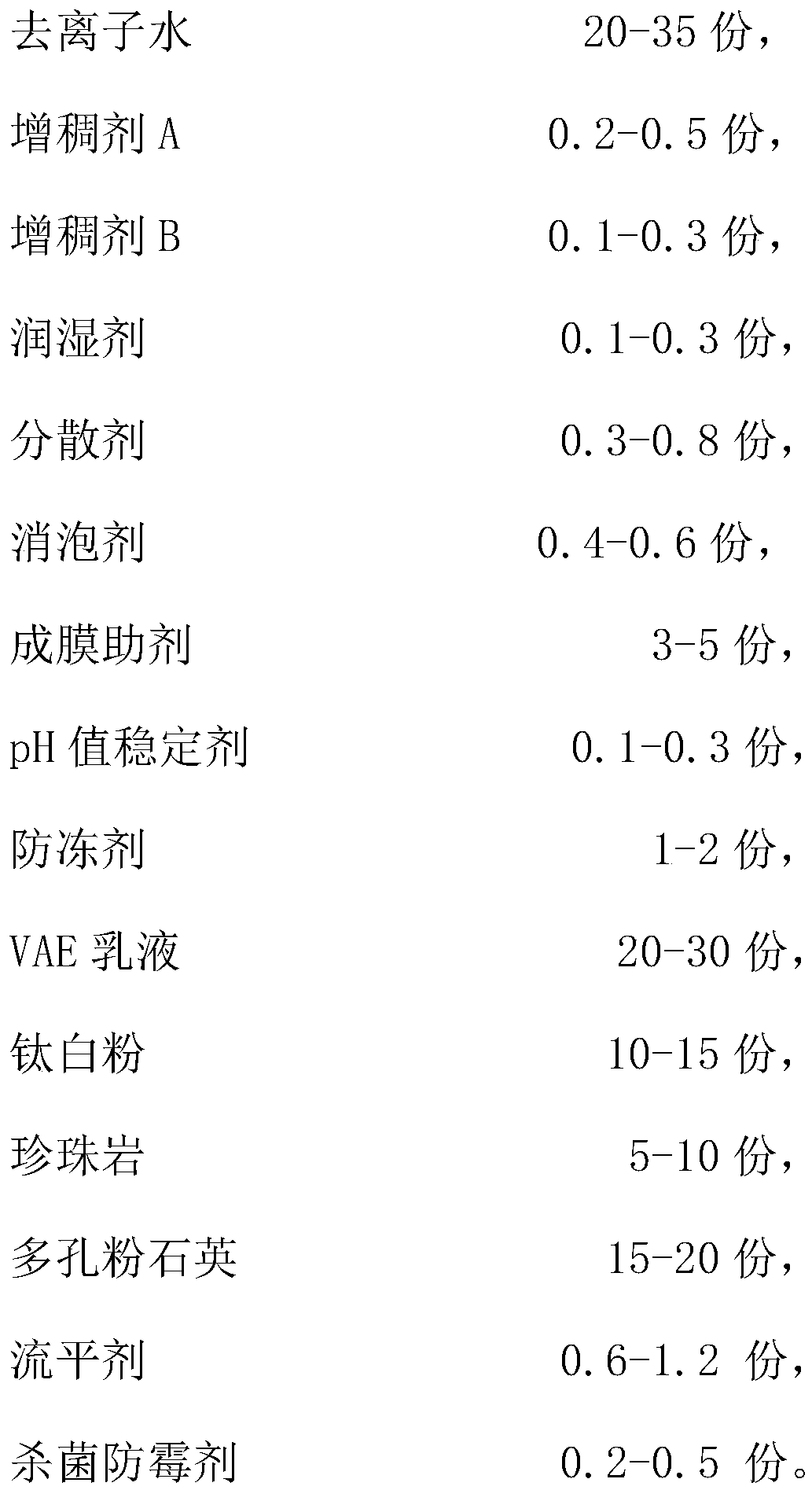

[0034] A water-based sound-absorbing, heat-insulating and fire-resistant coating of the present invention, said water-based sound-absorbing, heat-insulating and fire-proof coating comprises the following components by mass percentage:

[0035]

[0036]

[0037] The wetting agent is a non-ionic low-foaming alkyl polyoxyethylene ether, such as Dow's BD-109, Clariant's LCN407, and the present embodiment selects Dow's BD-109;

[0038] Described thickener is hydroxyethyl cellulose, prevents the sedimentation of heavy pigment and filler, introduces yield value and thixotropy for coating system, as the 250HBR of Ashland; Thickener B is polyurethane thickener; The leveling agent is matched with non-ionic polyurethane thickening and leveling agent, such as RM2020 or RM2050D of Dow Company, and RM2020 is selected in this embodiment. The two thickeners are used together to effectively adjust the rheological behavior of the paint at low, medium and high shear rates to obtain interio...

Embodiment 2

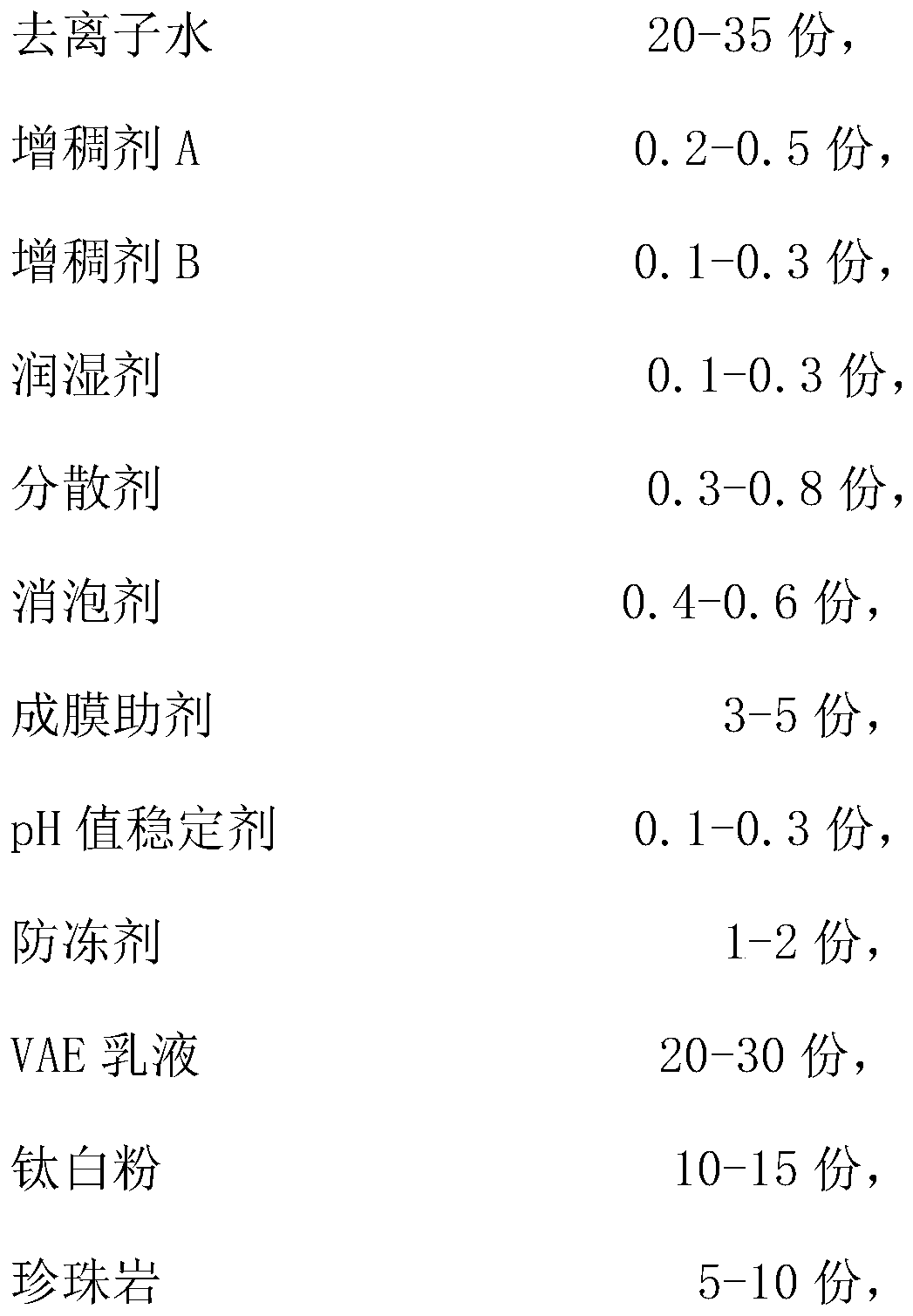

[0048] The difference between embodiment 2 and embodiment 1 is: a kind of water-based sound-absorbing heat-insulating fireproof coating of the present invention, described water-based sound-absorbing heat-insulating fireproof coating comprises the following components by mass percentage:

[0049]

[0050]

[0051] The fungicide and antifungal agent are 2-n-octyl-4-isothiazolin-3-ketone benzimidazole, isothiazole derivatives, hydroxymethyl urea 1,6 dihydroxy-2-5 dioxanes of Pvrogiven company A combination of three in cyclohexane.

[0052] Described antifreeze is propylene glycol.

[0053] The preparation method of water-based sound-absorbing heat-insulating fireproof coating of the present invention comprises the steps:

[0054] Preparation of pre-coagulated slurry in step (1): Add deionized water into the dispersion tank, start stirring, slowly add wetting agent, dispersant, thickener A while stirring at low speed, set the speed at 450r / min, and then disperse for 3min ...

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 1 is: a kind of water-based sound-absorbing heat-insulating fireproof coating of the present invention, described water-based sound-absorbing heat-insulating fireproof coating comprises the following components by mass percentage:

[0060]

[0061] The fungicide and antifungal agent is a combination of two kinds of isothiazole derivatives and hydroxymethylurea 1,6 dihydroxy-2-5 dioxane.

[0062] The preparation method of water-based sound-absorbing heat-insulating fireproof coating of the present invention comprises the following steps:

[0063] Preparation of pre-coagulated slurry in step (1): Add deionized water into the dispersion tank, start stirring, slowly add wetting agent, dispersant, thickener A while stirring at low speed, set the speed at 400r / min, and then disperse for 5min ;

[0064] Pre-mixing in step (2): Increase the dispersion speed, add antifreeze, defoamer, film-forming aid, and pH value stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com