Waterproof thermal-insulation coating with organosilicon-modified styrene-acrylic emulsion

A styrene-acrylic emulsion and thermal insulation coating technology, which is applied in fire-resistant coatings, reflective/signal coatings, etc., to achieve the effects of good fluidity, strong thermal insulation, and stress crack reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

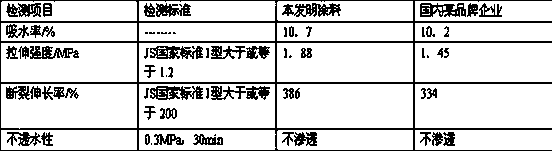

Image

Examples

Embodiment 1

[0022] A silicone-modified styrene-acrylic emulsion waterproof and heat-insulating coating, the raw materials of which include the following components by weight: 80 parts of silicone-modified styrene-acrylic emulsion, 20 parts of hollow glass microspheres, 8 parts of diatomite, and 5 parts of nano-titanium dioxide 30 parts of cement, 20 parts of talcum powder, 20 parts of quartz powder, 0.2 parts of silane coupling agent, 3 parts of dispersing agent, 2 parts of plasticizer, 0.2 parts of defoamer, 1.0 part of film-forming aid, wetting agent 0.1 part, preservative 0.2 part, deionized water 20 parts.

[0023] The hollow glass microspheres are hollow microspheres with a particle diameter of 50 μm.

[0024] The nano-titanium dioxide is rutile nano-titanium dioxide with a particle diameter of 15 nm.

[0025] Described cement is the white cement of 42.5 grades.

[0026] Described talcum powder is 200 mesh sieved powder.

[0027] The quartz powder is 120 mesh sieved powder.

[00...

Embodiment 2

[0031] A silicone-modified styrene-acrylic emulsion waterproof and heat-insulating coating, its raw materials include the following components by weight: 100 parts of silicone-modified styrene-acrylic emulsion, 25 parts of hollow glass microspheres, 15 parts of diatomite, 10 parts of nano-titanium dioxide 40 parts of cement, 30 parts of talcum powder, 30 parts of quartz powder, 0.5 parts of silane coupling agent, 6 parts of dispersing agent, 4 parts of plasticizer, 0.5 part of defoamer, 2.5 parts of film-forming aid, wetting agent 0.3 parts, preservatives 0.5 parts, deionized water 30 parts.

[0032] The hollow glass microspheres are hollow microspheres with a diameter of 100 μm.

[0033] The nano titanium dioxide is rutile nano titanium dioxide with a particle size of 160nm.

[0034] Described cement is the white cement of 42.5 grades.

[0035] Described talcum powder is 400 mesh sieved powder.

[0036] The quartz powder is 400 mesh sieved powder.

[0037] The dispersant ...

Embodiment 3

[0040] A silicone-modified styrene-acrylic emulsion waterproof and heat-insulating coating is characterized in that its raw materials include the following components in parts by weight: 88 parts of silicone-modified styrene-acrylic emulsion, 22 parts of hollow glass microspheres, and 12 parts of diatomite , 8 parts of nano titanium dioxide, 33 parts of cement, 28 parts of talcum powder, 26 parts of quartz powder, 0.4 parts of silane coupling agent, 5 parts of dispersant, 3 parts of plasticizer, 0.4 part of defoamer, 1. .5 parts, 0.2 parts of wetting agent, 0.3 parts of preservative, 26 parts of deionized water.

[0041] The hollow glass microspheres are hollow microspheres with a diameter of 58 μm.

[0042] The nano-titanium dioxide is rutile nano-titanium dioxide with a particle size of 30nm.

[0043] Described cement is the white cement of 42.5 grades.

[0044] Described talcum powder is the sieved powder of passing 300 meshes.

[0045] The quartz powder is 200 mesh sieved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com