Nickel-based high-temperature alloy repair material and preparation method thereof

A nickel-based superalloy and repair material technology, applied in the field of additive manufacturing, can solve the problems of affecting the service life of blades and inconvenient engineering application of preheating temperature, and achieve the effect of reducing stress cracking and improving grain boundary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a nickel-based superalloy repair material of the present invention is specifically implemented according to the following steps:

[0035] Step 1, weighing each component metal according to the percentage of each component in a nickel-based superalloy repair material, and smelting each component metal to obtain an alloy block;

[0036] Step 2, cold processing the alloy block to obtain a billet with a diameter of 50 mm and a length of 600 mm, processing the billet into a bright surface with a surface roughness of 6.3 to obtain a bar;

[0037] Step 3. Put the rod in the rotating electrode powder making equipment as the negative electrode and accelerate the rotation. The positive electrode uses a tungsten electrode. After the power is turned on, the negative electrode is heated and the rod is melted and thrown out. The molten metal material forms uniform powder particles in the inert gas space Scattered to obtain alloy powder;

[0038] Step 4, sievin...

Embodiment 1

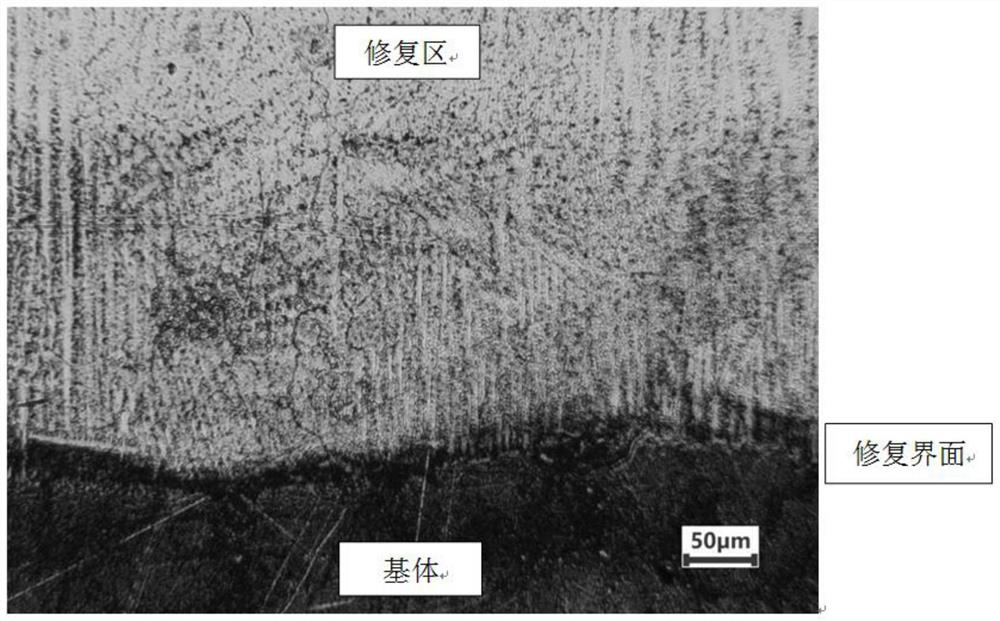

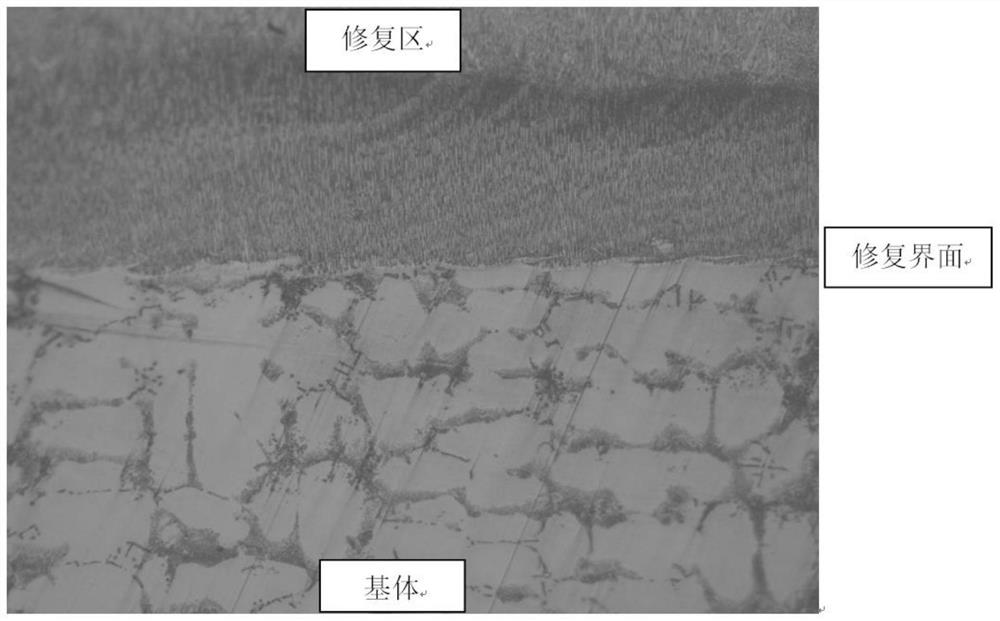

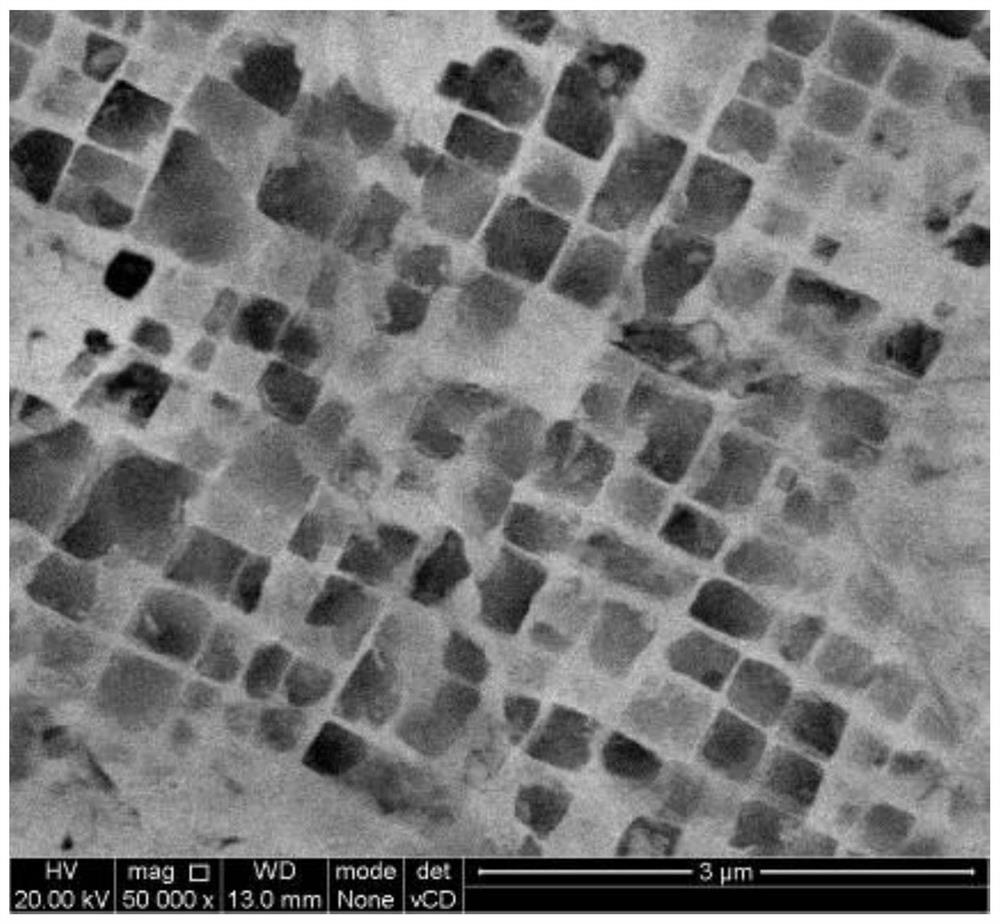

[0051] A nickel-based superalloy repair material, the material is a powder with a particle size of 75-175 μm, and consists of the following components according to mass percentage: Ni: 33%, Co: 47%, Cr: 10%, Al: 2%, Ta : 3%, W: 4%, Y: 0.5%, Hf: 0.5%, the nickel-based superalloy DZ125 is repaired by laser cladding repair method, and the repair material is clad on the surface of the part to be repaired by laser melting powder at high temperature, reaching Metallurgical bonding. Adopted laser repair process parameters: power 600W, scanning speed 420mm / min, powder feeding volume 11g / min. The laser repair process is carried out in an argon protection or vacuum glove box, which ensures the quality stability of the welding pool under high temperature conditions. After the repair, there is no crack on the surface and inside. The bonding interface between the repaired area and the matrix is metallurgical fusion. The structure is uniform and there is no interface. After the repair, t...

Embodiment 2

[0055] A nickel-based superalloy repair material, the material is a powder with a particle size of 75-175 μm, and consists of the following components according to mass percentage: Ni: 18%, Co: 54%, Hf: 1.5%, Al: 4%, Ta : 3%, W: 1.2%, Cr: 18%, Y: 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com