Thermal conductive plastic applying modified carbon material, and preparation method thereof

A technology of thermally conductive plastics and modified carbon, applied in thermally conductive plastics and their preparation, thermally conductive plastics using modified carbon materials and their preparation fields, can solve the effect of changing the surface properties of carbon fibers, fully mixing nano-carbon materials, and localizing Mixing unequal problems, to achieve the effect of improving compatibility, uniform internal structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

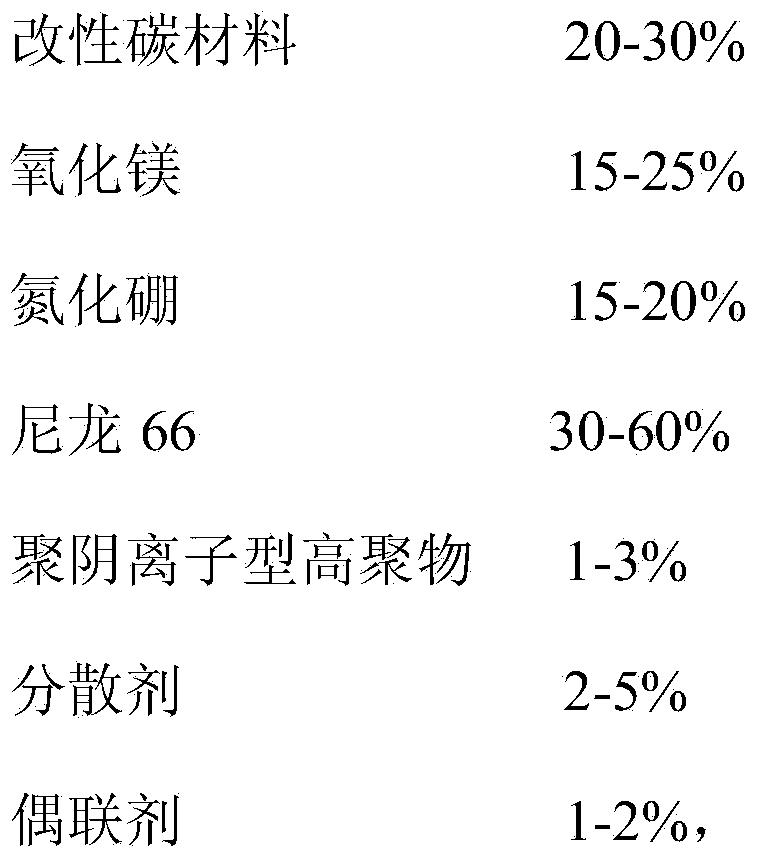

Method used

Image

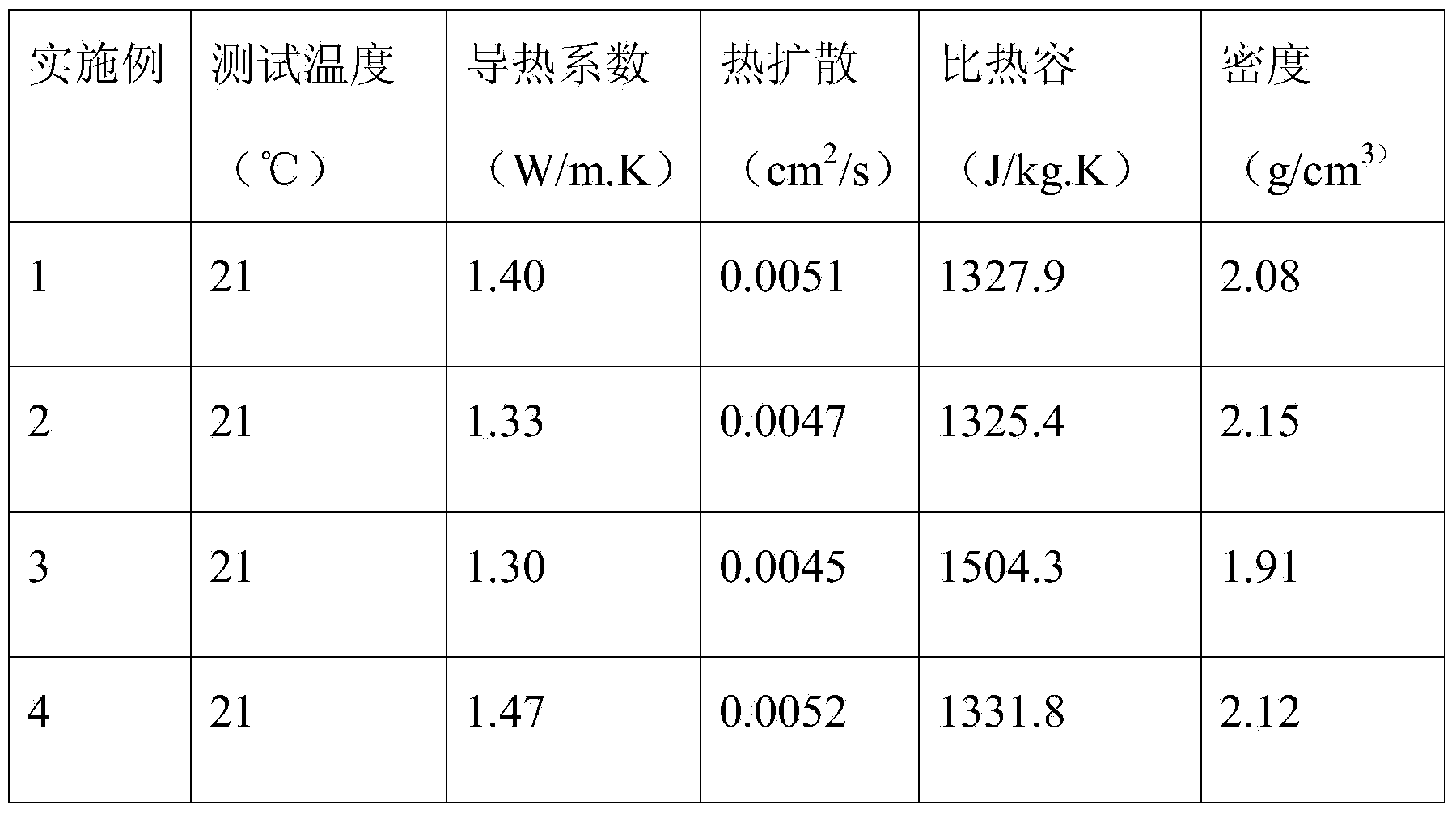

Examples

Embodiment 1

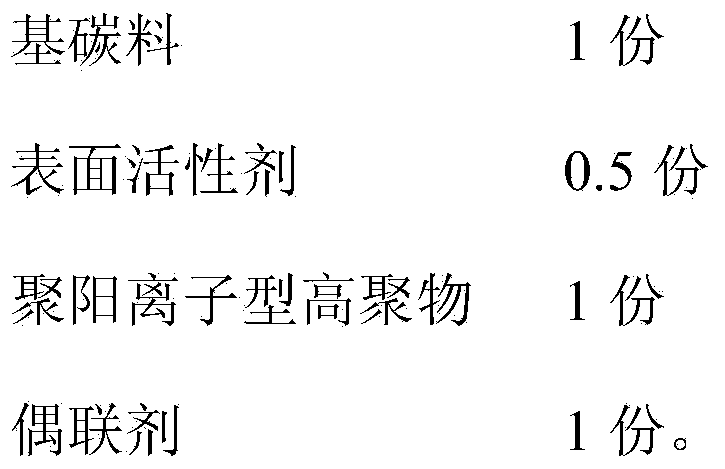

[0038] a. Preparation of modified carbon material: mix water: graphite: sodium chloride: surfactant: silane coupling agent at a mass ratio of 100:1:1:0.5:1 at room temperature to form a premix, and then put it into an ultrasonic Ultrasonic is carried out in the ultrasonic frequency range of 250W in the cleaner, polycationic polymer is slowly added during the ultrasonic process, and the ultrasonic is continued for 45 minutes, then stirred for 20 hours, and then filtered and dried to obtain the modified carbon material;

[0039] b. Preparation of heat-conducting plastics using modified carbon materials: 30% of the modified carbon materials prepared in step a, 20% of magnesium oxide, 15% of boron nitride, 30% of the main plastic, 1% of polyanionic polymers, After blending 2% of the dispersant and 2% of the silane coupling agent, extrude and granulate with a twin-screw extruder at an extrusion temperature of 200-210°C and a melt processing torque of 70N·m.

Embodiment 2

[0041] a. Preparation of modified carbon material: mix water: carbon black: sodium chloride: surfactant: silane coupling agent at a mass ratio of 100:1:1:0.5:1 at room temperature to form a premix, and then put Ultrasonic in the ultrasonic cleaner within the ultrasonic frequency range of 300W, slowly add polycationic high polymer during the ultrasonic process, continue to ultrasonic for 30min, then stir for 24h, then filter and dry to obtain the modified carbon material;

[0042] b. Preparation of heat-conducting plastics using modified carbon materials: 20% of the modified carbon materials prepared in step a, 15% of magnesium oxide, 20% of boron nitride, 39% of the main plastic, 2% of polyanionic polymers, After blending 3% of the dispersant and 1% of the silane coupling agent, extrude and granulate with a twin-screw extruder at an extrusion temperature of 220-230°C and a melt processing torque of 60N·m.

Embodiment 3

[0044] a. Preparation of modified carbon material: Mix water: carbon fiber: sodium chloride: surfactant: silane coupling agent at a mass ratio of 100:1:1:0.5:1 at room temperature to form a premix, and then put it into an ultrasonic Ultrasonic is carried out in the cleaning device within the ultrasonic frequency range of 200W. During the ultrasonic process, polycationic high polymer is slowly added, and the ultrasonic is continued for 60 minutes, then stirred for 22 hours, and then filtered and dried to obtain the modified carbon material;

[0045] b. Preparation of heat-conducting plastics using modified carbon materials: 20% of the modified carbon materials prepared in step a, 25% of magnesium oxide, 15% of boron nitride, 30% of the main plastic, 3% of polyanionic polymers, After blending 5% of the dispersant and 2% of the silane coupling agent, it can be extruded and granulated by a twin-screw extruder under the conditions of an extrusion temperature of 240-250° C. and a mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com