Environment-friendly high-solid-content waterborne polyurethane acrylate composite emulsion as well as preparation method and application thereof

A polyurethane acrylate, high solid content technology, used in polyurea/polyurethane adhesives, polyurea/polyurethane coatings, non-polymer adhesive additives, etc., can solve water resistance, mechanical strength, heat resistance and Poor barrier properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

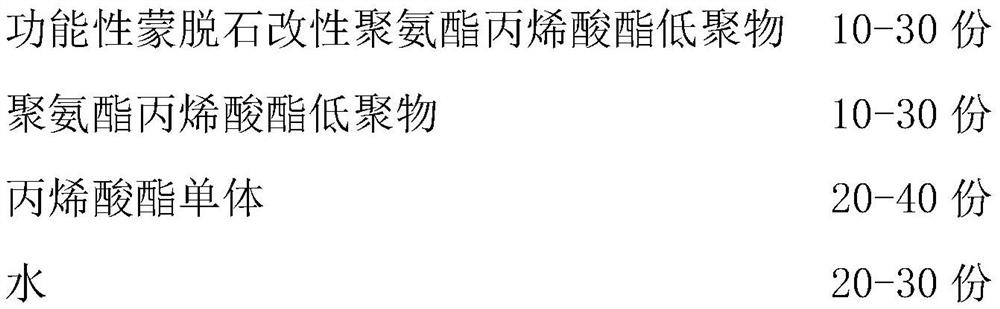

[0035] According to the preparation method of the environment-friendly high solid content aqueous polyurethane acrylate composite emulsion of the present invention, comprise the following steps: (1) mixing: functional montmorillonite modified polyurethane acrylate oligomer, polyurethane acrylate oligomer , acrylate monomer and water are mixed evenly, heated to 60-65°C, stirred by a mixer at 500-800r / min for 30min, and then naturally cooled to room temperature to obtain component A; (2) photoinitiator, leveling agent and After the water is stirred evenly at room temperature, component B is obtained; (3) component A and component B are mixed, stirred evenly at room temperature, left standing for defoaming, and stored away from light to obtain an environmentally friendly high-solid content water-based polyurethane acrylate composite emulsion.

[0036] The environment-friendly high-solid content aqueous polyurethane acrylate composite emulsion according to the present invention can...

Embodiment 1

[0039] (1) Preparation of functional montmorillonite modified polyurethane acrylate oligomer:

[0040] (1) According to the number of parts by mass, weigh 10 parts of sodium montmorillonite, disperse it in 50 parts of water, first add 2 parts of dodecyltrimethylammonium chloride, stir and heat in the mixer for 1h, and the speed is 500 rpm / min, temperature 70°C, suction filtration, washing with deionized water, drying to obtain primary intercalation montmorillonite;

[0041] (2) Disperse the above-mentioned primary intercalated montmorillonite in 50 parts of water, add 6 parts of methacryloyloxyethyltrimethylammonium chloride in parts by mass, stir and heat in a mixer for 1 hour, and rotate at 500 rpm / min, temperature 60°C, suction filtration, deionized water washing, drying, to obtain secondary intercalation montmorillonite;

[0042] (3) Disperse the above-mentioned secondary intercalated montmorillonite in 50 parts of aqueous solution of polyvinyl alcohol with a concentrat...

Embodiment 2

[0056] (1) Preparation of functional montmorillonite modified polyurethane acrylate oligomer:

[0057] (1) According to the number of parts by mass, weigh 20 parts of sodium montmorillonite, disperse in 50 parts of water, first add 4 parts of dodecyltrimethylammonium chloride, stir and heat in the mixer for 2 hours, the speed is 800 rpm min, temperature 80°C, suction filtration, deionized water washing, drying, to obtain primary intercalation montmorillonite;

[0058] (2) Disperse the above-mentioned primary intercalation montmorillonite in 50 parts of water, add 8 parts of methacryloyloxyethyltrimethylammonium chloride in parts by mass, stir and heat in a mixer for 2 hours, and the speed is 800 rpm / min, temperature 70°C, suction filtration, deionized water washing, drying, to obtain secondary intercalation montmorillonite;

[0059] (3) Disperse the above-mentioned secondary intercalation montmorillonite in 50 parts of aqueous solution of polyvinyl alcohol with a concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com