Patents

Literature

44results about How to "Reduce steam pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano metal fluid with high heat-transfer performance

ActiveCN1955252AImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalSolvent

This invention provides a high heat transfer performance liquid nano-metal. It relates to cooling fluid working medium, and especially it can be used under high rush density condition which need high intensity cooling fluid working medium for heat exchanging and cooling, such as computer array and reactor. The solvent of this invention is liquid metal, and the soluble of this invention is nanometer particle. This invention solve the problem of high price of present metal liquid cooling working medium and the limited performance of common metal liquid, leaking out easily taken place using common liquid and easy forming sediment of present nanometer cooling agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

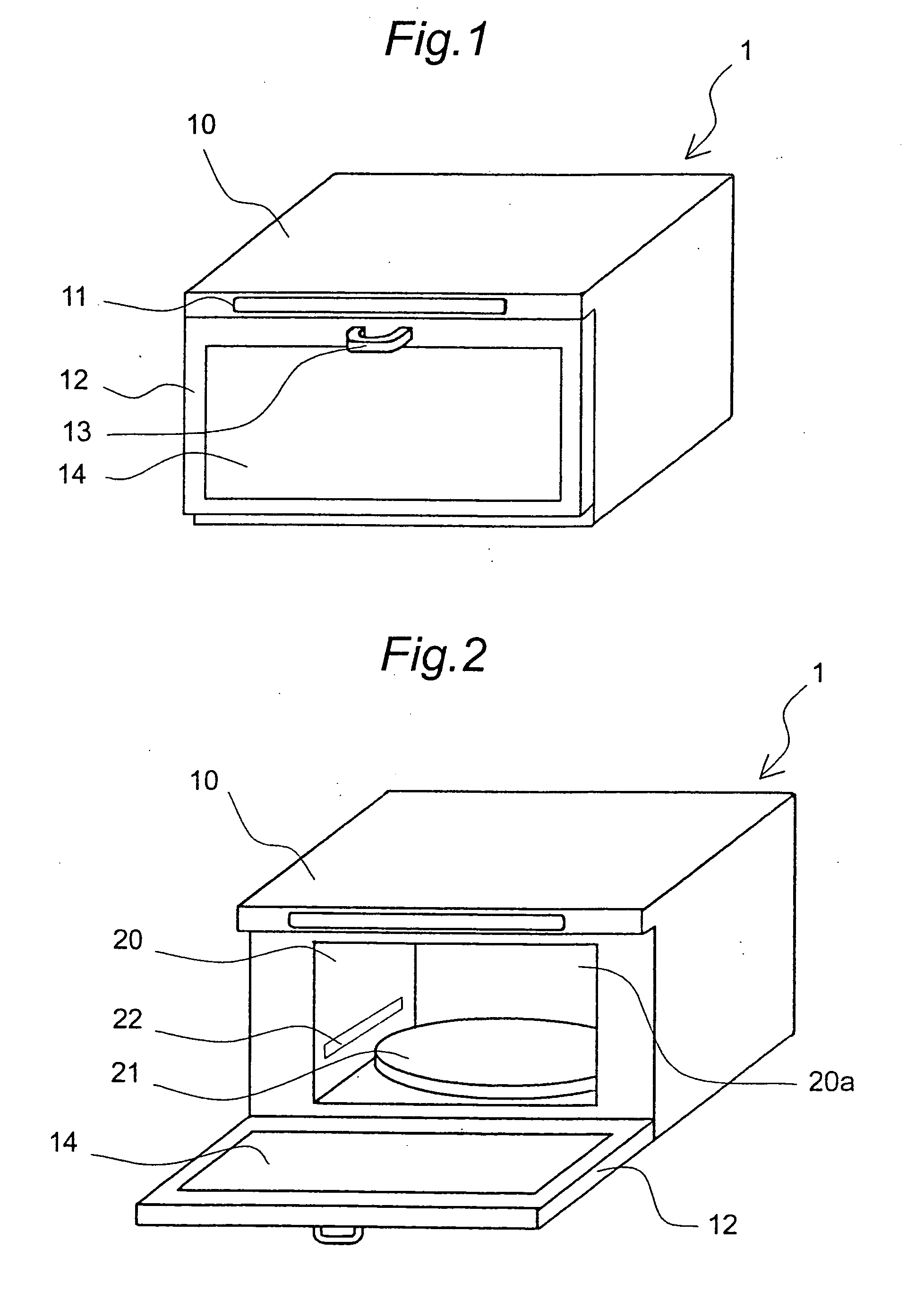

Heating cooker

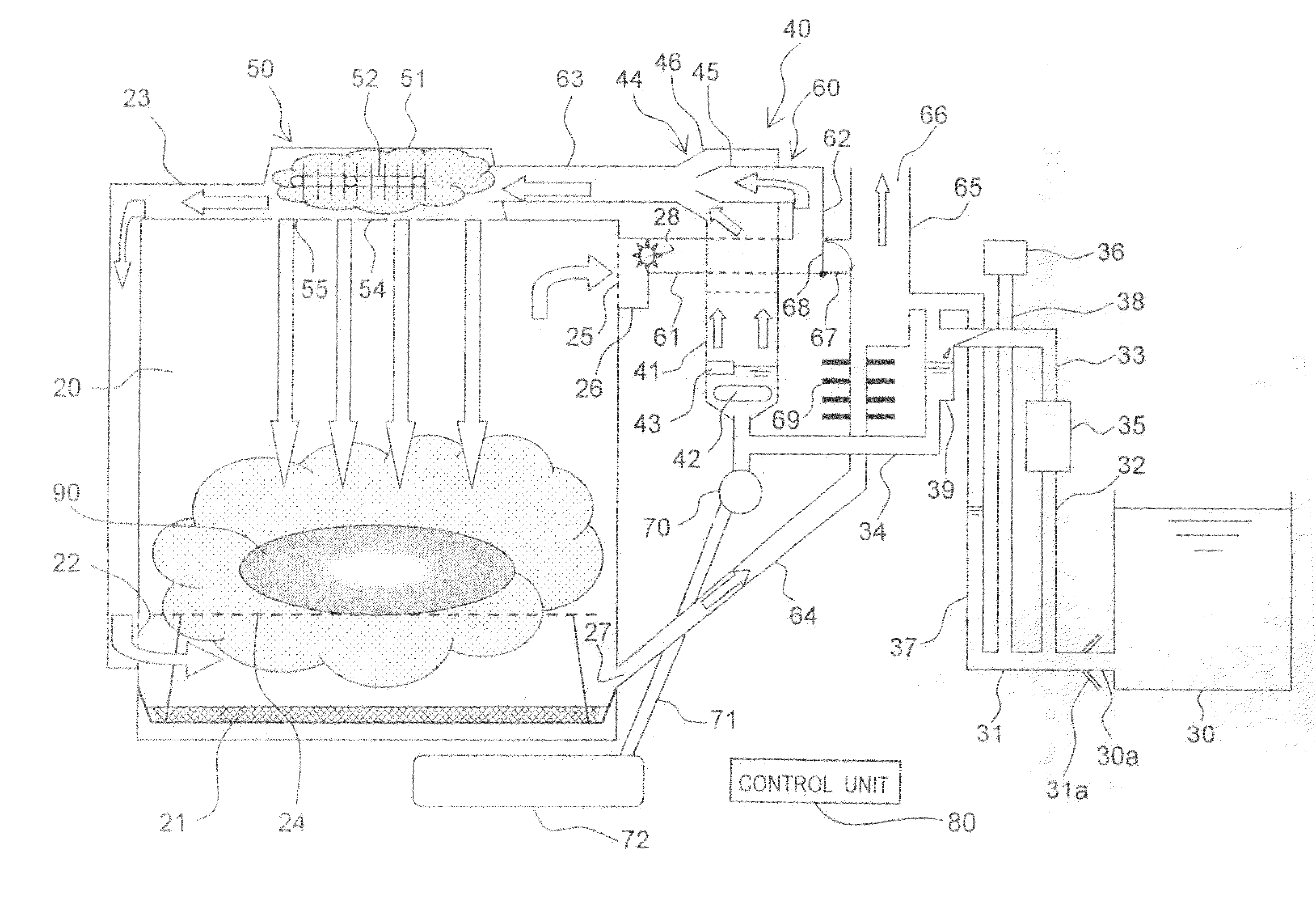

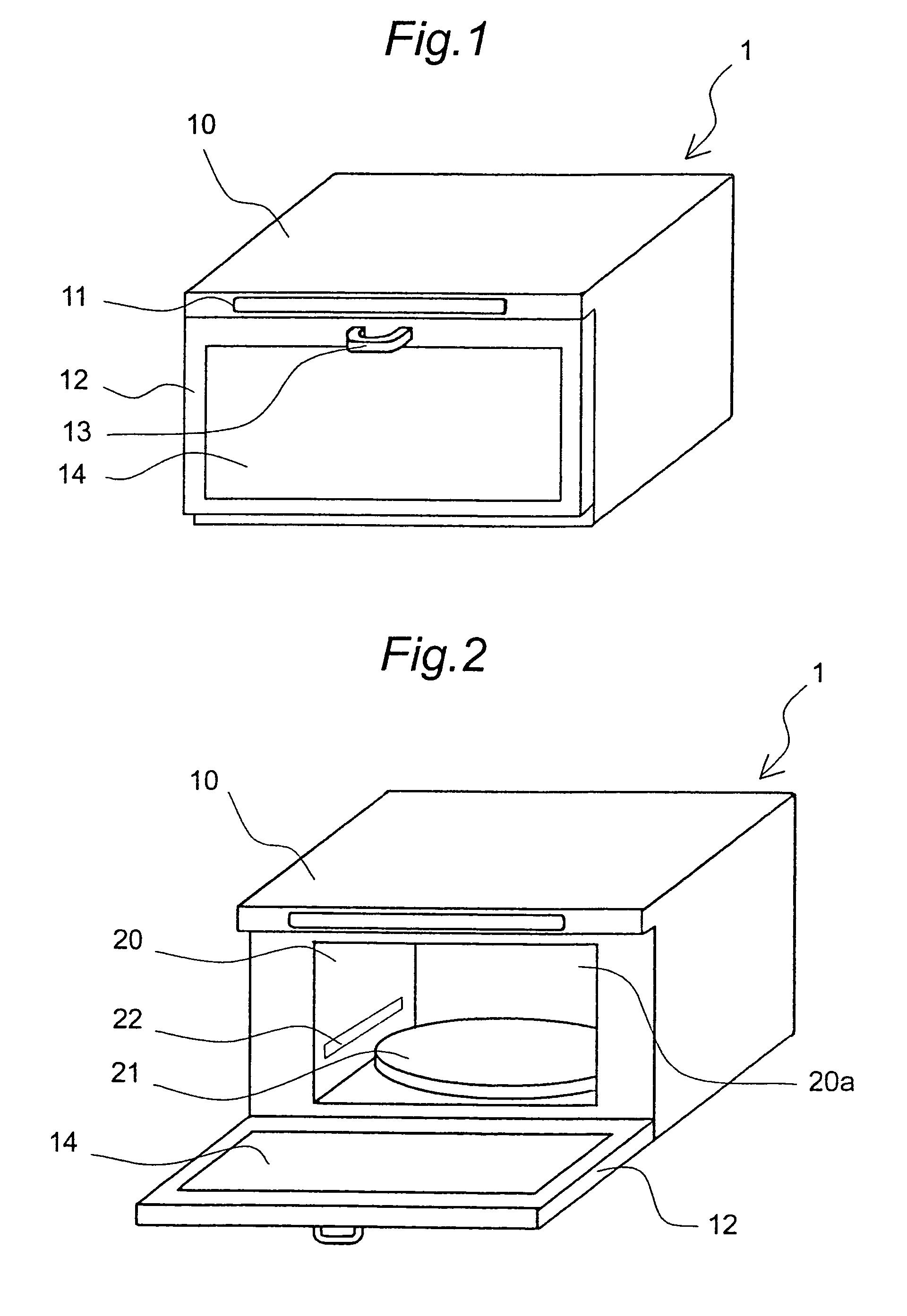

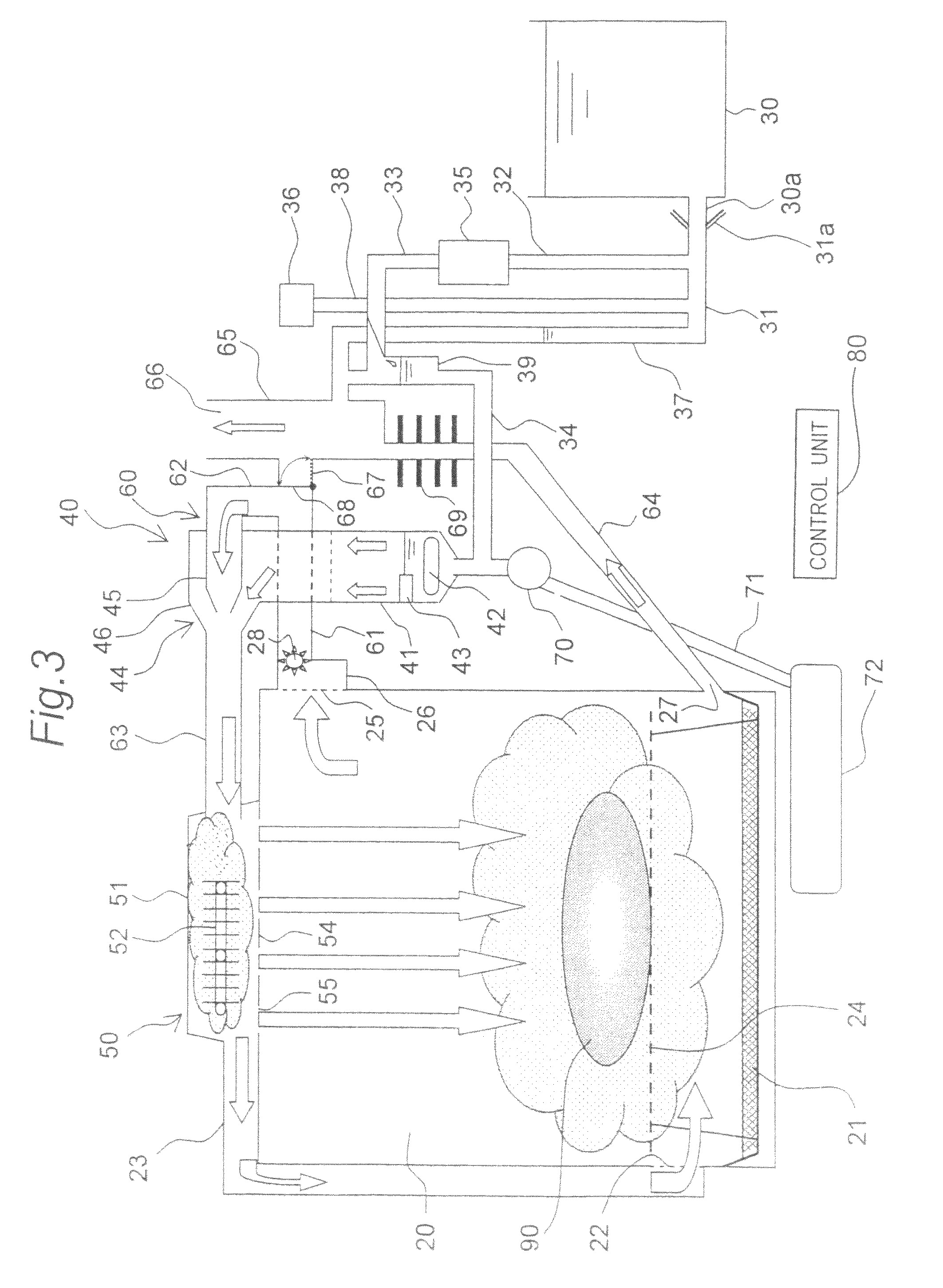

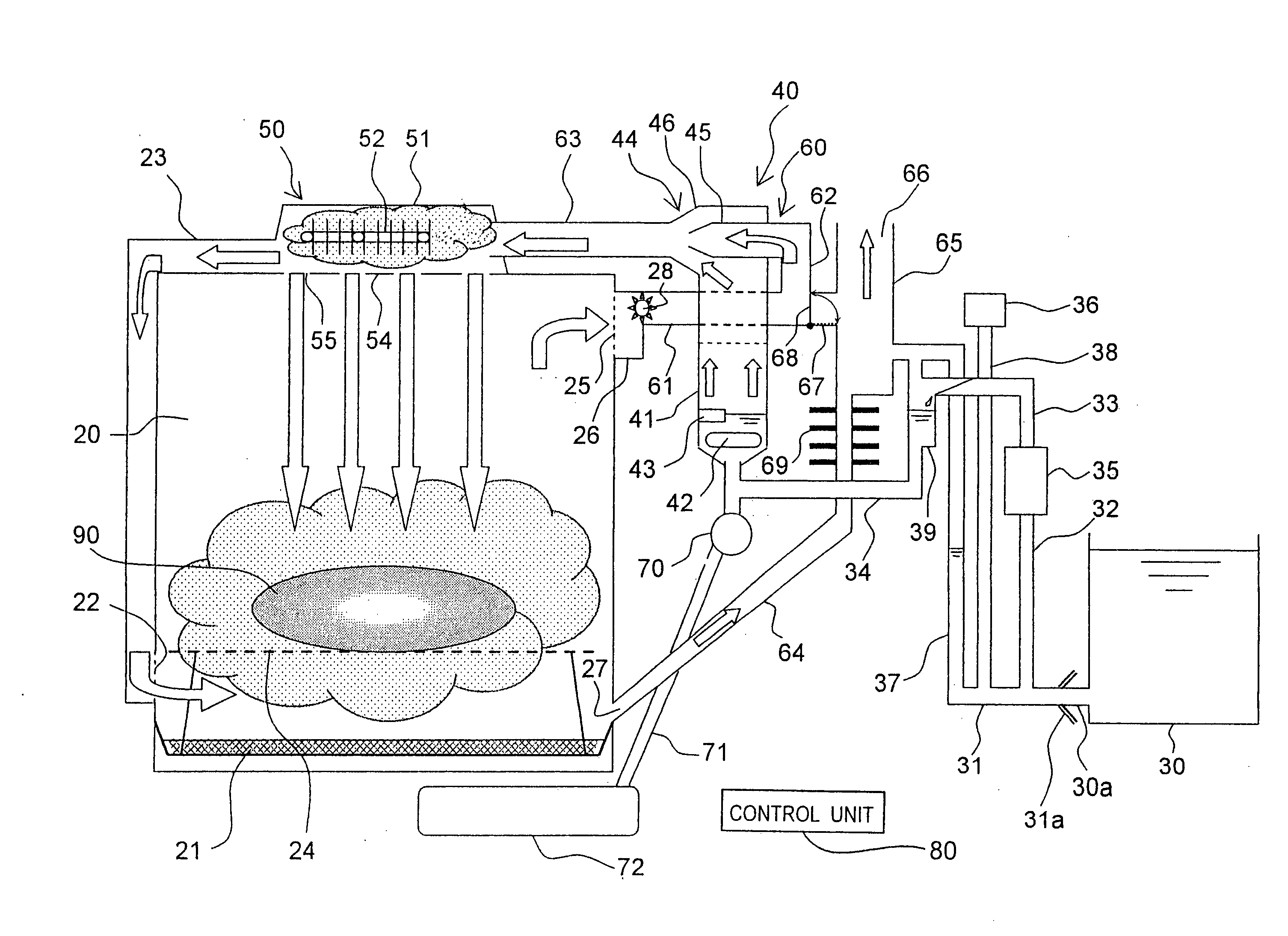

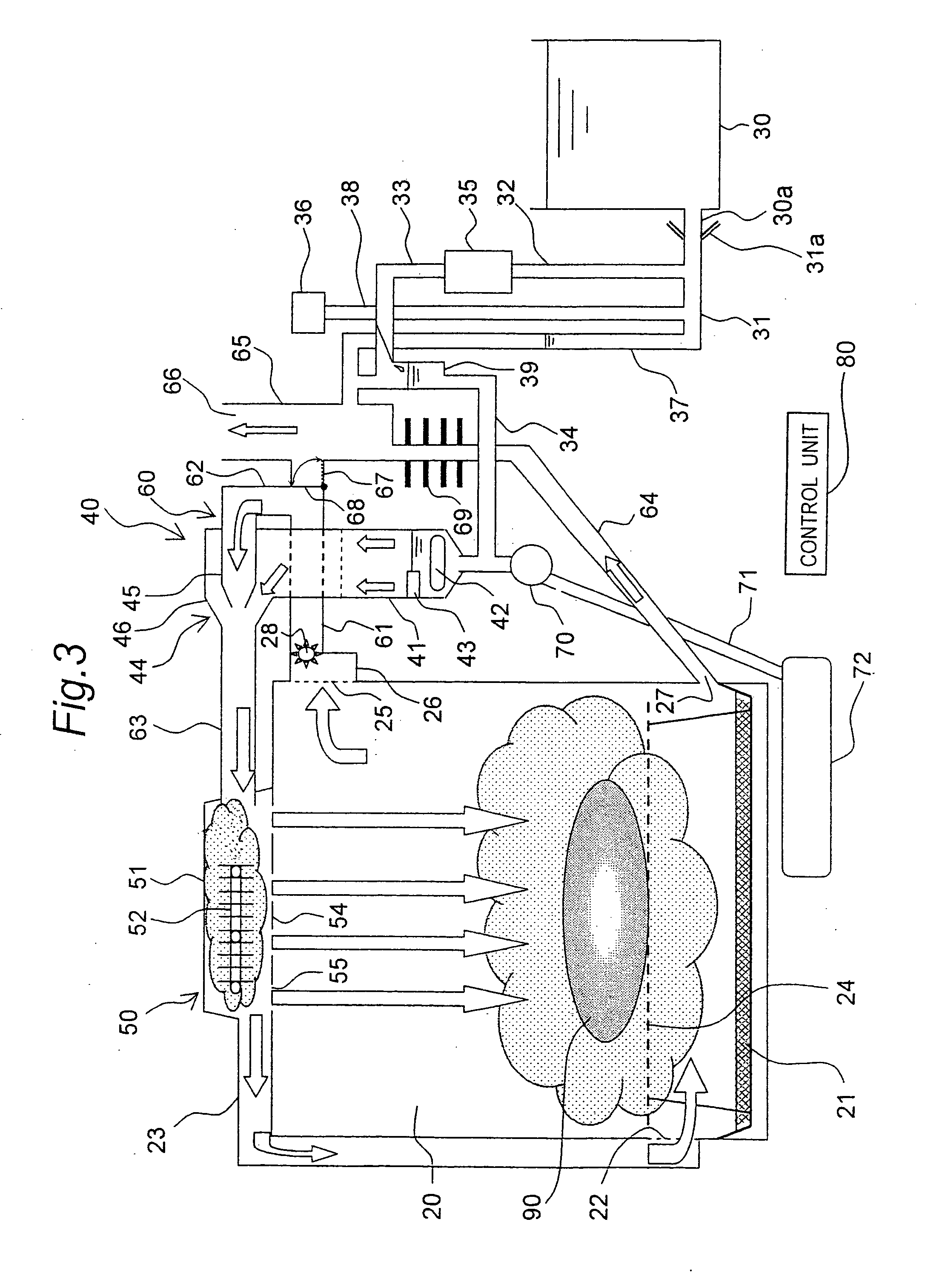

InactiveUS9173408B2Accurate detectionReduce steam pressureDomestic stoves or rangesSteam generation heating methodsSteam pressureWater level

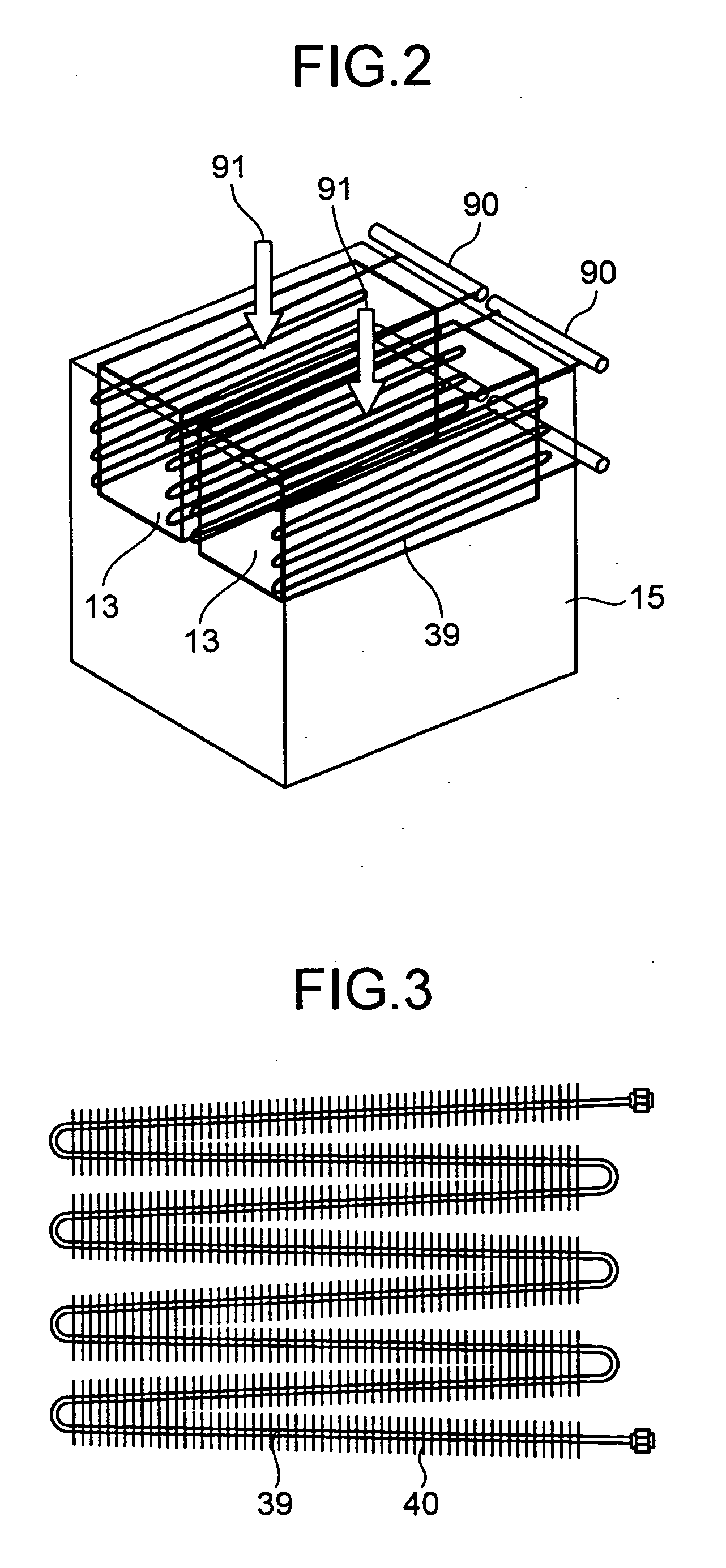

A water level sensor (91) is provided in an auxiliary tank (39) whose bottom portion communicates to a bottom portion of a pot (41) for generating steam and which is opened to the atmosphere. When water in the pot (41) keeps boiling and the stop time of a pump (35) reaches a predetermined time (e.g., 60 sec.), the pump (35) is driven for a predetermined time (e.g., 6 sec.) to supply water to the pot (41). This temporarily suppresses the boiling of water in the pot (41), lowering a steam pressure in a space formed by an external circulation passage (60), a heating chamber, and the pot (41). The water level in the auxiliary tank (39) then returns to a normal one, making it possible to correctly detect the water level in the pot (41).

Owner:SHARP KK

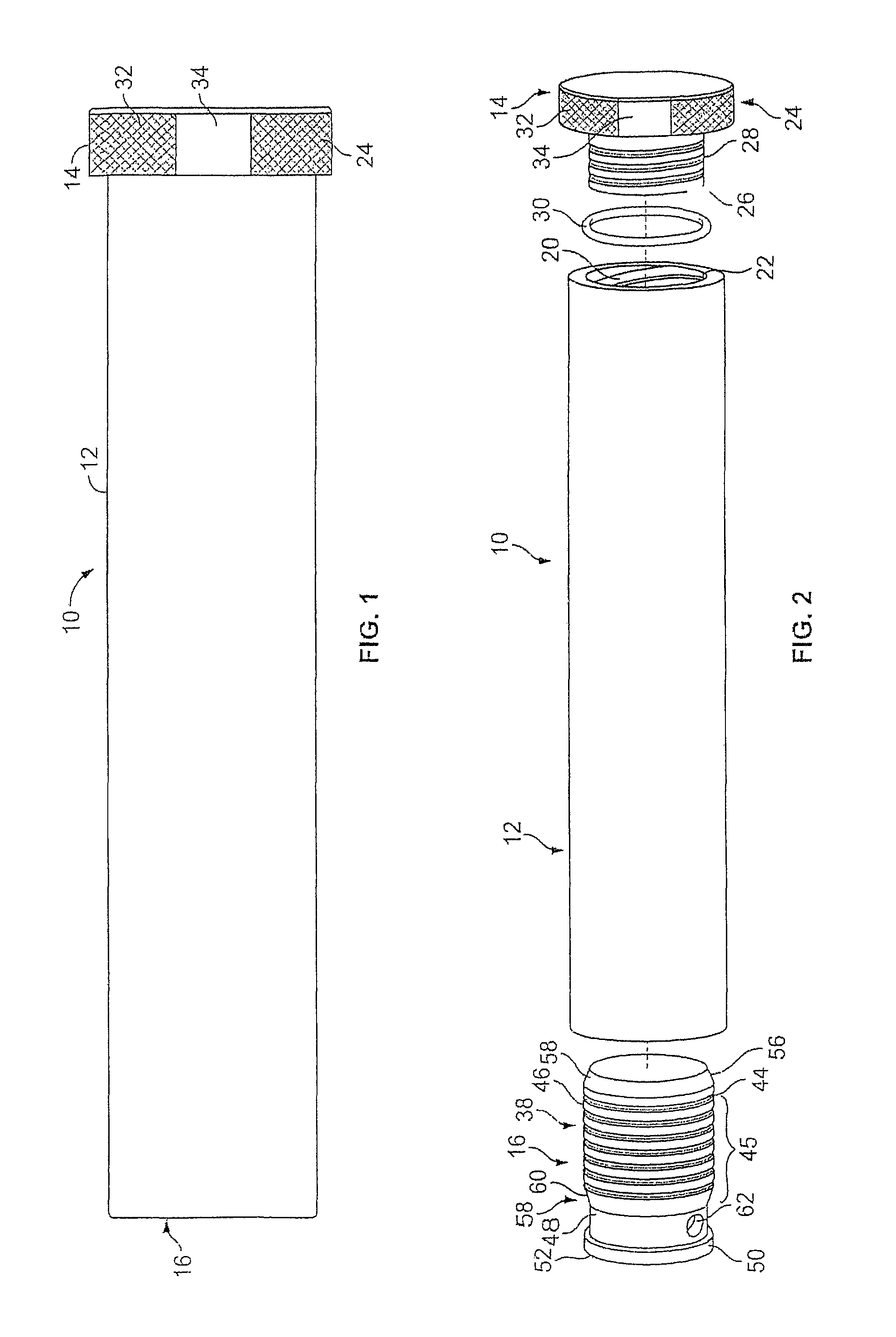

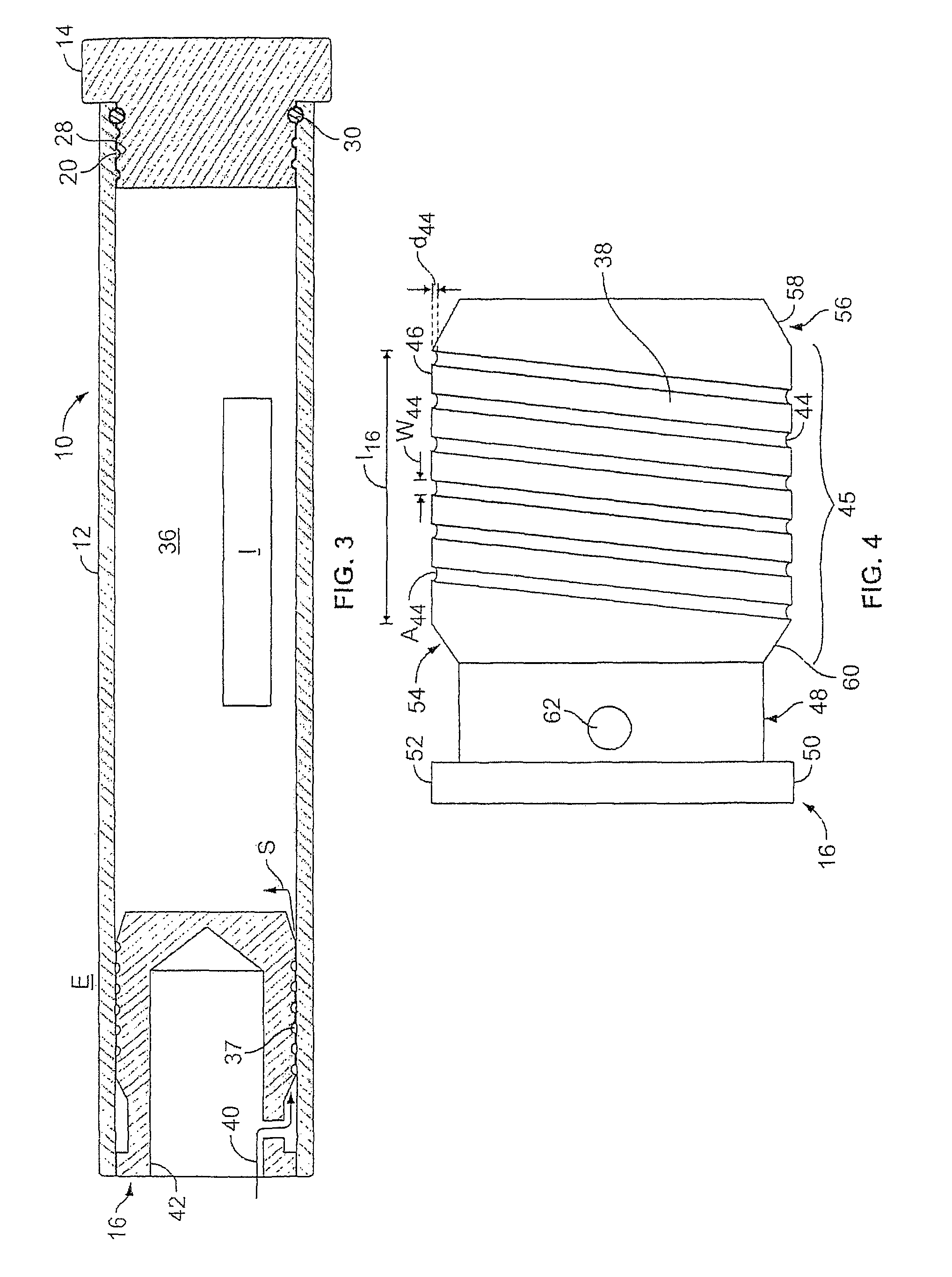

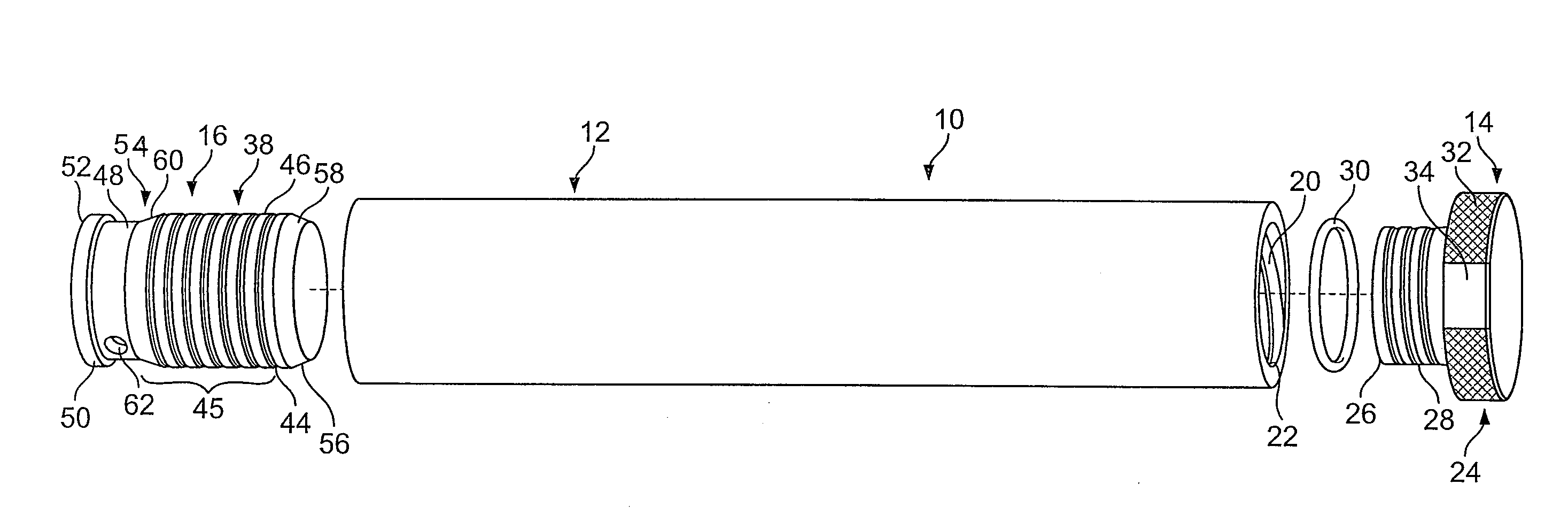

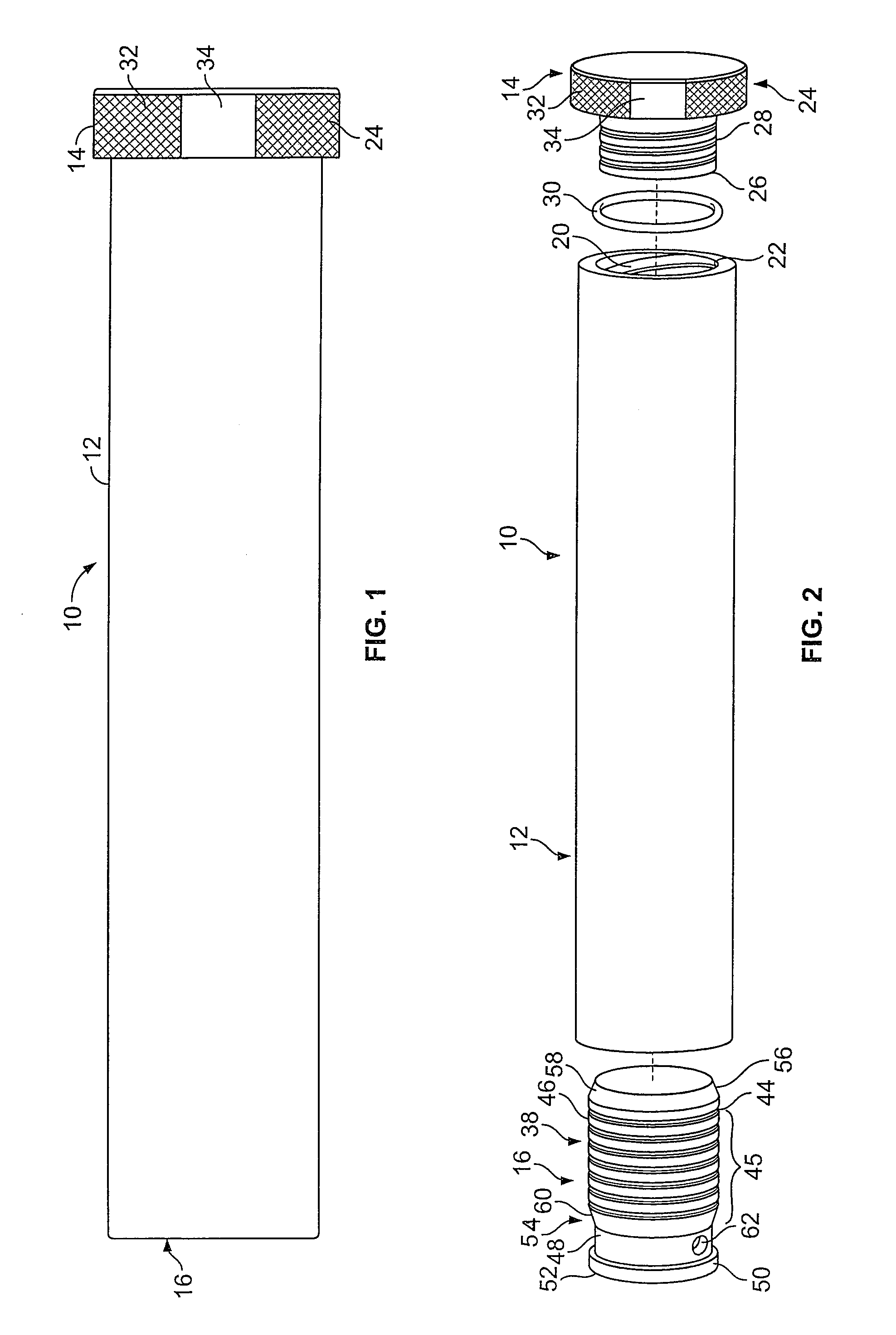

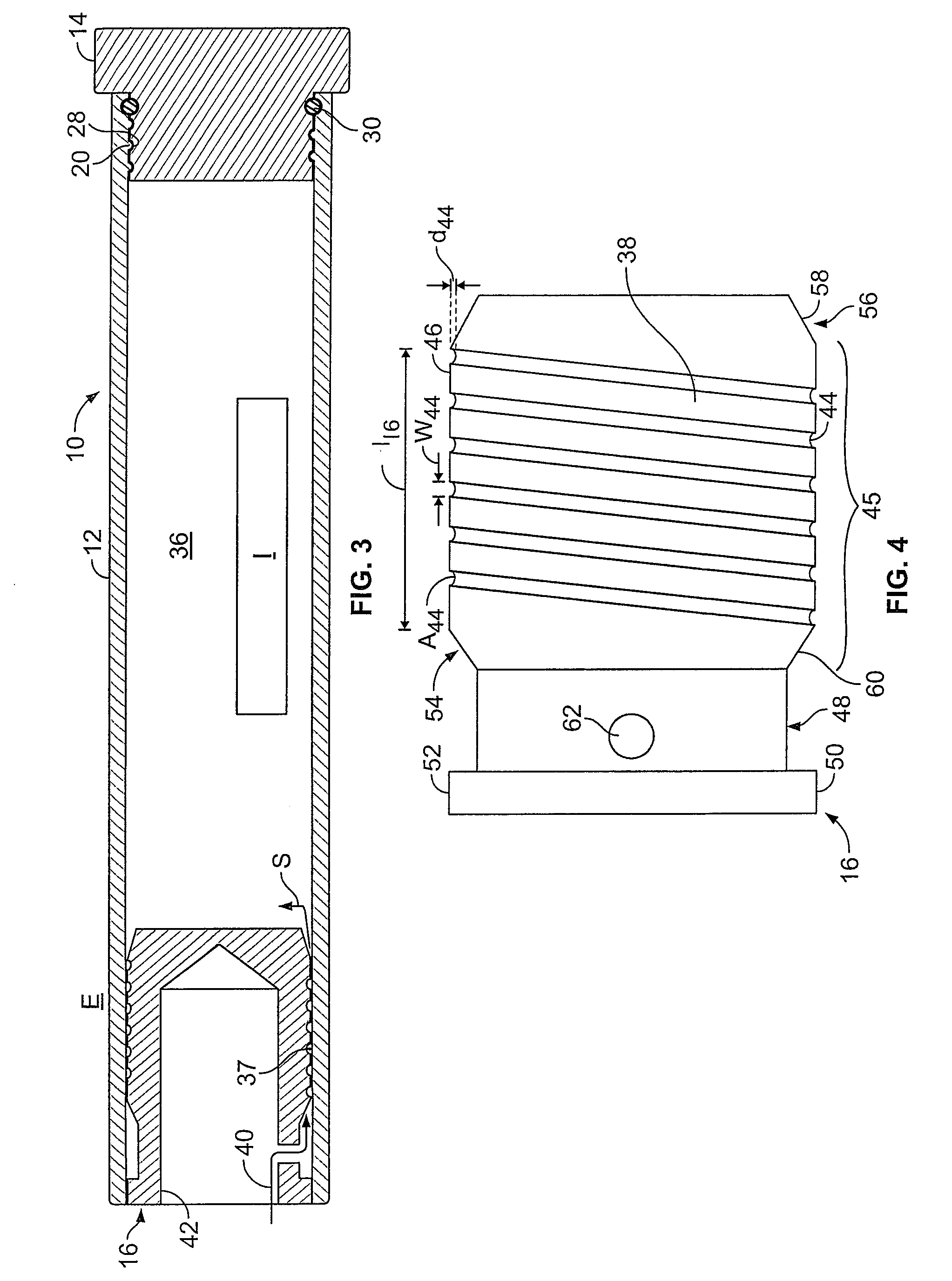

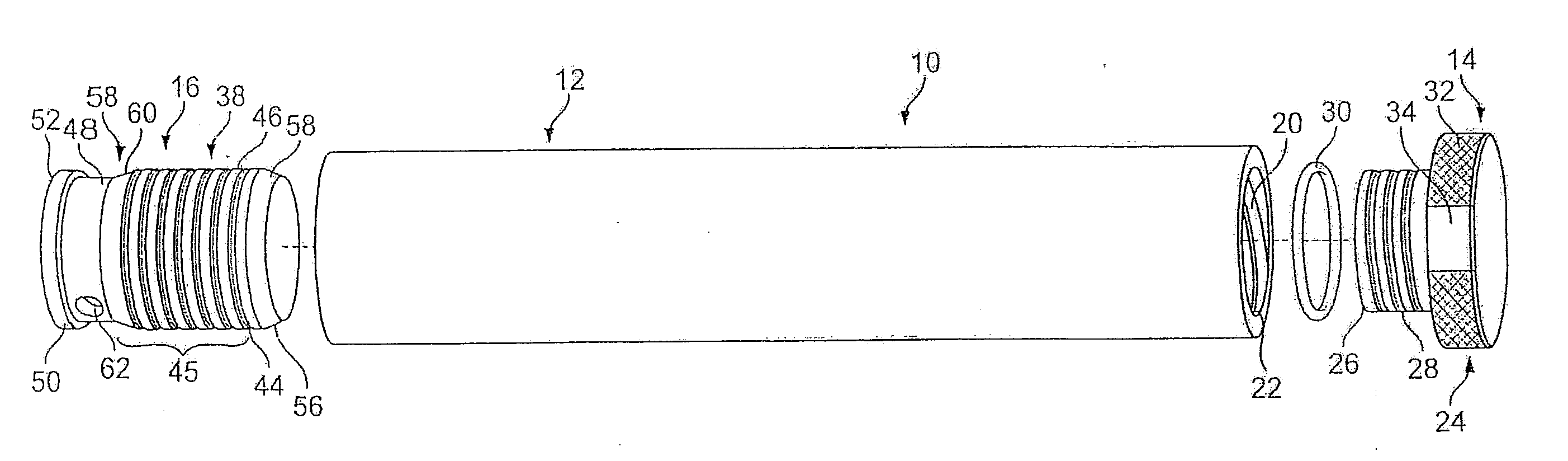

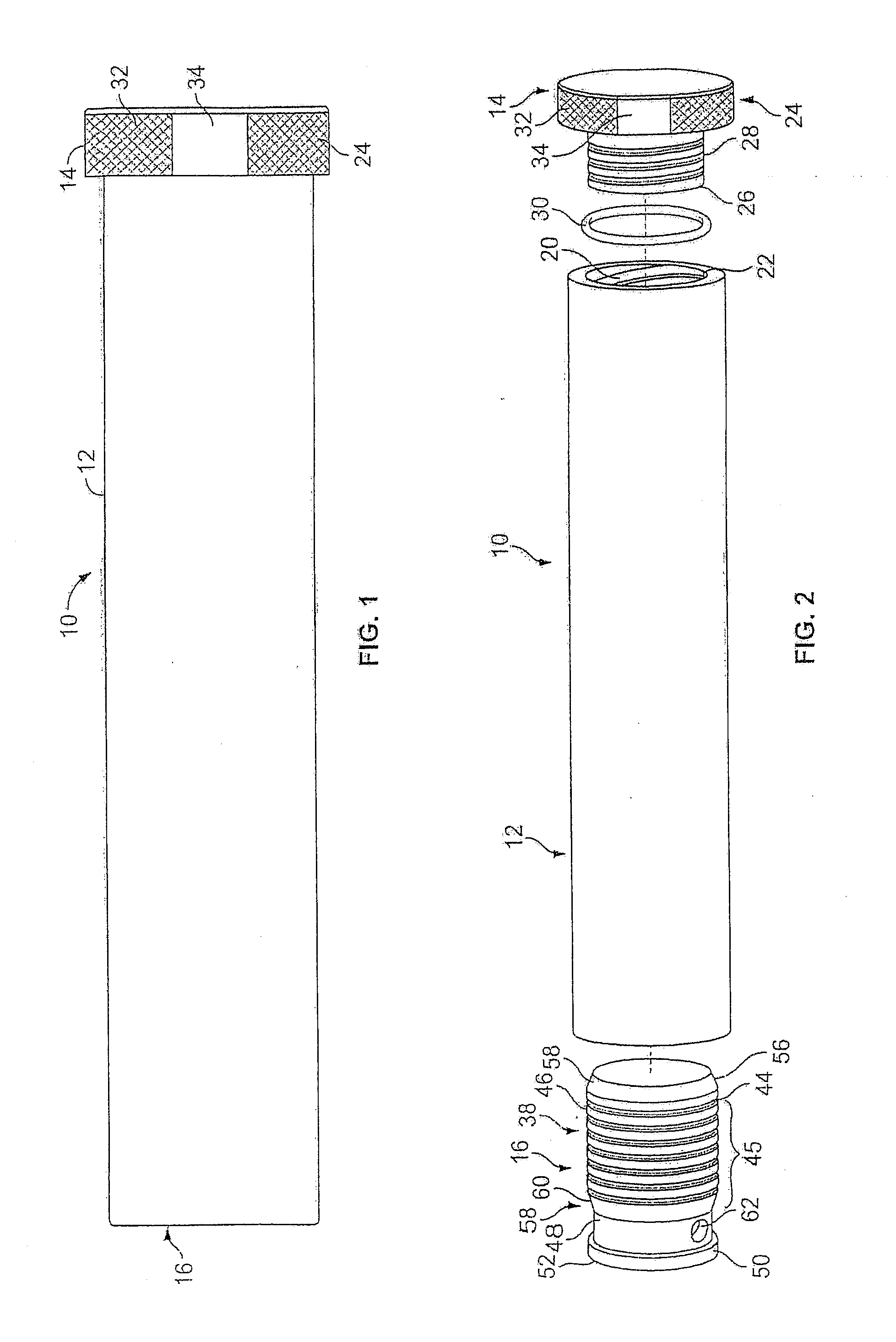

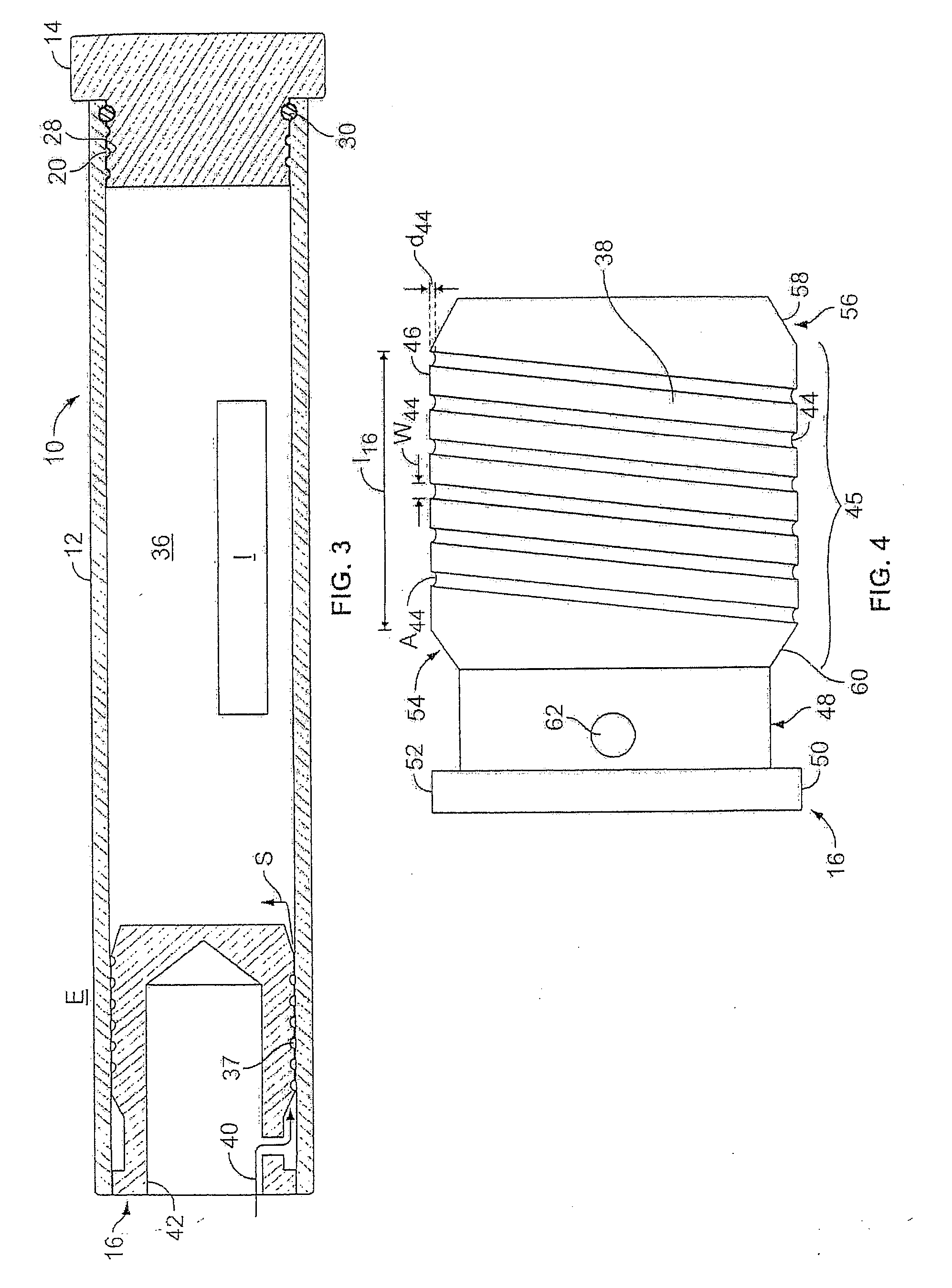

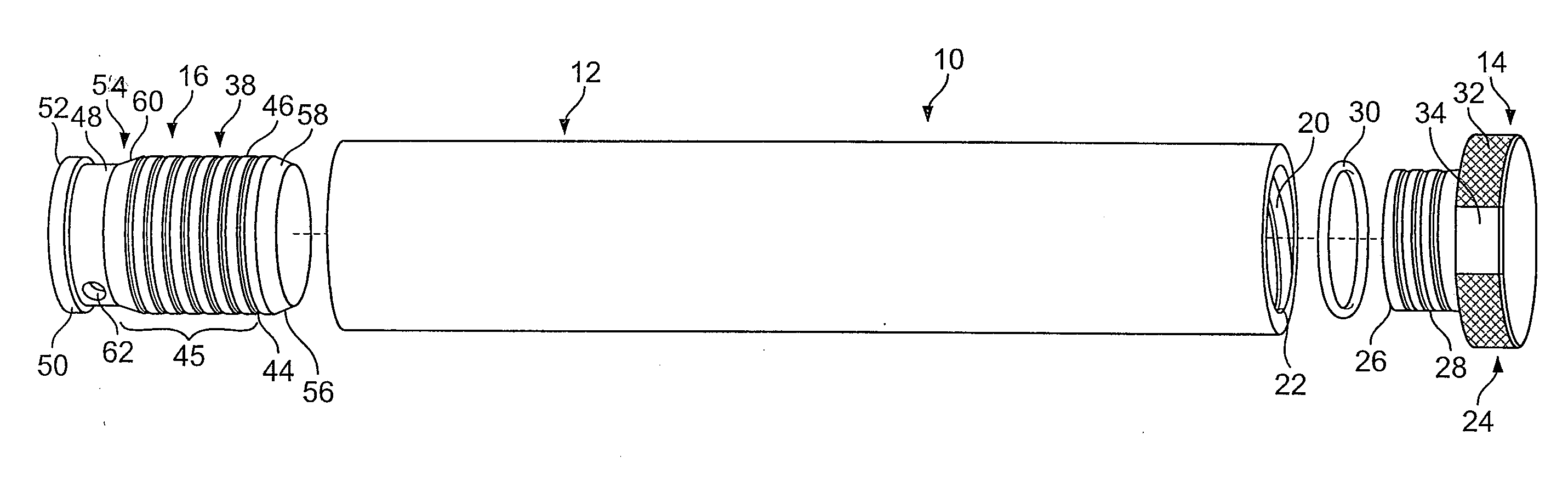

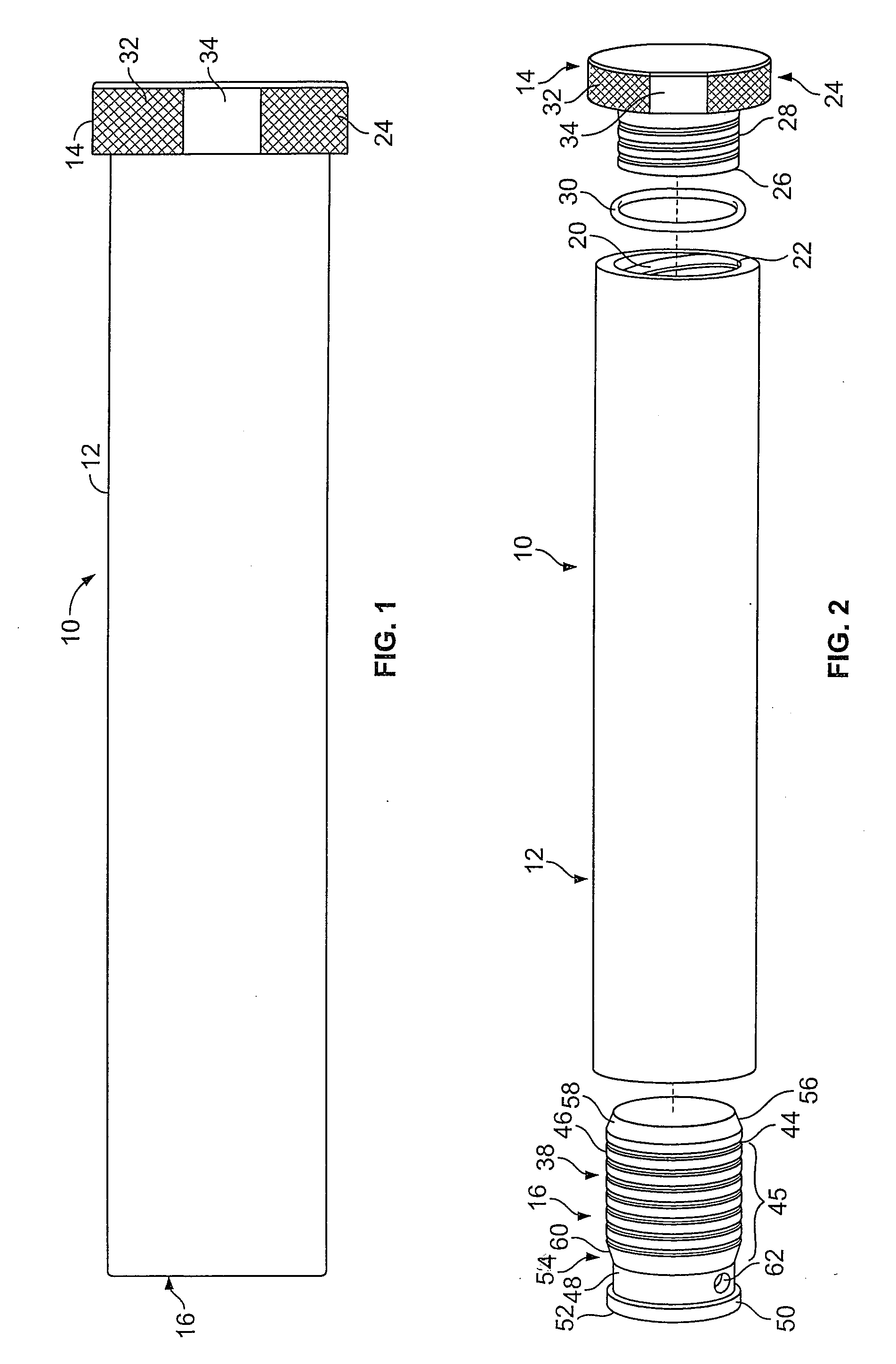

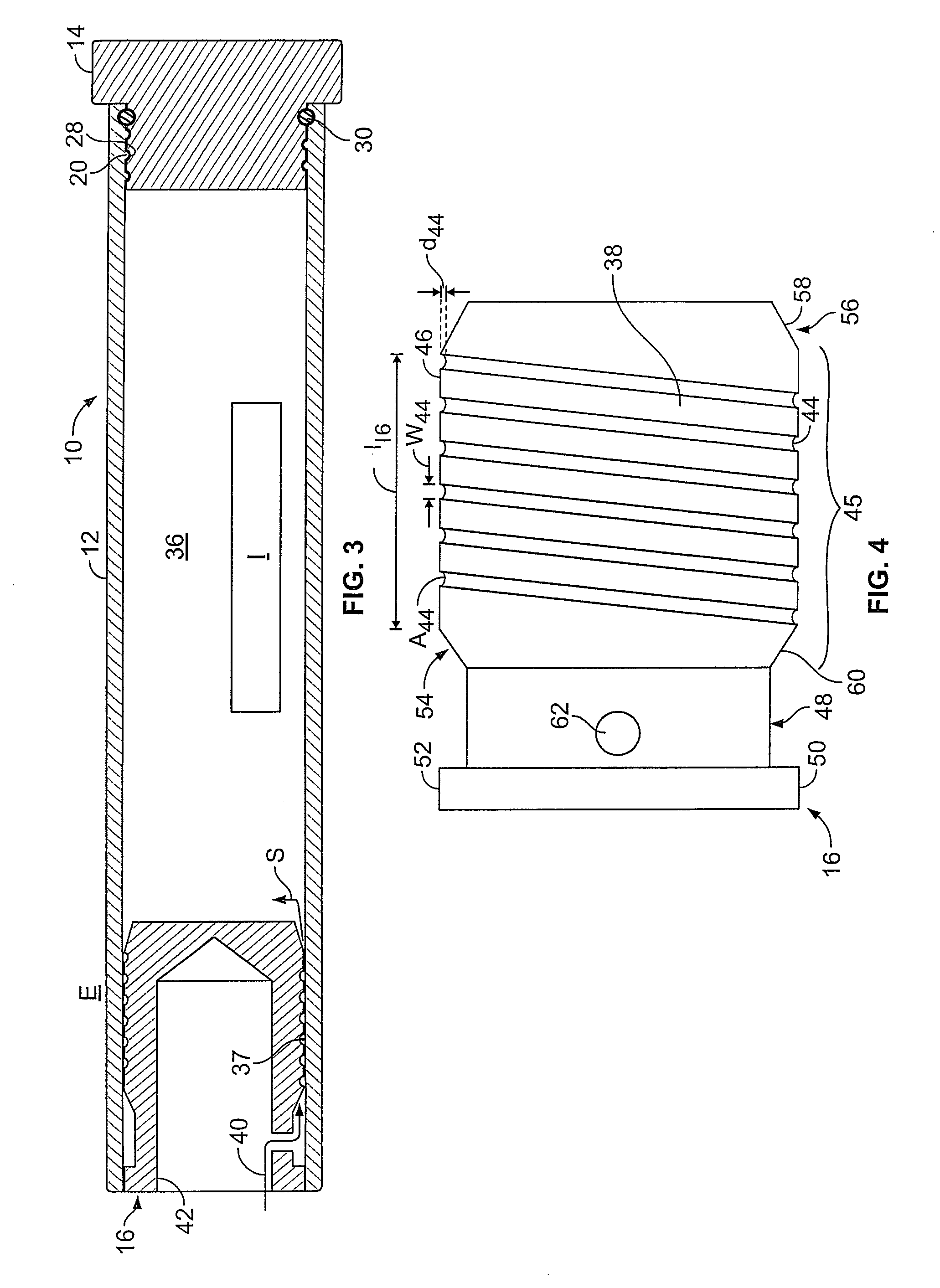

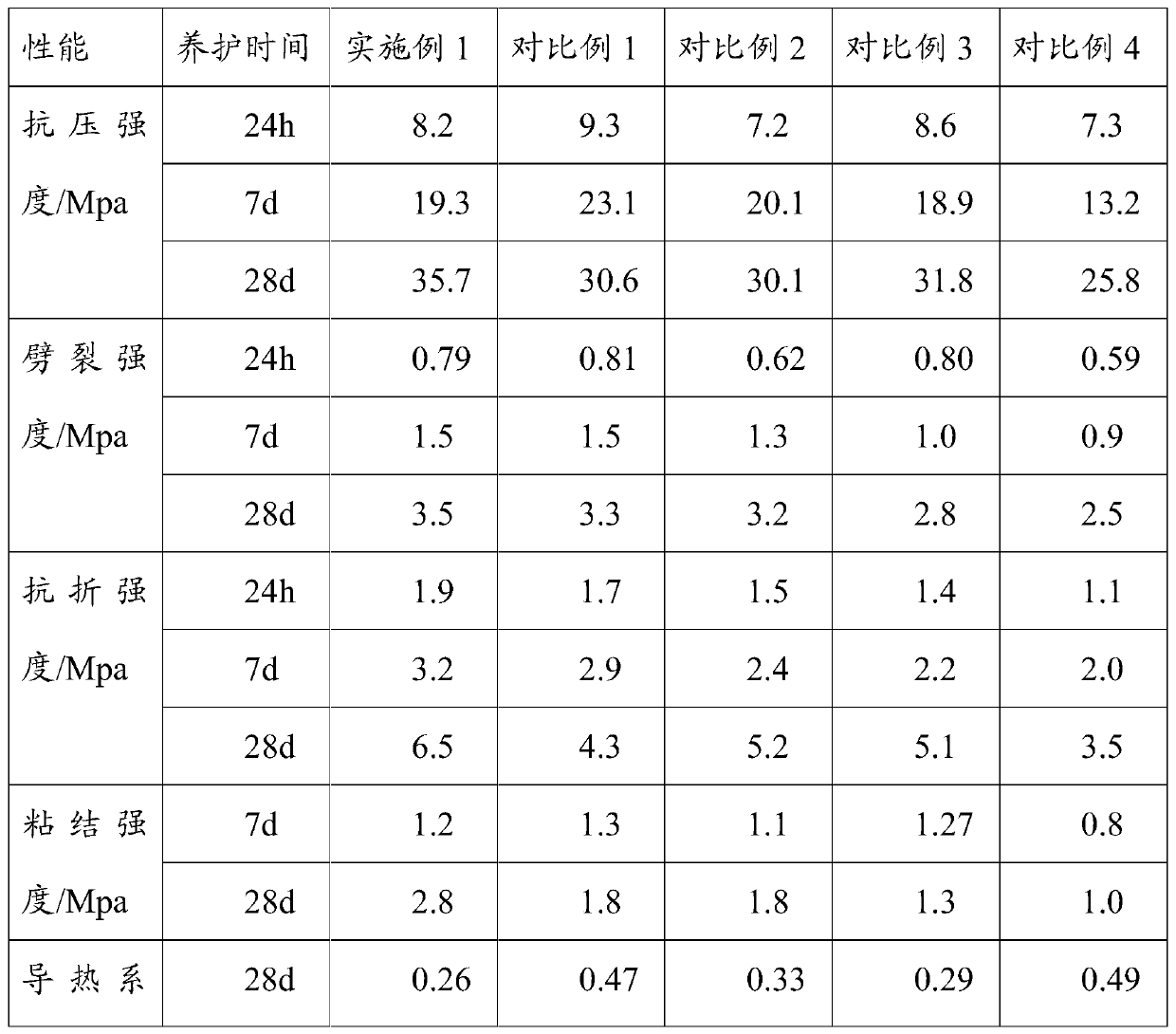

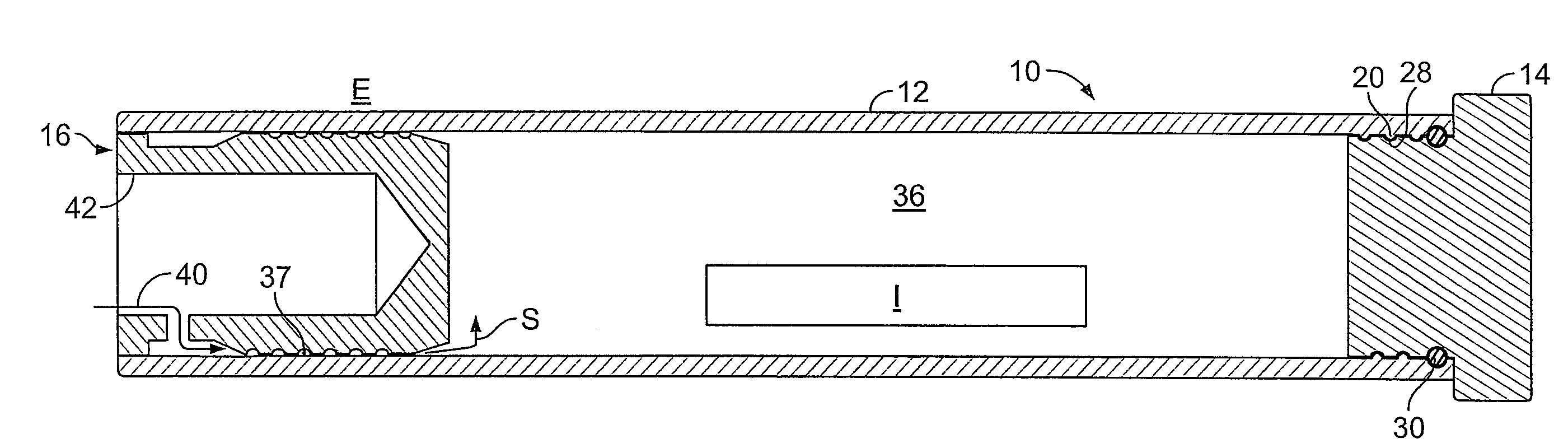

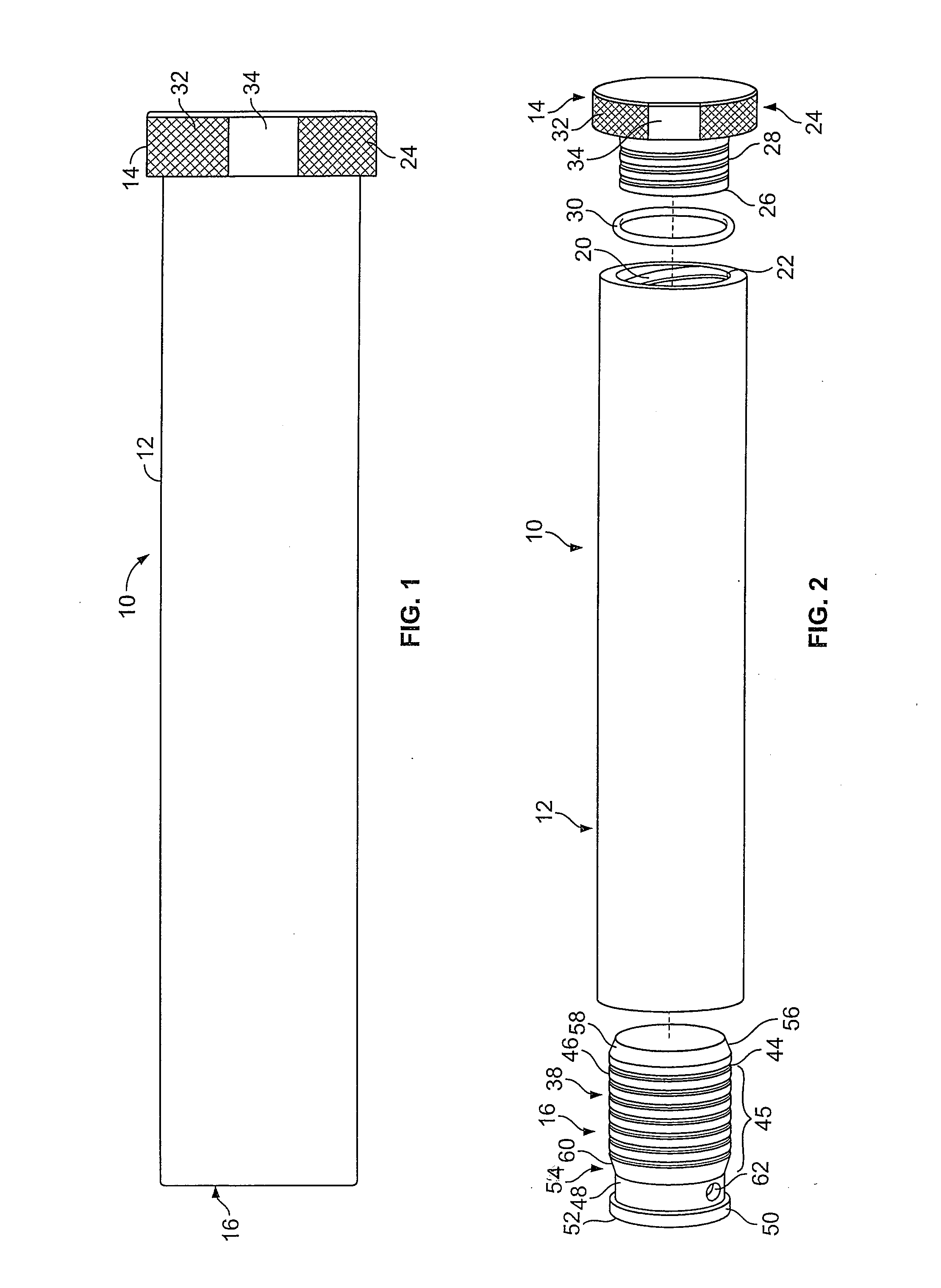

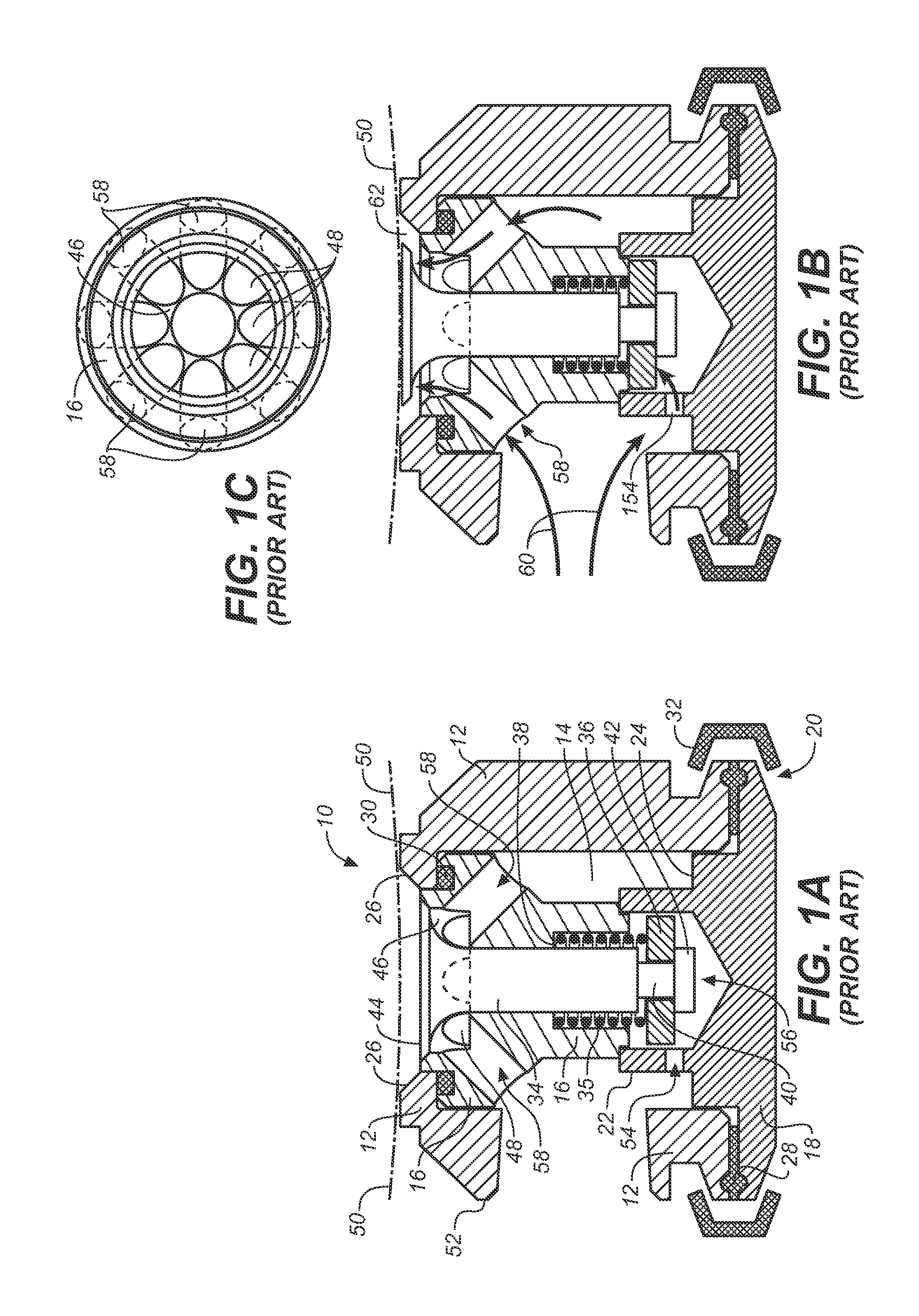

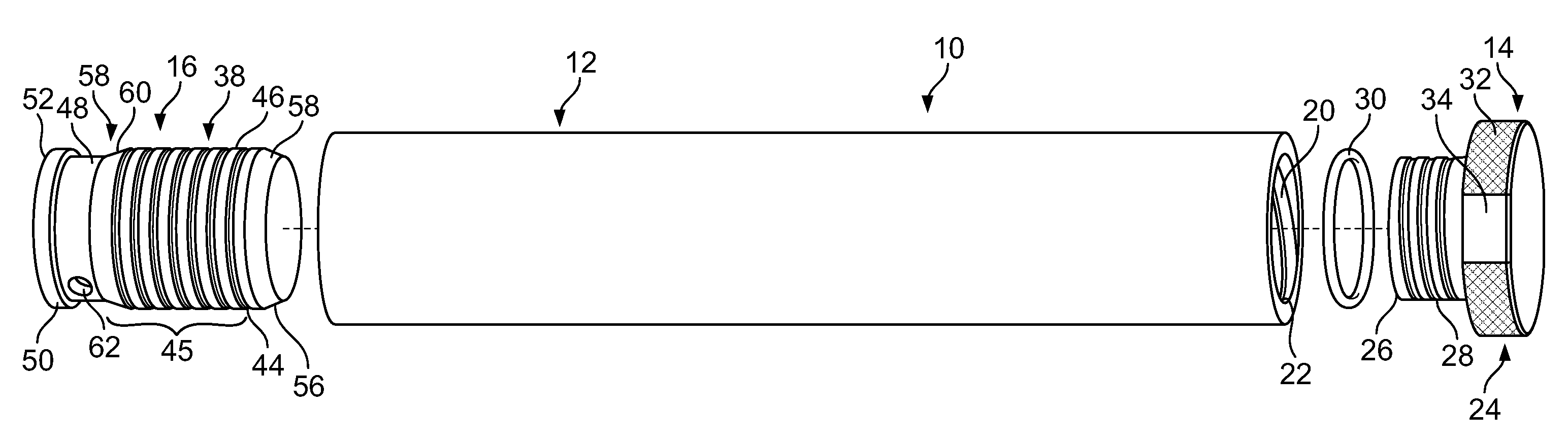

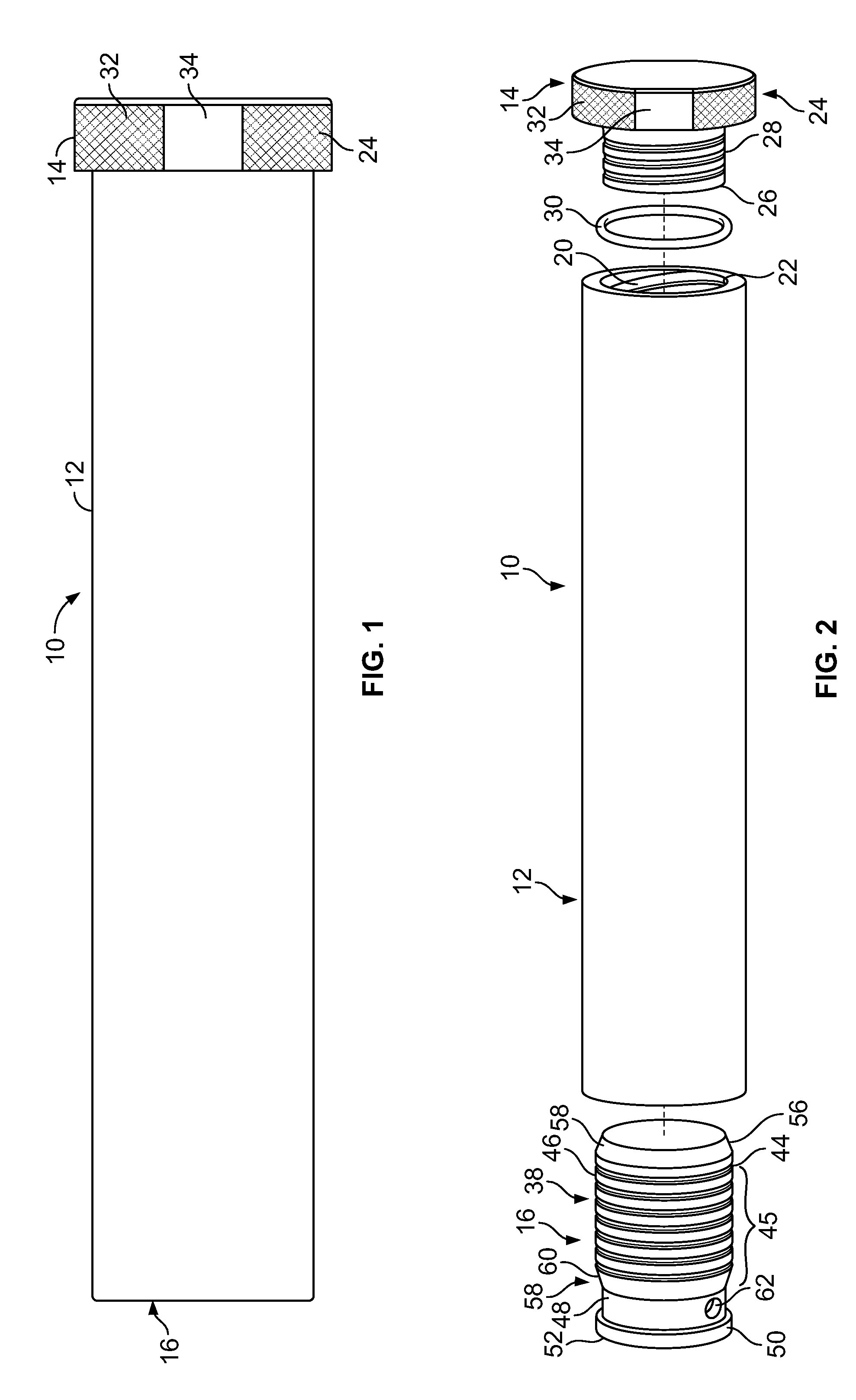

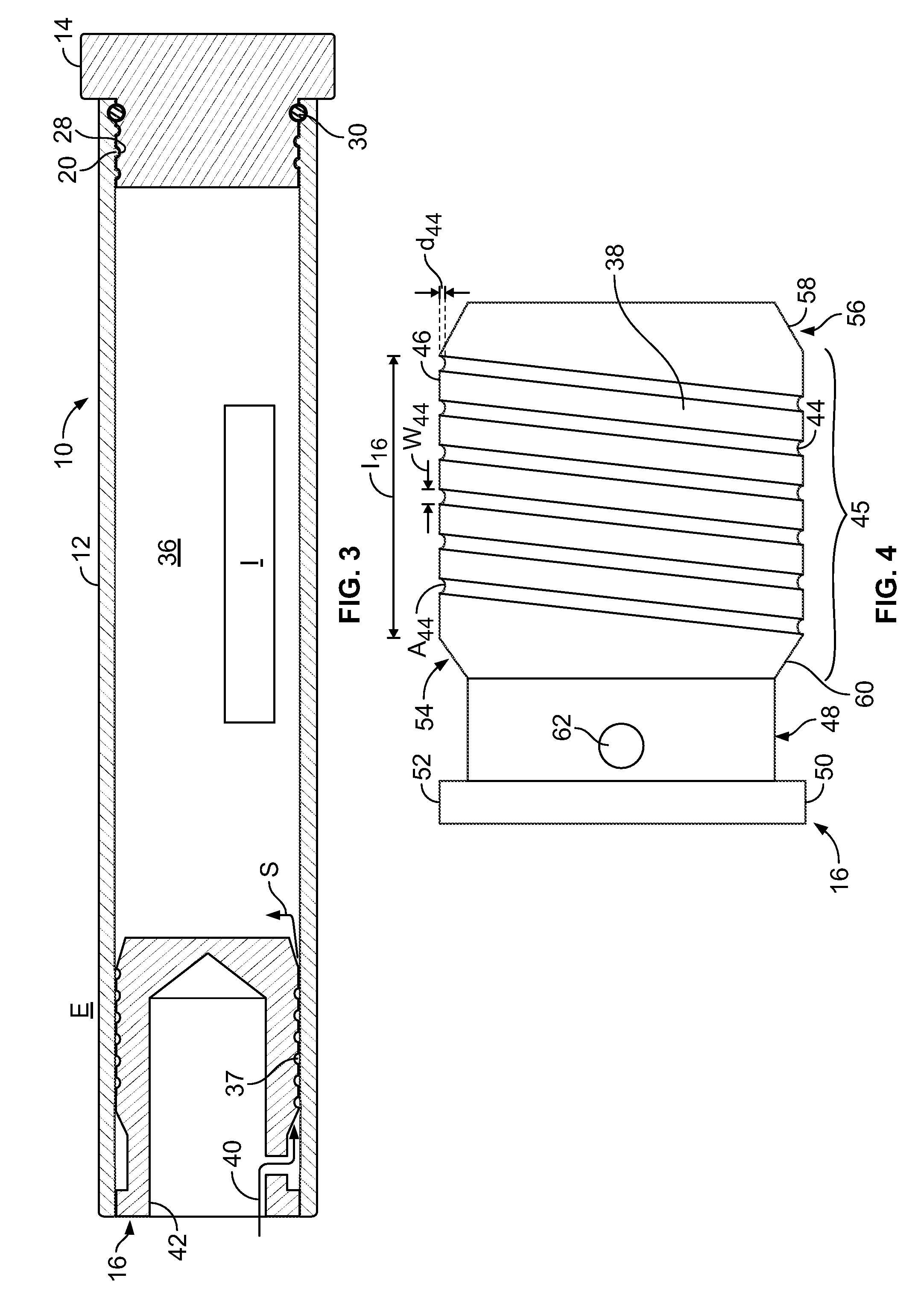

Sterilization challenge specimen holder

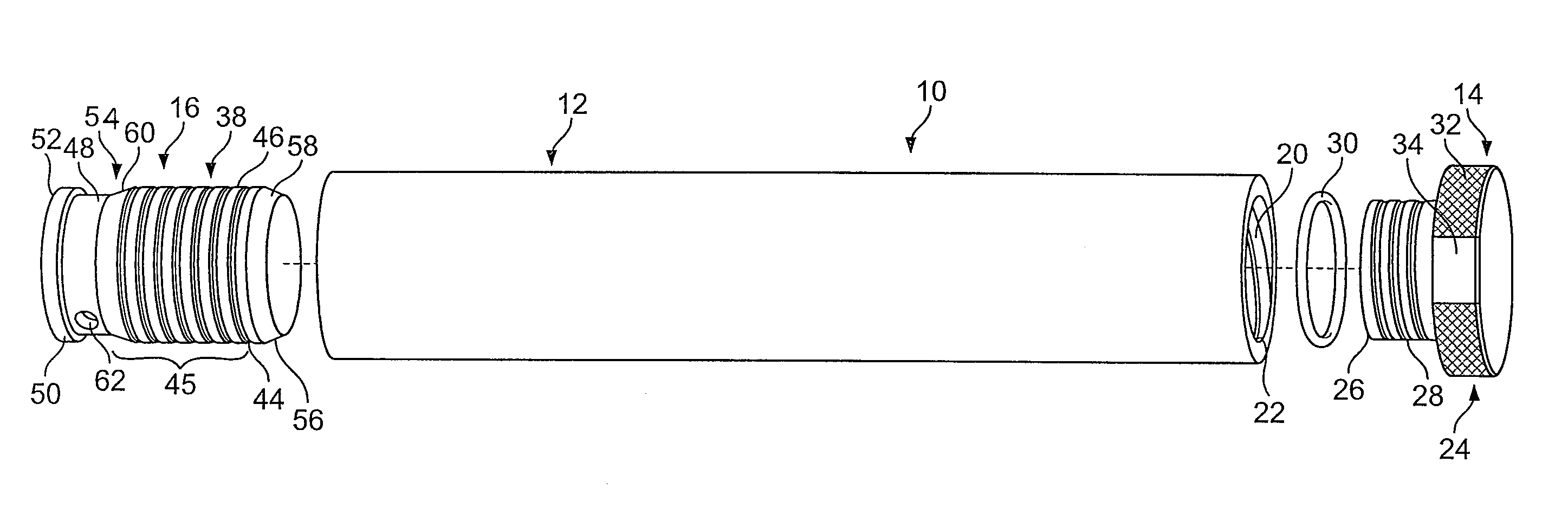

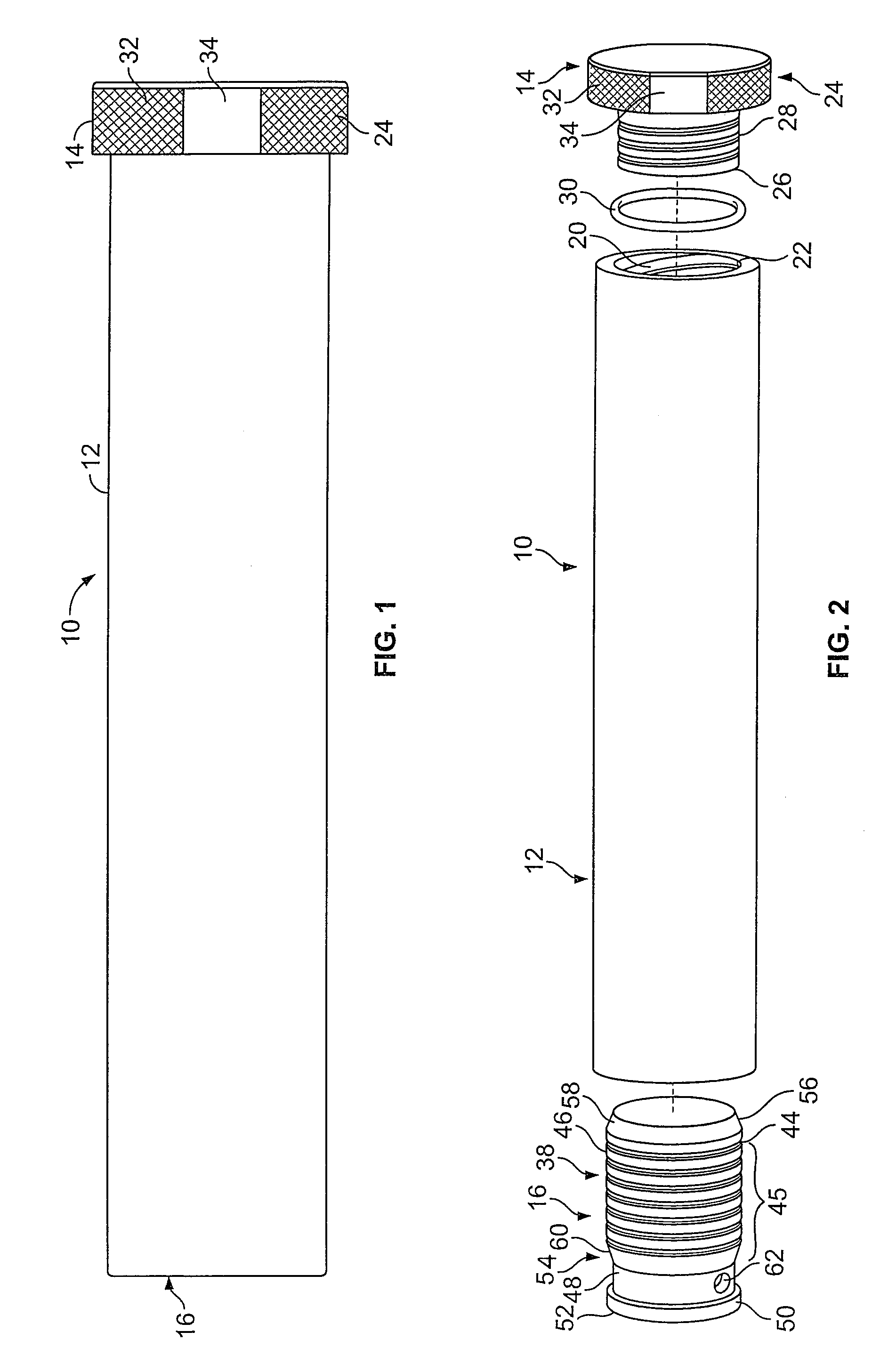

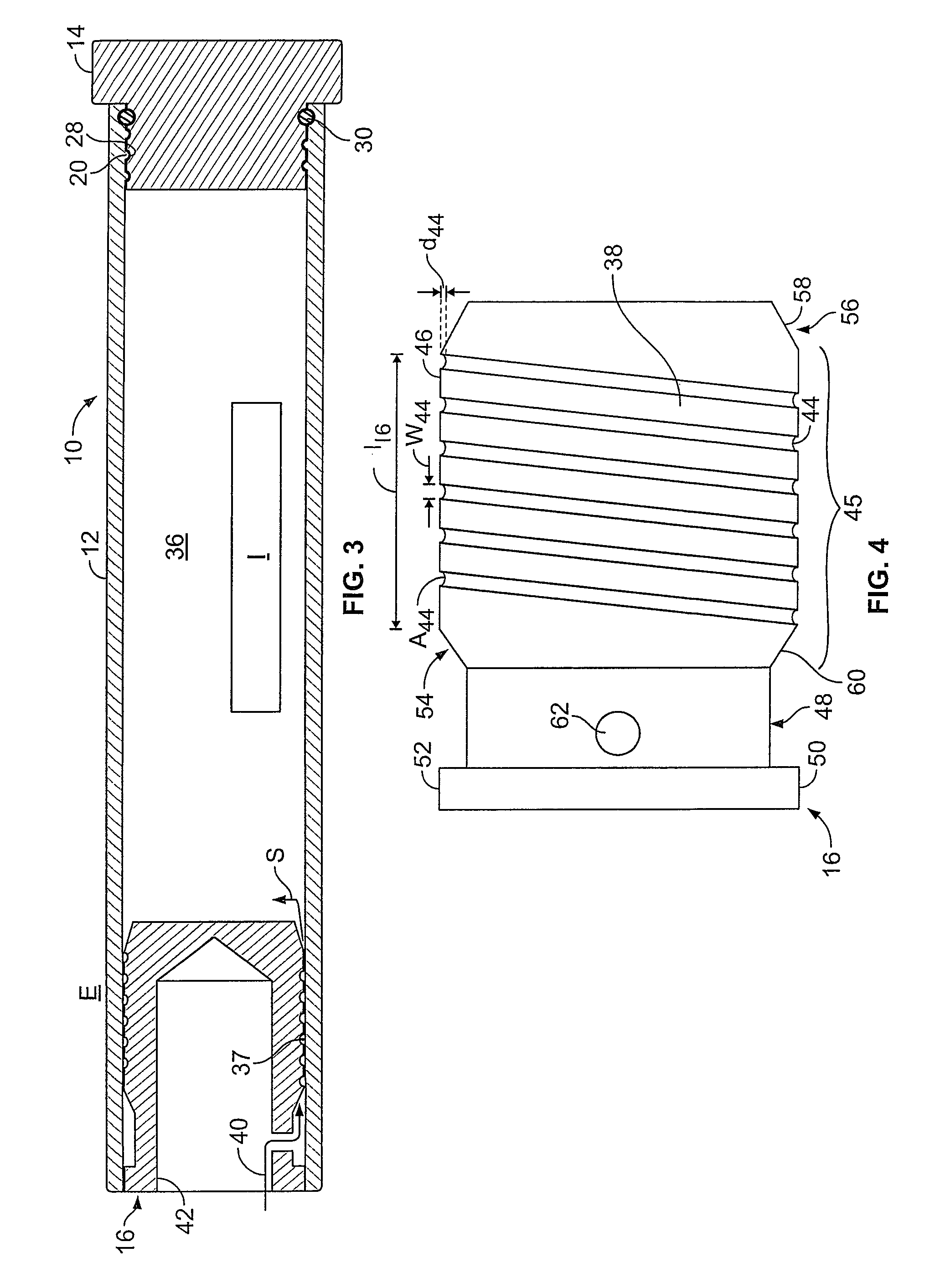

ActiveUS7790105B2Easy to carryPrevent rollingBioreactor/fermenter combinationsBiological substance pretreatmentsElectrical and Electronics engineering

Owner:AMERICAN STERILIZER CO

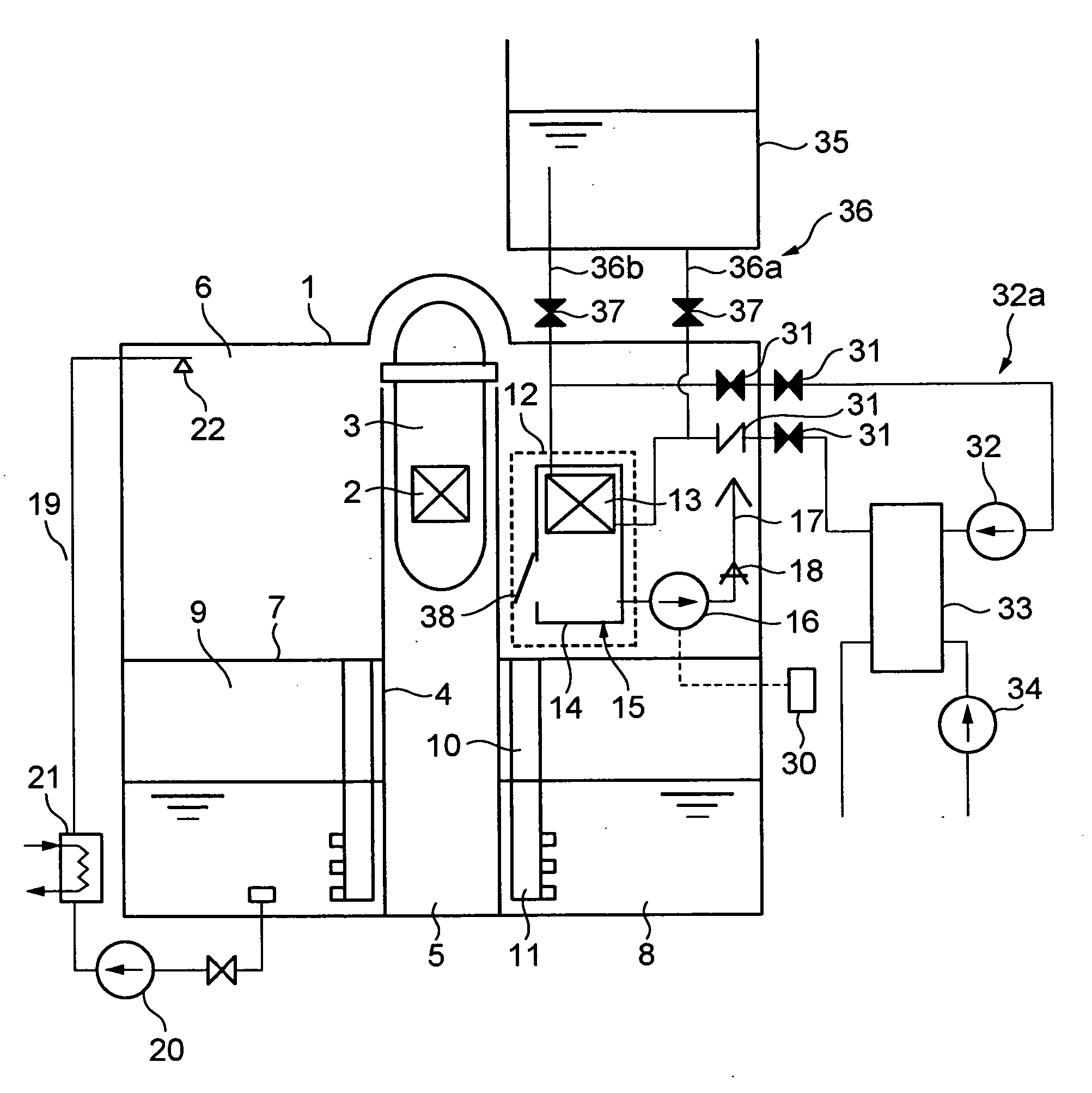

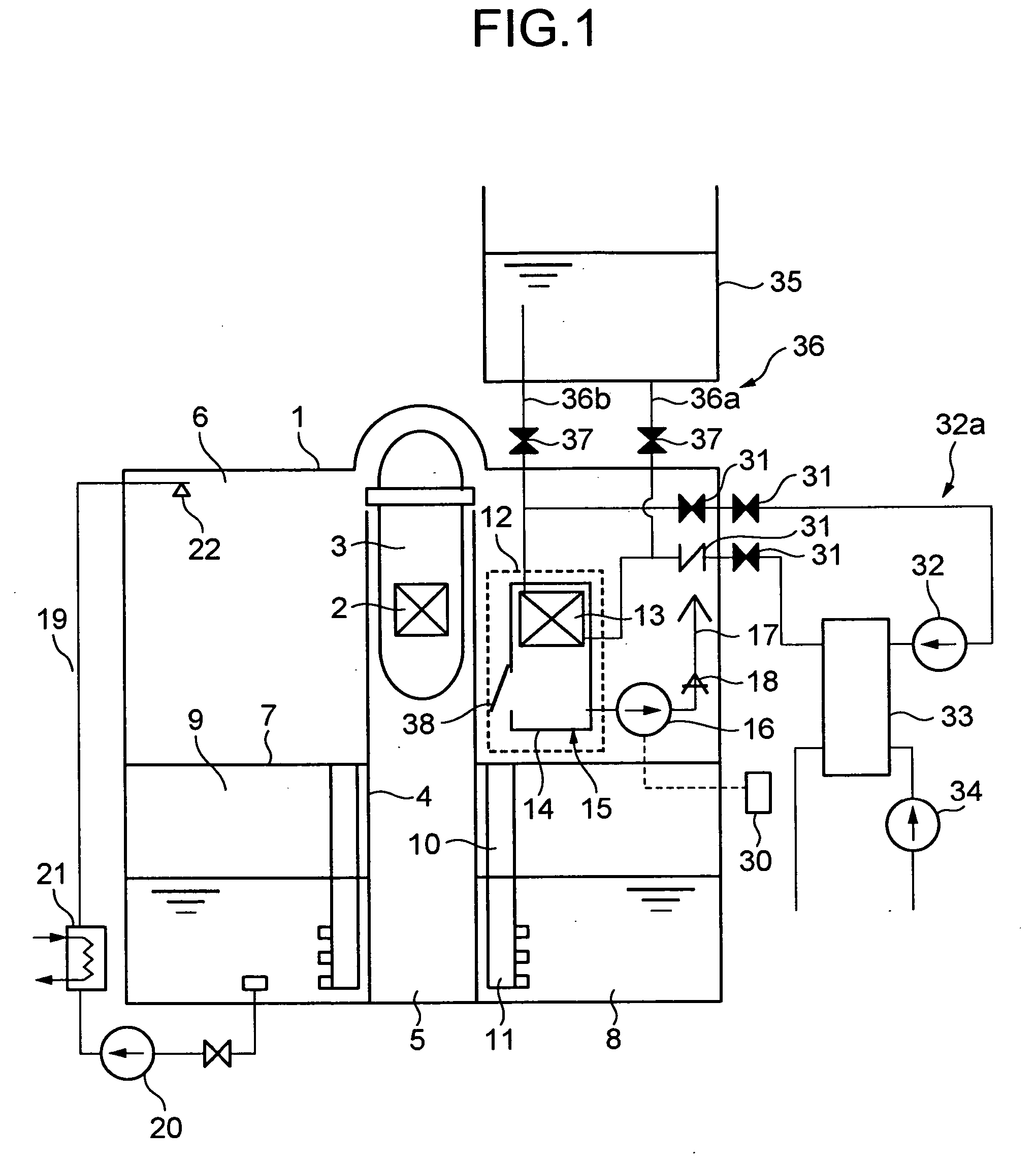

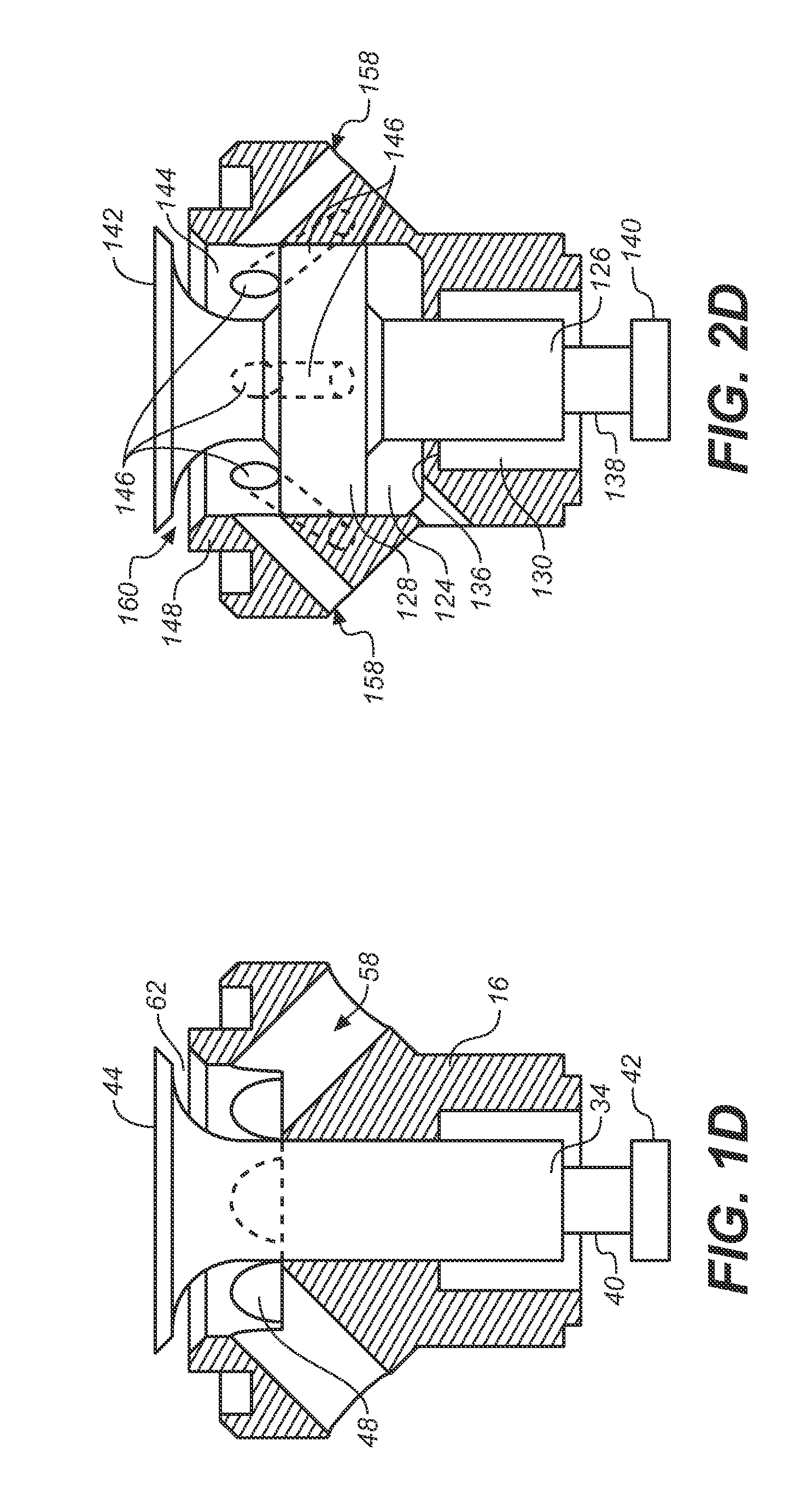

Reactor containment vessel cooling equipment

InactiveUS20070076835A1Reduce steam pressureNuclear energy generationEmergency protection arrangementsNuclear reactorWater circulation

A nuclear reactor containment vessel cooling equipment has: a dry well cooler casing in a containment vessel, having an opening at its top and a shutter at its lower part; a heat transfer tube arranged at an upper part in the dry well cooler casing; a forced cooling water circulation system for feeding cooling water from outside of the containment vessel into the heat transfer tube by a pump; a blower for mobilizing gas around the heat transfer tube; an external pool container arranged outside the containment vessel and above the heat transfer tube and containing cooling water; and a gravity-driven cooling system to supply cooling water in the external pool container into the heat transfer tube, utilizing gravity.

Owner:KK TOSHIBA

Sterilization challenge specimen holder

ActiveUS7740802B2Easy to carryPrevent rollingBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineering

Owner:AMERICAN STERILIZER CO

Sterilization challenge specimen holder

ActiveUS7718125B2Easy to carryPrevent rollingBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringEngineering

Owner:AMERICAN STERILIZER CO

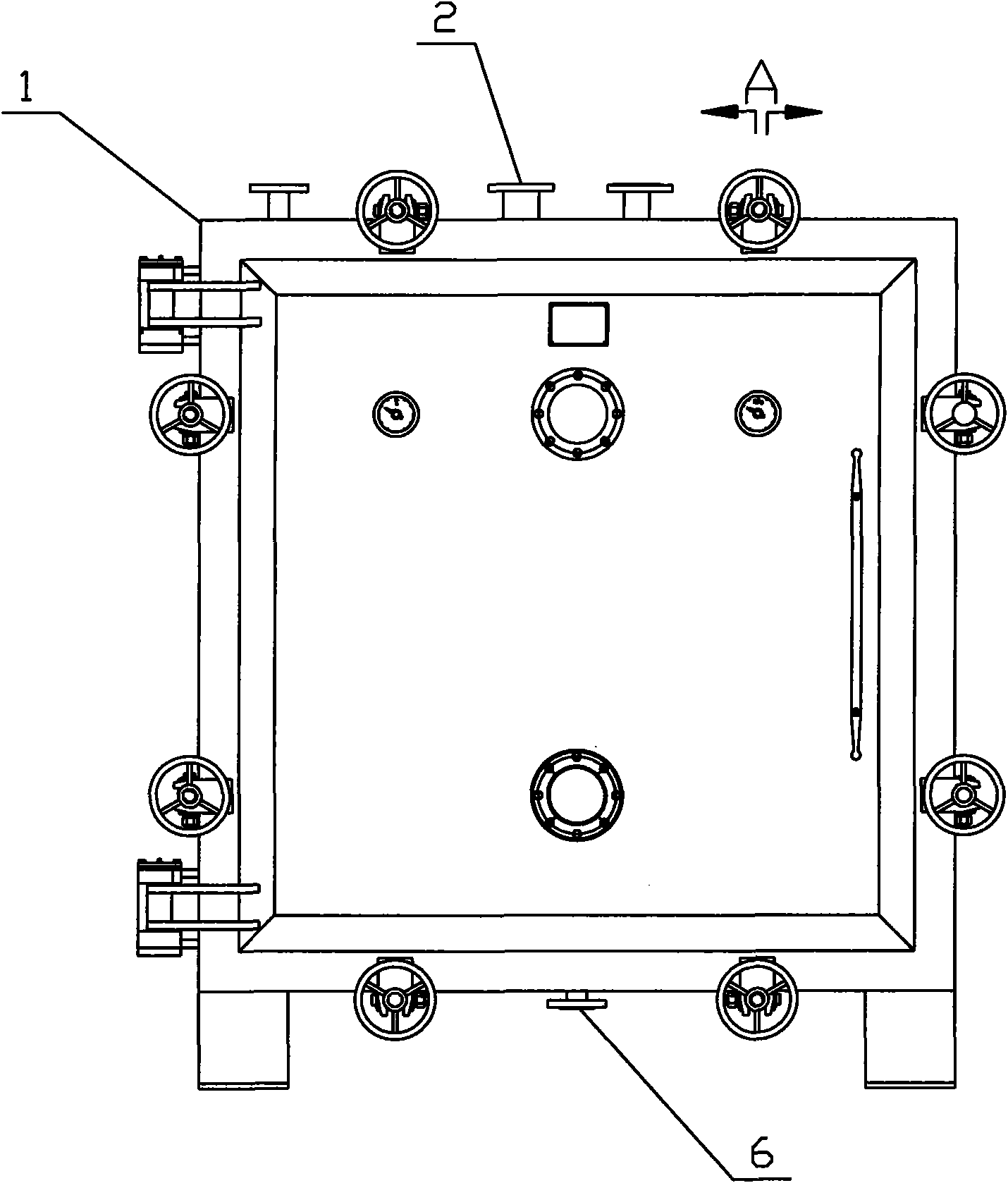

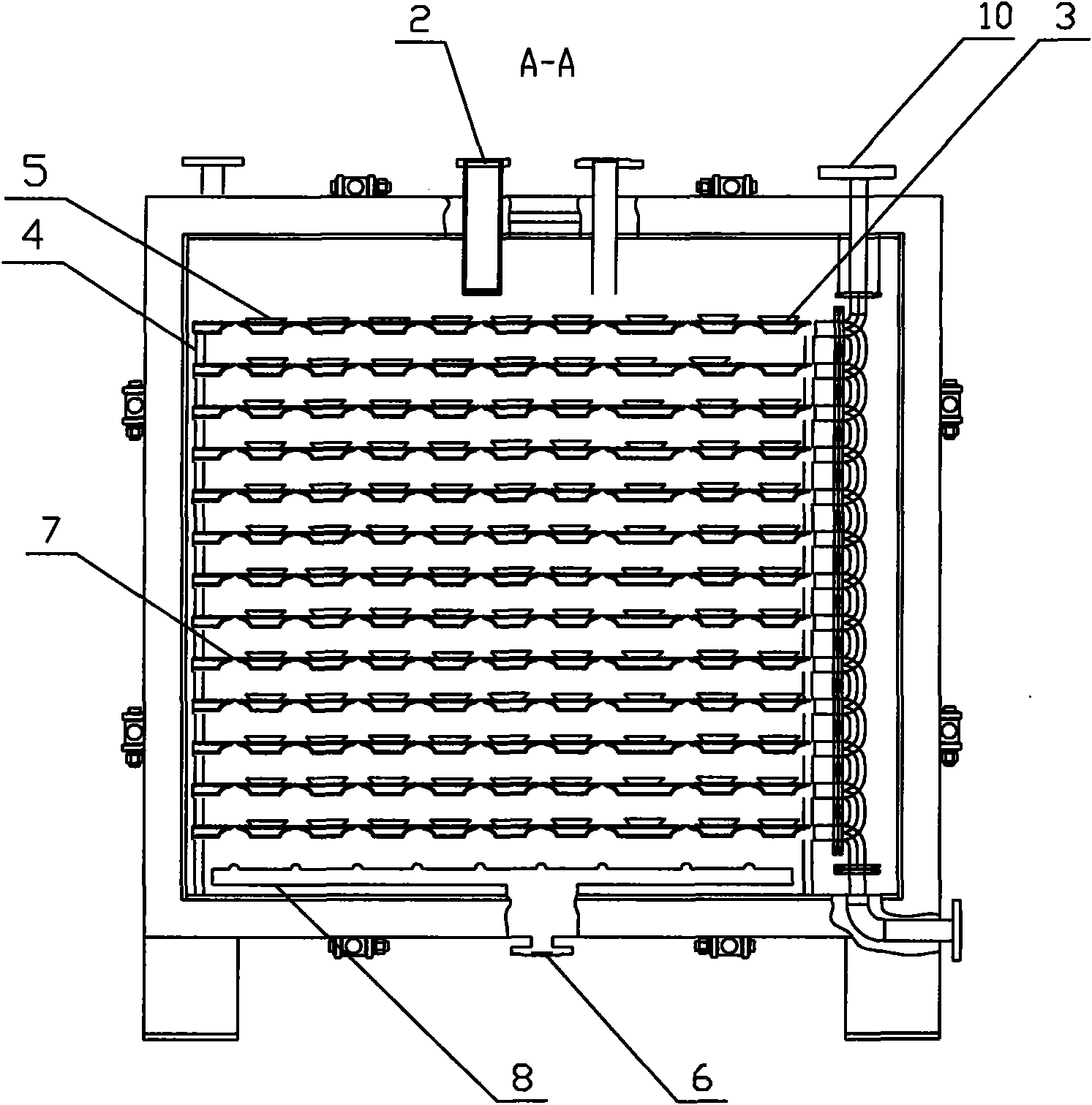

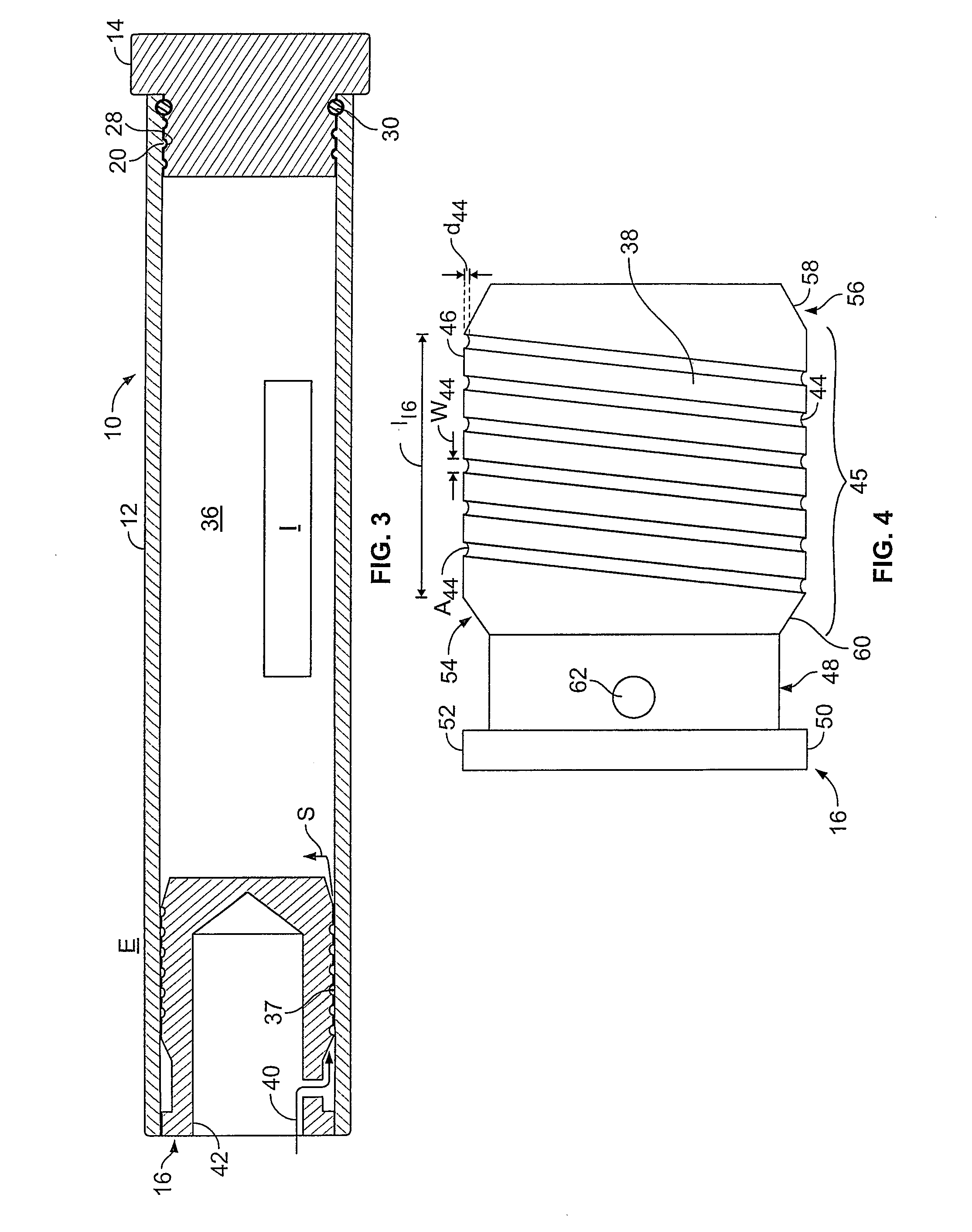

Novel drying oven and drying method thereof

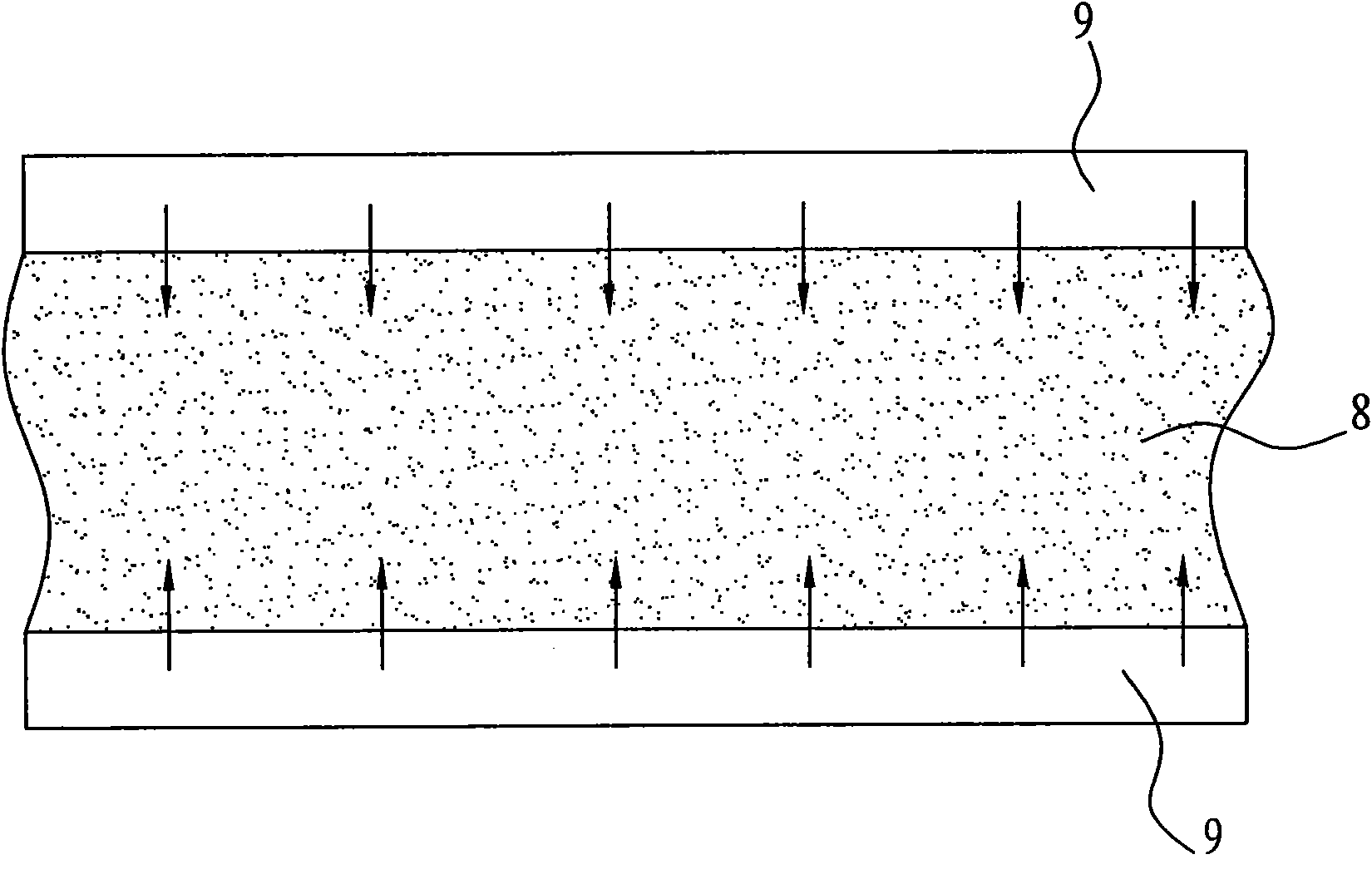

ActiveCN101818985ATake away quicklyReduce steam pressureDrying using combination processesDrying solid materials with heatSteam pressureNitrogen

The invention discloses a novel drying oven. The novel drying oven comprises an oven shell, an air exhaustion hole, an air inlet, a flat plate and a support used for placing the flat plate, wherein a tray used for placing dried materials is arranged on the flat plate; the flat plate is an air-permeable type flat plate; and an air inlet tube is arranged on a drying box for inlet nitrogen or carbon dioxide or inert gases. In the novel drying oven, steam evaporated from wet materials to be dried can be quickly exhausted through an air-permeable structure due to the adoption of the air-permeable type flat plate, and the mass transfer is rapid, so steam pressure of the evaporated steam is lowered, the steam is not easily detained and condensed, and the drying speed is greatly improved; and under the condition of introducing a proper gas such as nitrogen into the air inlet tube, permeable holes can obviously improve the flowing and distribution of the nitrogen in the drying oven, so the steam at all parts of the drying oven can be quickly taken away along with the nitrogen, and the drying speed is further quickened.

Owner:康纳新型材料(杭州)有限公司

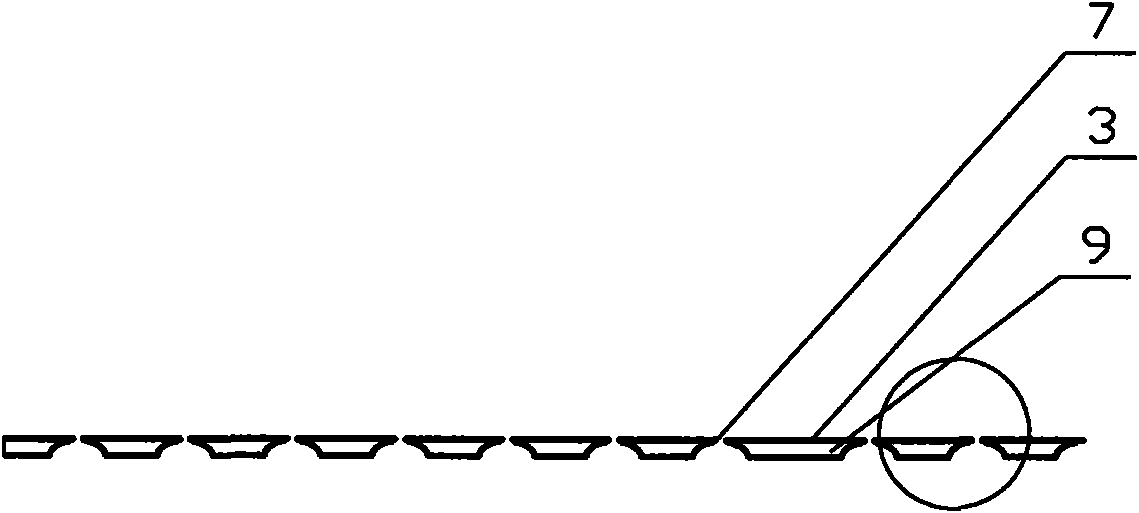

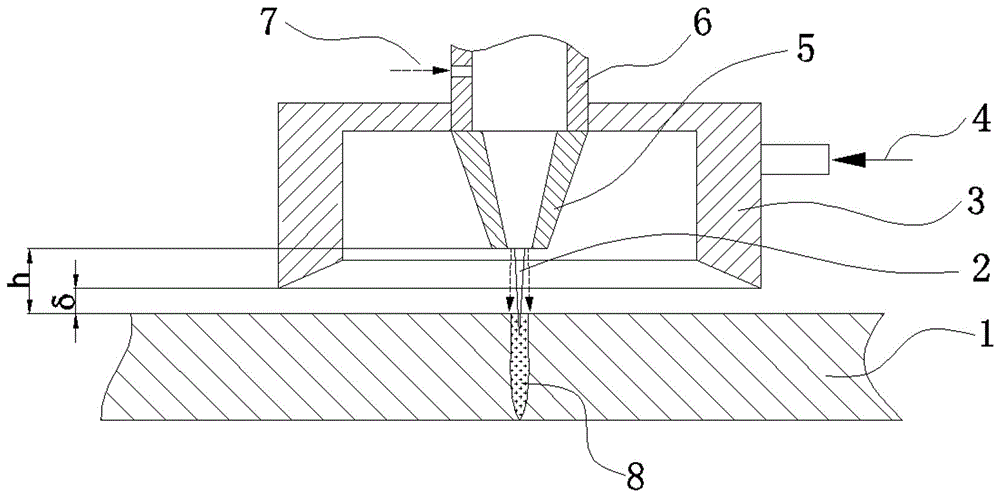

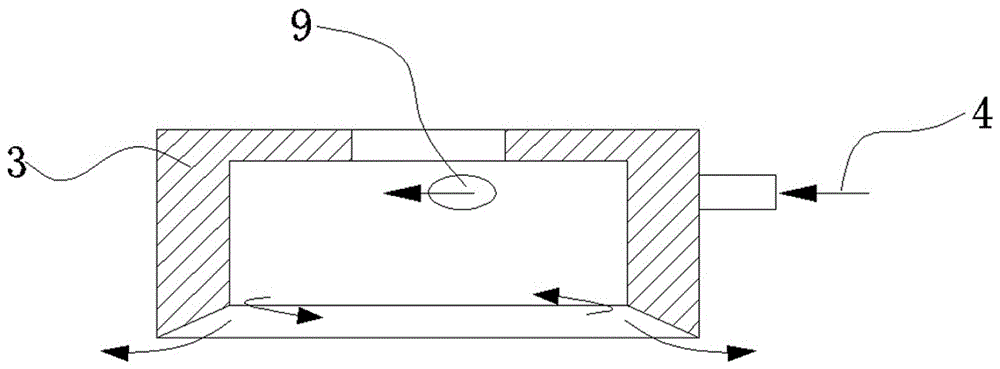

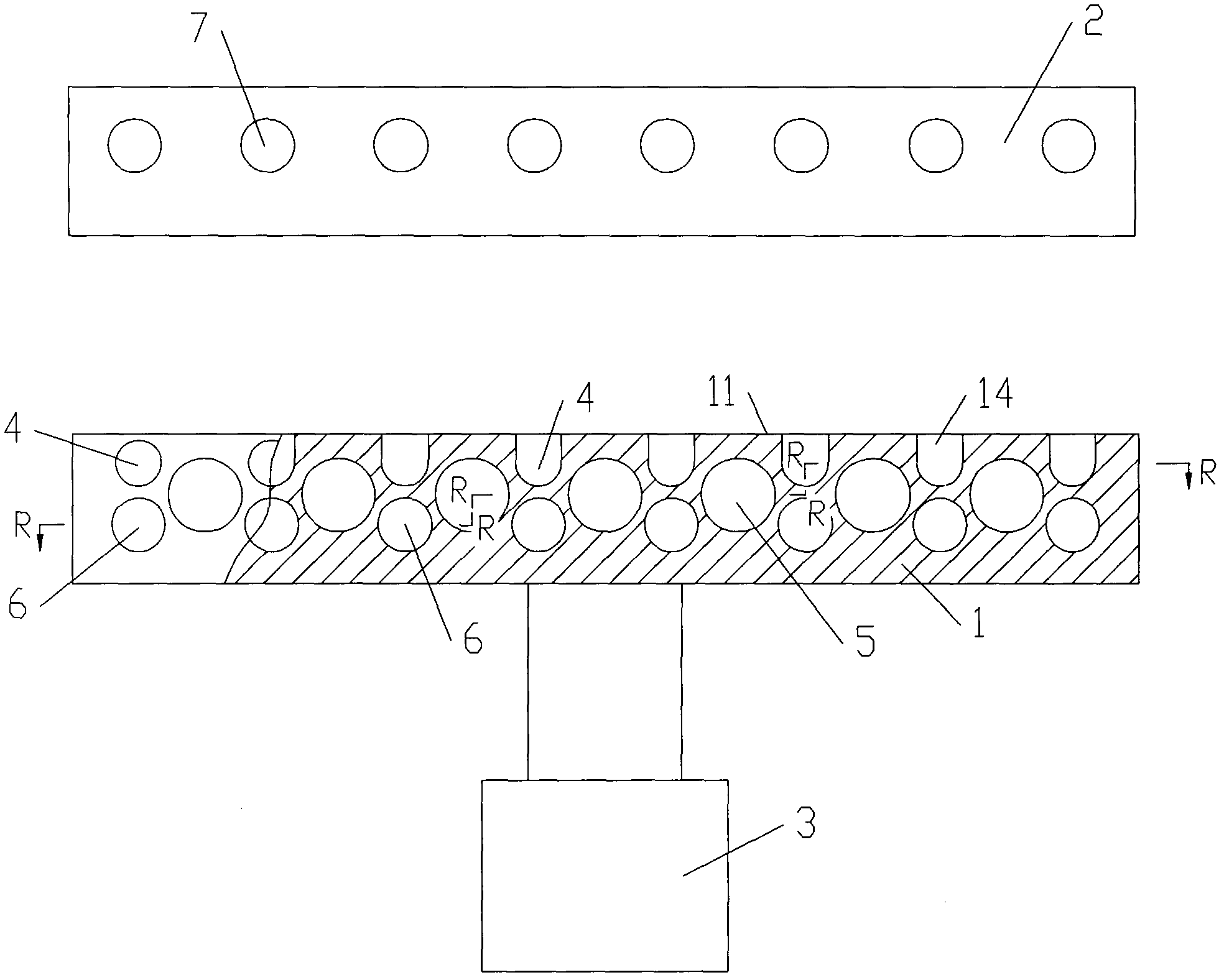

Laser drilling machining method

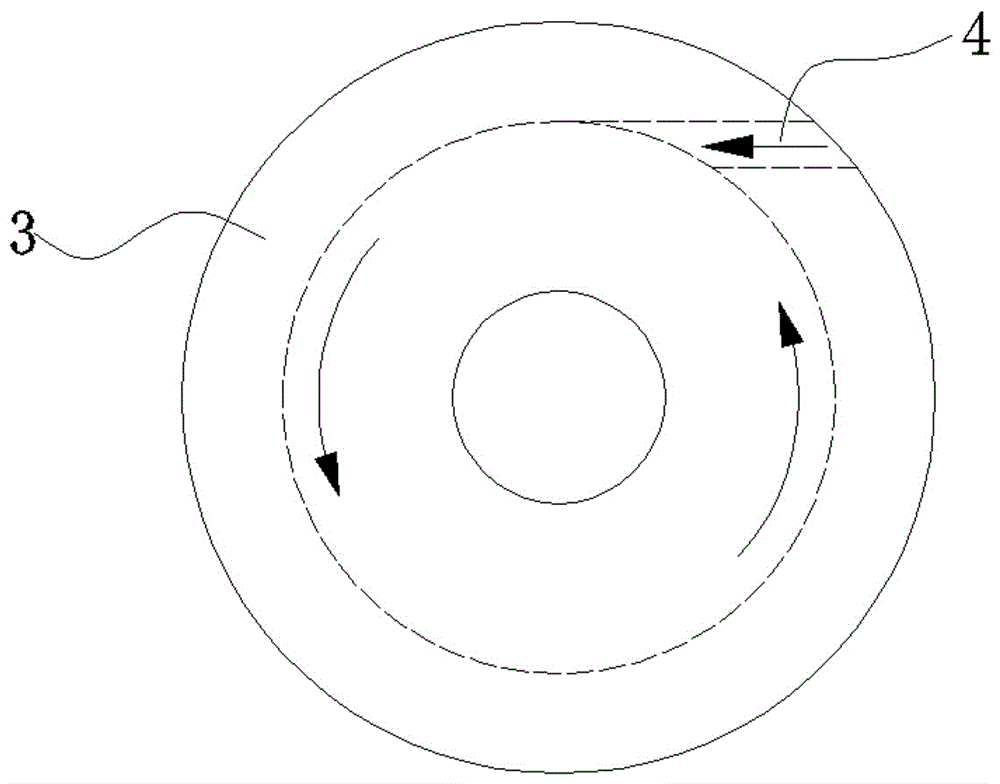

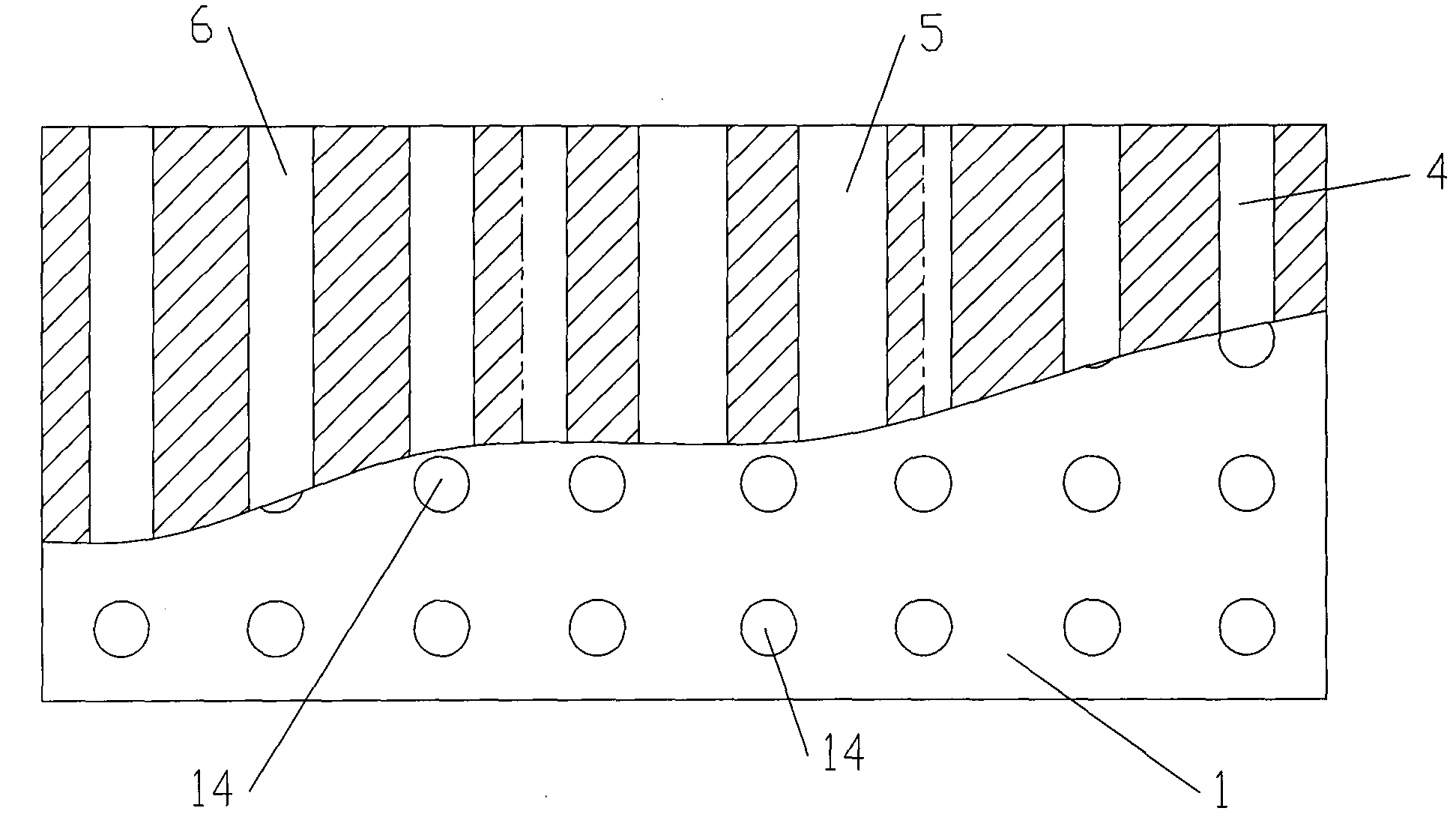

InactiveCN106112280AStrong melting abilityBlowout preventionLaser beam welding apparatusSpray nozzleLaser cutting

The invention relates to a laser drilling machining method. The laser drilling machining method comprises the following steps of step 1: preparing a workpiece (1) to be cut and removing impurities from the surface of the workpiece (1); step 2: connecting a vacuum hood (3) onto a laser cutting head (6), and enabling the distance from a cutting spray nozzle (5) and the the vacuum hood to the upper surface of the workpiece (1) to be adjustable; step 3: moving the laser cutting head above the workpiece, enabling the cutting spray nozzle to keep a certain distance from the surface of the workpiece and enabling the vacuum hood to keep a certain distance from the surface of the workpiece; setp 4: supplying dry compressed air from an air inlet port (4) of the vacuum hood; step 5: supplying drilling auxiliary gas from an auxiliary gas inlet port (7) of the laser cutting head; and step 6: starting a laser cutting system and enabling a laser beam (2) to radiate the upper surface of the workpiece vertically to complete the drilling process. According to the method, a partial vacuum environment is formed by the simple cyclonic-type vacuum hood, so that the problem can be avoided that large amounts of molten metal is injected upward and therefore a hole bursts, and the drilling efficiency and stability can be greatly improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heating cooker

ActiveUS20100126356A1Accurate detectionReduce steam pressureDomestic stoves or rangesSteam generation heating methodsSteam pressureWater level

A water level sensor (91) is provided in an auxiliary tank (39) whose bottom portion communicates to a bottom portion of a pot (41) for generating steam and which is opened to the atmosphere. When water in the pot (41) keeps boiling and the stop time of a pump (35) reaches a predetermined time (e.g., 60 sec.), the pump (35) is driven for a predetermined time (e.g., 6 sec.) to supply water to the pot (41). This temporarily suppresses the boiling of water in the pot (41), lowering a steam pressure in a space formed by an external circulation passage (60), a heating chamber, and the pot (41). The water level in the auxiliary tank (39) then returns to a normal one, making it possible to correctly detect the water level in the pot (41).

Owner:SHARP KK

Sterilization challenge specimen holder

ActiveUS20100036357A1Easy to carryPrevent rollingBioreactor/fermenter combinationsBiological substance pretreatmentsElectrical and Electronics engineering

Owner:AMERICAN STERILIZER CO

Sterilization challenge specimen holder

ActiveUS20090028752A1Smooth transitionAvoid improper sealingBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringSample plane

Owner:AMERICAN STERILIZER CO

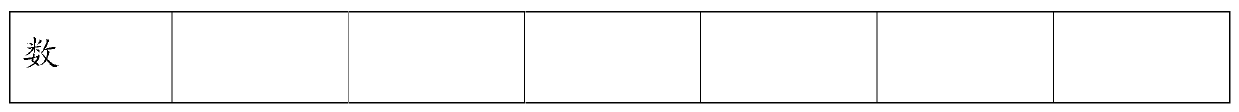

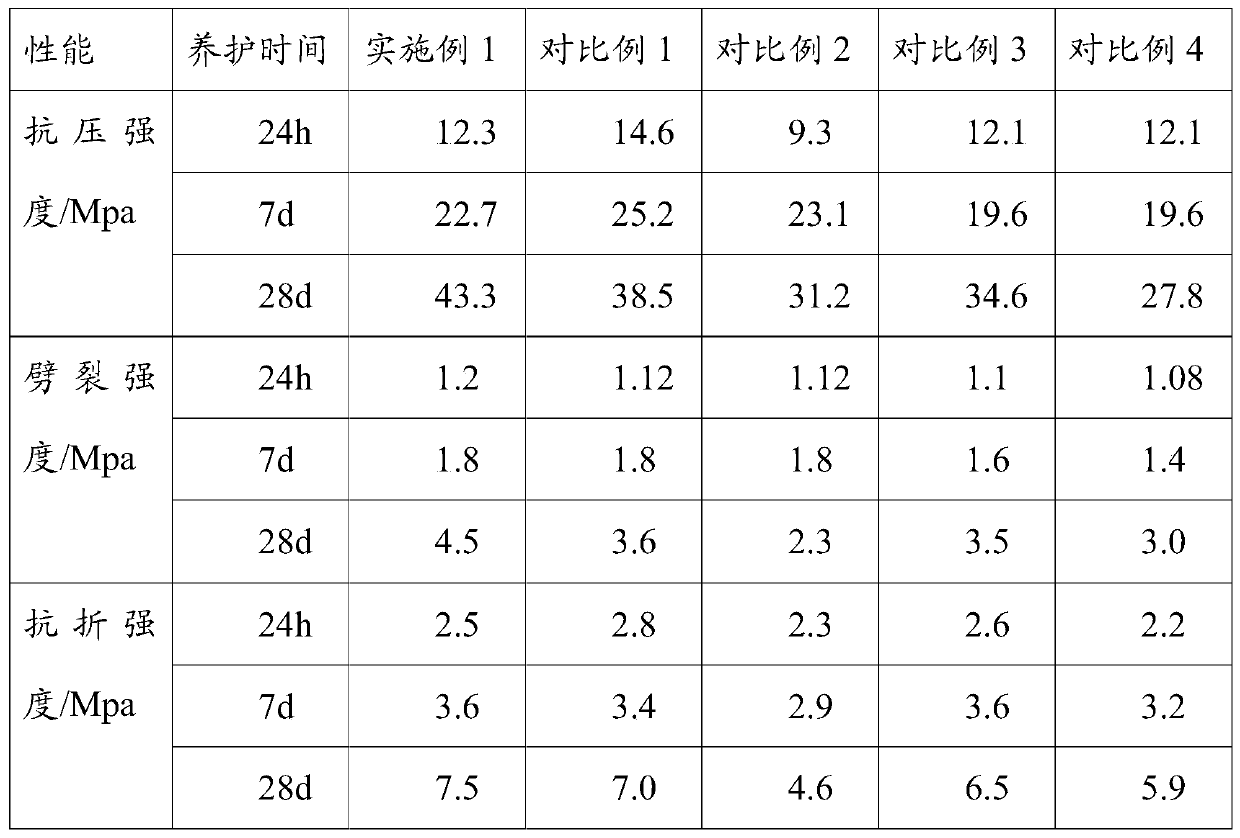

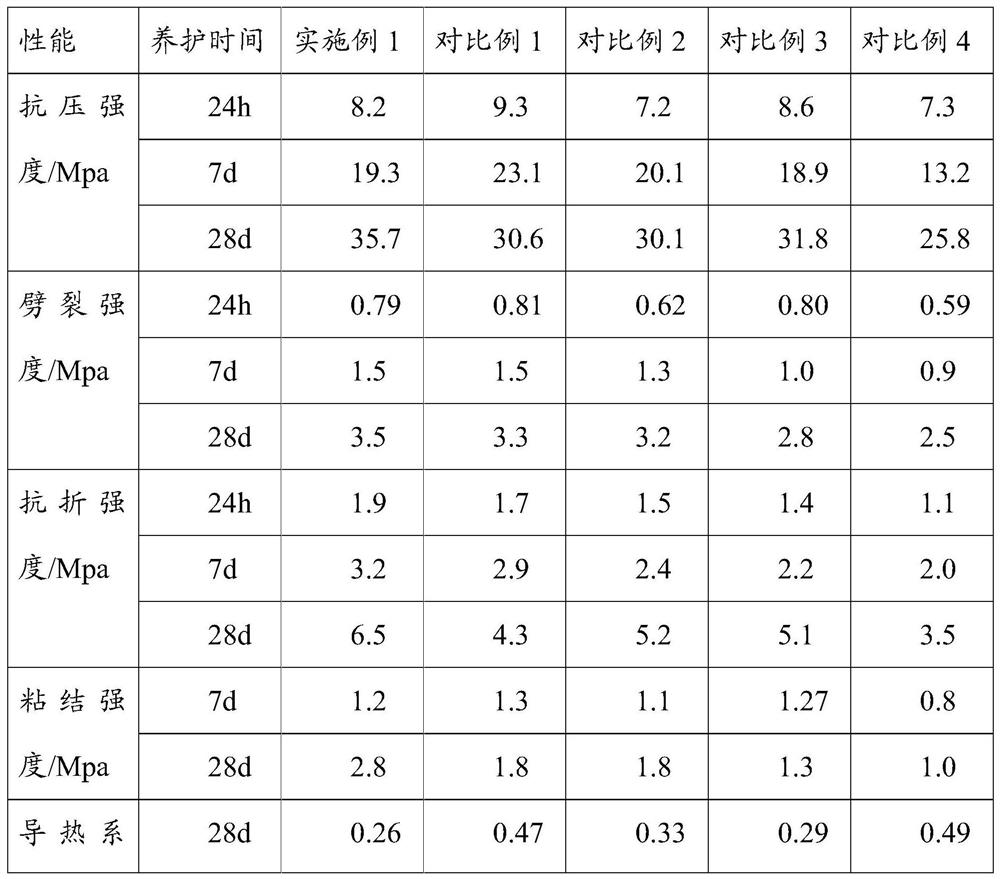

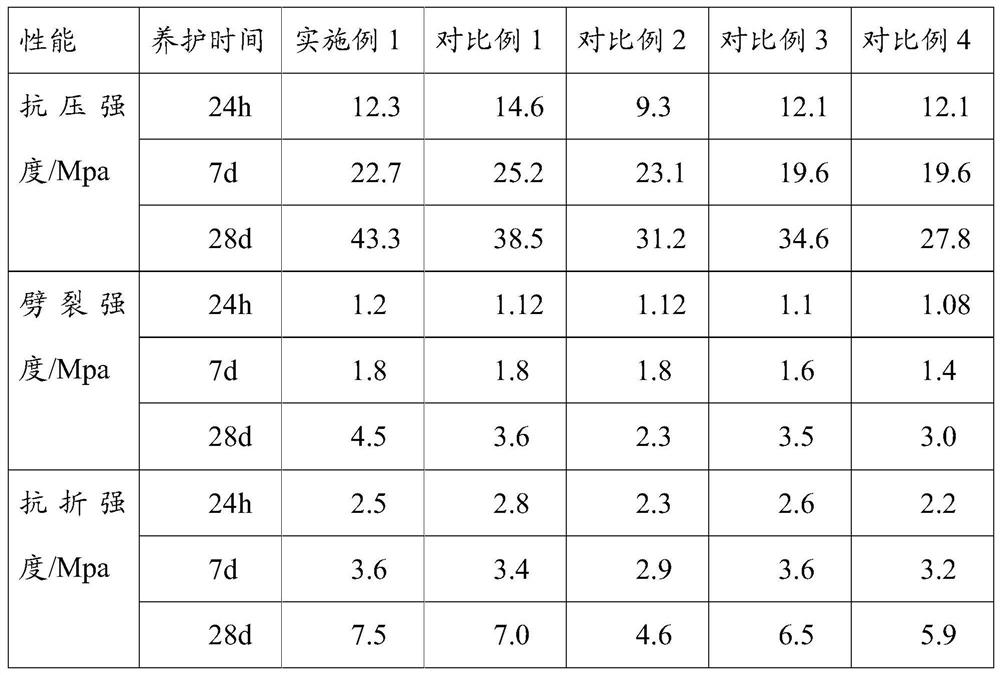

High strength sprayed concrete for high ground temperature tunnels and preparation method thereof

The invention discloses a high strength sprayed concrete for high ground temperature tunnels and a preparation method thereof. The concrete comprises following raw materials: cement, fly ash, slag powder, sand, coarse aggregate, glass beads, PVA fibers, steel fibers, modified rubber, a water reducer, a setting accelerator, and water. Low melting point water-soluble PVA fibers are adopted, after concrete reaches the melting point of the PVA fibers, fibers are melted, tunnels are formed, thus water steam in the concrete can be conveniently dissipated through the tunnels, the steam pressure in the concrete is reduced, the risk of bursting is reduced, at the same time, the melted water-soluble PVA fibers can largely enhance the inner cohesive force of concrete, and the cracking of a cement face is avoided. Through the cooperation of all raw materials, the prepared concrete has the characteristics of low heat conductivity coefficient, good anti-permeability, high interfacial bond strength,and little long-term strength loss. The long-term strength of concrete after spraying is largely improved. The cracking of high ground temperature concrete is avoided.

Owner:CHANGAN UNIV

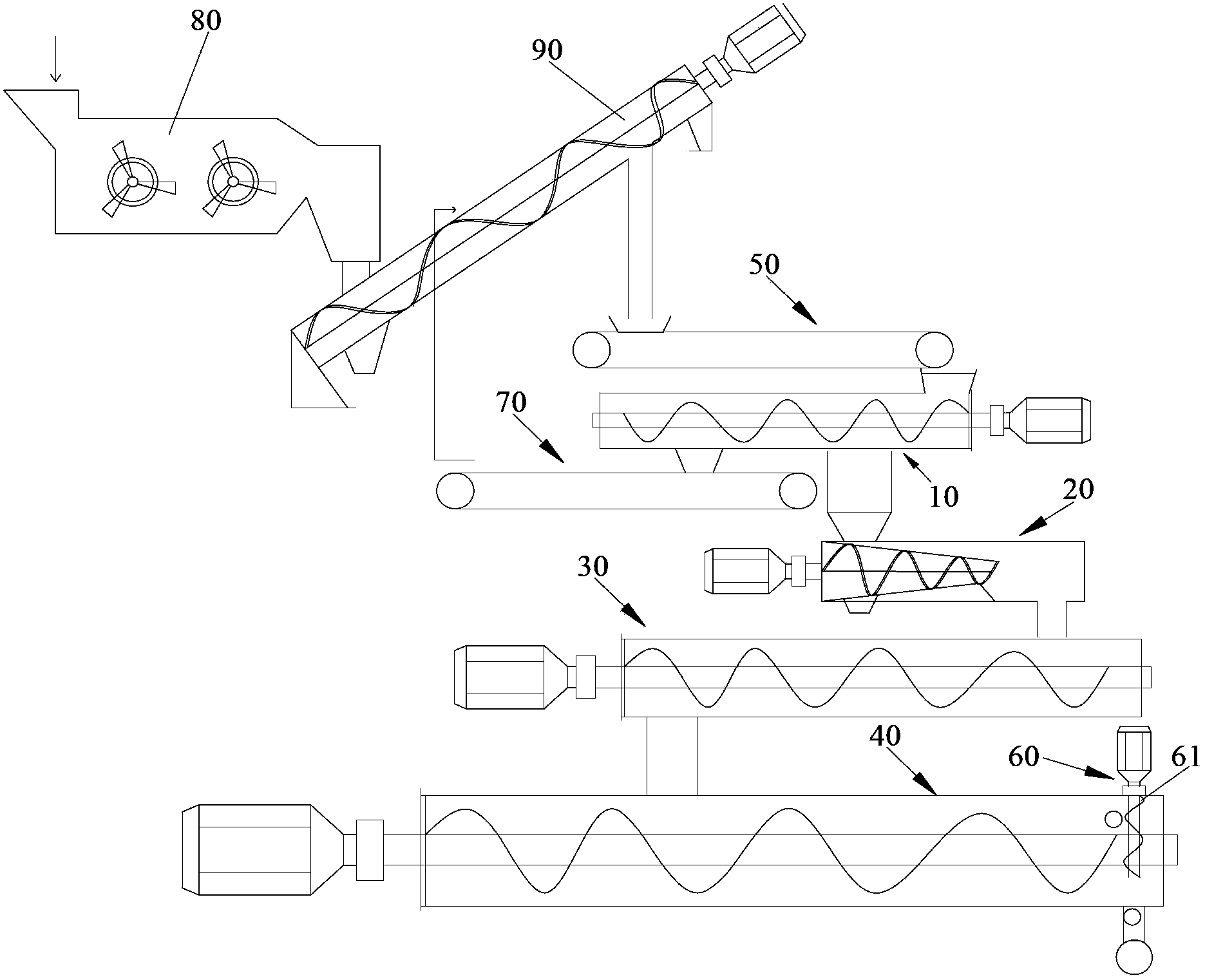

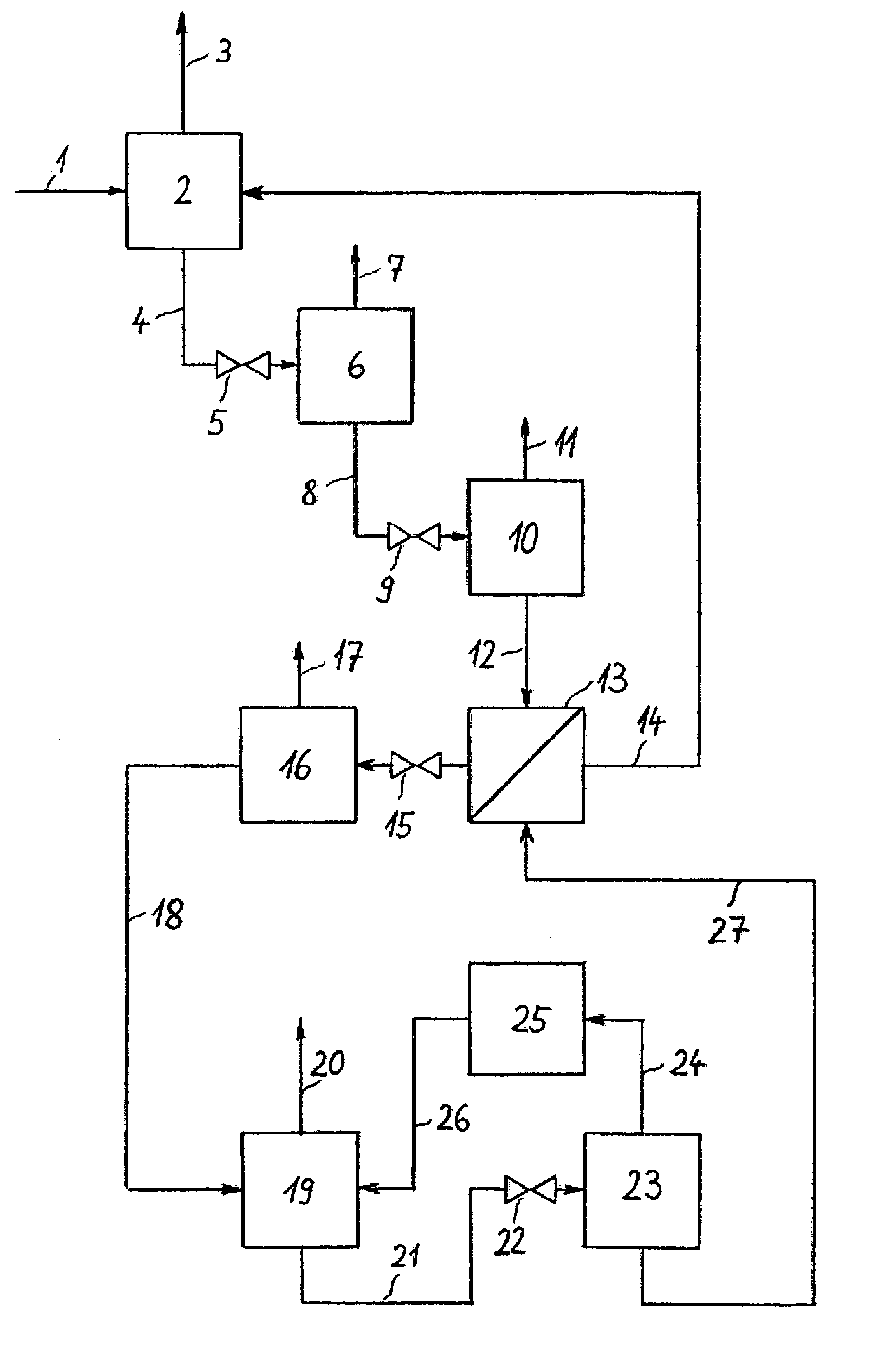

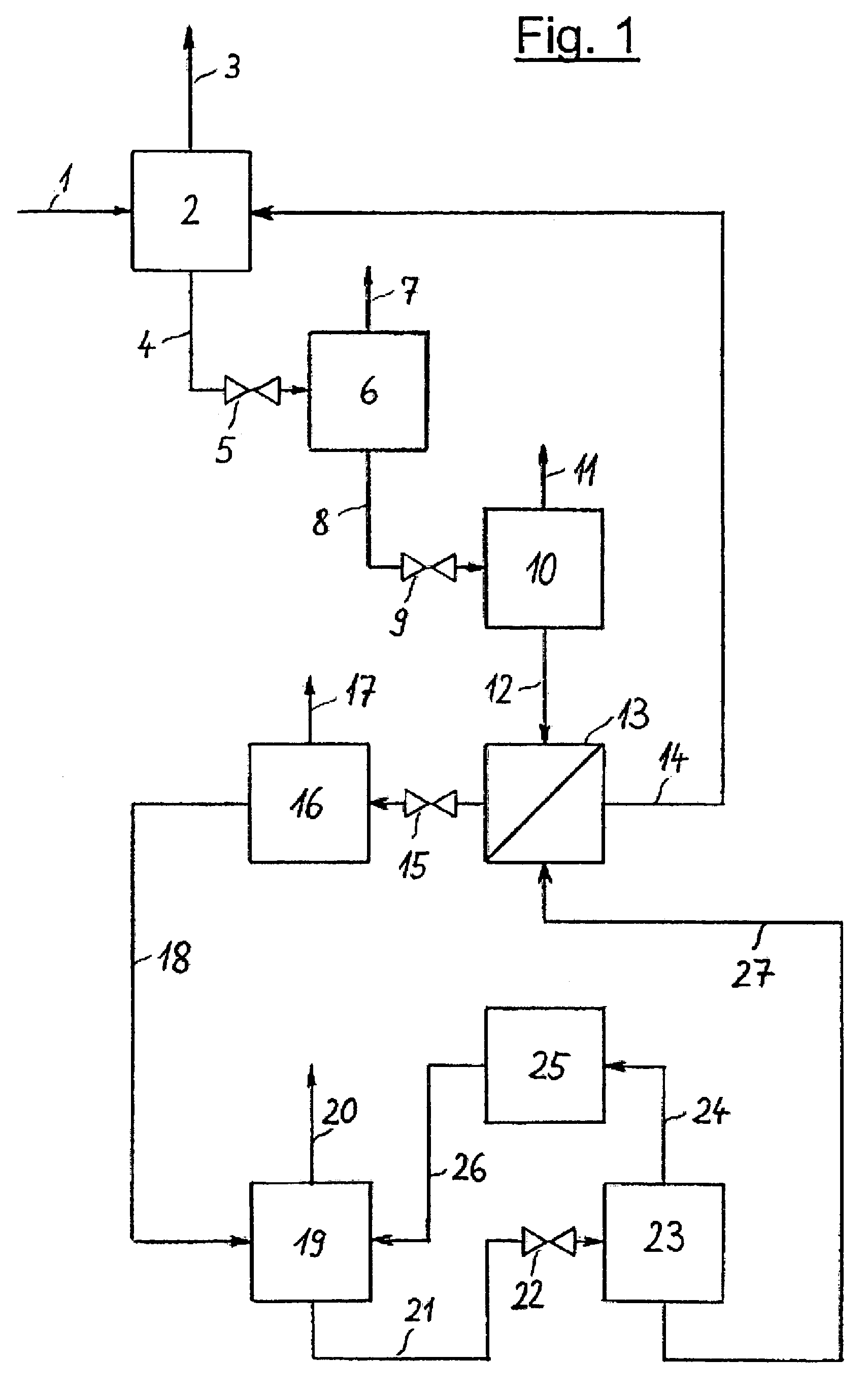

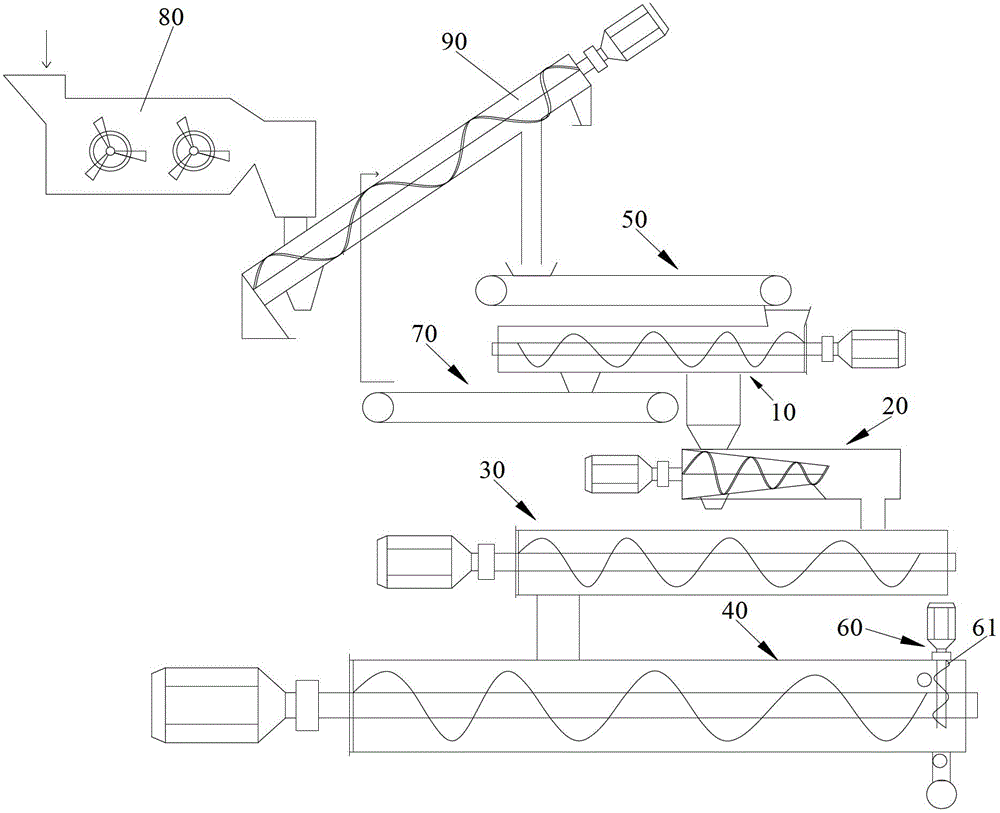

Pretreatment method of cellulosic ethanol raw materials

ActiveCN103898788AEasily damagedReduce the temperaturePaper material treatmentPretreatment methodPre treatment

The invention discloses a pretreatment method of cellulosic ethanol raw materials. The pretreatment method is characterized in comprising following steps: step 1, cellulose raw material is delivered into a screw feeder (20) for squeeze dehydration so as to remove at least a part of water of the cellulose raw material and obtain a compact product, wherein dry substance content of the compact product accounts for 20 to 50wt%; step 2, the compact product is delivered into a first-stage steam receiver (30), and is scattered, and the scattered cellulose raw material is subjected to first-stage steam treatment, wherein pH value of steam in the first-stage steam receiver (30) is lower than 7; and step 3, the cellulose raw material processed via first-stage steam treatment is delivered into a second-stage steam receiver (40) for second-stage steam treatment. The pretreatment method is used for pretreatment of cellulose raw material so as to reduce energy consumption; and the amount of inhibition substances generated when the cellulose raw material is subjected to steam treatment can be reduced; and recovery rate of cellulose and recovery rate of hemicellulose are increased.

Owner:COFCO NUTRITION & HEALTH RES INST +2

Sterilization challenge specimen holder

ActiveUS20090029451A1Smooth transitionAvoid improper sealingBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineering

Owner:AMERICAN STERILIZER CO

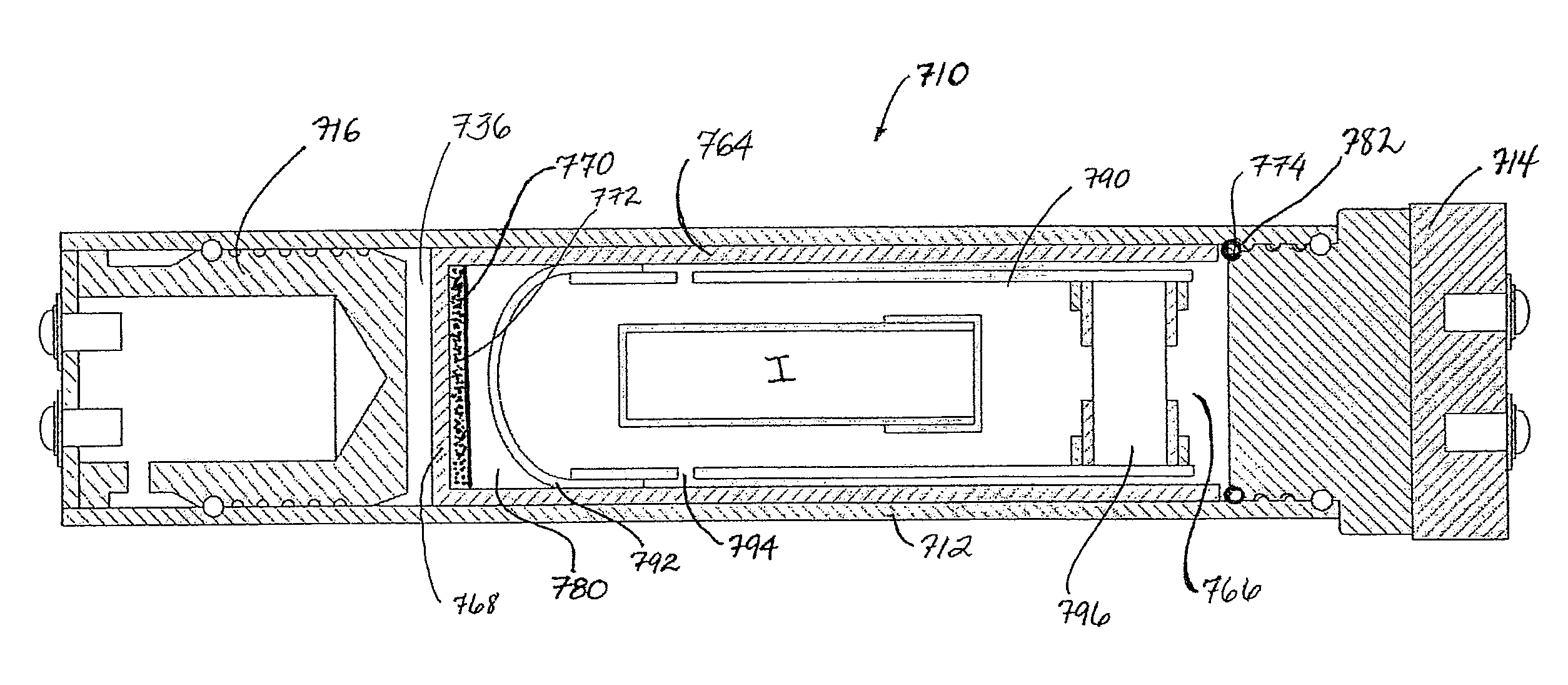

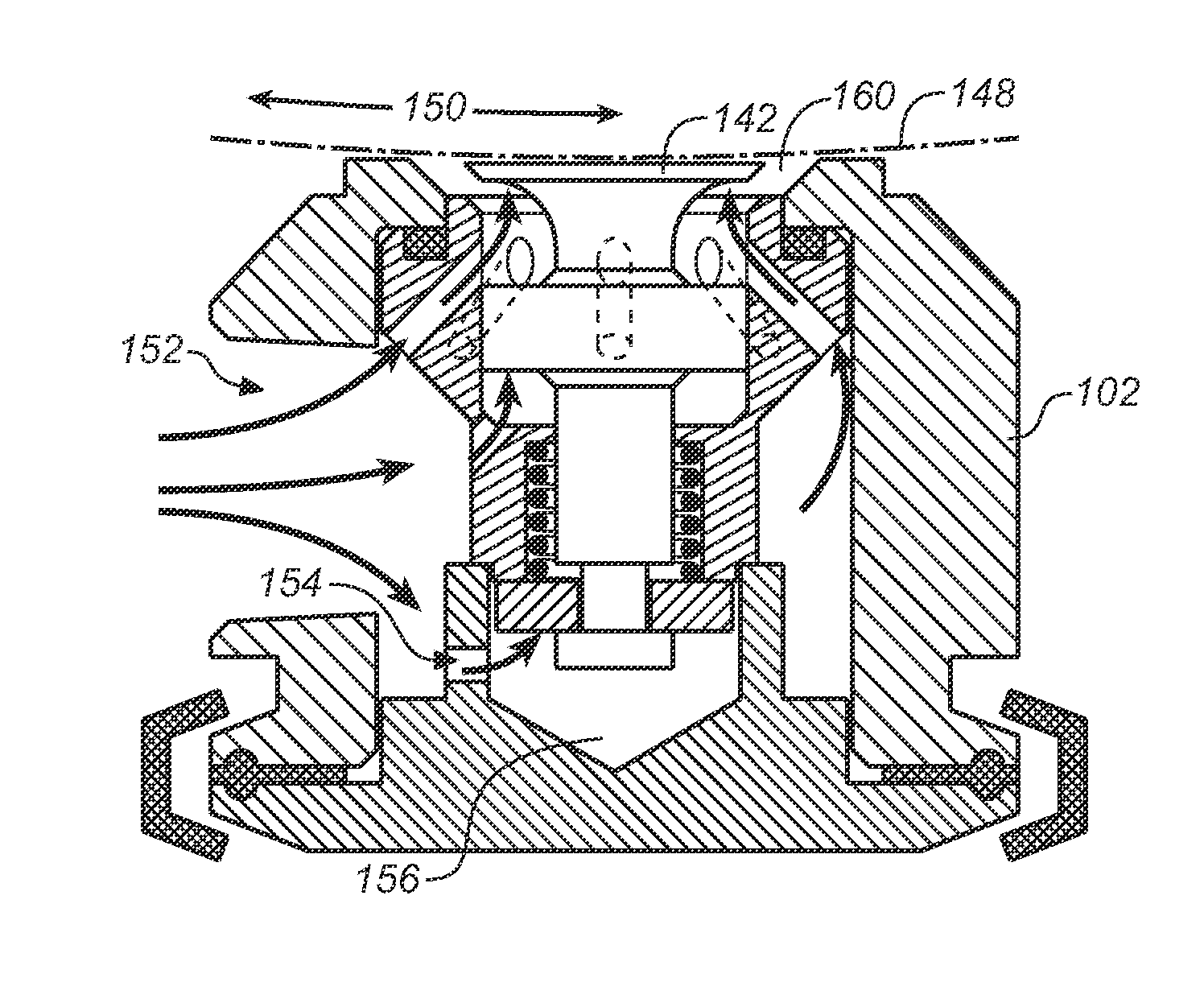

Low pressure, low velocity steam injector

A direct steam injector for use in cooking food products by injecting live steam directly into the product to heat the food to cook temperatures. The injector operates under relatively low source steam manifold pressure while urging the valve return spring wide open, thus reducing the pressure of the steam flowing into the product. In addition to reducing the pressure of the steam, the steam injector reduces the velocity of the steam and better distributes it as the steam exits the injector, thereby reducing damage to the food product.

Owner:HORN DARRELL C +1

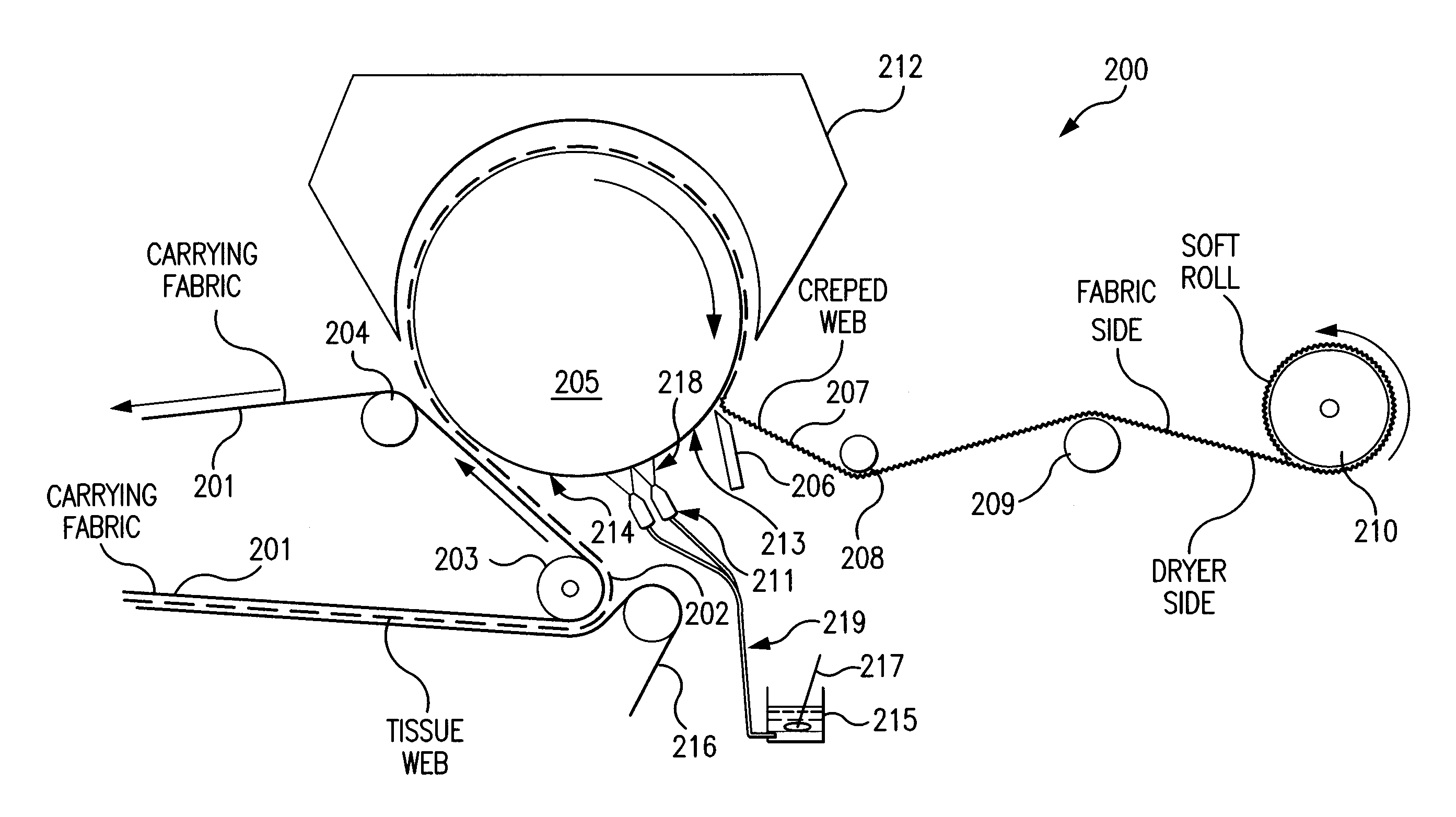

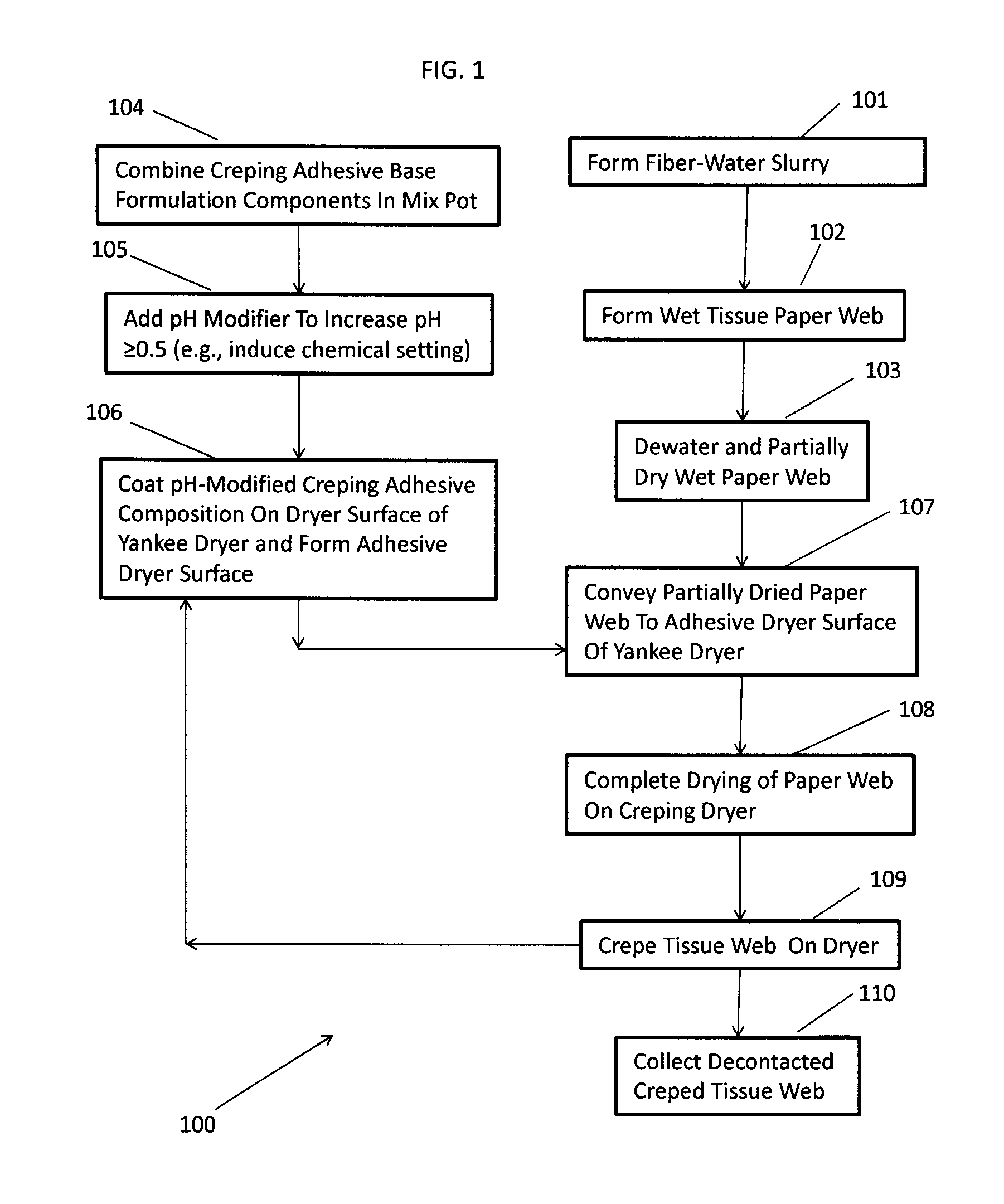

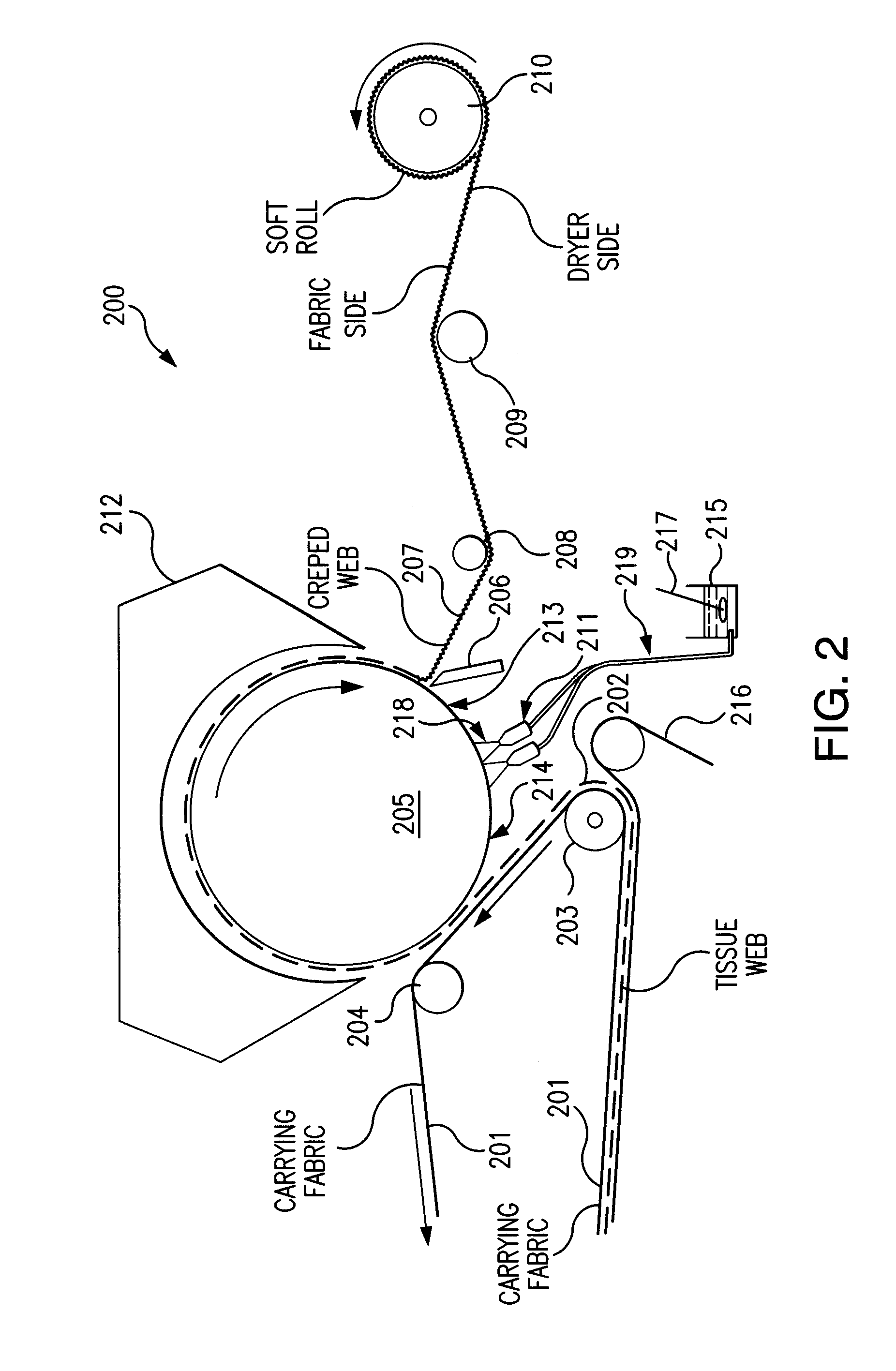

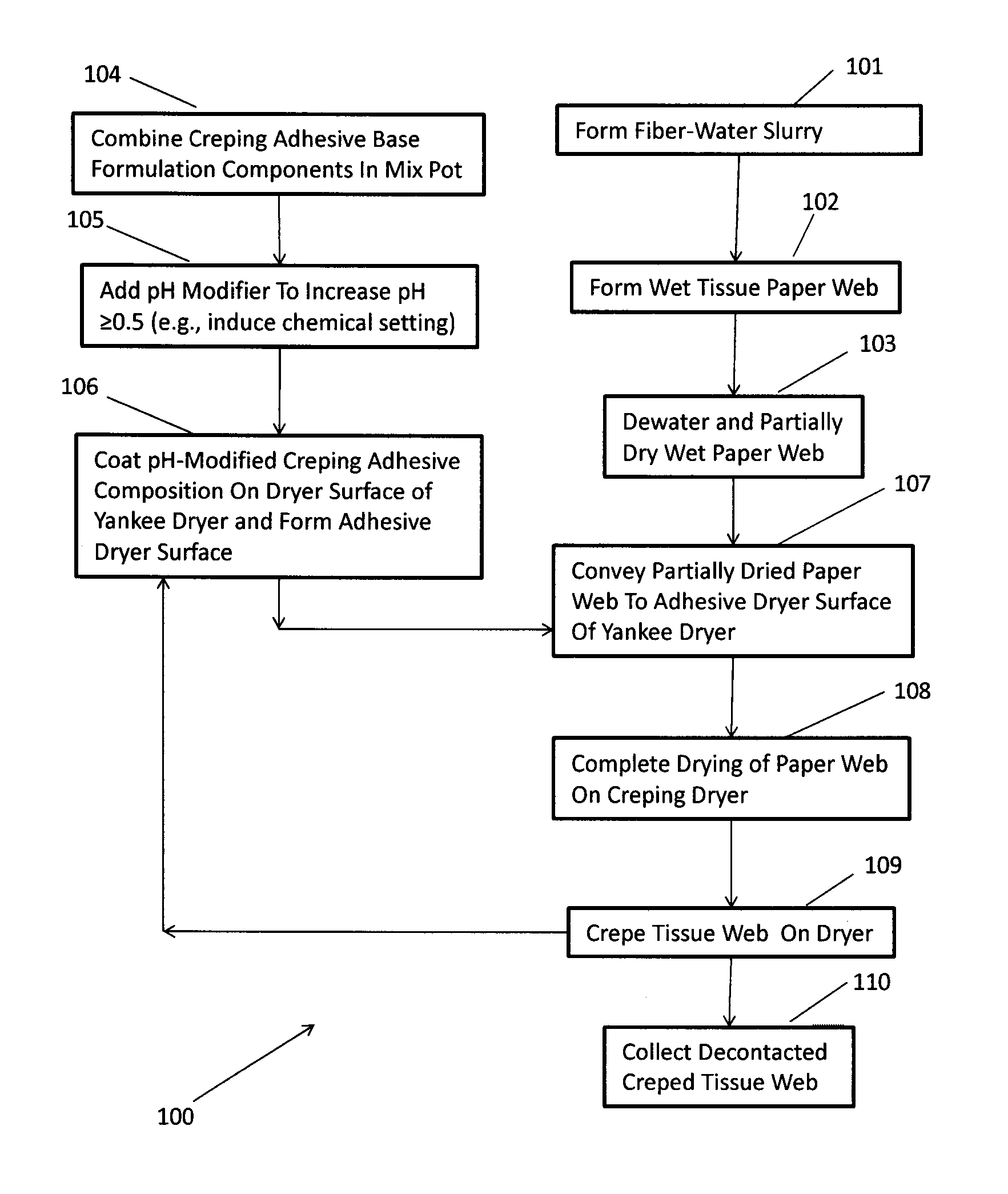

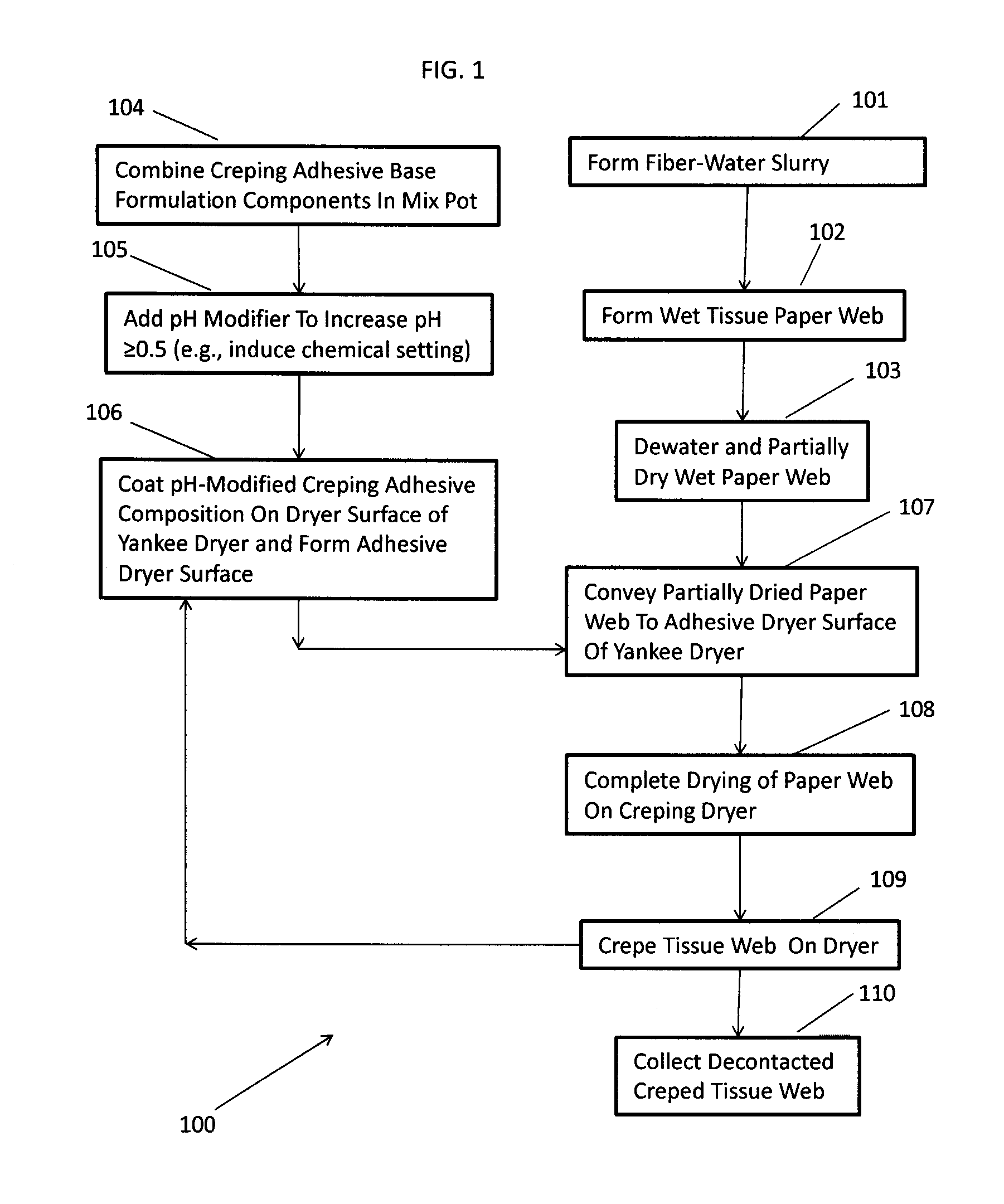

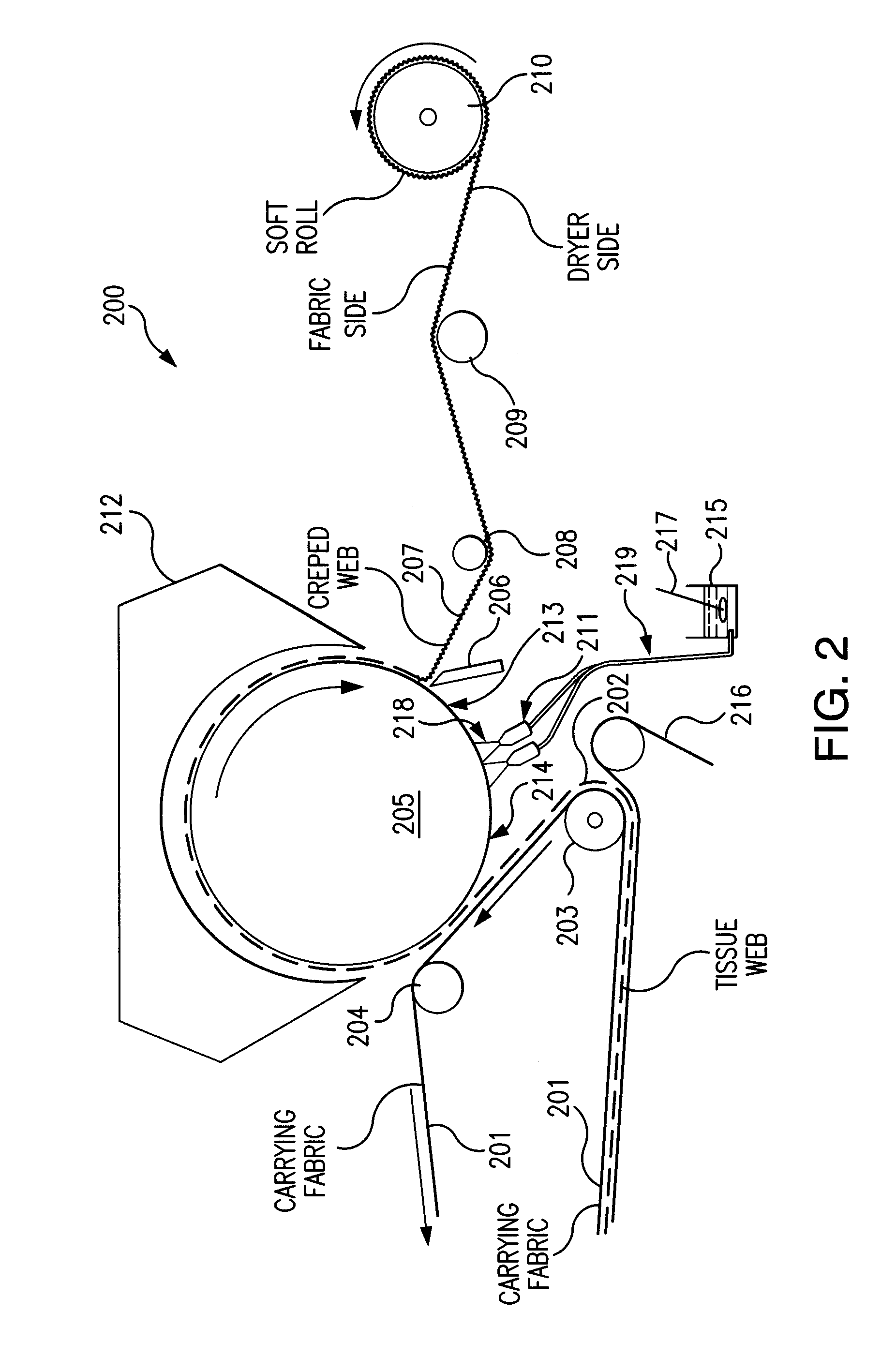

Creping Methods Using pH-Modified Creping Adhesive Compositions

InactiveUS20130032302A1Enhancing creping performanceImprove performanceNatural cellulose pulp/paperMechanical working/deformationFiberCrosslinked polymers

A method for manufacturing a creped fiber web is provided and includes providing a rotating cylindrical dryer surface, providing a creping adhesive composition or coating package having a pH boosted at least 0.5 pH units relative to its original base formulation pH in the range of from about 4.5 to about 9, for chemically setting a crosslinkable polymer component at least in part before applying the creping adhesive composition to the rotating cylindrical dryer surface to provide an adhesive dryer surface on which a fiber web can be transferred, dried, and creped.

Owner:BUCKMAN LAB INT INC

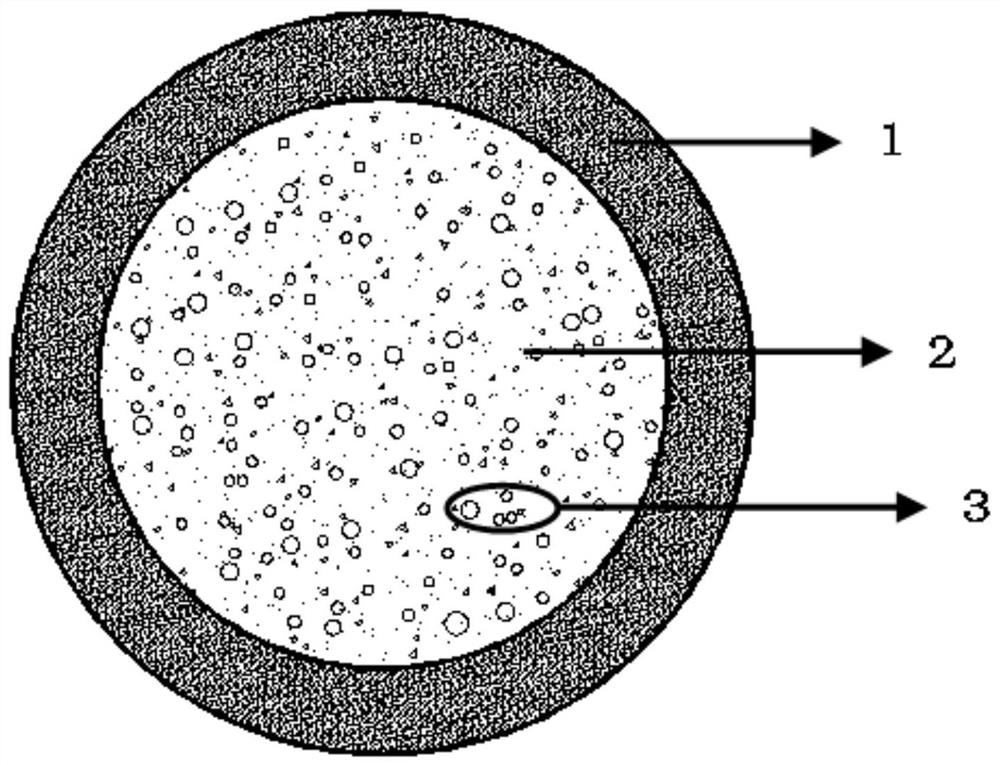

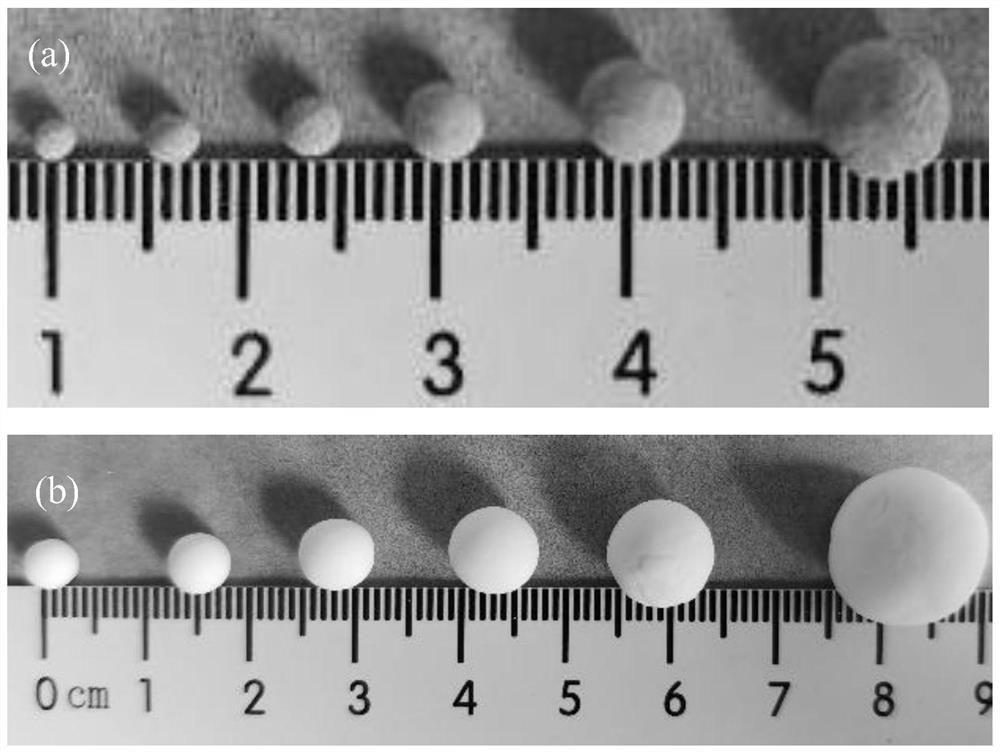

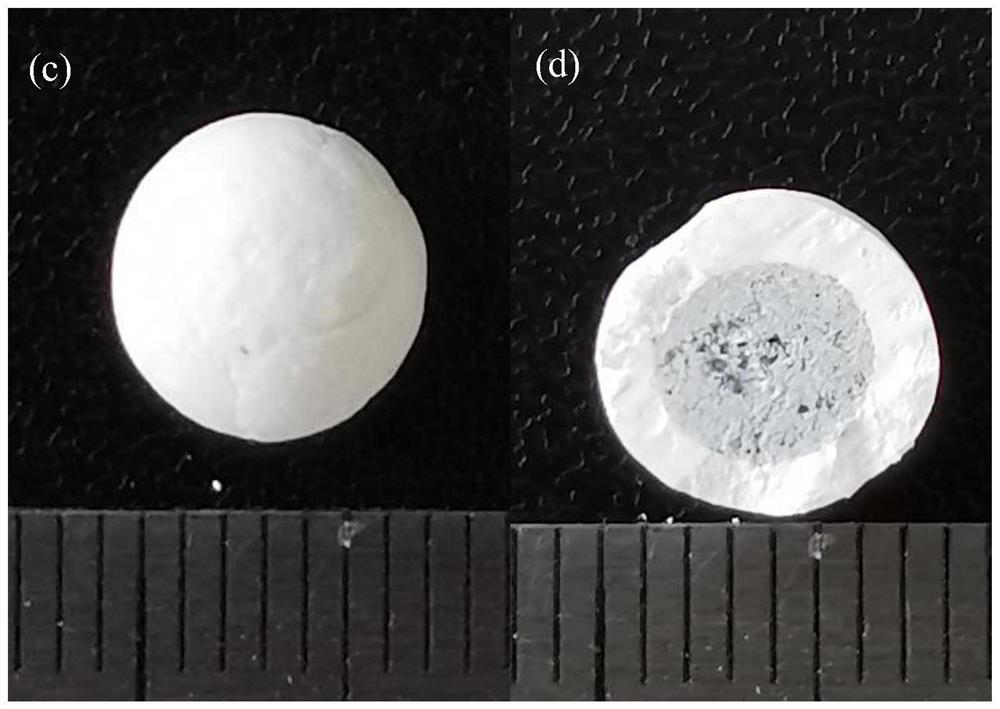

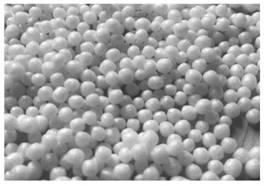

Phase-change heat-storage large capsule with metal core material coated with ceramic shell and preparation method of phase-change heat-storage large capsule

PendingCN112111250AHigh heat storage densityGood thermal cycle performanceTransportation and packagingMetal-working apparatusSlurryMetal powder

The invention discloses a phase-change heat-storage large capsule with a metal core material coated with a ceramic shell and a preparation method of the phase-change heat-storage large capsule. The preparation method comprises the following steps: preparing a spherical metal core material from a metal powder raw material, then evenly coating the surface of the spherical metal core material with alayer of ceramic slurry, conducing forming and drying to obtain the large capsule with the metal core material coated with the ceramic shell, and finally, carrying out two-stage heat treatment consisting of low-temperature presintering and high-temperature sintering to prepare the phase-change heat-storage large capsule with the metal core material coated with the ceramic shell. The large capsuleis a spherical capsule with a diameter of 1-50 mm and structurally comprises a ceramic shell layer and a metal core, wherein the diameter of the metal core is 0.5-30 mm, and a hole is formed in the metal core layer. The spherical large capsule prepared by the method can effectively solve the problems of volume expansion of metal at high temperature and liquid phase leakage at high temperature; andthe preparation method is simple in process, friendly to environment and suitable for industrial batch production.

Owner:CHINA UNIV OF MINING & TECH

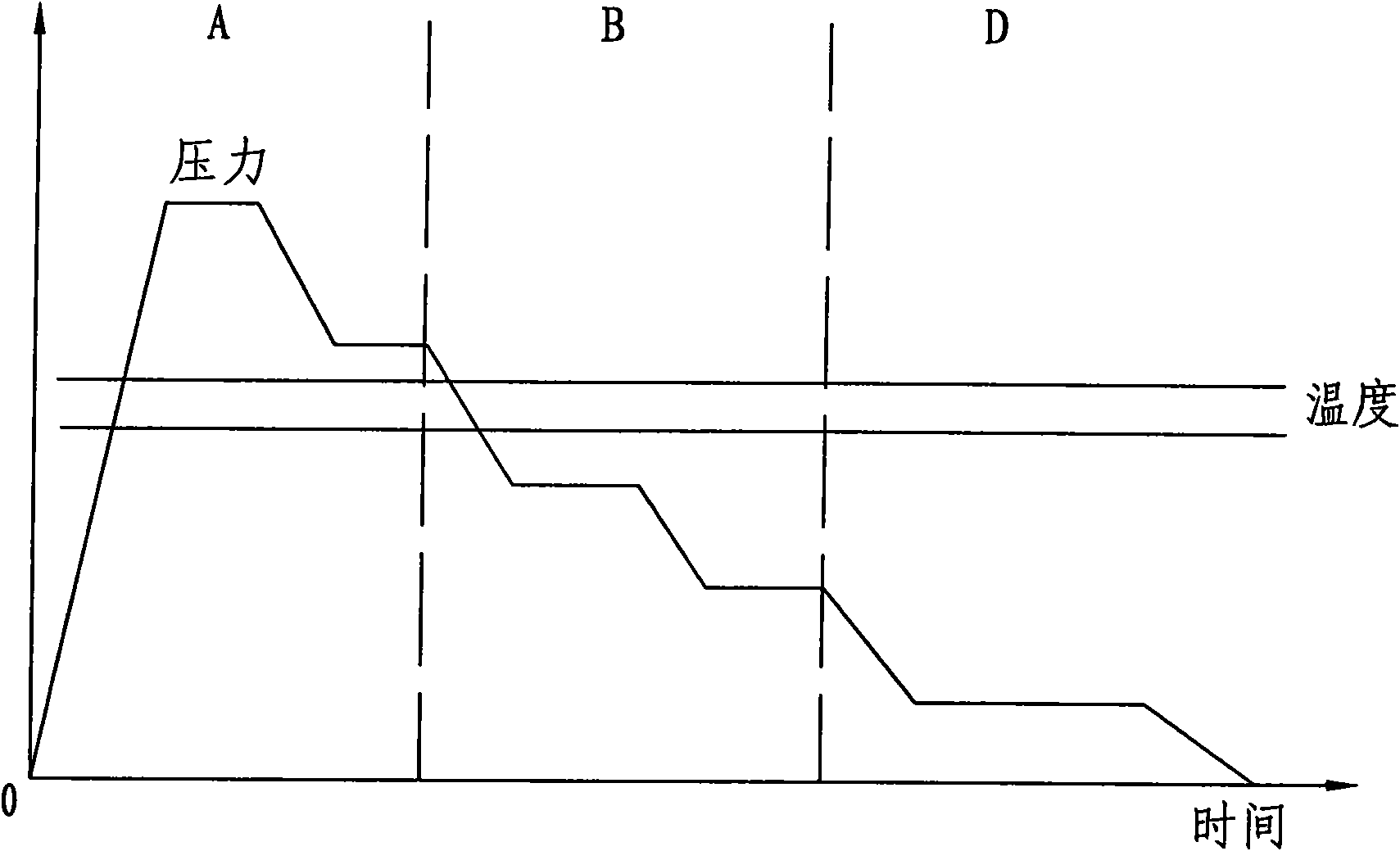

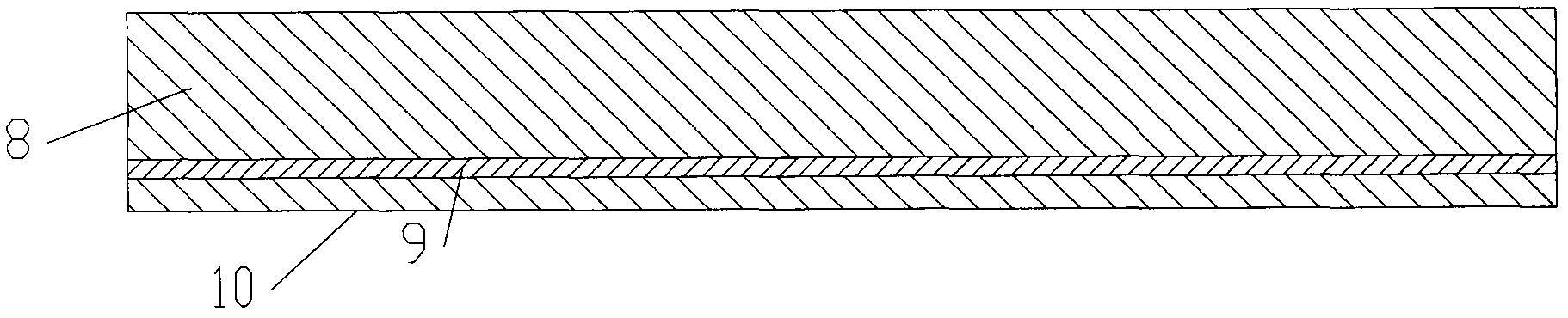

Processing technology for manufacturing board by utilizing crop straws

ActiveCN101670604AReduce the temperatureReduce steam pressureDomestic articlesFlat articlesAdhesiveMixed materials

The invention relates to processing technology for manufacturing a board by utilizing crop straws, which is characterized in that the processing technology comprises the steps of: a, preparing materials, namely performing processing treatment on the crop straws to prepare needed raw materials, and evenly mixing the raw materials with an adhesive; b, paving the materials namely paving the mixed materials to form a board blank to be hot-pressed; c, carrying out hot pressing on the board, namely molding the board blank into the needed board with the hot-pressing board; dividing the hot-pressing process on the board blank into a compression stage, a molding stage and a tempering treatment stage, wherein a molding temperature set value in the molding stage is lower than a compression temperature set value in the compression stage, and a tempering temperature set value in the tempering treatment is between the molding temperature set value and the compression temperature set value; and d, post processing, namely carrying out post processing on the board after the hot pressing to obtain a finished product. Therefore, the processing technology has no technological design of the conventional steam release stage, can solve the problems of layering, board bursting and bubbling in the process of manufacturing the board, save the time, and improve the rate of finished products and processing efficiency..

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

Creping methods using pH-modified creping adhesive compositions

InactiveUS8568562B2Improve performanceReduce dependenceNatural cellulose pulp/paperMechanical working/deformationFiberCrosslinked polymers

A method for manufacturing a creped fiber web is provided and includes providing a rotating cylindrical dryer surface, providing a creping adhesive composition or coating package having a pH boosted at least 0.5 pH units relative to its original base formulation pH in the range of from about 4.5 to about 9, for chemically setting a crosslinkable polymer component at least in part before applying the creping adhesive composition to the rotating cylindrical dryer surface to provide an adhesive dryer surface on which a fiber web can be transferred, dried, and creped.

Owner:BUCKMAN LAB INT INC

Sterilization challenge specimen holder

ActiveUS20090028753A1Smooth transitionAvoid improper sealingBioreactor/fermenter combinationsBiological substance pretreatmentsElectrical and Electronics engineeringEngineering

Owner:AMERICAN STERILIZER CO

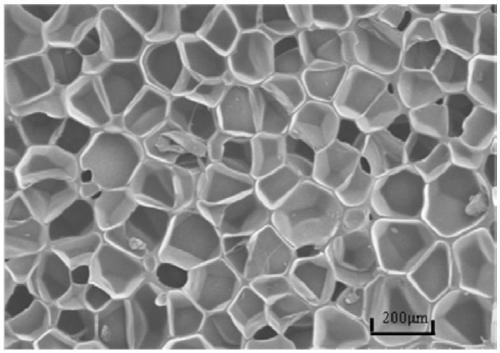

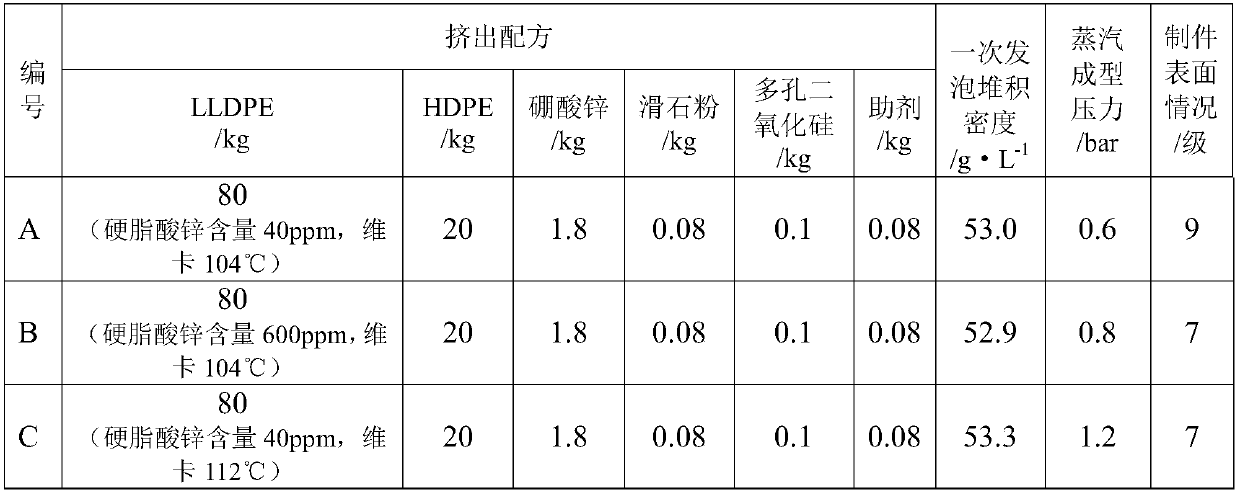

Easily melted foamed polyethylene bead with strong temperature tolerance and preparation method thereof

ActiveCN109651695AIncrease elasticityImprove temperature resistanceLow-density polyethyleneThermal insulation

The invention discloses an easily melted foamed polyethylene bead with strong temperature tolerance and a preparation method thereof. Low density polyethylene with a Vicat softening point of 90 to 105DEG C and high density polyethylene are compounded, at the same time, an inorganic compounding foaming aid is adopted, and through the synergistic effect generated by three components, goals of easily melting and high temperature tolerance are realized. Through the cooperation of formula and technology, the size of inner pores of primarily foamed EPE beads is controlled in a range of 200 to 230 [mu]m, after foaming, no thermal insulation device is needed, and a step of introducing steam with a certain air pressure into a pipe for delivering polypropylene resin particles is not needed either.The moulding steam pressure is obviously reduced, the melting stability between particles is excellent, and the curing degree is 95% or more. Because the inner pores in the beads are increased, and the pore uniformity is increased, the polyethylene bead can tolerate a certain moulding temperature, the stiffness of pores in the surface of a moulded product is improved, and the beauty of the surfaceof a EPE bead moulded product is obviously improved.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

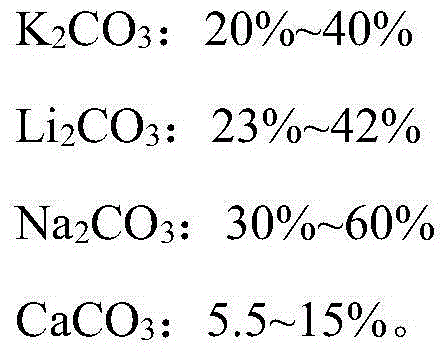

Mixed carbonate heat transfer and heat storage working medium

InactiveCN104479645AHigh chemical inertnessLow configuration costHeat-exchange elementsWorking temperatureMolten salt

A mixed carbonate heat transfer and heat storage working medium comprises the following molten salt components by mole fraction: 20%-40% of K2CO3, 23%-42% of Li2CO3, 30%-60% of Na2CO3, and 5.5-15% of CaCO3. The molten salt working medium has the advantages of high heat transfer coefficient, high working temperature, less corrosion, low vapor pressure, environmental-friendliness, good safety and the like.

Owner:BEIJING UNIV OF TECH

Preparation method of block-shaped rice noodles

The invention relates to a preparation method of block-shaped rice noodles. The preparation method comprises the following steps of uniformly mixing potato starch with sweet potato starch, pea starch, corn starch, buckwheat flour, black rice, sorghum and wheat kernels, then performing grinding to obtain mixed powder materials, and screening the mixed powder materials with a 160-200-mesh screen stencil; adding purified water to the screened mixed powder materials to form paste, wherein the mixed powder materials are 30-40% of the total weight of the paste, then adding carrageenin which is 0.3% of the total weight of the paste to be used as a texture improver, performing stirring and uniform mixing to obtain noodle dough, letting steam in, performing primary steaming, wherein the primary steaming time is 5-12 minutes, and the steam pressure is 0.3-0.5MPa; putting the steamed noodle dough into a rice noodle making machine, performing vermicelli extruding to obtain rice vermicelli, performing re-steaming under the condition of re-steaming time being 8-12 minutes and re-steaming pressure being 0.1MPa, and after re-steaming, cutting the steamed rice vermicelli into segments; and conveying the rice vermicelli segments into a drying box for drying, after drying, controlling the water content to be 11-13wt%, and performing cooling so as to obtain finished products. The block-shaped rice noodles produced by the method disclosed by the invention are good in mouth feel and rich in nutrition.

Owner:紫金县金霸食品有限公司

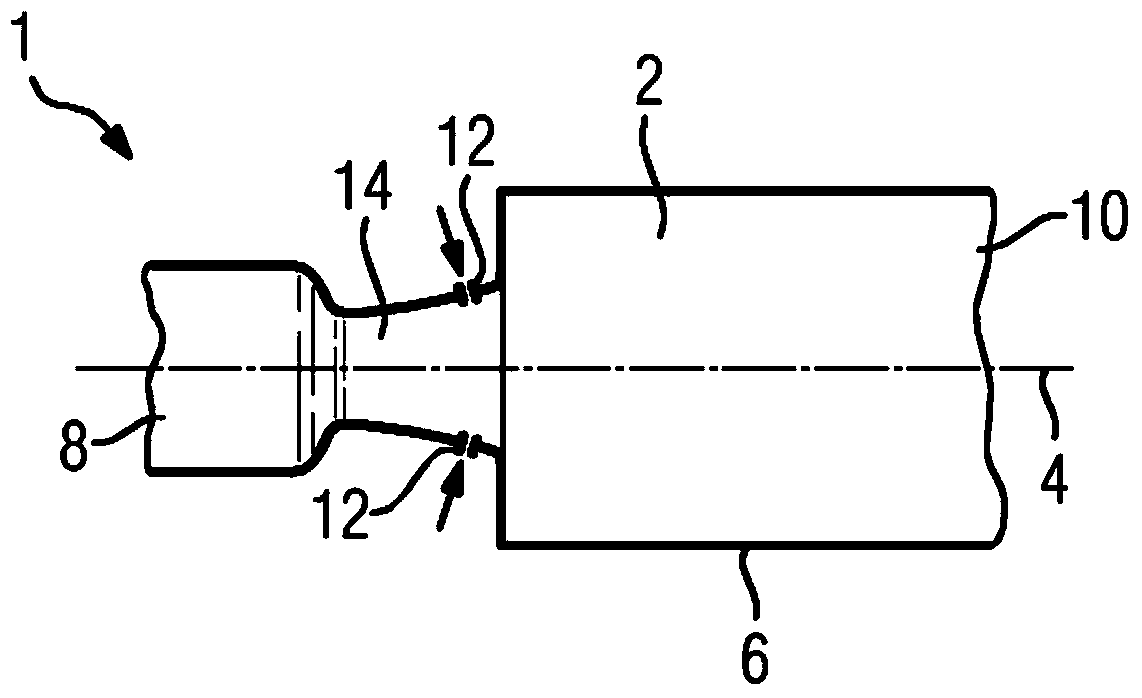

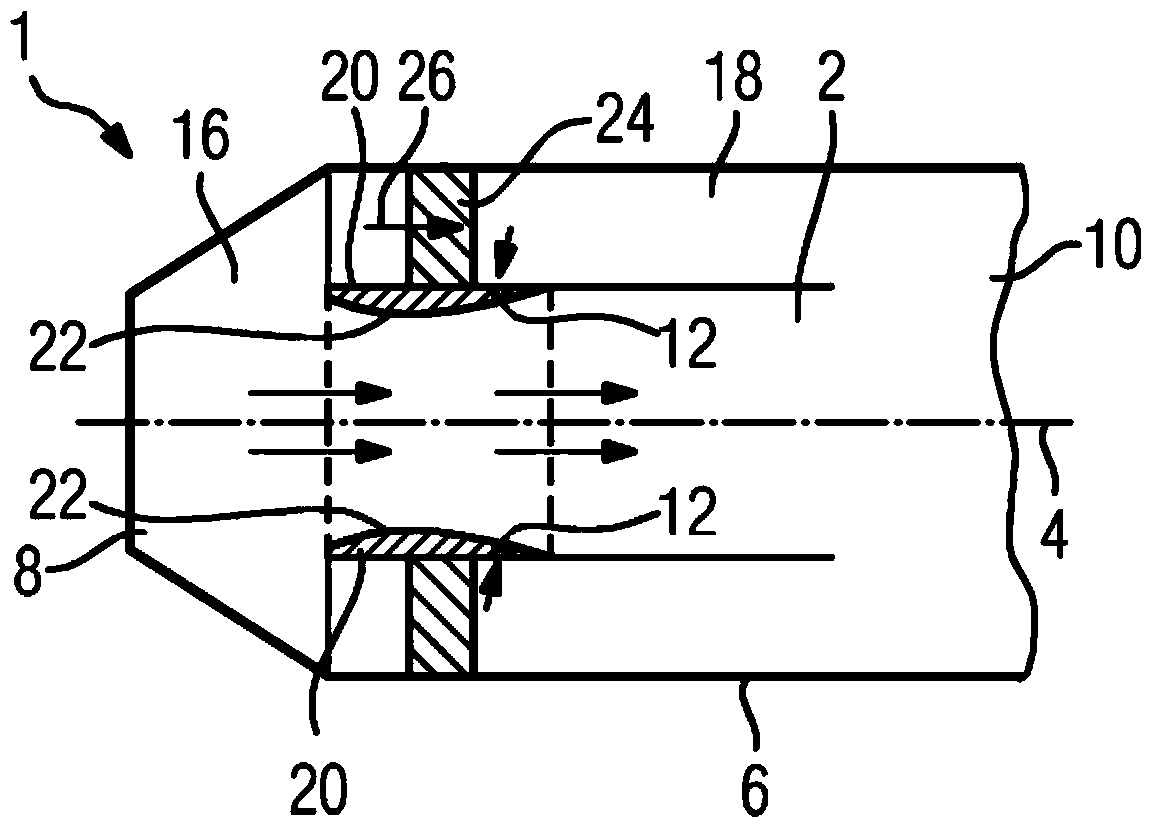

Water injection device for a bypass steam system of a power plant

InactiveCN104094053AAccelerate evaporationWon't accumulateSuperheating controlFlow mixersPower stationEngineering

A water injection device (1) for a bypass steam system of a power plant, comprising a flow channel (2) for steam with a steam inlet (8) and a steam outlet (10), and an injection nozzle (12) which is arranged between the steam inlet and outlet (8, 10), is to have a particularly satisfactory cooling action in order to avoid condenser damage by way of technically particularly simple means. To this end, the injection nozzle (12) is arranged on a wall (20) which extends substantially in the direction of the gas flow and is arranged spaced apart from an inner wall (6) of the flow channel (2).

Owner:SIEMENS AG

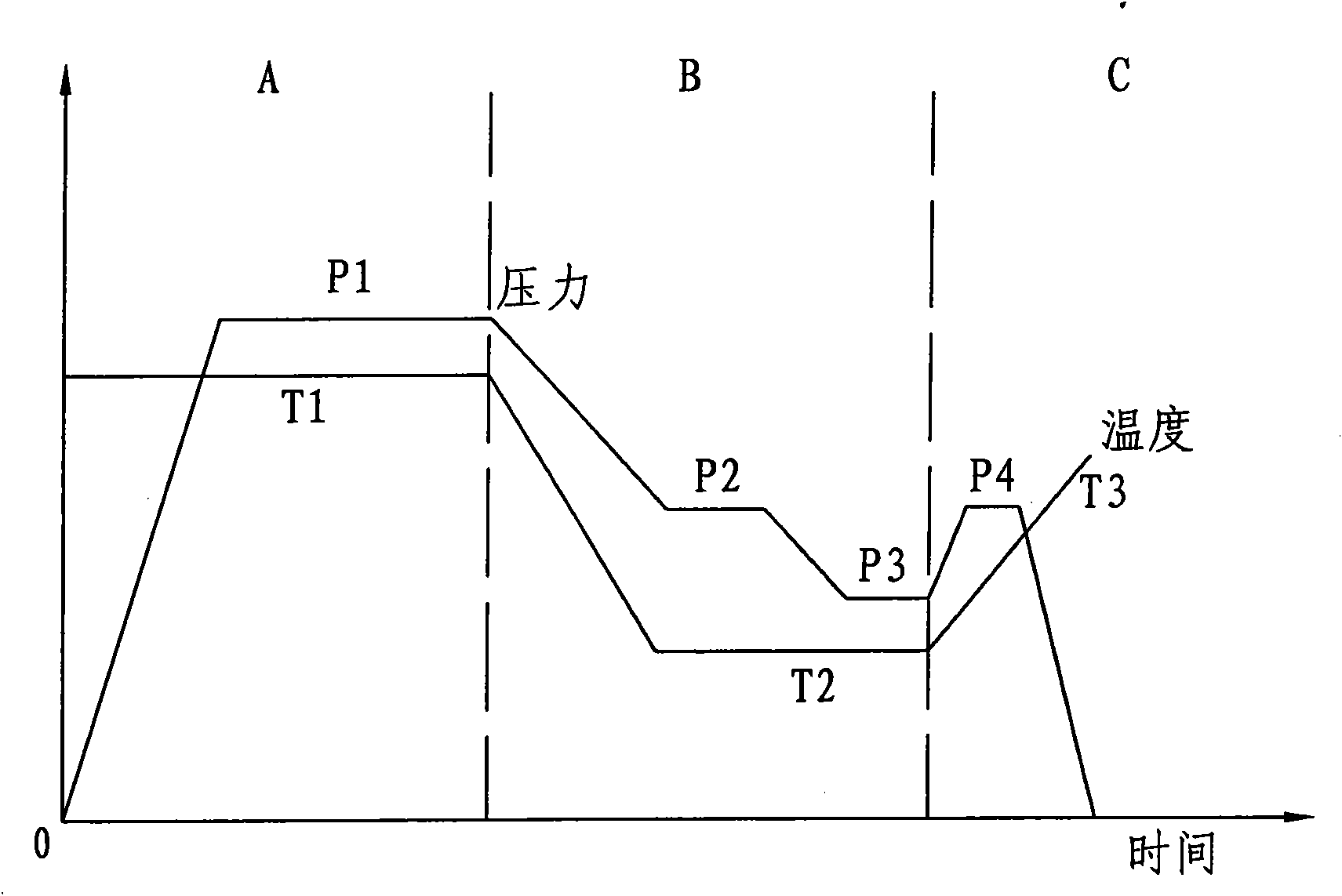

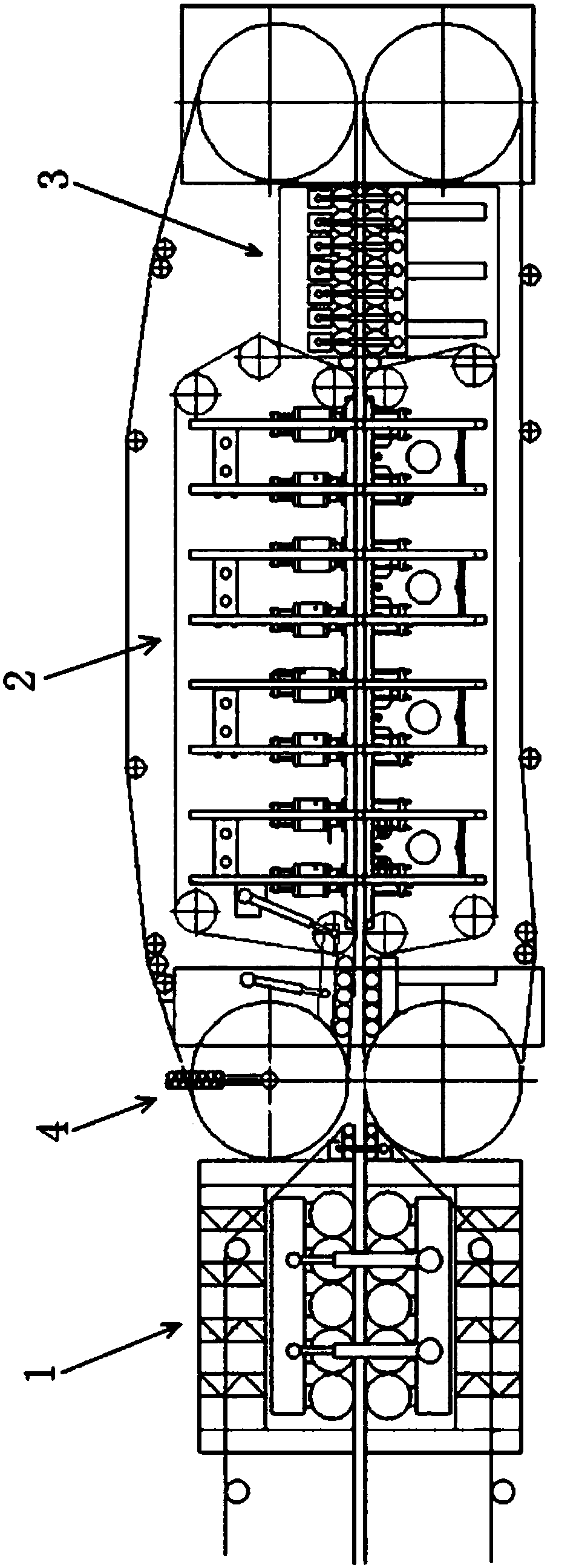

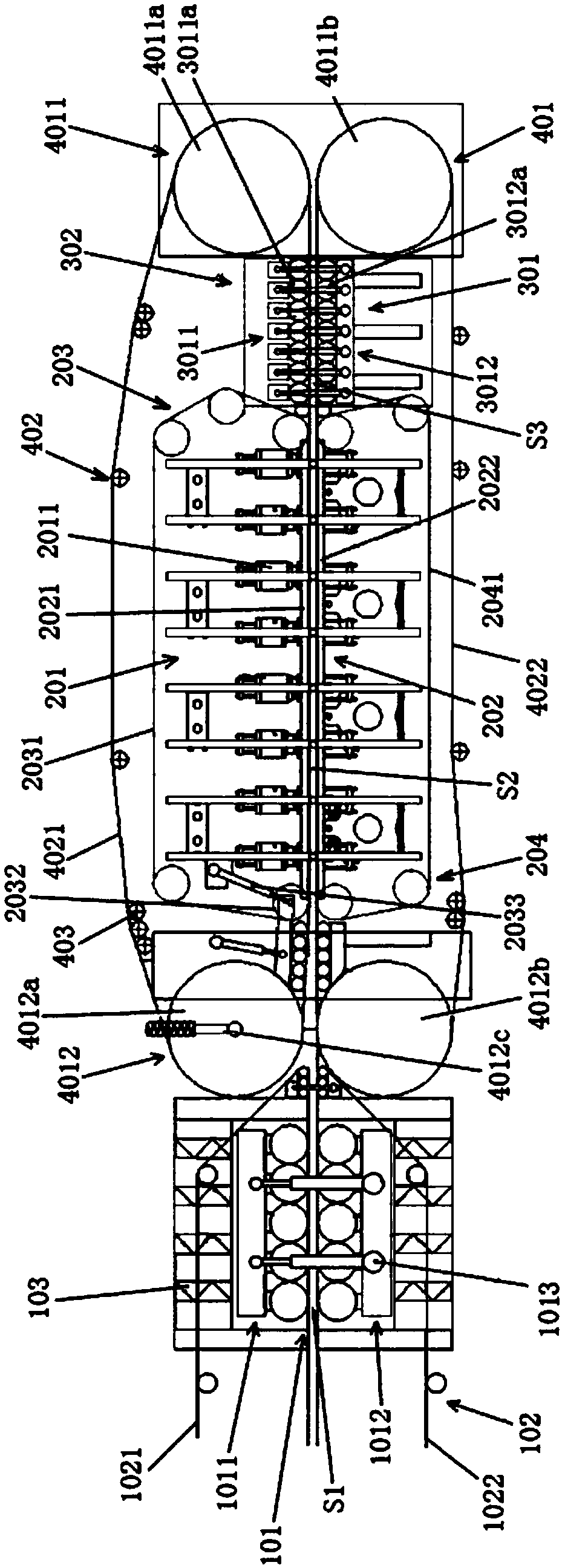

How plywood is made

ActiveCN106903761BImprove efficiencyShorten the production cycleOther plywood/veneer working apparatusPlywood pressesThree stageMetallurgy

The invention discloses a preparation method of plywood. The preparation method is characterized in that the preparation method comprises the following steps: a) a continuous plywood blank formed by a continuous transverse veneer band and continuous longitudinal veneer band assembly and an adhesive enters a preheating and pressurizing unit and is subjected to preheating and pressurizing treatment simultaneously; b) after the preheating and pressurizing treatment, the plywood blank enters a heating and pressurizing unit from the preheating and pressurizing unit and is subjected to heating and pressurizing treatment; and c) the plywood blank subjected to the heating and pressurizing treatment enters a cooling and pressurizing unit from the heating and pressurizing unit through the conveying of a steel band conveying unit, and is subjected to thickness-fixed forming. According to the preparation method of the plywood, the plywood blank is made into the finished plywood by one step, so that a production cycle is short and the plywood production efficiency is high; and the finished plywood produced after the plywood blank is subjected to the three stages, namely, the preheating and pressurizing treatment, the heating and pressurizing treatment and the cooling thickness-fixed forming is stable and reliable in quality and durable in use.

Owner:CHINA FOMA GROUP

A kind of high-strength shotcrete for high ground temperature tunnel and its preparation method

The invention discloses a high strength sprayed concrete for high ground temperature tunnels and a preparation method thereof. The concrete comprises following raw materials: cement, fly ash, slag powder, sand, coarse aggregate, glass beads, PVA fibers, steel fibers, modified rubber, a water reducer, a setting accelerator, and water. Low melting point water-soluble PVA fibers are adopted, after concrete reaches the melting point of the PVA fibers, fibers are melted, tunnels are formed, thus water steam in the concrete can be conveniently dissipated through the tunnels, the steam pressure in the concrete is reduced, the risk of bursting is reduced, at the same time, the melted water-soluble PVA fibers can largely enhance the inner cohesive force of concrete, and the cracking of a cement face is avoided. Through the cooperation of all raw materials, the prepared concrete has the characteristics of low heat conductivity coefficient, good anti-permeability, high interfacial bond strength,and little long-term strength loss. The long-term strength of concrete after spraying is largely improved. The cracking of high ground temperature concrete is avoided.

Owner:CHANGAN UNIV

Spray evaporation cooling hot press, and single-sided compressed wooden plate and production method thereof

The invention provides a spray evaporation cooling hot press which can shorten cooling time, improve productivity and effectively prevent a plate from being cracked and is used for producing a single-sided compressed wooden plate. The spray evaporation cooling hot press comprises upper and lower hot pressing plates, wherein a steam channel, a steam outlet communicated with the steam channel, a heating device and a cooling channel are formed in the lower hot pressing plate. The invention also provides the single-sided compressed wooden plate which can be more practical and by which the utilization rate of wood is improved, and a production method thereof. The production method comprises the following steps of: putting a plate blank between the two hot pressing plates, heating the lower hot pressing plate to a certain temperature, moving the lower hot pressing plate relative to the upper hot pressing plate to press the plate blank, spraying steam with 5 to 8 atmospheric pressures into the steam channel for 5 to 10 seconds, stopping heating the lower hot pressing plate when the compression ratio of the plate blank meets the requirement, introducing a cooling medium into the cooling channel, cooling the lower hot pressing plate, and releasing pressure.

Owner:NANJING FORESTRY UNIV

Nano metal fluid with high heat-transfer performance

ActiveCN100537697CImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidNanoparticle

Nano metal fluid with high heat transfer performance, it relates to a cooling flow working medium for ultra-high power density radiators, especially a kind of fluid suitable for high heat flux conditions such as computer chips and reactors, which require high-intensity heat exchange And the cooling fluid working medium used in the cooling environment. The invention is a fluid with liquid metal as solvent and nano particles as solute. The invention solves the problems that the current metal fluid is used as the cooling working medium, the price is too high, the cooling performance of the conventional metal fluid is limited, the ordinary fluid is used as the coolant, which is easy to cause leakage, and the existing nano coolant is easy to deposit.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

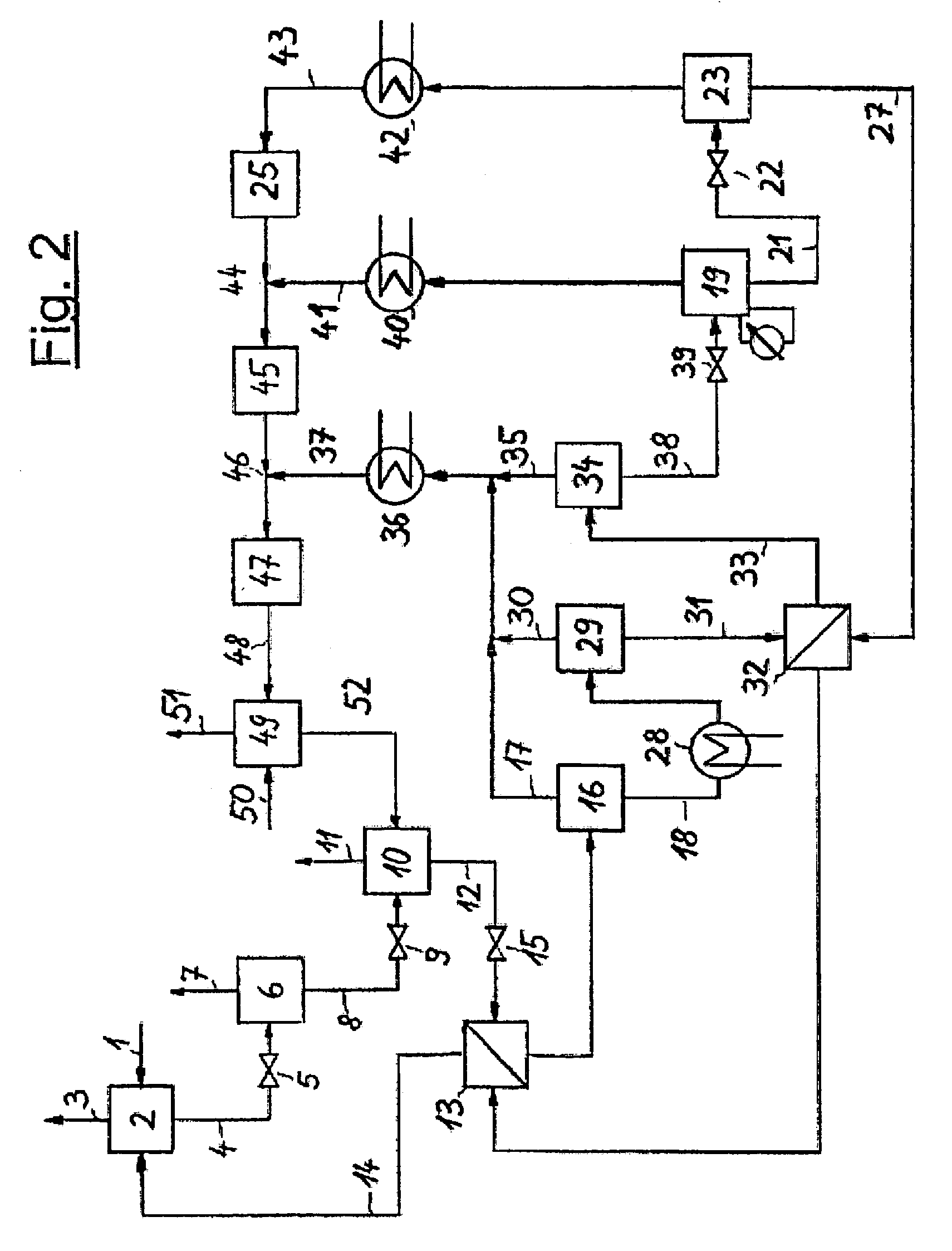

Method for the absorptive outward transfer of ammonia and methane out of synthesis gas

InactiveUS6989047B2Low operating pressureIncrease working temperatureMethane captureUsing liquid separation agentAmmonia productionBoiling point

The invention relates to a process for the absorptive separation of NH3 and CH4 from a gas under high pressure, which at least contains NH3, H2, N2 and CH4, using a high-boiling, physically acting and regenerable solvent which contains homologues of alkylene glycol-alkyl-ether and which also may contain water, the absorbed components NH3, H2, N2 and CH4 being separated from the laden solvent in at least two further process steps at different pressure rates, thereby withdrawing at least one NH3-rich and at least one CH4-rich gas fraction from the solvent. This process is particularly suitable to be incorporated as unit in an ammonia production plant.

Owner:UHDE GMBH

Pretreatment method of cellulosic ethanol feedstock

ActiveCN103898788BEasily damagedReduce the temperaturePaper material treatmentPretreatment methodPre treatment

The invention discloses a pretreatment method of cellulosic ethanol raw materials. The pretreatment method is characterized in comprising following steps: step 1, cellulose raw material is delivered into a screw feeder (20) for squeeze dehydration so as to remove at least a part of water of the cellulose raw material and obtain a compact product, wherein dry substance content of the compact product accounts for 20 to 50wt%; step 2, the compact product is delivered into a first-stage steam receiver (30), and is scattered, and the scattered cellulose raw material is subjected to first-stage steam treatment, wherein pH value of steam in the first-stage steam receiver (30) is lower than 7; and step 3, the cellulose raw material processed via first-stage steam treatment is delivered into a second-stage steam receiver (40) for second-stage steam treatment. The pretreatment method is used for pretreatment of cellulose raw material so as to reduce energy consumption; and the amount of inhibition substances generated when the cellulose raw material is subjected to steam treatment can be reduced; and recovery rate of cellulose and recovery rate of hemicellulose are increased.

Owner:COFCO NUTRITION & HEALTH RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com