Mixed carbonate heat transfer and heat storage working medium

A carbonate and mixed salt technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of inflammability and explosion, low efficiency, complex structure, etc., and achieve no toxic and harmful gases, simple preparation process, The effect of chemical inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

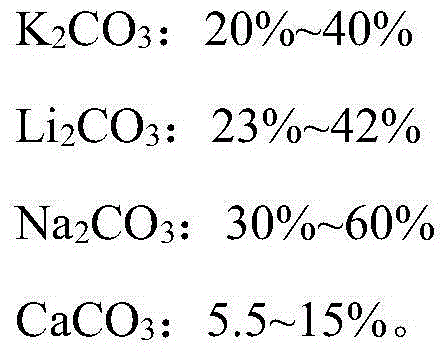

[0013] Take the mole fraction as 40% K 2 CO 3 , 18% Li 2 CO 3 , 30%Na 2 CO 3 , 12% CaCO 3 Put the analytical pure into a beaker for initial stirring for 2 minutes; put the mixed salt that has been initially stirred in a high-speed mixer and stir for 20 seconds, so that the three salt components are basically mixed evenly; then put the basically evenly mixed mixed salt into Heat in a heating tank with a liquid agitator until the powder melts, stabilize the melt temperature at 400°C, turn on the agitator in the tank and stir at a medium speed for 50 minutes, stop stirring to complete the preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com