Titanium fire resistance coating

A technology of coating and titanium fire, which is applied in the direction of coating, metal material coating technology, etc., can solve the problems of reducing the fatigue performance of the substrate, poor impact resistance of the anti-titanium fire coating, and weak bonding of the substrate, so as to ensure fatigue resistance Effect of properties, high bond strength, strong oxidation tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

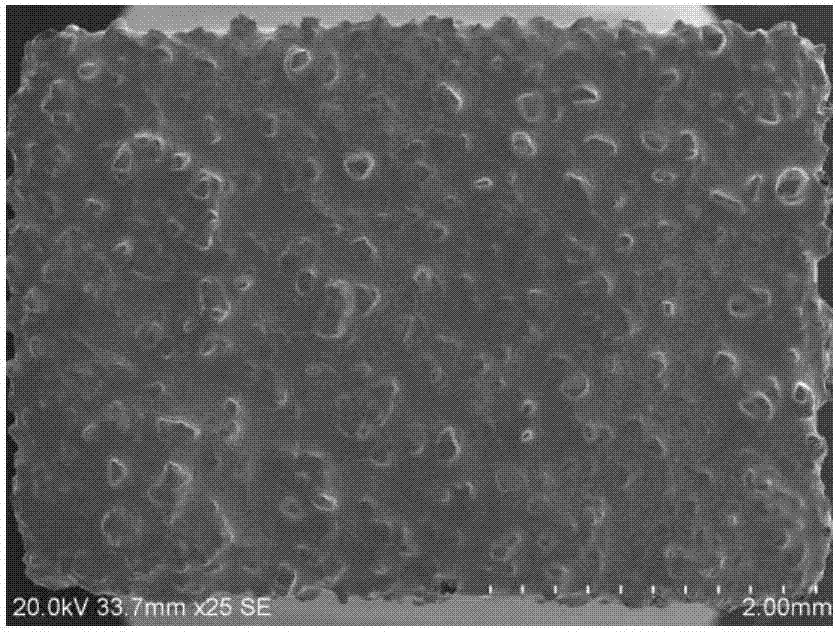

Embodiment 1

[0032] The titanium alloy base material is Ti60 alloy,

[0033] The brazing material is a continuous thin strip Ti-37.5Zr-15Cu-10Ni-based amorphous alloy with a thickness of 50 μm.

[0034] Cubic boron nitride CBN particles are selected as hard wear-resistant particles, and the cubic boron nitride CBN particles are electroless Ni-plated (containing Ni wt.30%),

[0035] The mass ratio of CBN particles to solder is: 8:2

[0036] First place a thin strip of brazing material on the tip of the blade in advance, so that the brazing material wraps the tip of the blade that needs to be coated with an anti-titanium fire coating, and uses an organic adhesive to mix with Ni-plated cubic boron nitride CBN particles (volume ratio 1:10), and then evenly coated on the solder (using the organic binder mixed with CBN particles can avoid the falling and loss of powder particles during furnace loading and vacuuming, and the organic binder will gradually volatilize);

[0037] at greater than o...

Embodiment 2

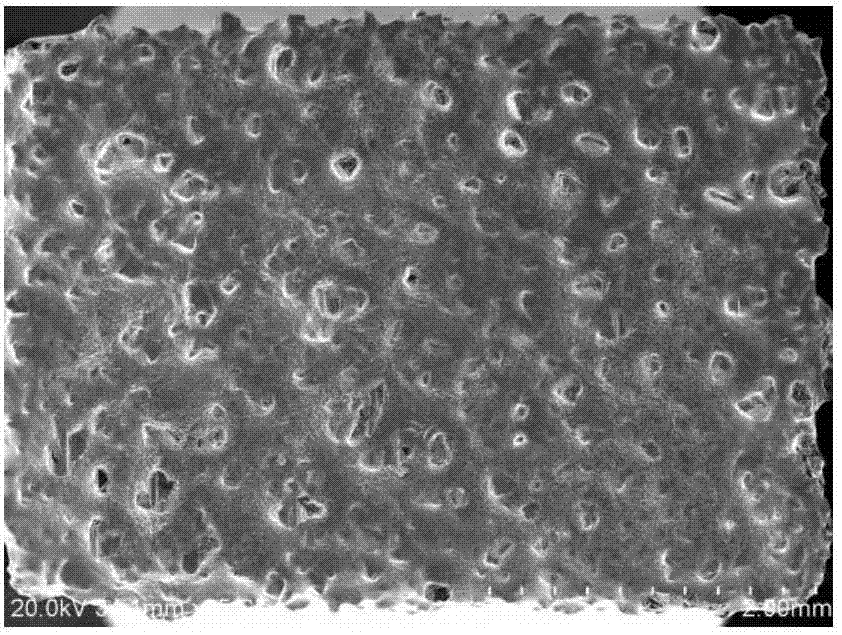

[0051] The base material is Ti60 alloy,

[0052] The brazing material is a continuous thin strip Ti-37.5Zr-15Cu-10Ni-based amorphous alloy with a thickness of 50 μm.

[0053] Cubic boron nitride CBN particles are selected as hard wear-resistant particles, and the cubic boron nitride CBN particles are electroless Ni-plated (containing Ni wt.30%),

[0054] The mass ratio of CBN particles to solder is 7:3

[0055] First place a thin strip of brazing filler metal on the tip of the blade, so that the brazing filler metal wraps the tip of the blade that needs to be laid with an anti-titanium fire coating, and uses an organic adhesive to mix with Ni-plated cubic boron nitride CBN particles (volume ratio 1:10), and then evenly coated on the solder;

[0056] at greater than or equal to 8 x 10 -4 In the high vacuum environment of Pa, the rotor blade tip is locally heated by the medium frequency induction coil (the size and shape of the coil can be designed according to the shape of t...

Embodiment 3

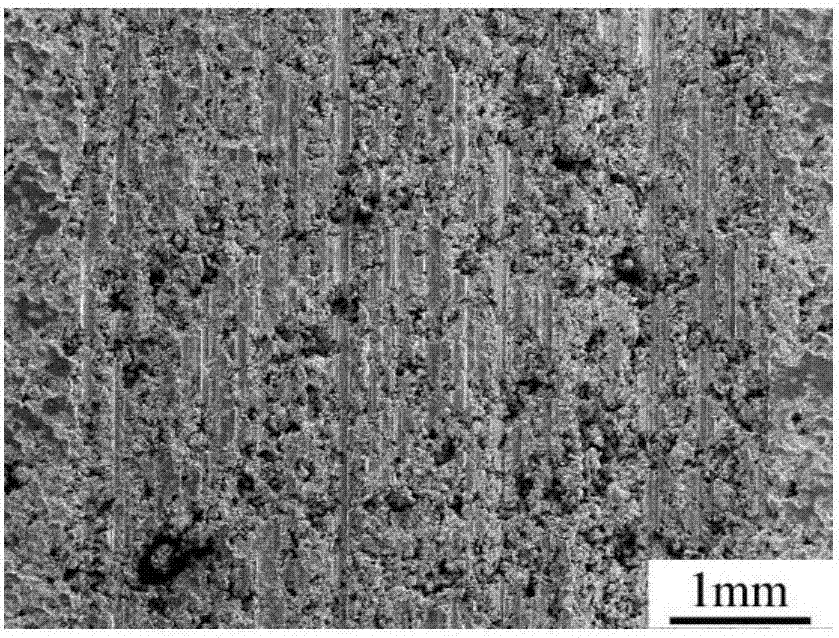

[0071] The base material is Ti60 alloy,

[0072] The brazing material is a continuous thin strip Ti-37.5Zr-15Cu-10Ni-based amorphous alloy with a thickness of 50 μm.

[0073] Cubic boron nitride CBN particles are selected as hard wear-resistant particles, and the cubic boron nitride CBN particles are electroless Ni-plated (containing Ni wt.30%),

[0074] The mass ratio of CBN particles to solder is 6:4,

[0075] First place a thin strip of brazing filler metal on the tip of the blade in advance, so that the brazing filler metal wraps the tip of the blade that needs to be laid with an anti-titanium fire coating, and uses an organic adhesive to mix with Ni-plated cubic boron nitride CBN particles (volume ratio 1 : 10), then evenly coated on the solder;

[0076] at greater than or equal to 8 x 10 -4 In the high vacuum environment of Pa, the rotor blade tip is locally heated by the medium frequency induction coil (the size and shape of the coil can be designed according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com