Patents

Literature

128results about How to "Meet mechanical strength requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

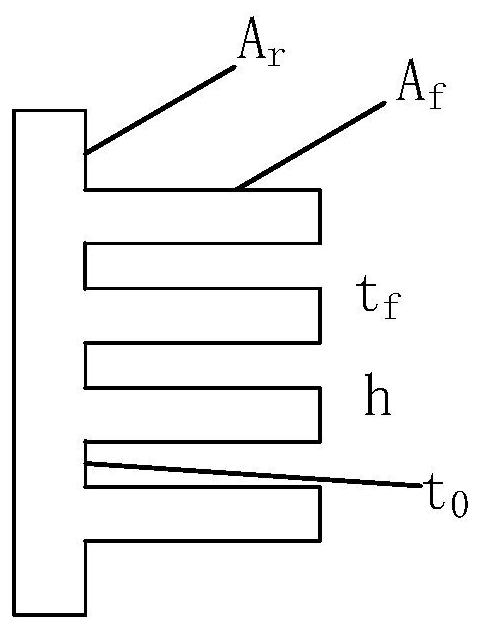

Nanoscale double-cylindrical-bore filter membrane

InactiveCN107875860AImprove permeabilityLow flow resistanceMembranesSemi-permeable membranesMembrane permeabilityFiltration

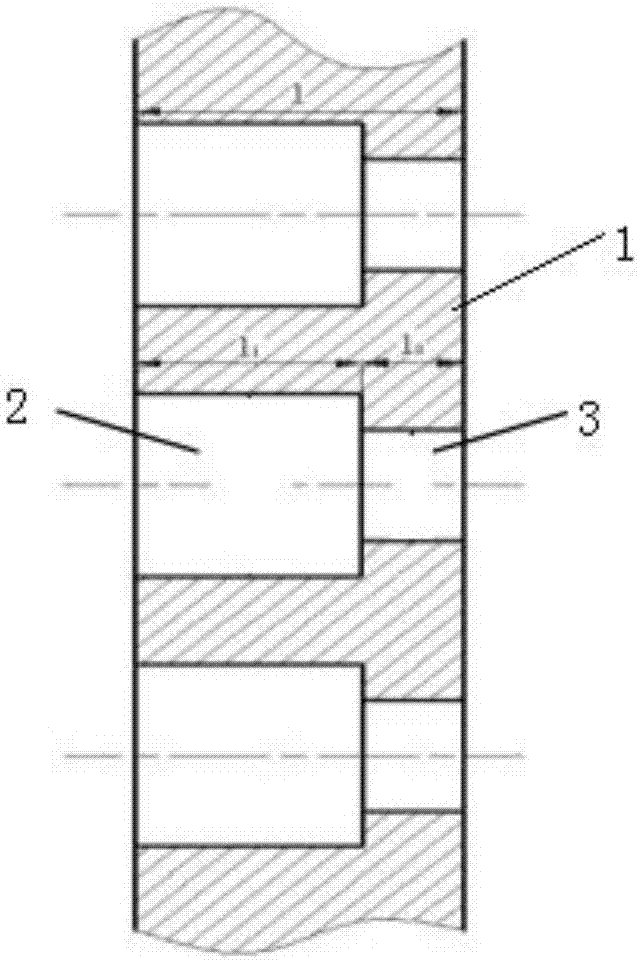

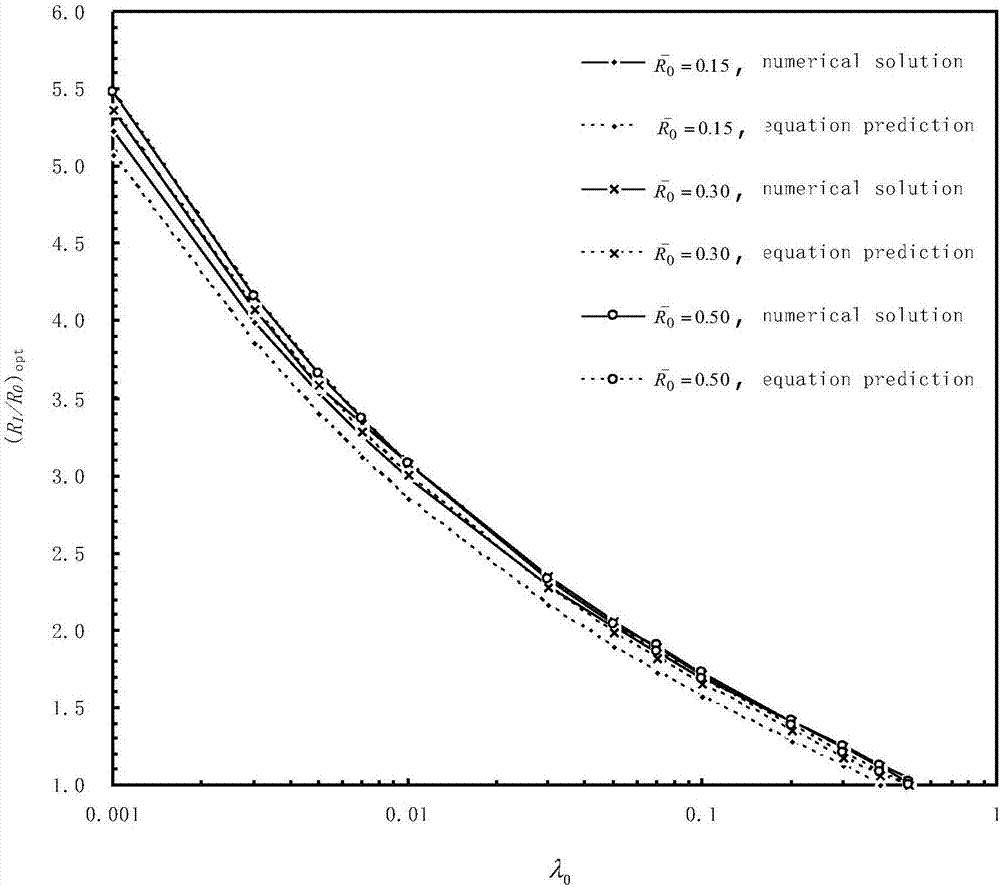

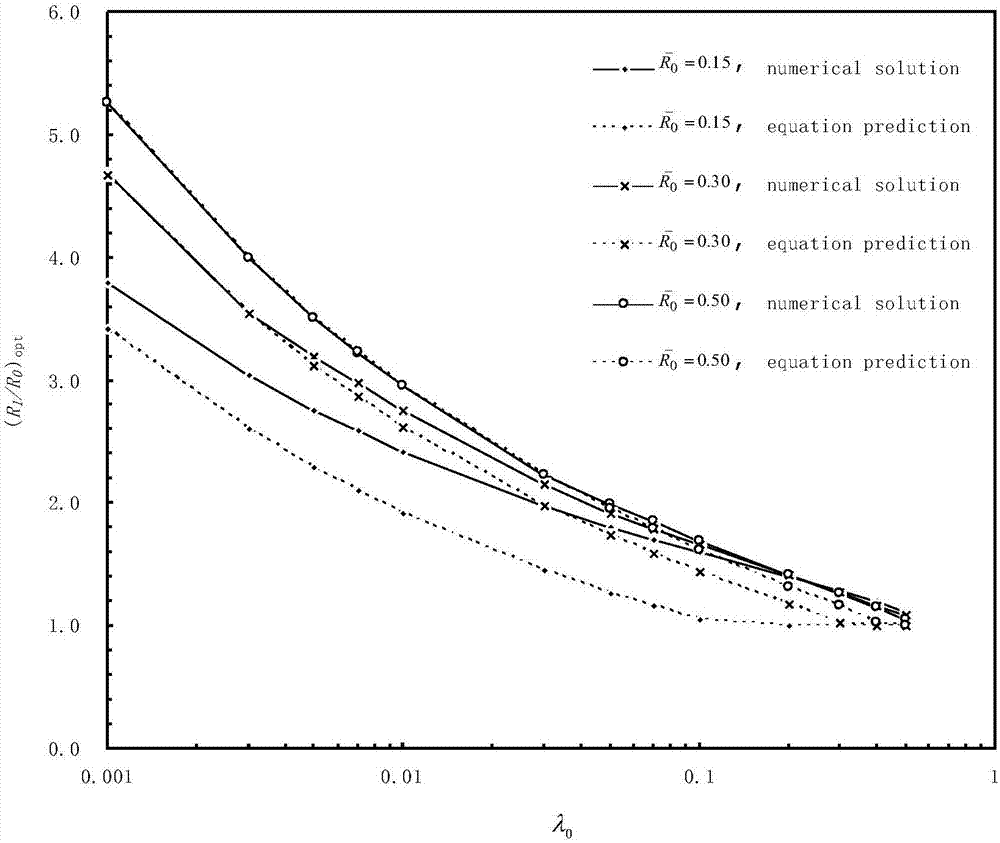

The invention provides a nanoscale double-cylindrical-bore filter membrane. According to the invention, two sides of a layer of a solid material are provided with two cylindrical bores which are in communication; the cylindrical bore with a small bore diameter is a filtration bore with a length of L0, a diameter of 2R0 and a radius of R0; the value of the L0 is determined according to the requirement for strength of the filtration bore; the radius R0 is determined according to the requirements of filtration and is at a nanometer scale; the cylindrical bore with a large bore diameter is a dragreduction bore with a length of L1 and a radius of R1; the value of the L1 is determined according to the requirement for mechanical strength of a filter membrane; R1 is no less than R0; the radius R1is determined according to the requirement for the maximum penetration capacity of the filter membrane; the cylindrical bores are uniformly distributed on the surface of the solid material; and the layer of the solid material is the filter membrane. The filter membrane provided by the invention can realize ultrafine filtration, has excellent penetration capacity, and can meet the requirement formechanical strength during filtration at the same time.

Owner:袁虹娣

Acellular matrix with natural level of glycosaminoglycan and preparation and application thereof

InactiveCN104888274AGuaranteed sterilityImprove decellularization efficiencyProsthesisCell-Extracellular MatrixAdditive ingredient

The invention discloses an acellular matrix with natural level of glycosaminoglycan and preparation and application thereof. The preparation method comprises the following steps: carrying out acellular disposal on natural biological tissue to obtain an acellular matrix; detecting missing amount of glycosaminoglycan in the acellular matrix; and supplementing glycosaminoglycan by means of natural ingredients in the acellular matrix to obtain the acellular matrix with natural level of glycosaminoglycan. Through the method, a lot of the glycosaminoglycan component in the acellular matrix is recovered. The acellular matrix has good biocompatibility. The natural biological structure is recovered, and the acellular matrix is beneficial to cell growth. glycosaminoglycan is supplemented for the acellular matrix, and a tissue engineering carrier is constructed. According to the invention, a biological carrier which meets cell growth requirement and mechanical strength requirement and has similar structural components as a natural extracellular matrix can be prepared rapidly. The invention is a great breakthrough of the tissue engineering construction technology. Meanwhile, principle of the invention is reliable, the technology is simple and flexible, product reproducibility is good, and industrialization is easy to realize.

Owner:JINAN UNIVERSITY

Controlled-release carbon source material for repairing polluted underground water organisms and preparation method thereof

ActiveCN102491497AGuaranteed uptimeNutritionally stableBiological water/sewage treatmentMicroorganismNutrition

The invention discloses a controlled-release carbon source material for repairing polluted underground water organisms and a preparation method thereof and belongs to the field of underground water repairing. The controlled-release carbon source material comprises a core and a shell wrapping the core, wherein the core comprises the following components in percentage by weight: 40 to 86 percent ofcarbon releasing raw material, 1 to 25 percent of nutritional raw material, 5 to 45 percent of plastic bonding raw material, 5 to 20 percent of high-permeability raw material and the balance of water; the shell comprises the following components in percentage by weight: 10 to 40 percent of carbon releasing raw material, 1 to 10 percent of nutritional raw material, 20 to 80 percent of plastic bonding raw material, 0 to 40 percent of high-permeability raw material and the balance of water; and the controlled-release carbon source material is prepared by a compound formula consisting of the carbon releasing raw materials, nutritional elements and multi-component inorganic combined raw materials. The controlled-release carbon source material meets a microbial nutrition demand and requirementsfor long-time stable material supply during underground water repairing, certain mechanism strength and uniform sphericity; furthermore, the defects of high carbon loss, uncontrollable releasing rateand the like in the conventional carbon source compensation method are overcome; and the continuity of the underground water organism repairing effect is realized.

Owner:HOHAI UNIV +1

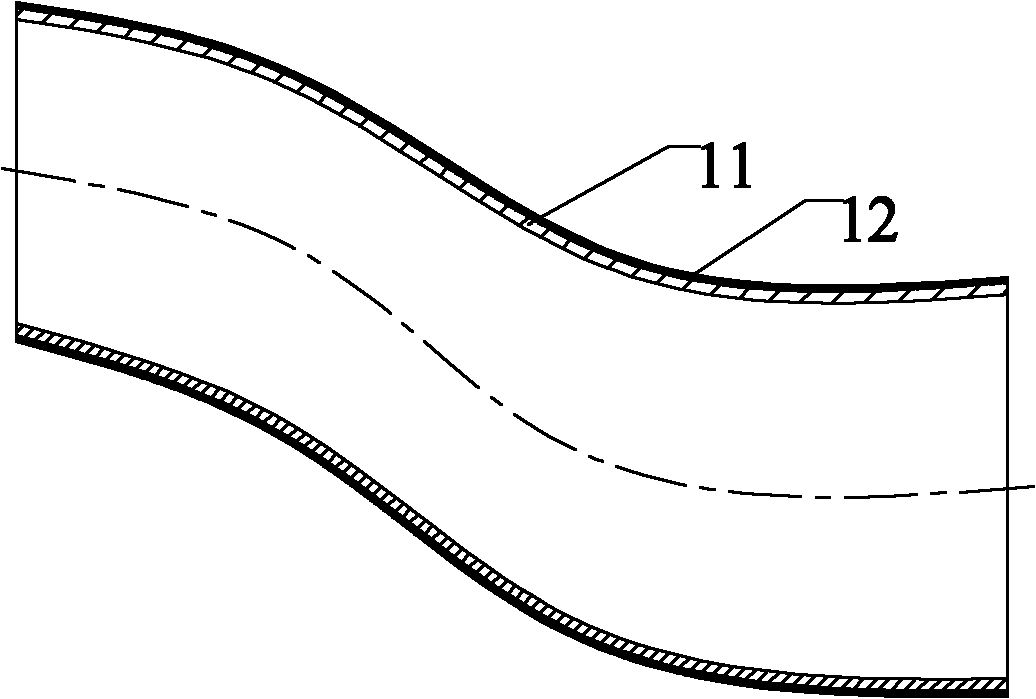

Concrete delivery tube and preparation method thereof

InactiveCN102032397AImprove wear resistanceImprove toughnessBuilding material handlingRigid pipesEngineeringHigh wear resistance

The invention provides a concrete delivery tube, which has at least two bent parts and comprises an inner tube and an outer tube compounded outside the inner tube, wherein the outer tube at least consists of an outer tube first part and an outer tube second part; the shapes of cross sections of the outer tube first part and the outer tube second tube are circular arcs; the outer tube is formed by connecting the outer tube first part and the outer tube second part; and the wear resistance of the inner tube is higher than that of the outer tube, and the roughness of the outer tube is higher than that of the inner tube. Compared with the prior art, a high-priced surfacing welding process is not required to improve the wear resistance of the inner surface of the delivery tube, and with the composite tube having the inner tube with high wear resistance and the outer tube which is compounded outside the inner tube and has high roughness, the concrete delivery tube meet the requirements on wear resistance and mechanical strength.

Owner:湖南三一中阳机械有限公司

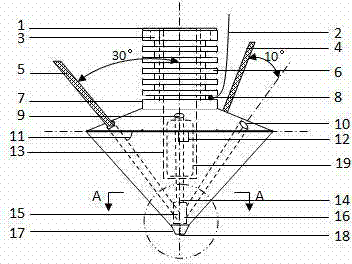

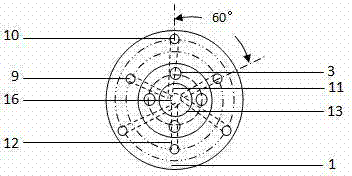

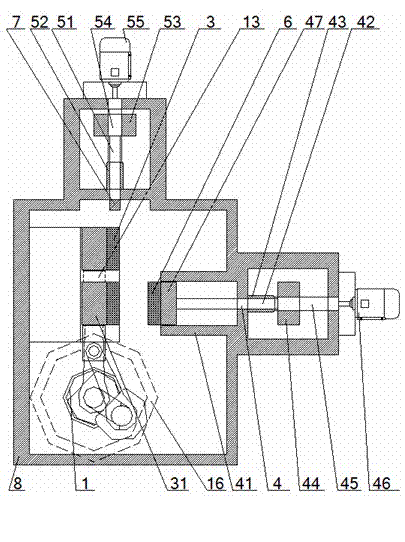

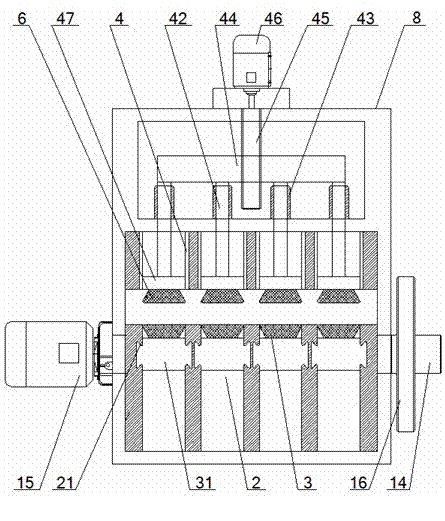

Six-channel aggregation-fusion type squeezing nozzle for fused deposition modeling type color three-dimensional printer

ActiveCN104742364AHigh thermal efficiency utilizationImprove energy efficiencyComputer printingControl system

The invention discloses a six-channel aggregation-fusion type squeezing nozzle. The squeezing nozzle is provided with six thread inlets and one thread outlet and is suitable for a fused deposition modeling type (FDM) all-true color three-dimensional printer control system capable of achieving precision printing. Raw material printing threads of each color can be fused without a temperature difference in a nozzle aggregation fusion mixing and stirring cavity in a process of printing a color three-dimensional stereoscopic workpiece, the colored threads are extruded, a thread outlet caliber can be changed, and printing, all true color and high precision can be achieved. Accordingly, the mechanical strength of the printed workpiece reaches the mechanical strength index of the material, maintenance and replacement are convenient, resources are saved, energy consumption is reduced, the cost is reduced, and the nozzle is simple in structure, stable and reliable.

Owner:辽宁重彩立体打印机有限公司

Calcium phosphate-based bone repair scaffold and preparation method thereof

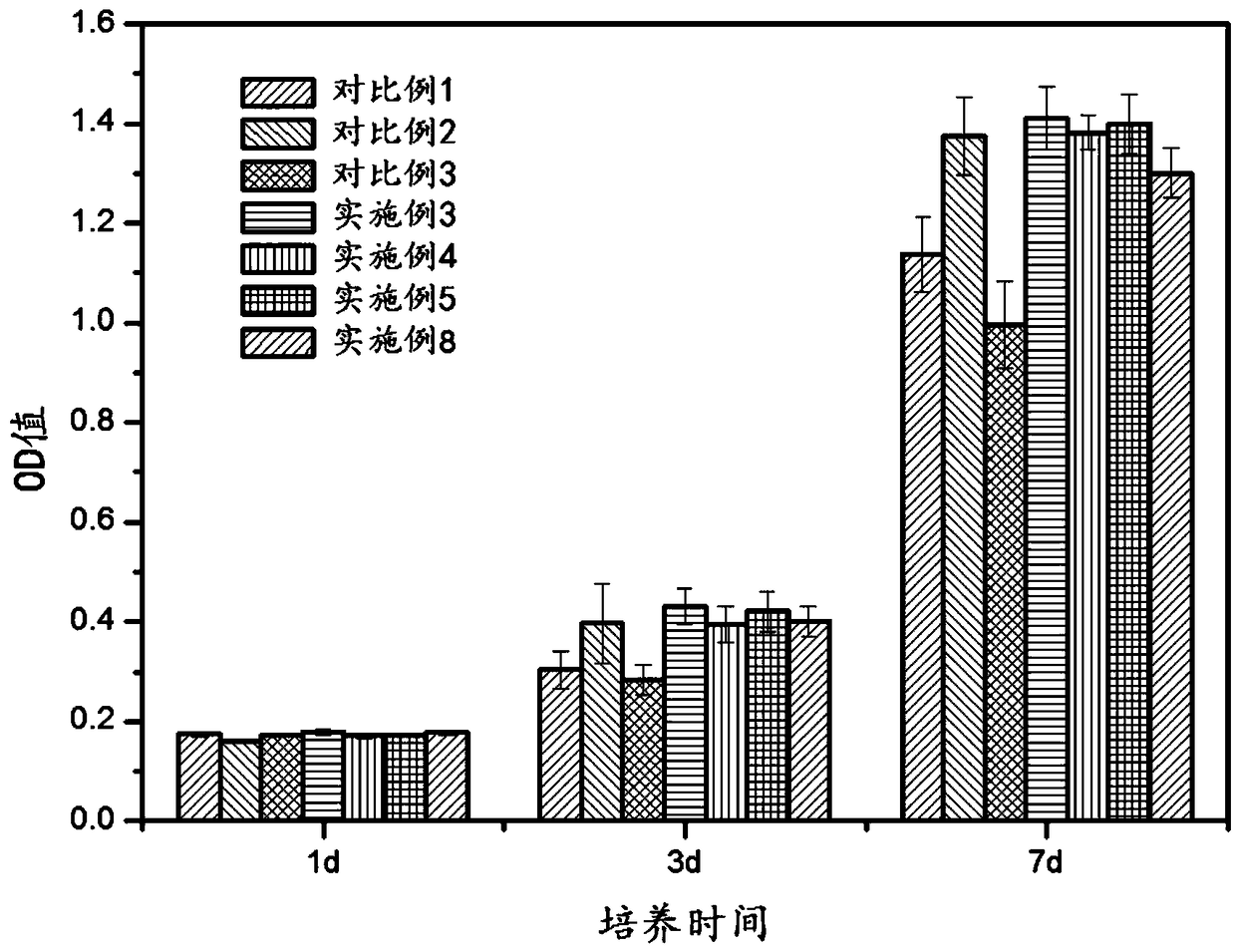

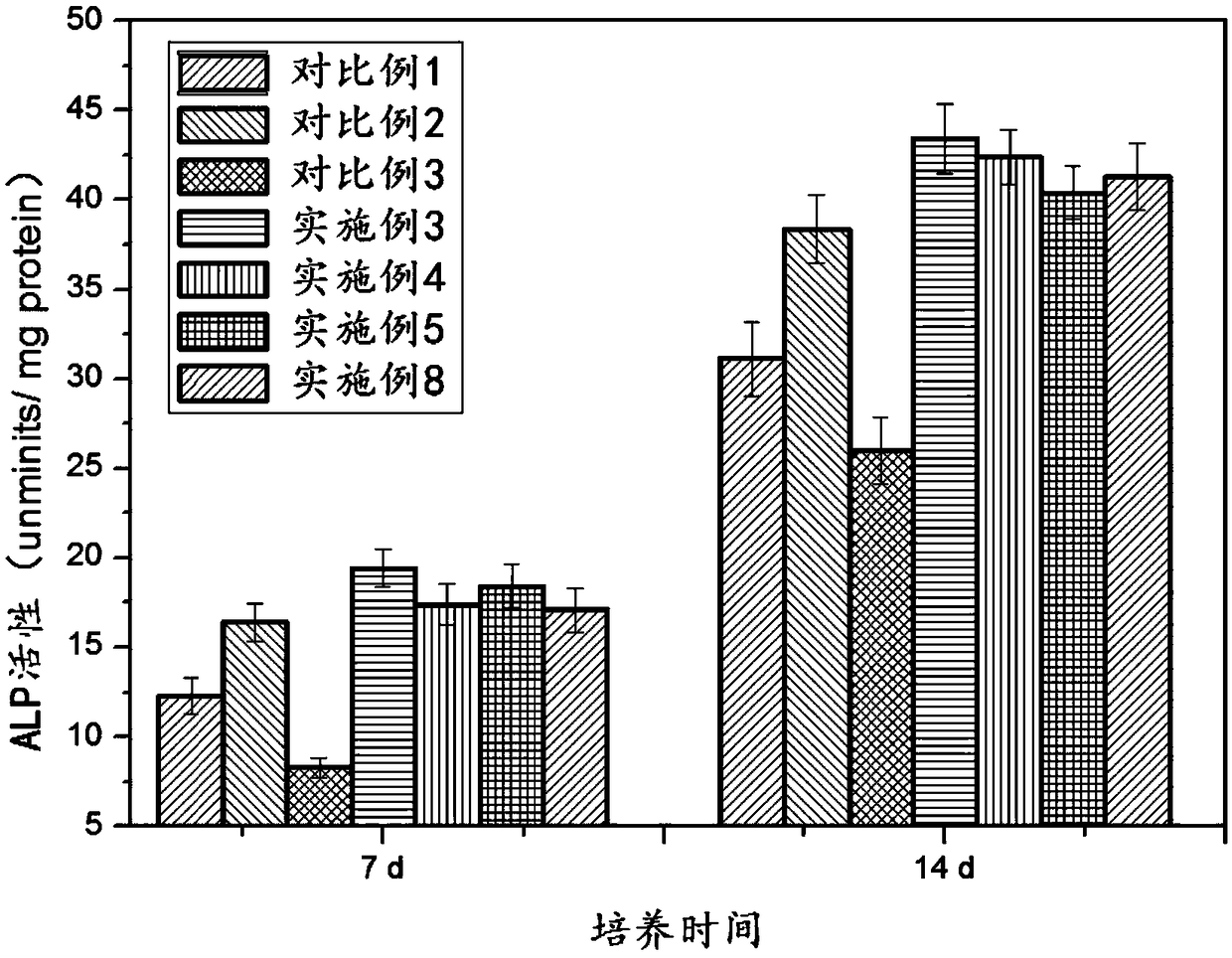

InactiveCN109381744AImprove mechanical strengthPromotes cell adhesion and proliferationAdditive manufacturing apparatusTissue regenerationBiocompatibility TestingMacropore

The invention discloses a calcium phosphate-based bone repair scaffold and a preparation method thereof. Calcium phosphate bone cement is used as a raw material and is combined with a 3D printing technology to obtain a calcium phosphate bone cement scaffold with through macropores; a dopamine solution is used for modifying the surface of the scaffold; dopamine forms a polydopamine layer on the surface of the scaffold through self-oxidation under alkaline conditions; polydopamine has good viscosity and biocompatibility, can be used as an adhering coating layer of BMP-2, improves the content offixed BMP-2, and promotes cell adhesion and proliferation; the BMP-2 loaded on the scaffold can also effectively promote the proliferation and osteogenic differentiation of bone marrow mesenchymal stem cells. The prepared calcium phosphate-based bone repair scaffold has through macropores, meets the mechanical strength requirements of cancellous bones, has excellent biocompatibility, can effectively promote bone tissue regeneration, and has potential application value in the field of bone tissue repair.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Artificial quartz stone and preparation method thereof

The invention relates to an artificial quartz stone and a preparation method thereof. The quartz stone is composed of the main raw materials of, by mass: 3-10% of aqueous resin, a curing agent with a mass accounting for 5-200% of that of the aqueous resin, 55-65% of quartz sand, glass sand and mirror glass sand, 25-35% of quartz powder, a coupling agent with a mass accounting for 0.05-0.2% of the total mass of quartz sand, glass san, mirror glass sand, and quartz powder, and 1% of a color paste. The preparation method comprises the steps that: the raw materials are fetched according to mass percentages; the curing agent, the coupling agent, and the color paste are added into aqueous resin, and the mixture is uniformly dispersed; the mixture is mixed with already uniformly mixed quartz sand, glass sand and mirror glass sand; the mixture is well mixed; quartz powder is added; the mixture is well mixed by stirring, such that a half-dry material is obtained; the material is distributed by using a mold; and vacuuming, molding, curing, thickness setting, and polishing are carried out, such that a finished product is obtained. According to the invention, aqueous resin and a water solvent are used for replacing oleiferous resin and an organic solvent, such that the harm to the environment caused by evaporation of the organic solvent is solved, viscosity is reduced, and manufacturability is improved.

Owner:WUHAN UNIV OF TECH

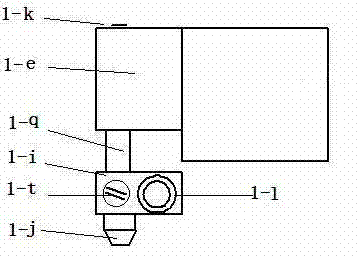

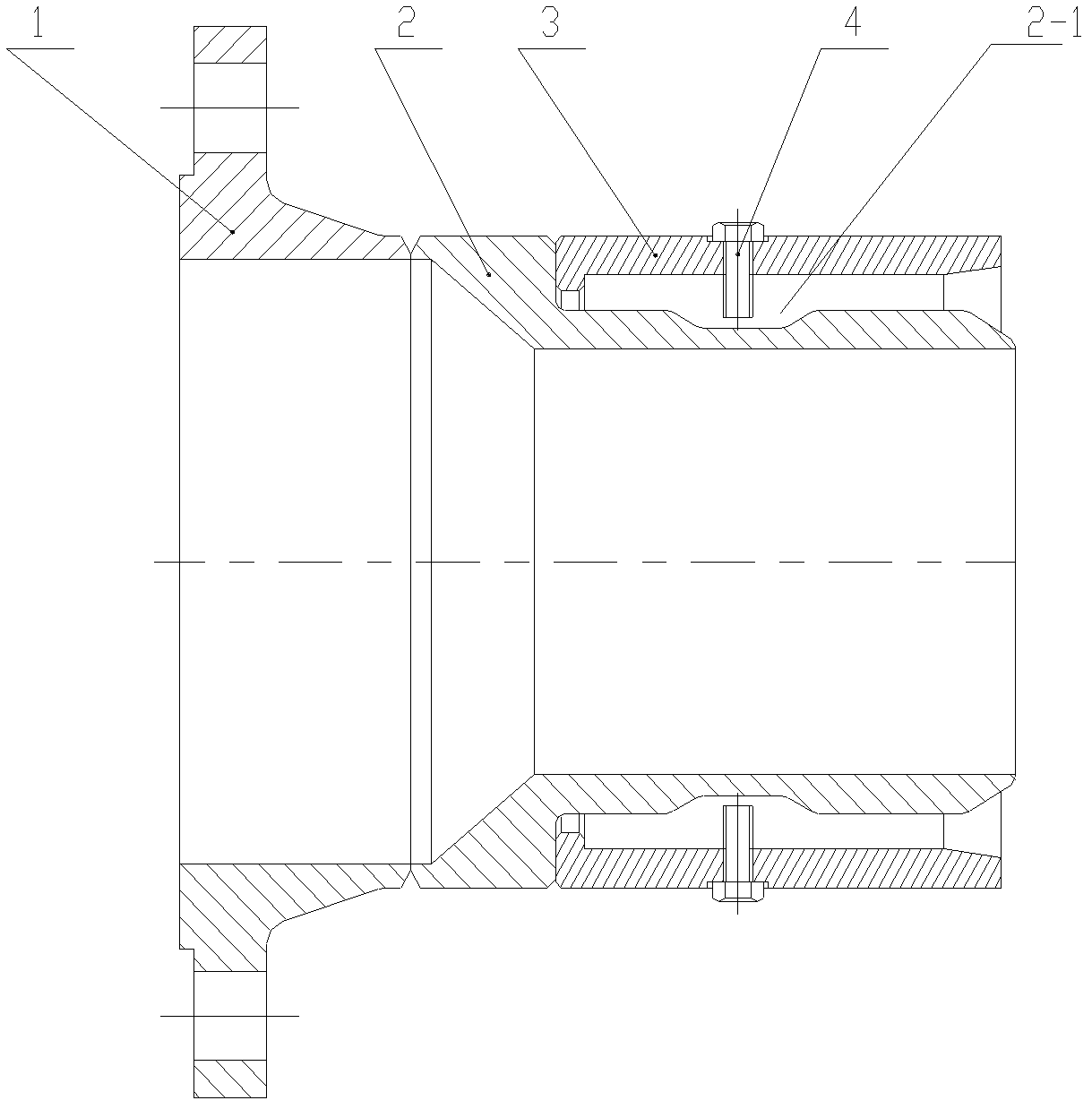

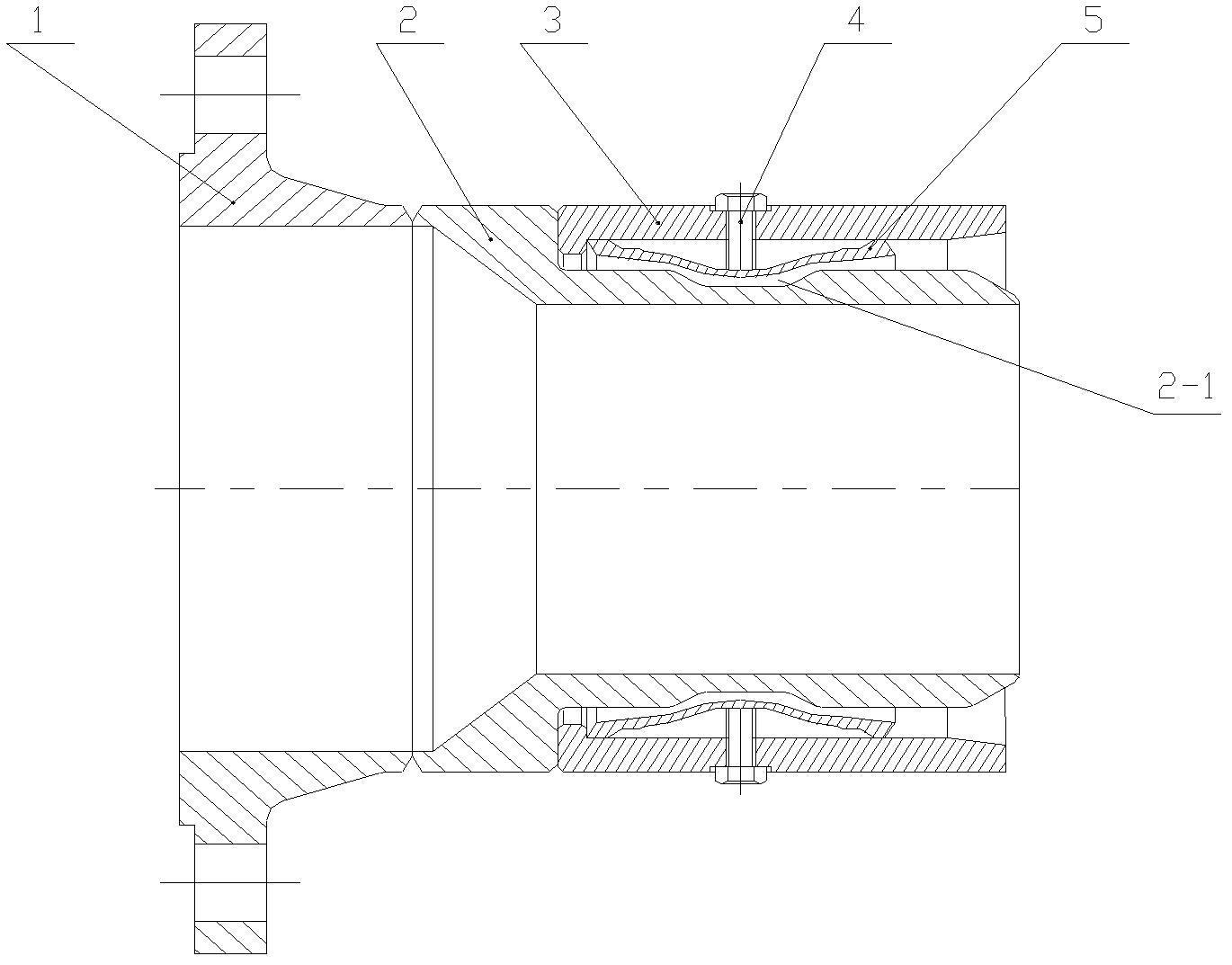

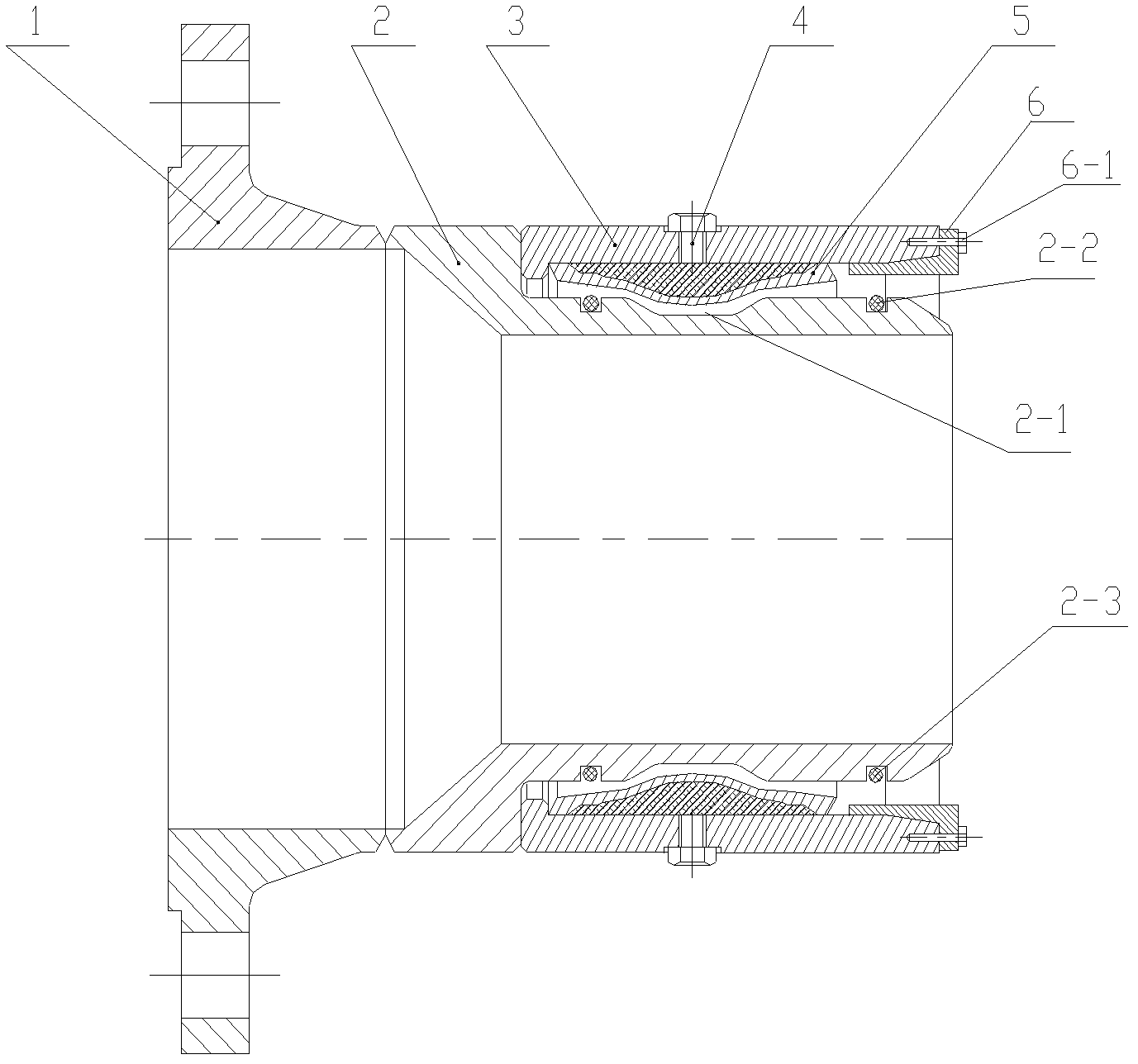

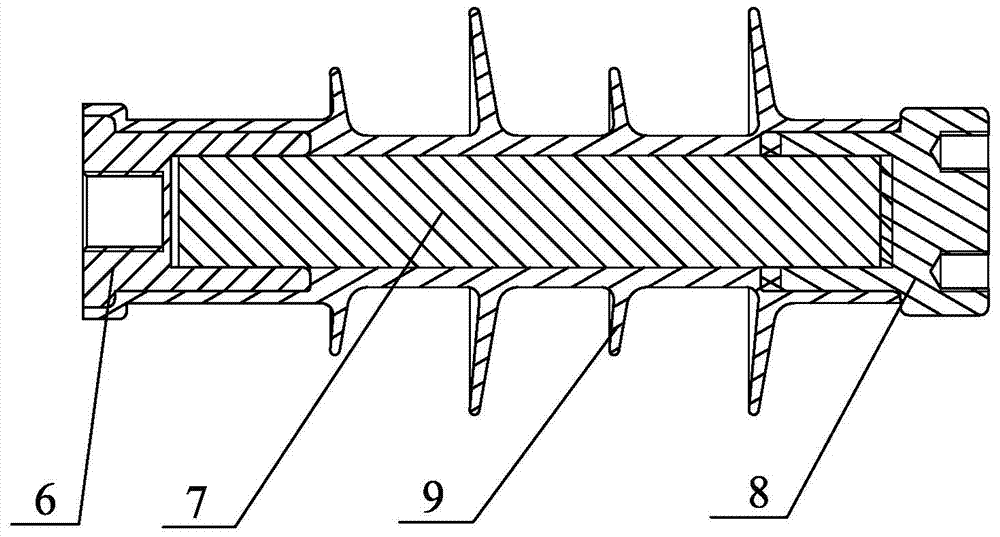

Lining pipe joint of marine oil pipeline

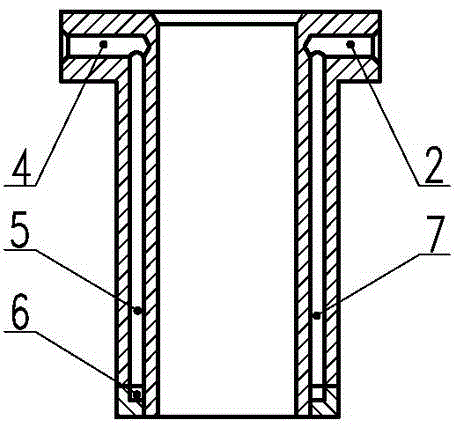

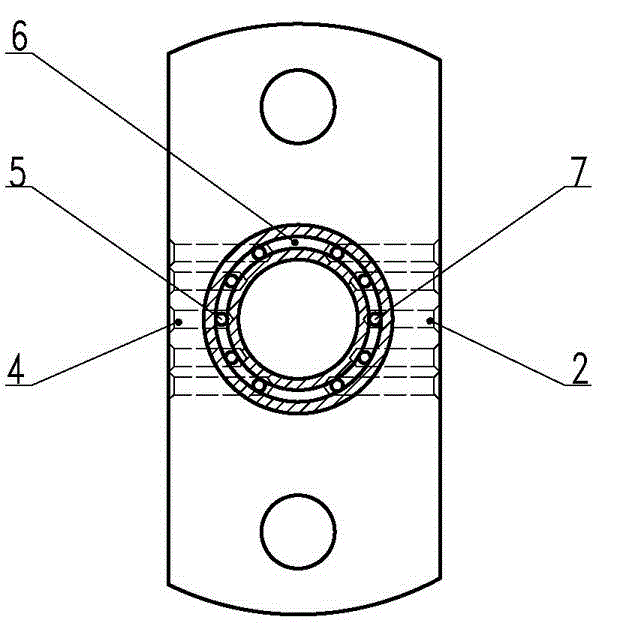

InactiveCN102620080AAchieve connectionIncrease frictionCorrosion preventionPipe protection against corrosion/incrustationEngineeringUltimate tensile strength

The invention discloses a lining pipe joint of a marine oil pipeline to solve the problem of low mechanical strength of the conventional lining pipe joint. The lining pipe joint comprises a flange (1), an inner sleeve (2), an outer sleeve (3) and a plurality of jackscrews (4), wherein the inner sleeve (2) is arranged in the outer sleeve (3) and is coaxial with the outer sleeve (3); the flange (1) is fixed with one end of the inner sleeve (2) and one end of the outer sleeve (3) and is coaxial with the inner sleeve (2) and the outer sleeve (3); the outer surface of the inner sleeve (2) is provided with an annular groove (2-1); a plurality of threaded holes are uniformly formed in the outer sleeve (3) along the circumferential direction; and each jackscrew (4) is screwed in a threaded hole, and the front end of each jackscrew (4) extends into the inner surface of the outer sleeve (3) and jacks the groove (2-1) on the outer surface of the inner sleeve (2). The lining pipe joint can be applied to connection of hoses with various diameters.

Owner:HANGZHOU OPR OFFSHORE ENG CO LTD

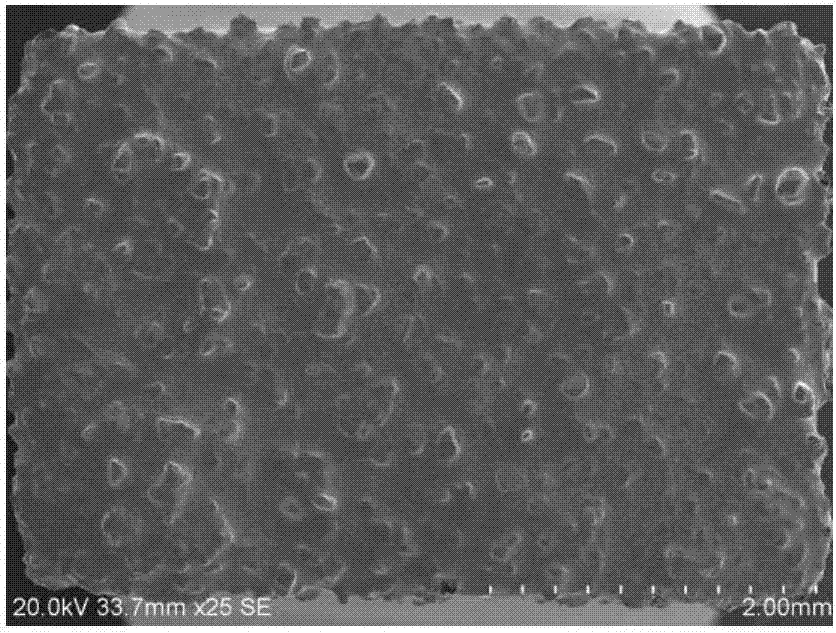

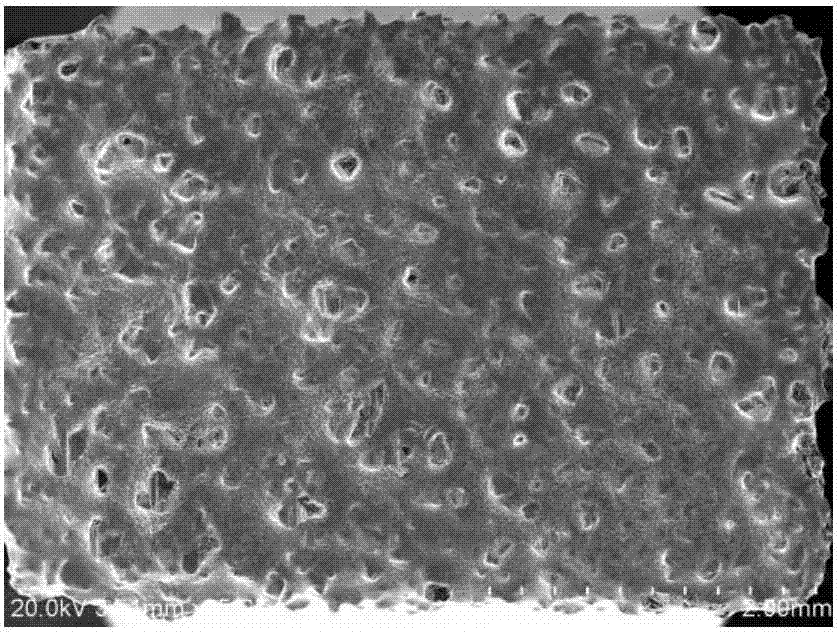

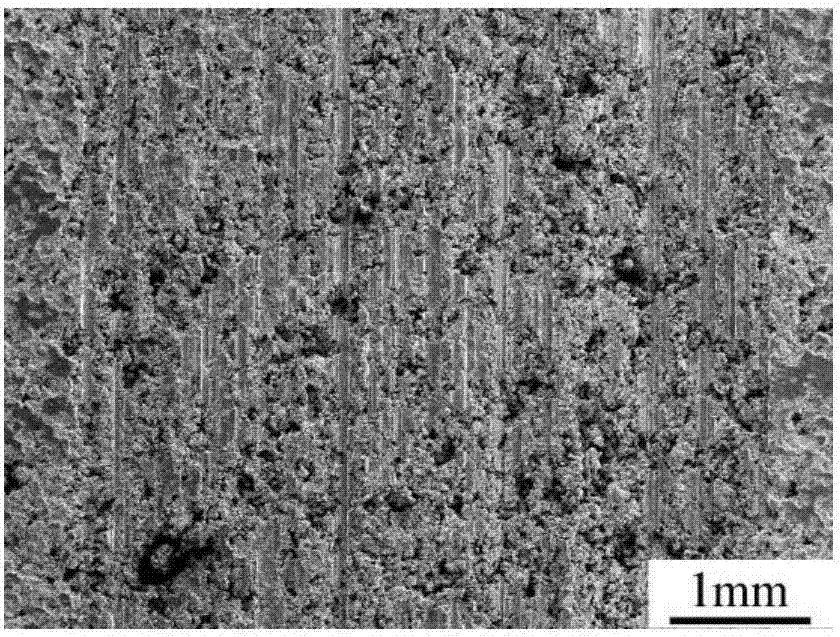

Preparing method of titanium fire resistance coating

ActiveCN107138878AHigh hardnessHigh temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaAlloyFire resistance

The invention discloses a preparing method of a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal can be completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

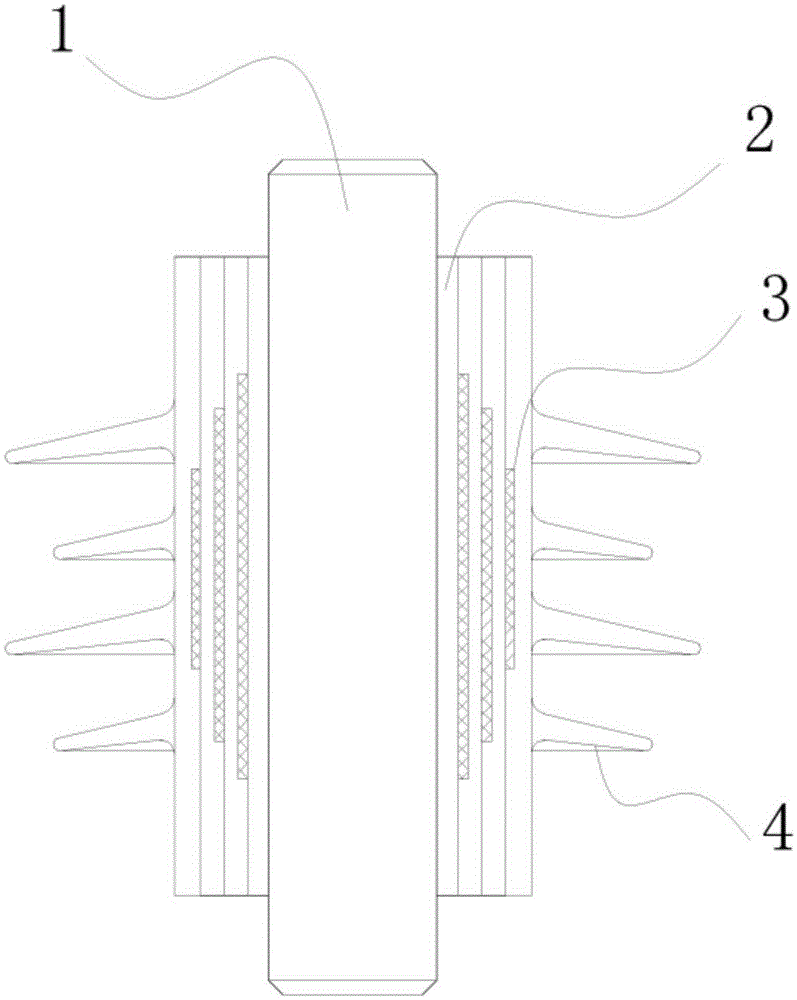

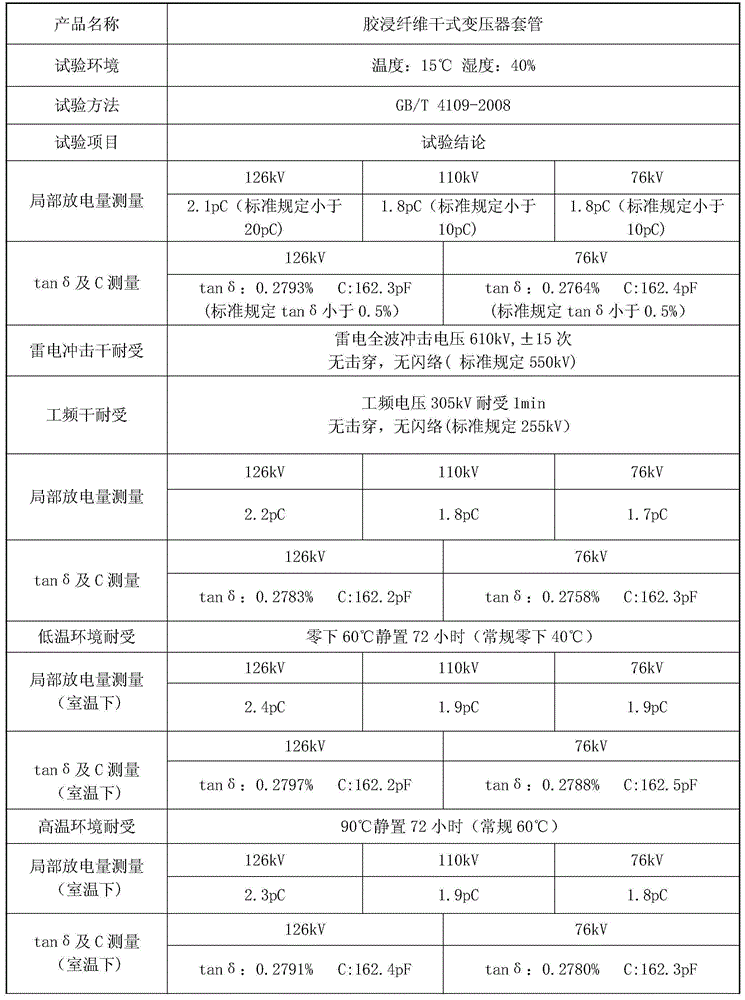

High-voltage bushing and processing technology thereof

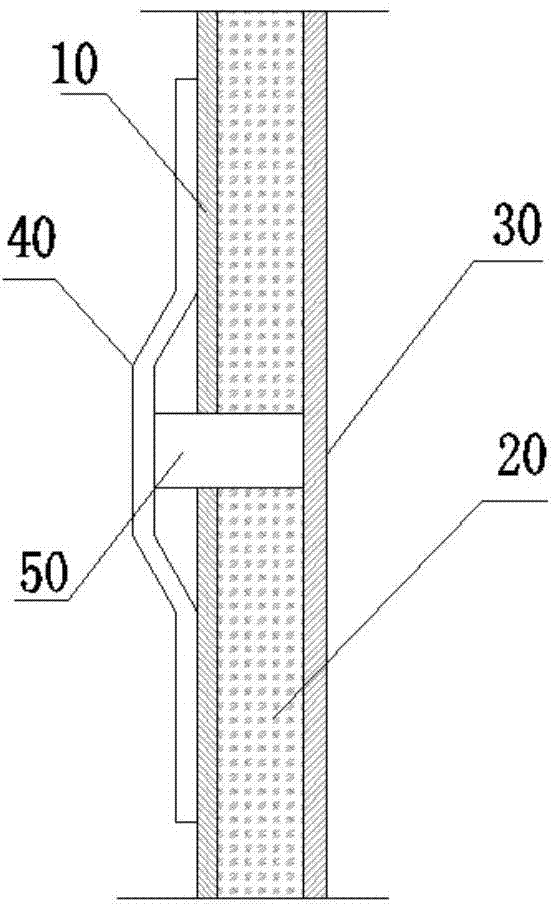

InactiveCN105355344AIncreased dielectric lossImprove insulation performanceInsulating bodiesLead-in/lead-through insulatorsCapacitanceEpoxy

The invention relates to a high-voltage bushing and a processing technology thereof. A capacitor electrode of the high-voltage bushing adopts one or more of conductive fabric, a conductive net and conductive yarn. The processing technology of the high-voltage bushing comprises steps as follows: an insulating layer is prepared in a winding manner firstly, and a capacitor electrode layer is prepared in a winding manner; the steps are repeated alternately until a core is formed; finally, vacuum impregnation is performed, and the high-voltage bushing is formed. According to the high-voltage bushing and the processing technology thereof, the conductive fabric, the conductive net or the conductive yarn is adopted as the capacitor electrode, and epoxy resin or insulating oil can smoothly run through the capacitor electrode and is fused with the insulating layer; the dielectric loss of the high-voltage bushing is reduced from 5 permillage to 3 permillage, the magnitude of partial discharge is reduced from the value lower than 10 pC to the value lower than5 pC, the insulating property is improved by higher than 10%, and the qualified rate of production is increased to be higher than 90% from 40%.

Owner:西安神电高压电器有限公司

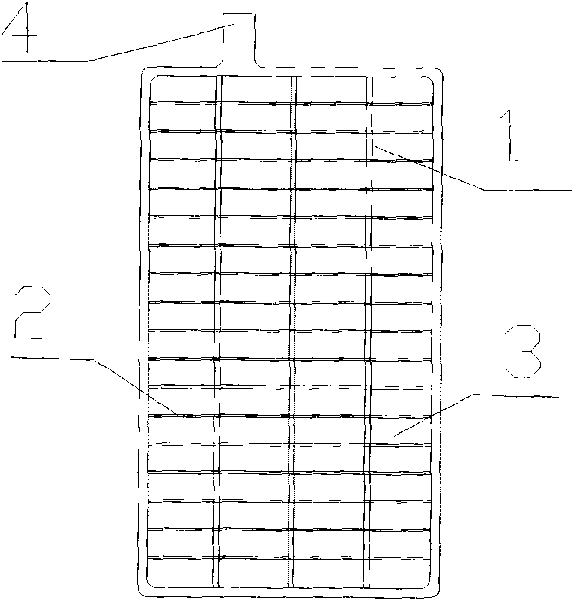

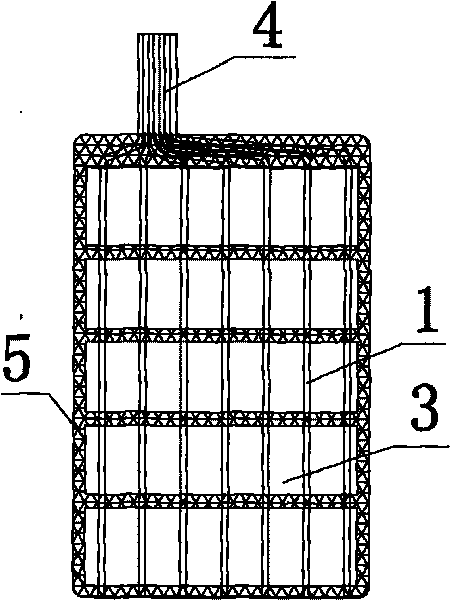

Hybrid current collector used for lead storage batteries

InactiveCN101694878AReduce weightWidely meet the needs of useElectrode carriers/collectorsCell component detailsElectricityEngineering

The invention discloses a hybrid current collector used for lead storage batteries, which is characterized in that the hybrid current collector comprises at least one conducting framework and a shaping framework, the conducting framework is molded in a hybrid form, the shaping framework is manufactured by lightweight hard materials, and the hybrid current collector is a grid plate with hollow grids or a plate-shaped current collector without grids. The hybrid process of the conducting framework and the shaping framework includes injection molding and joggle fixing molding, wherein the injection molding utilizes thermal plastic and cold extrusion or uses cement concrete, the joggle fixing comprises steps of utilizing the lightweight hard material to manufacture a substrate module which is used as the shaping framework and then joggling and fixing the shaping framework with the conducting framework which is designed as a coupling module. The conducting framework of the current collector can extend to form an integrated lead electrode or is electrically fixedly connected with a split lead electrode. The polar plate manufactured by utilizing the current collector is light in weight, high in specific energy, simple in manufacture and low in material cost.

Owner:东莞恒量新能源科技有限公司 +1

Sensor mounting base with cooling function

ActiveCN104535208AReduce R&D costsReduce installation costsThermometers using electric/magnetic elementsUsing electrical meansAviationEngineering

The invention discloses a sensor mounting base with a cooling function. The sensor mounting base is formed by coaxially assembling a platform, a cylindrical boss and a sealing ring in an integrated manner. The cylindrical boss is hollow, and is provided with at least two vertical air ducts in the wall surface. The sealing ring is connected to the bottom of the cylindrical boss, and forms a horizontal annular groove communicating all the air ducts. The platform is provided with horizontal air outlet holes and air inlet holes externally connected with aviation cold air. The air inlet holes, the air outlet holes and the air ducts are gradually communicated in a crossed manner, and form an air flow channel space inside the sensor mounting base together with the horizontal annular groove. By adopting the technical scheme of the invention, through cooling structure improvement and cooling treatment, the mounting base, even made by common nickel-based alloy, can meet the mechanical strength requirement of application in an about-1600K high-temperature gas environment. The surface temperature can be effectively reduced, measurement precision out-of-tolerance caused by temperature overrun of a compensation wire part of a thermocouple is reduced, and the weight load on and the cost of aero engines are reduced.

Owner:SUZHOU CHANGFENG AVIATION ELECTRONICS

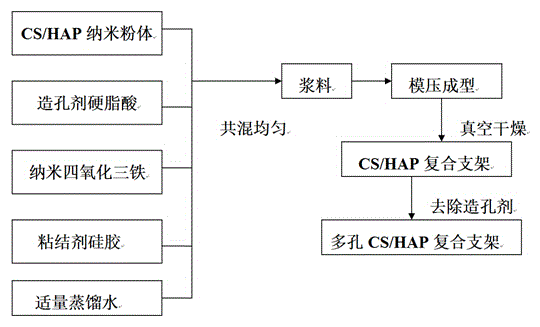

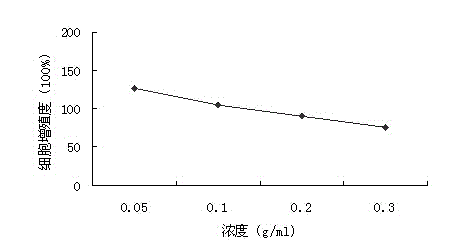

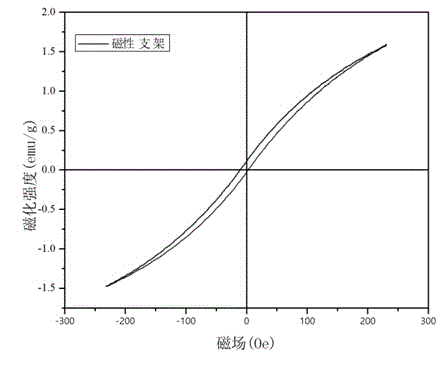

Preparation method of chitosan/hydroxyapatite magnetic bone repair support material

InactiveCN104888281AGood biocompatibilityImprove biological activityProsthesisSlurryBiocompatibility

The invention discloses a preparation method of a chitosan / hydroxyapatite magnetic bone repair support material, and belongs to the field of chemical and biological engineering materials. The method specifically comprises the steps that chitosan / hydroxyapatite nano-composite powder is prepared; magnetic nano-powder, the chitosan / hydroxyapatite nano-composite powder and pore forming substance particles are evenly mixed; then binder silica sol and water are added to be fully mixed to obtain needed slurry; and extrusion forming, drying, demolding, pore forming substance removal and sintering are carried out on the slurry to obtain a composite support. The method is simple and convenient to operate, and the porosity of the obtained support is high. Mechanical performance is good and is equivalent to cancellous bone performance. The cancellous bone repair need can be met, certain magnetism is achieved, and the proliferation and differentiation of osteoblast can be stimulated. Hydroxyapatite in the composite powder is distributed in a chitosan matrix in a needle shape with nanometer as the scale, biocompatibility can be improved, the toxic reaction of cells can be reduced, and the good application prospect is achieved.

Owner:KUNMING UNIV OF SCI & TECH

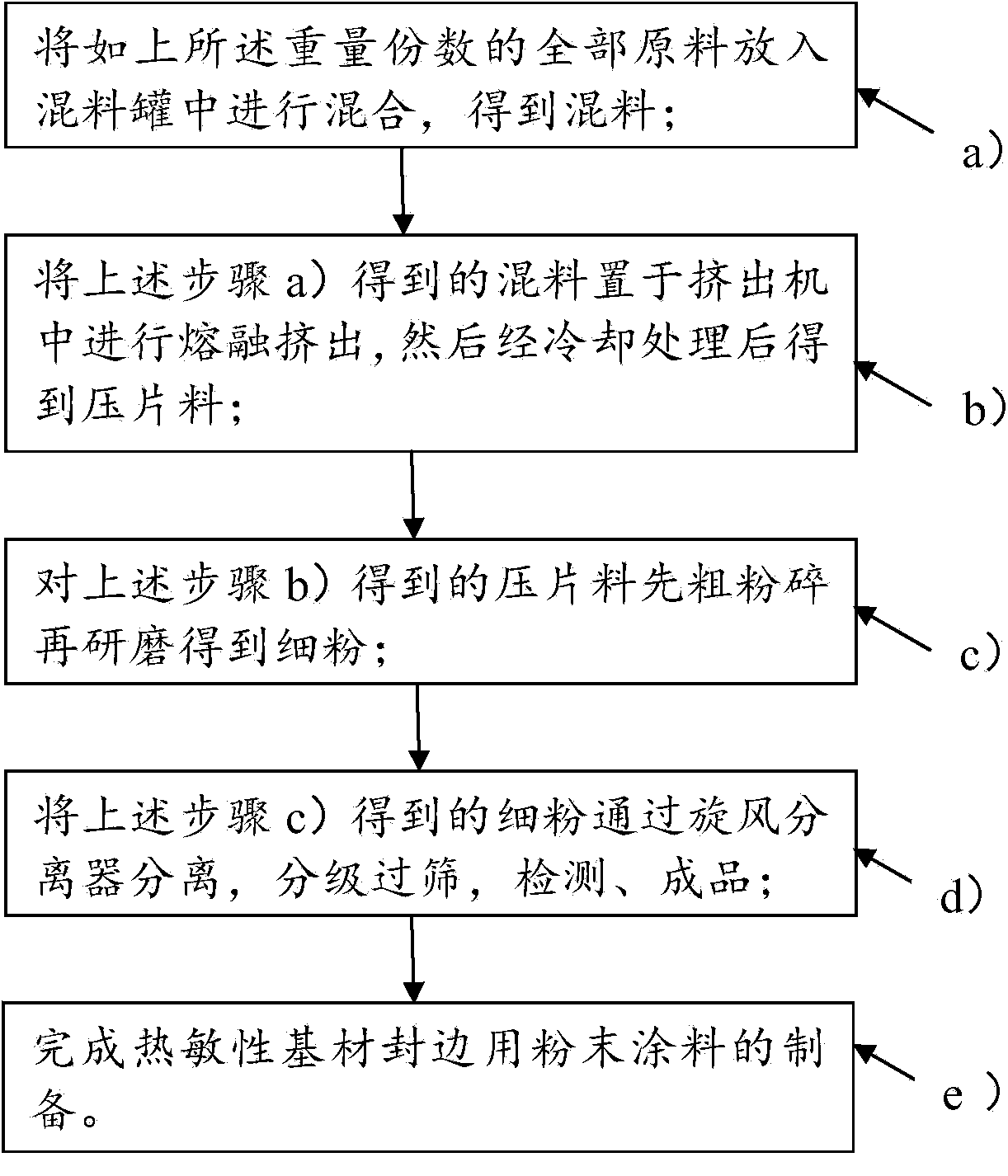

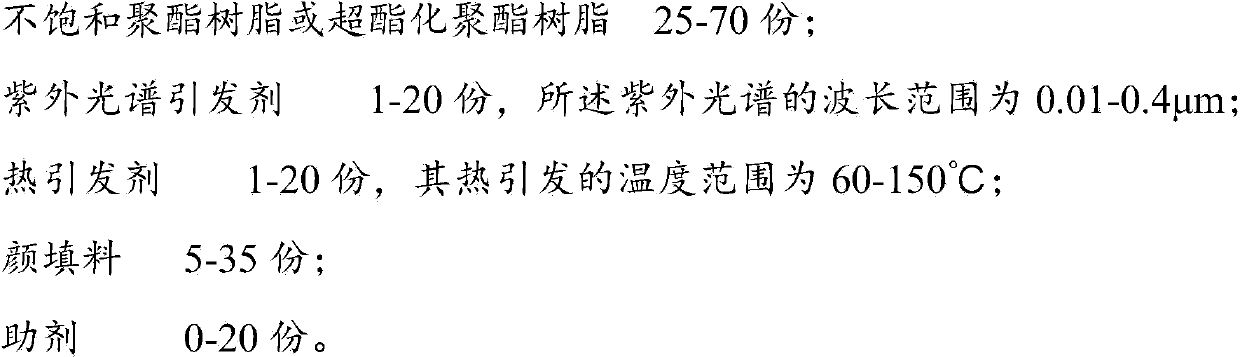

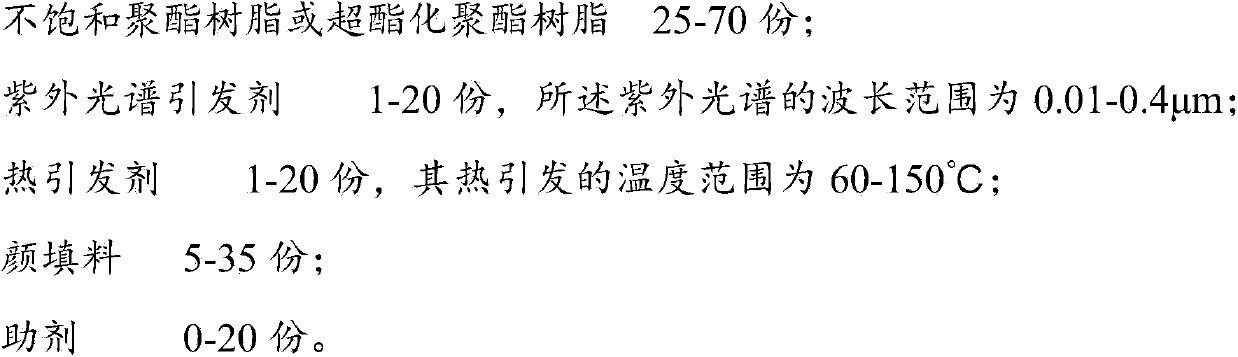

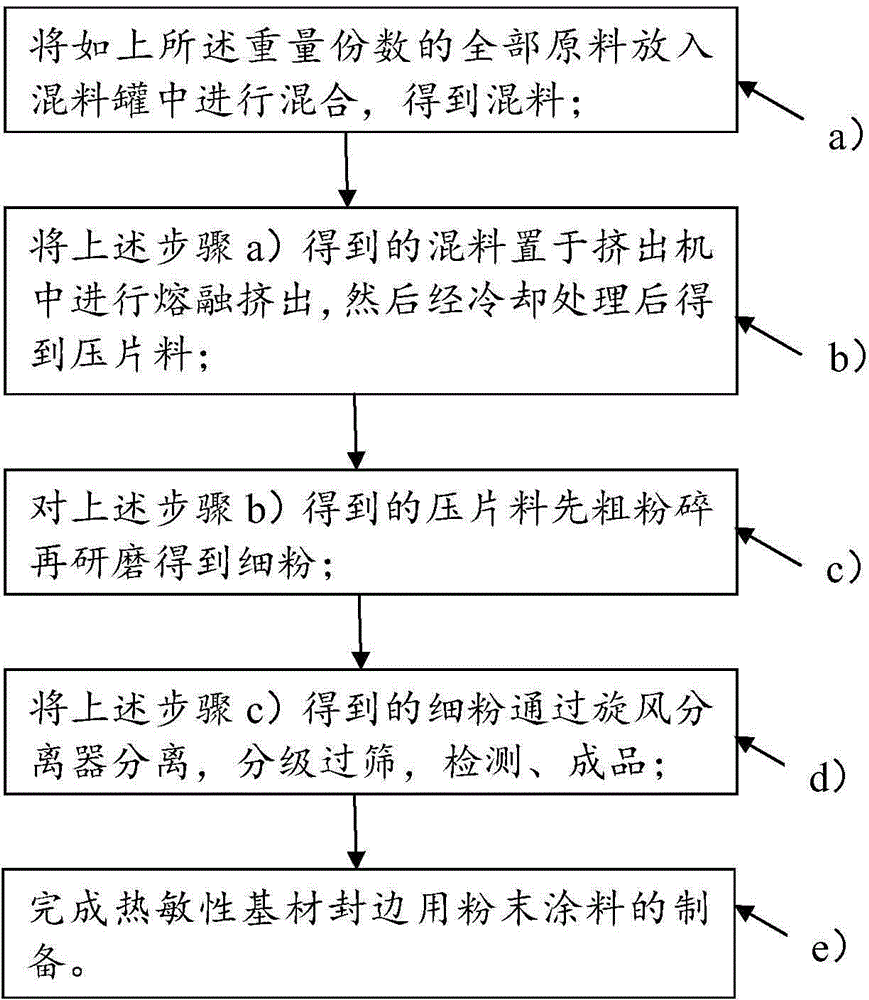

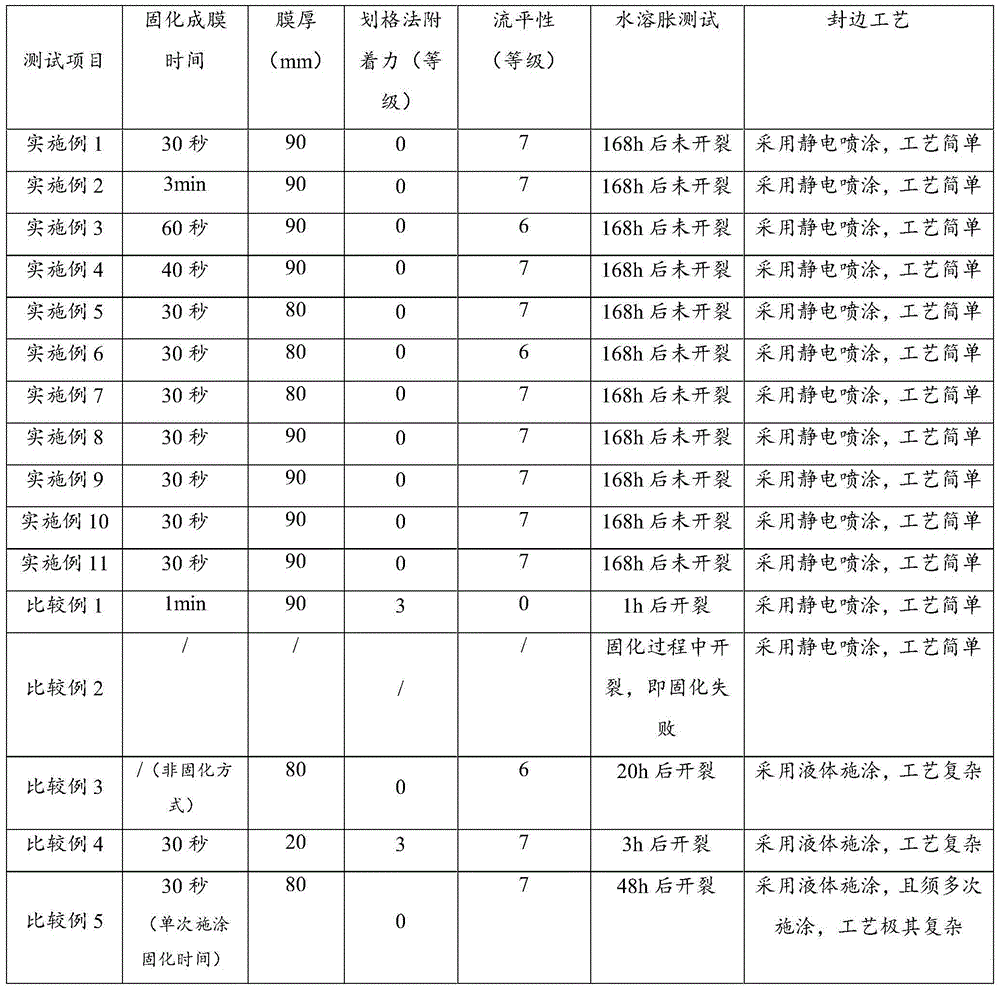

Powder coating for edge sealing of heat-sensitive base material and edge-sealing coating and preparation method thereof

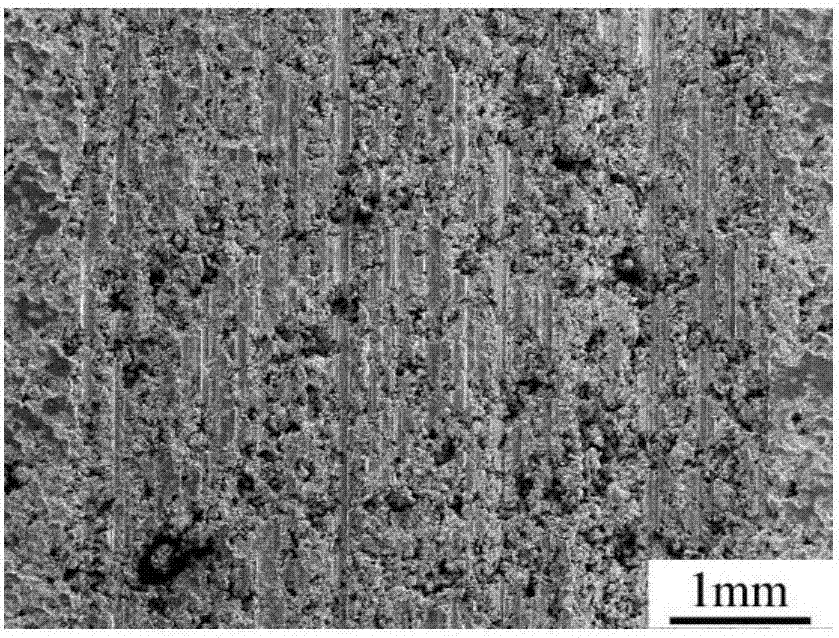

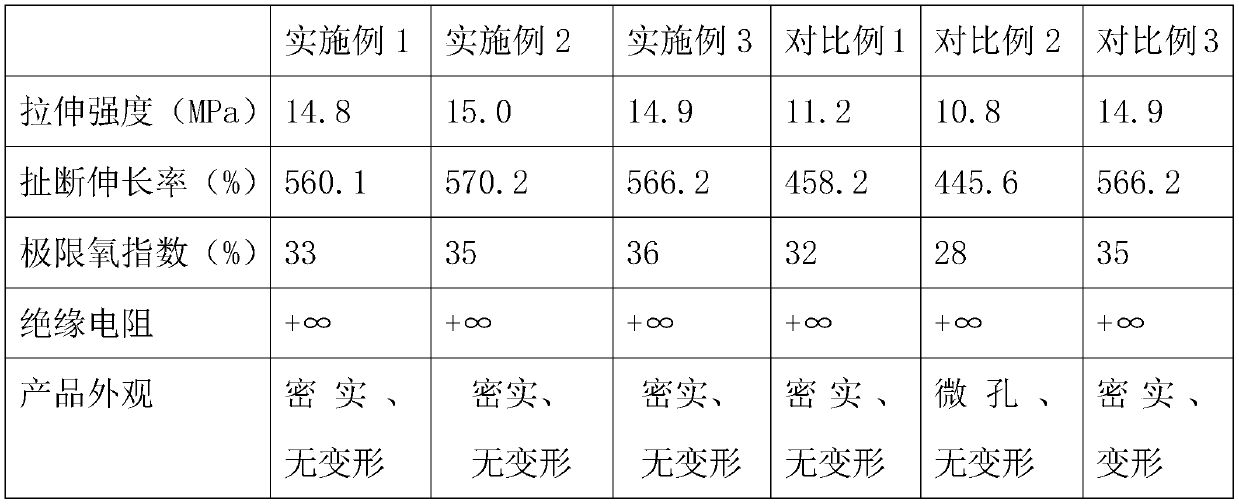

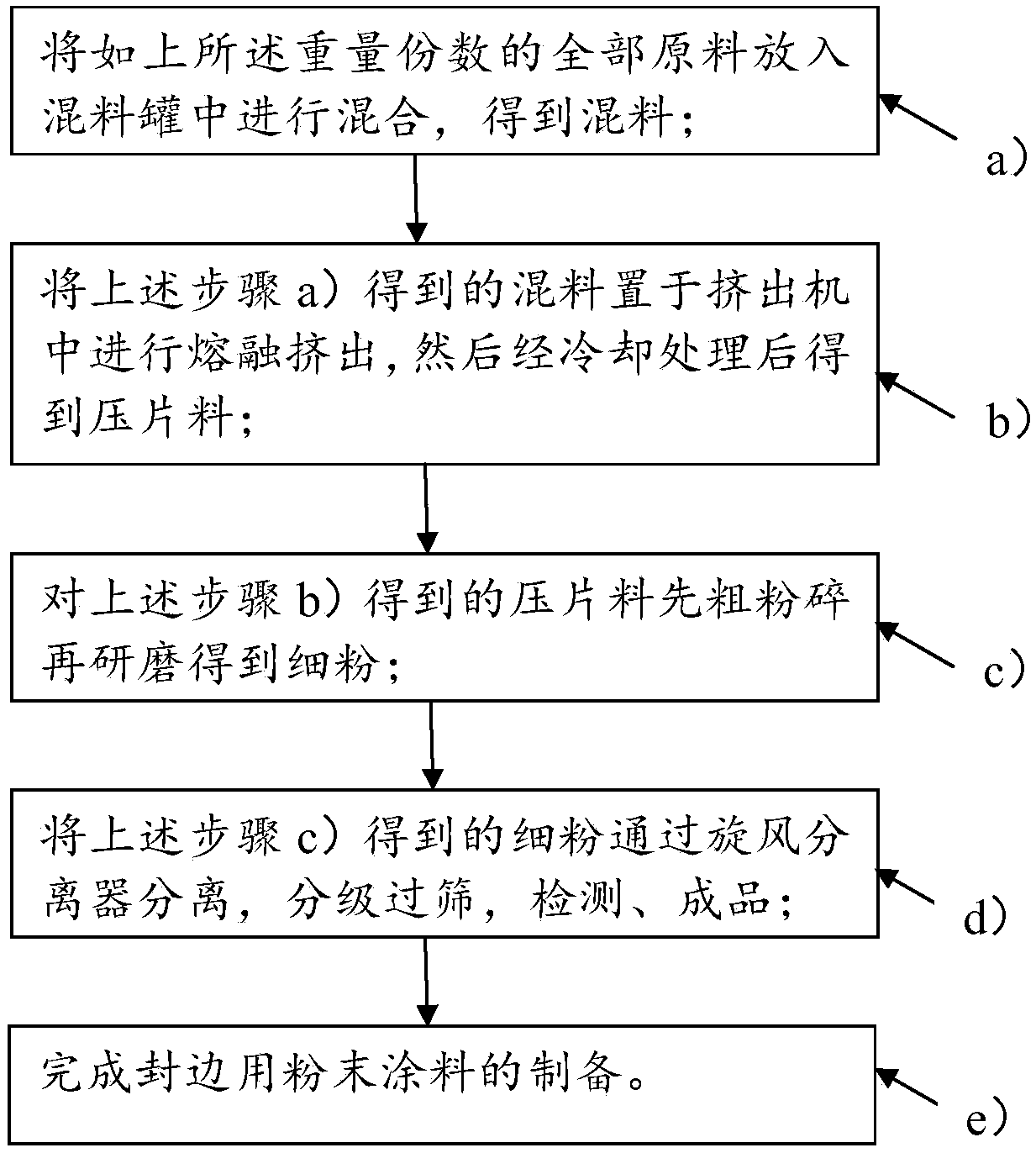

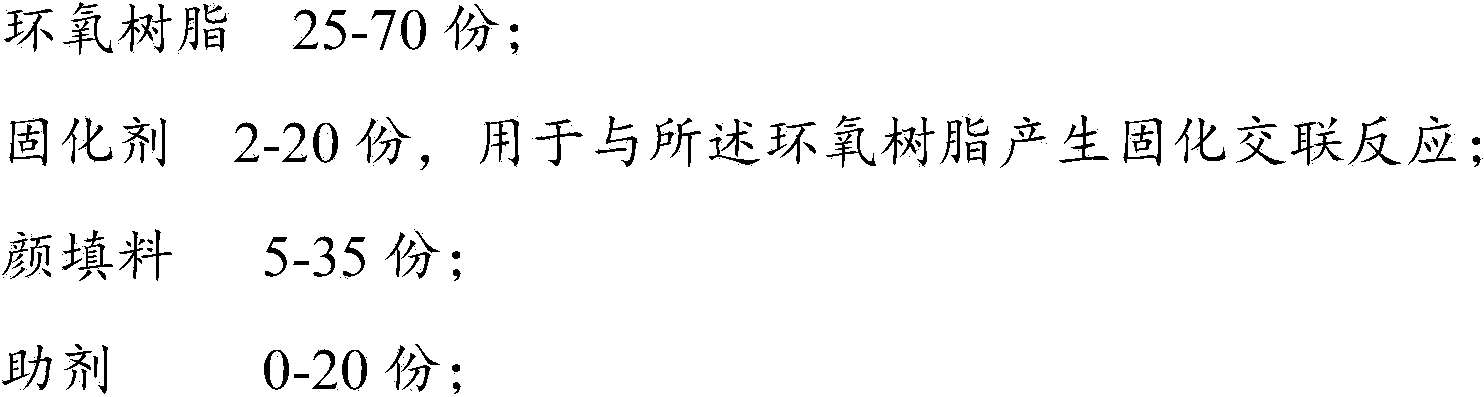

InactiveCN103773189AImprove the level ofMeet strength requirementsRadiation-absorbing paintsPowdery paintsPolyester resinWavelength range

The invention relates to a powder coating for edge sealing of a heat-sensitive base material and an edge-sealing coating and a preparation method thereof. The powder coating is prepared from the following raw materials in parts by weight: 25-70 parts of unsaturated polyester resin or super-esterified polyester resin, 1-20 parts of ultraviolet spectrum initiator in the wavelength range of 0.01-0.04mu m, 1-20 parts of thermal initiator in the thermal initiation temperature range of 60-150 DEG C, 5-35 parts of pigments and fillers and 0-20 parts of aids. A good edge-sealing effect on the heat-sensitive base material is achieved, cracks generated on the side face of the heat-sensitive base material are effectively avoided, electrostatic spraying is adopted, the edge-sealing process is simple and convenient, and the powder coating is suitable for edge sealing of base material workpieces of various shapes.

Owner:TIGER DRYLAC TAICANG

Titanium fire resistance coating

ActiveCN107142474AHigh hardnessHigh temperature oxidation resistanceMetallic material coating processesBand shapeAlloy

The invention discloses a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal is completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Insulating flame-retardant ethylene-propylene-diene monomer hose composition and preparation method thereof

ActiveCN110240760AMeet mechanical strength requirementsMeet performance requirementsRubber insulatorsAntimony trioxideStearic acid

The invention discloses an insulating flame-retardant ethylene-propylene-diene monomer hose composition which is characterized by comprising the following components in parts by weight: 100 parts of an EPDM (ethylene-propylene-diene monomer) 5890F, 2-6 parts of kaolin, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 2-5 parts of paraffin, 1-3 parts of an anti-aging agent MB, 50-70 parts of carbon black SP6400A, 130-190 parts of a flame retardant, 10-30 parts of paroline, 1-2 parts of sulfur, 10-15 parts of calcium oxide and 1.6-3 parts of an accelerant, wherein the accelerant comprises 0.2-0.5 part of an accelerant TT; and the flame retardant comprises 80-100 parts of aluminum hydroxide, 20-40 parts of zinc borate, 10-20 parts of antimonous oxide and 20-30 parts of decabromodiphenyl ethane. The invention has another purpose of providing a preparation method of the insulating flame-retardant ethylene-propylene-diene monomer hose composition, and on premise that electric insulation and insulation resistance of vulcanized rubber are met, mechanical strength requirements of rubber can be met.

Owner:青岛铁路橡胶厂

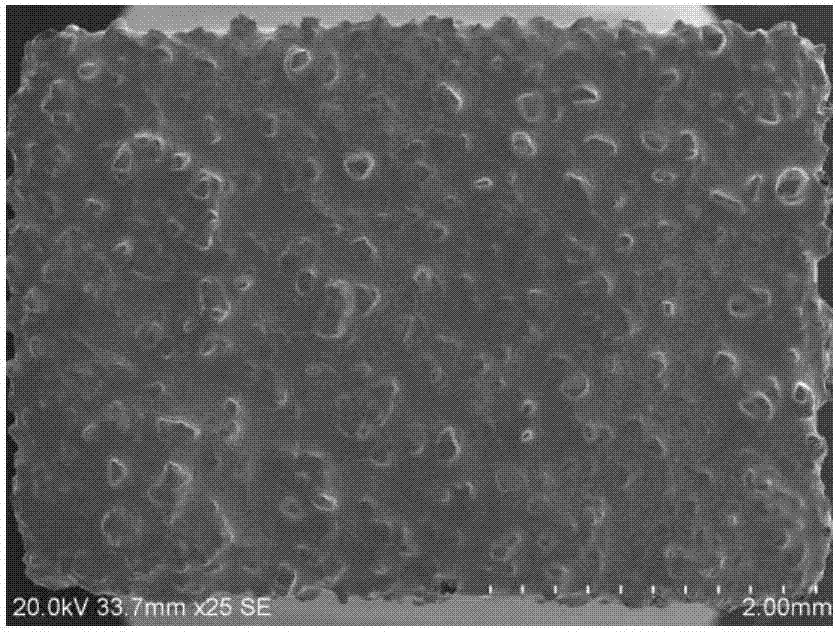

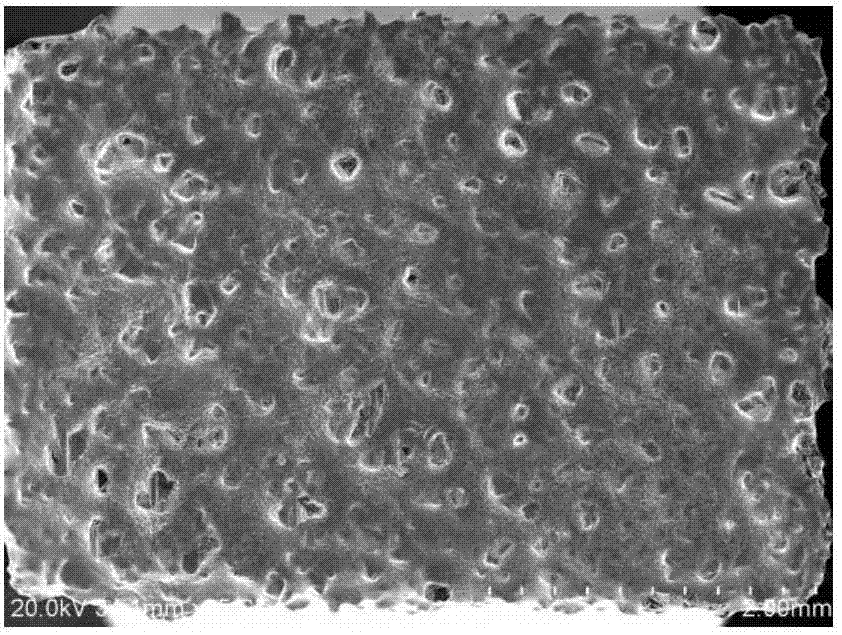

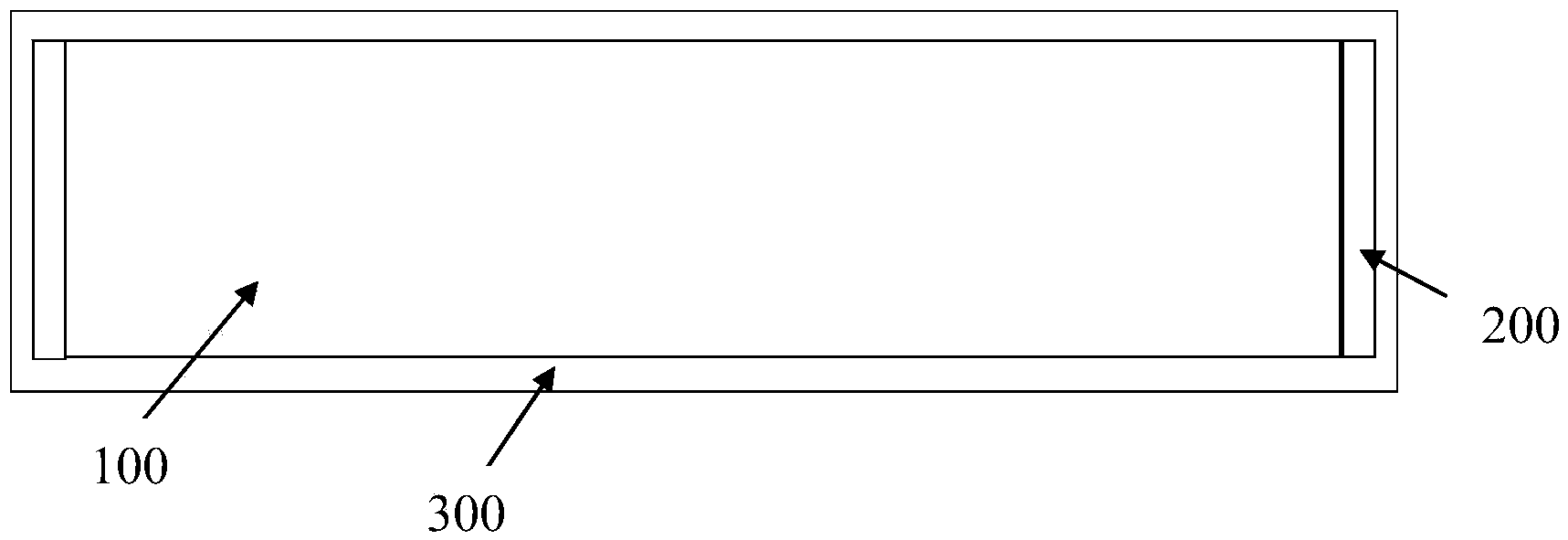

Medium-density fiberboard

InactiveCN103805026AMechanical strength requirements are metThe edge banding process is simple and convenientPretreated surfacesPowdery paintsMetallurgySpray coating

The invention relates to a medium-density fiberboard, which comprises a medium-density fiberboard body, wherein an edge-sealing coating is arranged on the lateral surface of the board body; a thermosetting coating is arranged on the edge-sealing coating and the surface of the board body; the edge-sealing coating is obtained by electrostatically spray-coating and curing an edge-sealing powder coating on the lateral surface of the board body; the thermosetting coating is obtained by electrostatically spray-coating and curing a low-temperature curing powder coating on the edge-sealing coating and the surface of the board body. According to the medium-density fiberboard, a good edge sealing effect can be achieved, and cracks in the lateral surface of the medium-density fiberboard are effectively avoided; an electrostatic spray-coating mode is adopted, so that an edge-sealing process is simple, convenient and suitable for the edge sealing of substrate workpieces in various shapes.

Owner:TIGER DRYLAC TAICANG

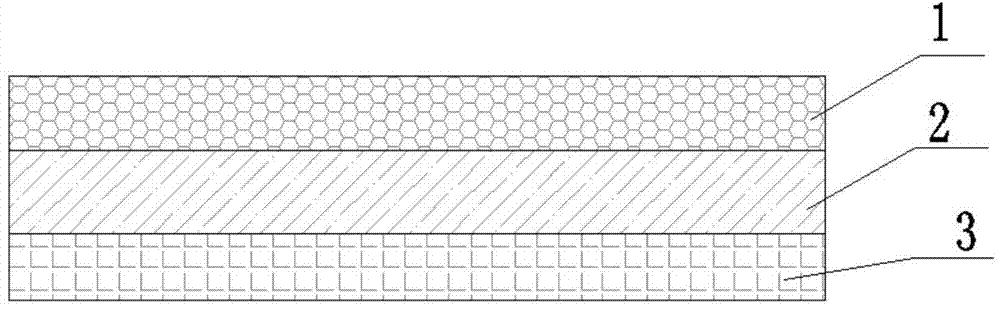

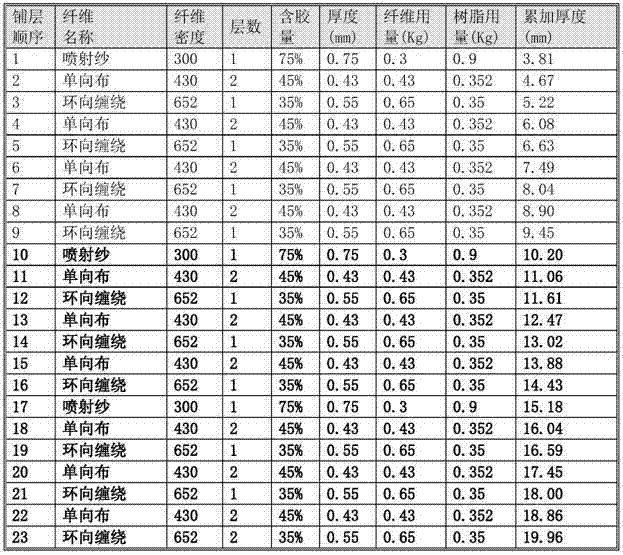

Multilayer composite fiber-reinforced-plastic coating

ActiveCN104501192AImprove the ability to resist internal pressure failureGuaranteed bondingSynthetic resin layered productsGlass/slag layered productsYarnFiber

The invention provides a multilayer composite fiber-reinforced-plastic coating used for being adhered to a base body. The multilayer composite fiber-reinforced-plastic coating comprises an adhesion layer, a reinforcement layer and an anticorrosive layer. The reinforcement layer and the anticorrosive layer are adhered to the adhesion layer sequentially. The adhesion layer is a film layer formed by interface resin adhesive with high ductility and is used for being adhered to the outer surface of the base body to improve adhesive force to the base body. The reinforcement layer is formed by spraying of chopped fiberglass yarns, vinyl ester resin is sprayed continuously during spray forming, and the content of the vinyl ester resin is 30-60%. The anticorrosive layer is formed by spraying of fiberglass and vinyl ester resin, and the content of the vinyl ester resin is not lower than 80%. The fiber-reinforced-plastic coating has the advantages that due to the multilayer composite structure, good anticorrosion effect is achieved, strength and good adhesion performance of the coating are guaranteed, and the coating is easy to construct and operate and good in use effect.

Owner:河南省兴洋环保科技有限公司

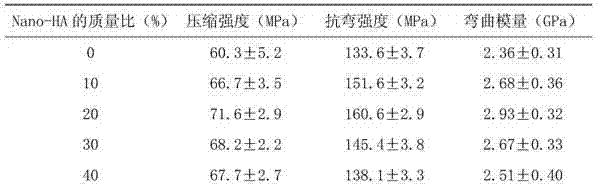

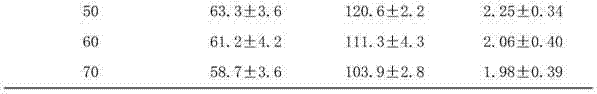

Preparation method for porous nano-composite support material of bone tissue engineering

The invention relates to biomedical composites, particularly to a preparation method for a porous nano-composite support material of bone tissue engineering. The scheme of the invention is that the preparation method comprises the following steps: mixing Nano-HA ((Hydroxy-apatite) and PLLA (Polylactic acid) materials at the temperature of 50-70 DEG C, carrying out ultrasonic oscillation, and then performing electromagnetic stirring until the NAno-HA is uniformly and completely dispersed to obtain gel; transferring the gel to the environment with the temperature of minus 5 DEG C to minus 3 DEG C to be subjected to low-temperature formation, and filling biological materials, so as to obtain the porous nano-composite support material of the bone tissue engineering. According to the method, provided by the invention, a three-dimensional porous Nano-HA / PLLA artificial bone can be prepared through the combination of the Nano-HA and the PLLA; the three-dimensional porous artificial bone support material integrates the advantages of both the Nano-HA and the PLLA, the flexibility, biodegradability and biomechanical property are improved, adhesion growth and vascularization of bone cells can be better facilitated, and the healing speed and effect of bone defect parts with transplanted artificial bones are greatly improved.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

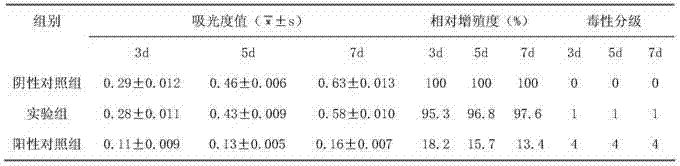

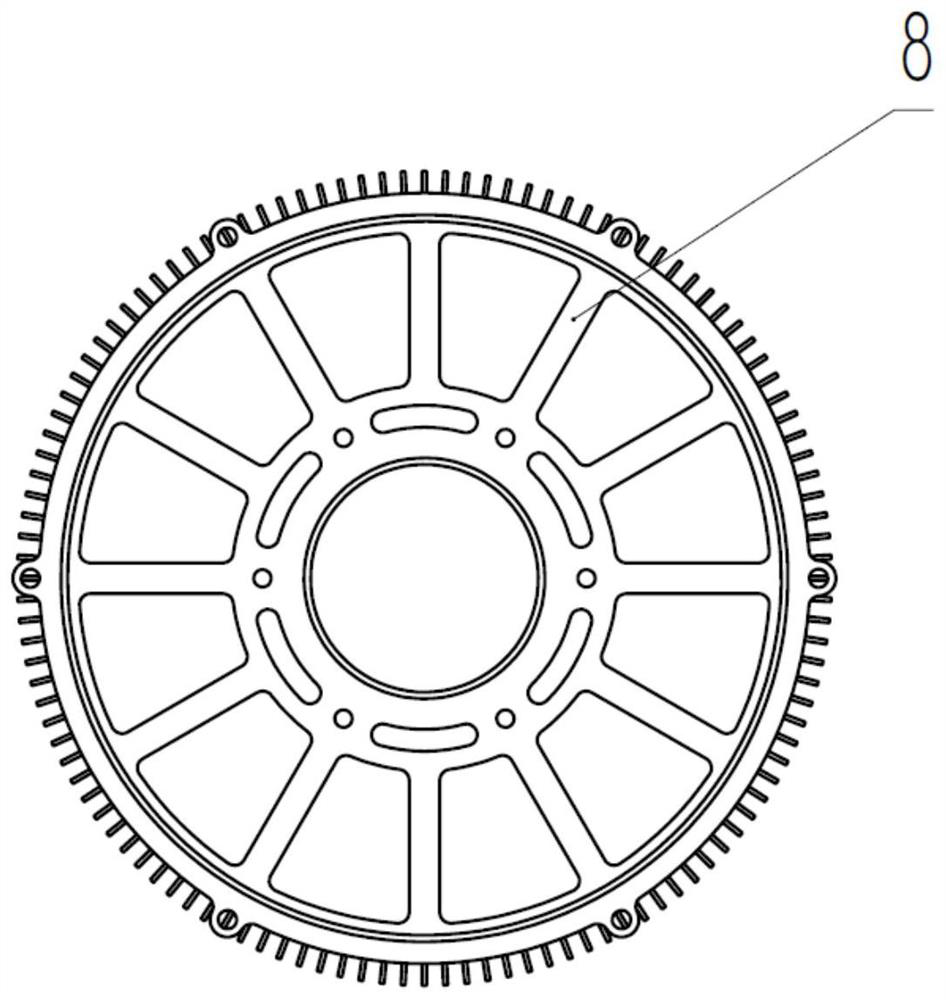

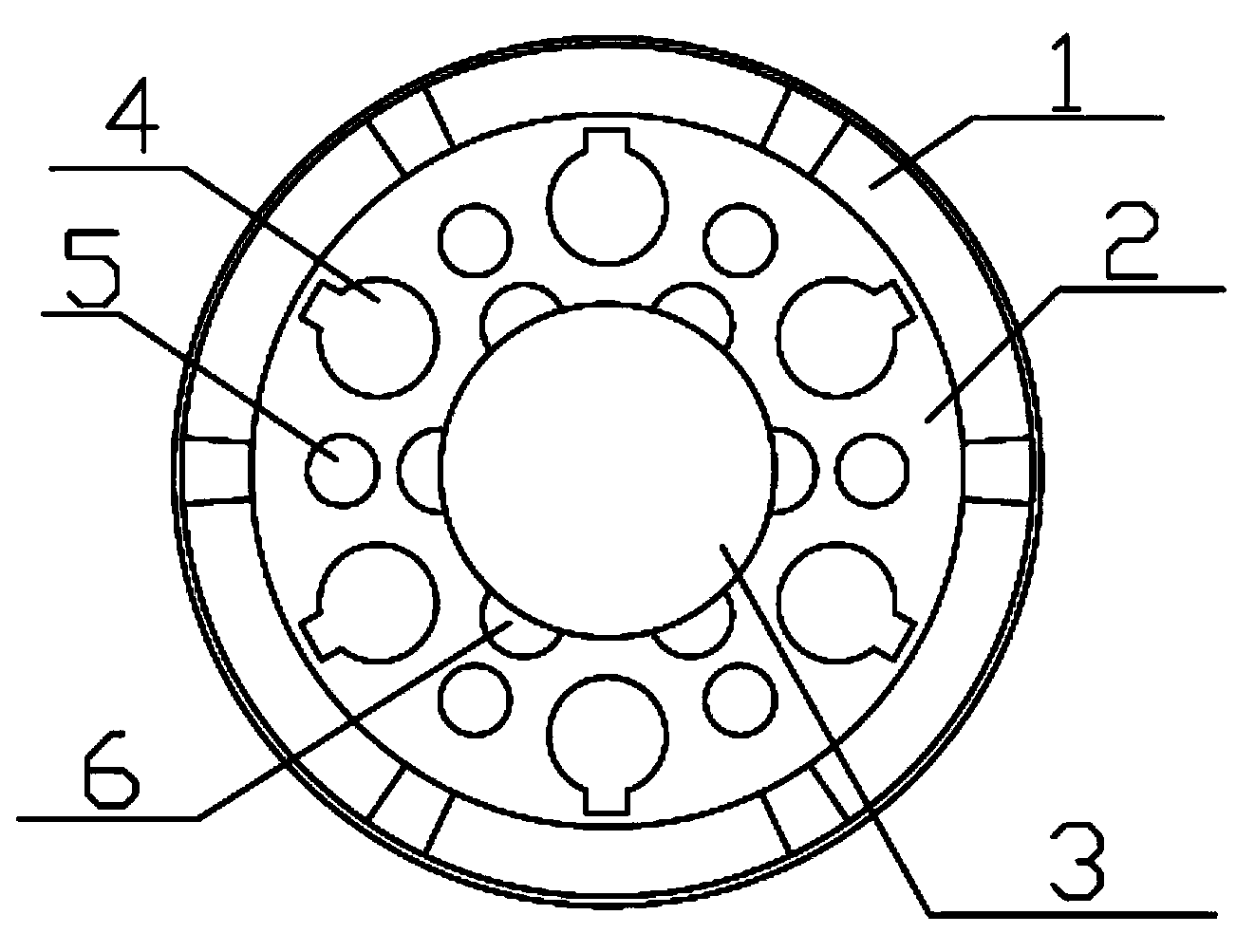

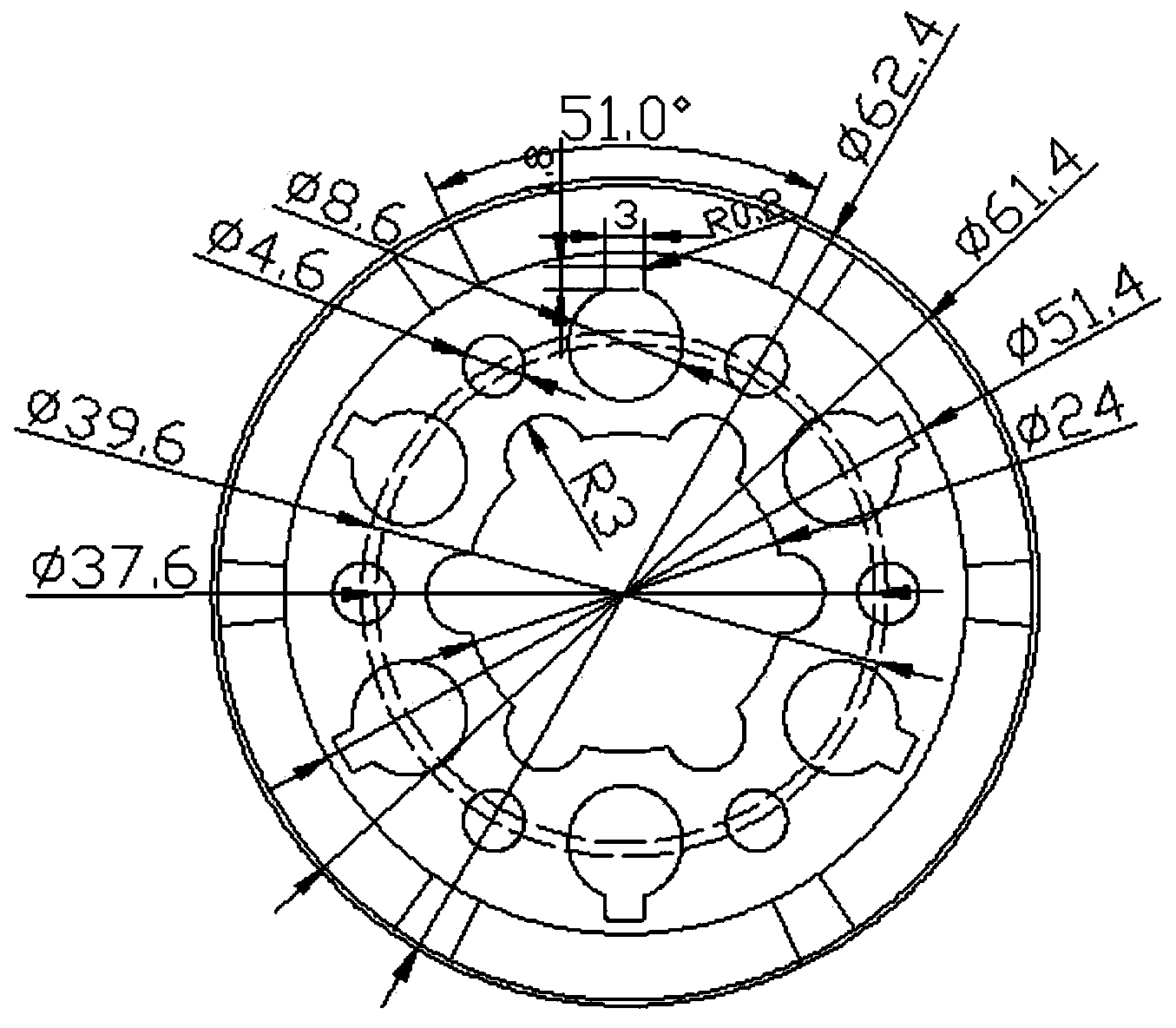

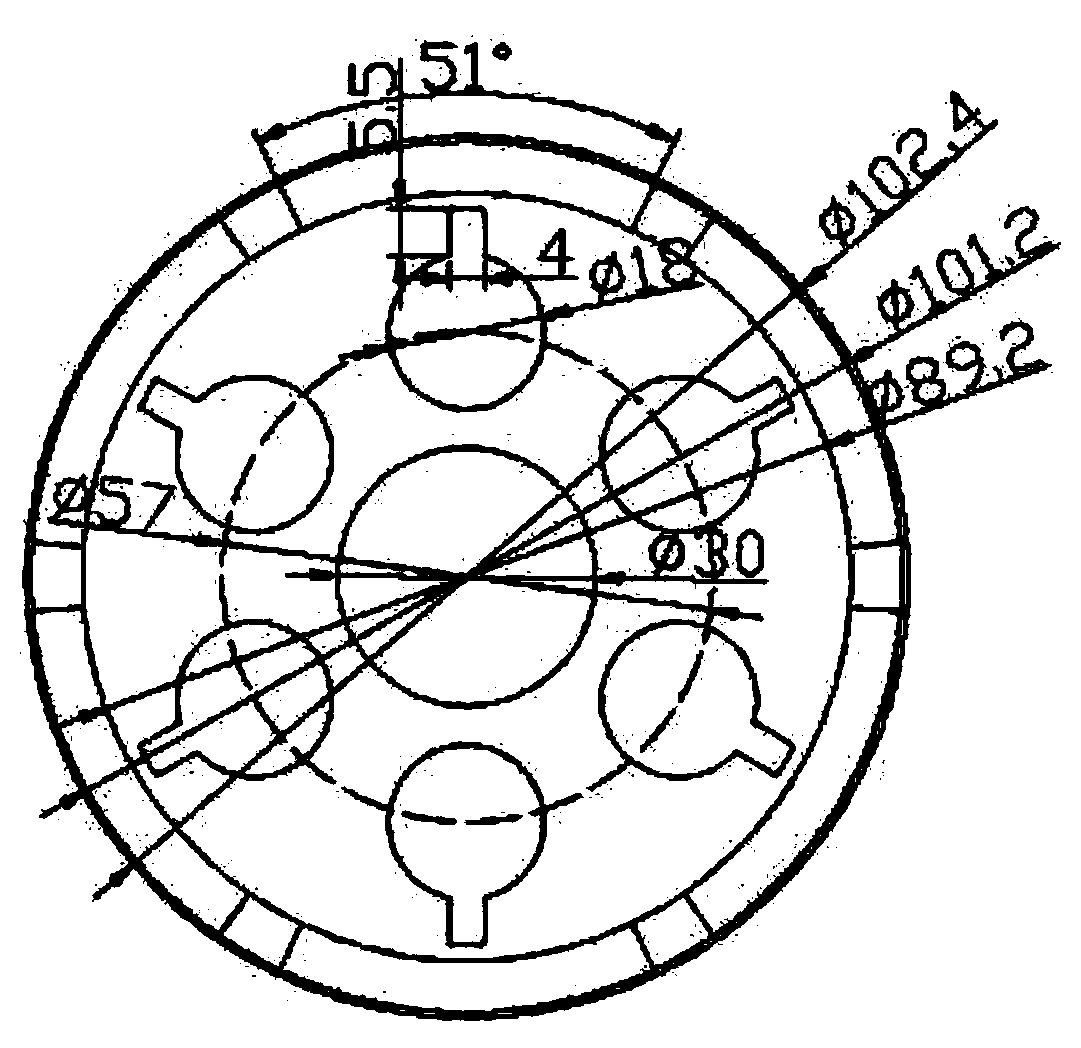

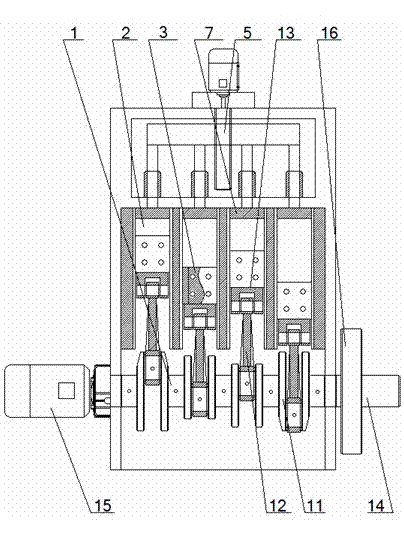

Permanent magnetic synchronous generator rotor for wind power generation

InactiveCN105490417ASimple structureImprove reliabilityMagnetic circuit rotating partsInterference fitPermanent magnet synchronous motor

The invention discloses a permanent magnetic synchronous generator rotor for wind power generation. The permanent magnetic synchronous generator rotor comprises permanent magnetic steel bars, a rotor core and a rotating shaft. The permanent magnetic synchronous generator rotor further comprises first hole slots and air slots. The permanent magnetic steel, the rotor core and the rotating shaft are successively distributed in a clinging manner from outside to inside in one circumferential axis. The rotating shaft is a solid shaft. Hot interference fit is utilized between the rotating shaft and the circumference which engages with the rotor core. Furthermore one side circumference of the rotor core is provided with a plurality of semicircular air slots. The central circumference between the outer diametric plane and the inner diametric plane of the rotor yoke is provided with a plurality of circular first hole slots. The number of the first hole slots is equal with that of the permanent magnetic steel bars. Furthermore the center of each first hole slot is in the central axis of each magnetic steel bar. The permanent magnetic synchronous generator rotor satisfies technological requirements of small weight, high control flexibility, simple structure, high vibration resistance, high efficiency and high reliability in a power generator in a wind power generation field.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +2

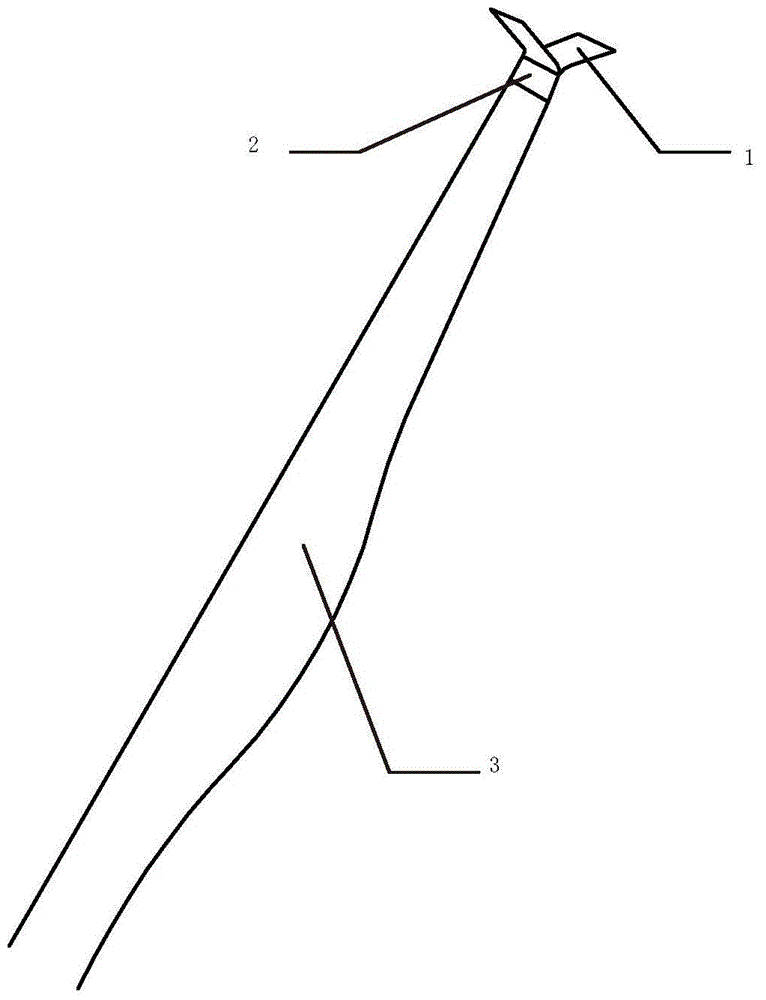

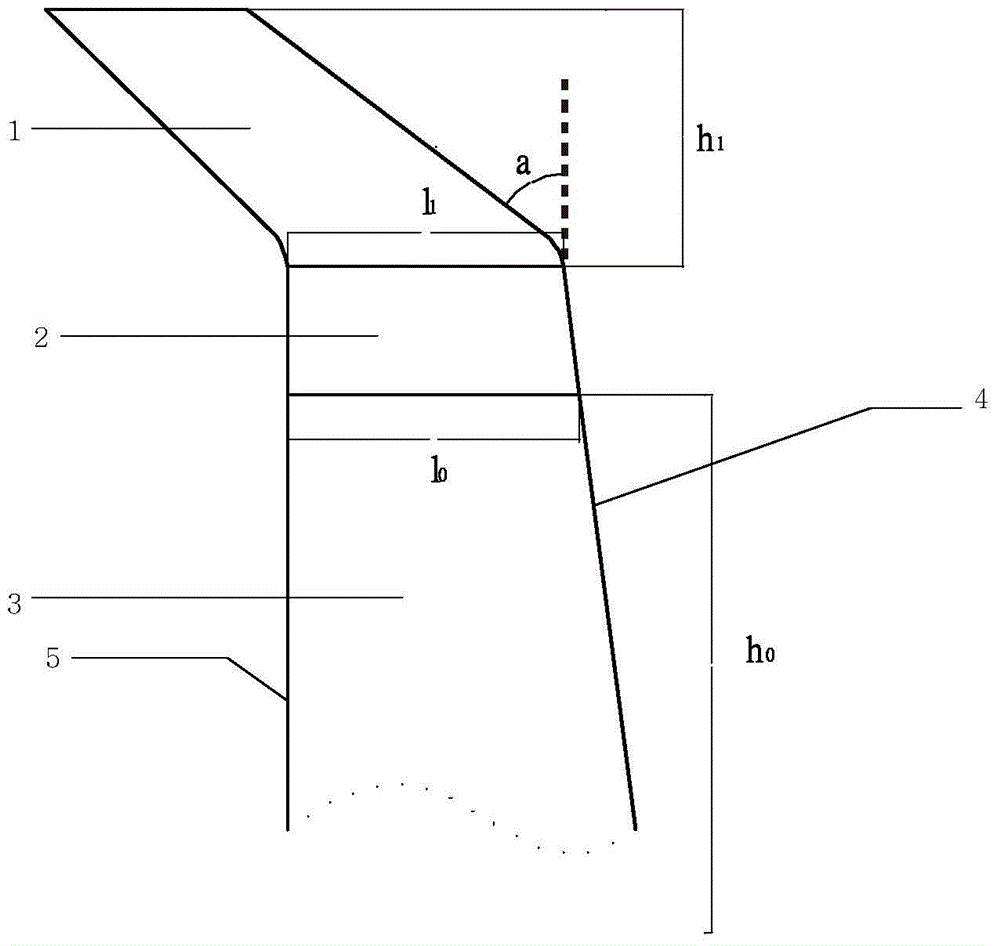

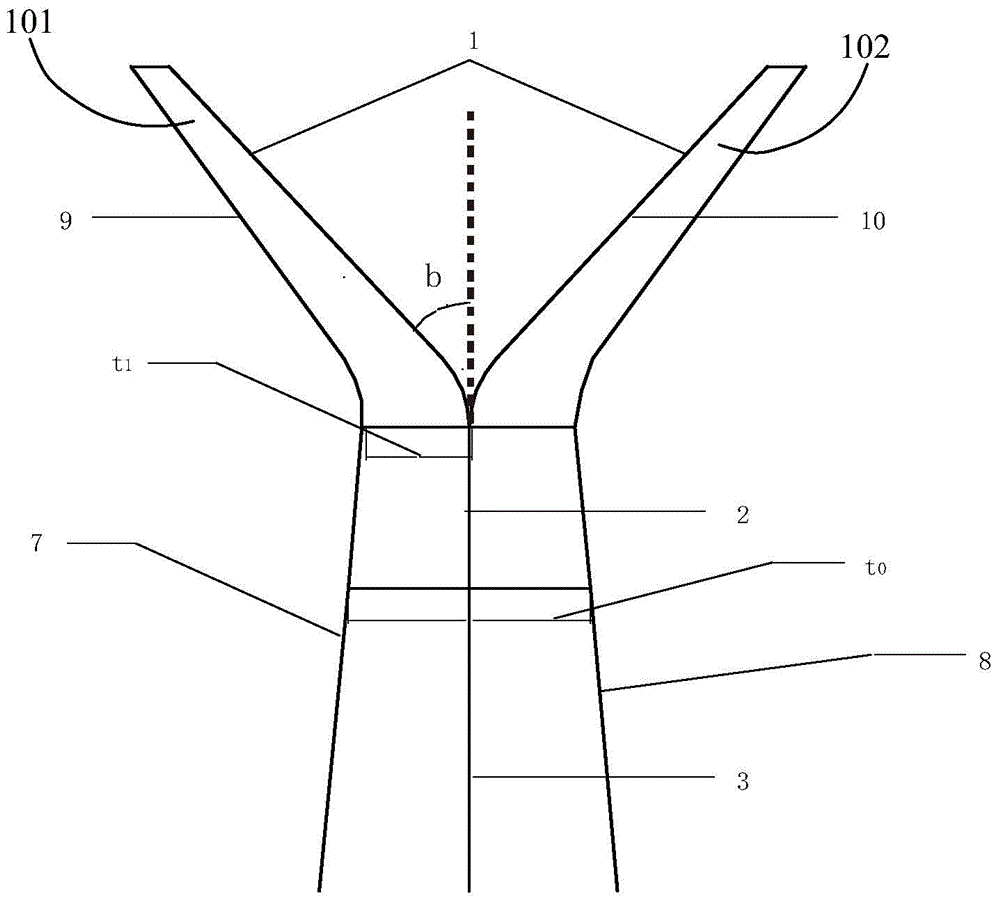

Novel wind turbine blade

InactiveCN104863791AImproved aerodynamic layoutReduce intensityMachines/enginesEngine componentsTurbine bladeUltimate tensile strength

The invention provides a novel wind turbine blade which comprises a main blade body, a blade tip extension segment and symmetrical little wings. The blade tip extension segment is connected with the main blade body and the symmetrical little wings respectively. The chord length of the blade tip extension segment is in smooth transition from the blade tip chord length to the little wing root chord length. The symmetrical little wings comprise the first little wing and the second little wing. The first little wing and the second little wing are symmetrical to each other. Both the first little wing and the second little wing are provided with lifting airfoils. Both the suction surface of the first little wing and the suction surface of the second little wing face a wind turbine body. The novel wind turbine blade has the advantages that the blade tip vortex is reduced, the blade stress is balanced, the pneumatic efficiency of the wind turbine is improved, the blade root waving moment is lowered, the requirement for the strength level of all components of the wind turbine is lowered, the reliability degree of the components of the wind turbine is increased, and the power generation cost of the wind turbine is reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

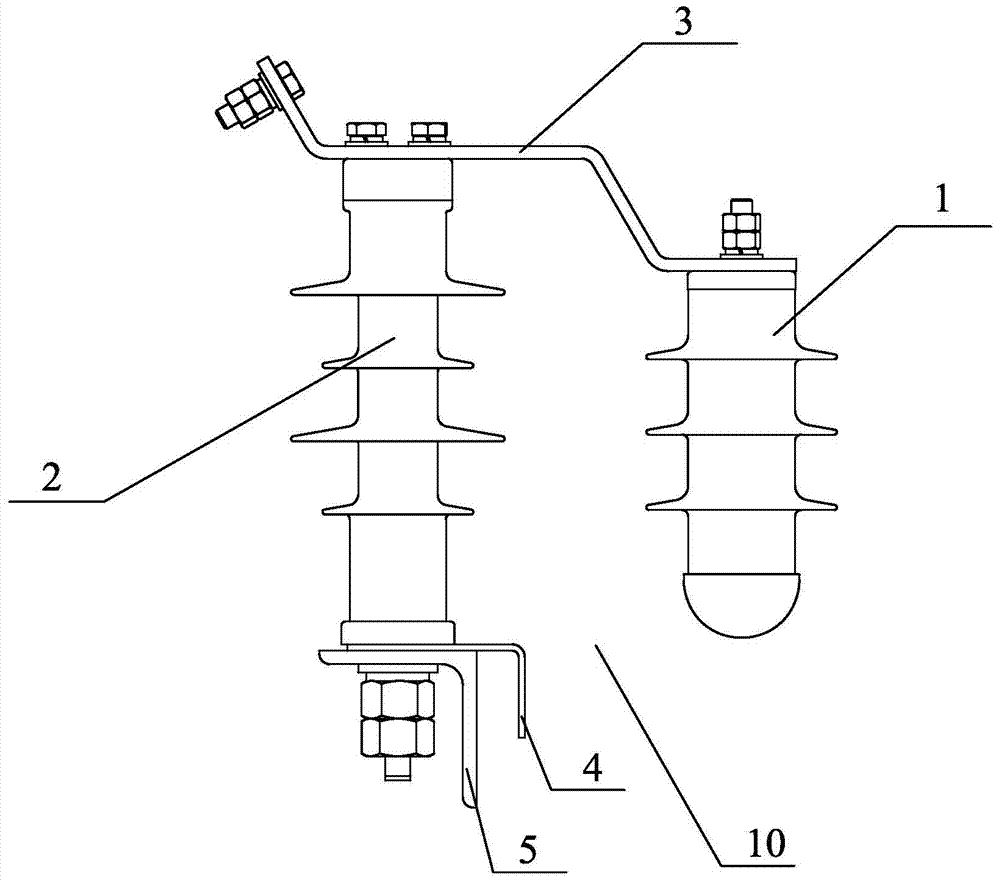

External column type voltage limiter for urban rail catenary

InactiveCN103490284AReduce volumeReduce weightOvervoltage protection resistorsOvervoltage arrestors using spark gapsElectricityEngineering

The invention relates to an external column type voltage limiter for an urban rail catenary. The external column type voltage limiter comprises a cross arm of a tower and further comprises a lightning arrester body and a post insulator. A spherical electrode is installed on the lightning arrester body, the lightning arrester body is connected with the post insulator through a conductive metal bar, a run-on plate is further installed between the tower cross arm and the post insulator and is in tight electric connection with the tower cross arm, the lightning arrester body is in tight electric connection with a fitting positioned on the post insulator, and an air gap is formed between the run-on plate and the spherical electrode. The external column type voltage limiter can be installed away from the insulator and provide multiple protections for the insulator and is suitable for being used on an urban rail catenary system.

Owner:SHANDONG XUNSHI ELECTRIC

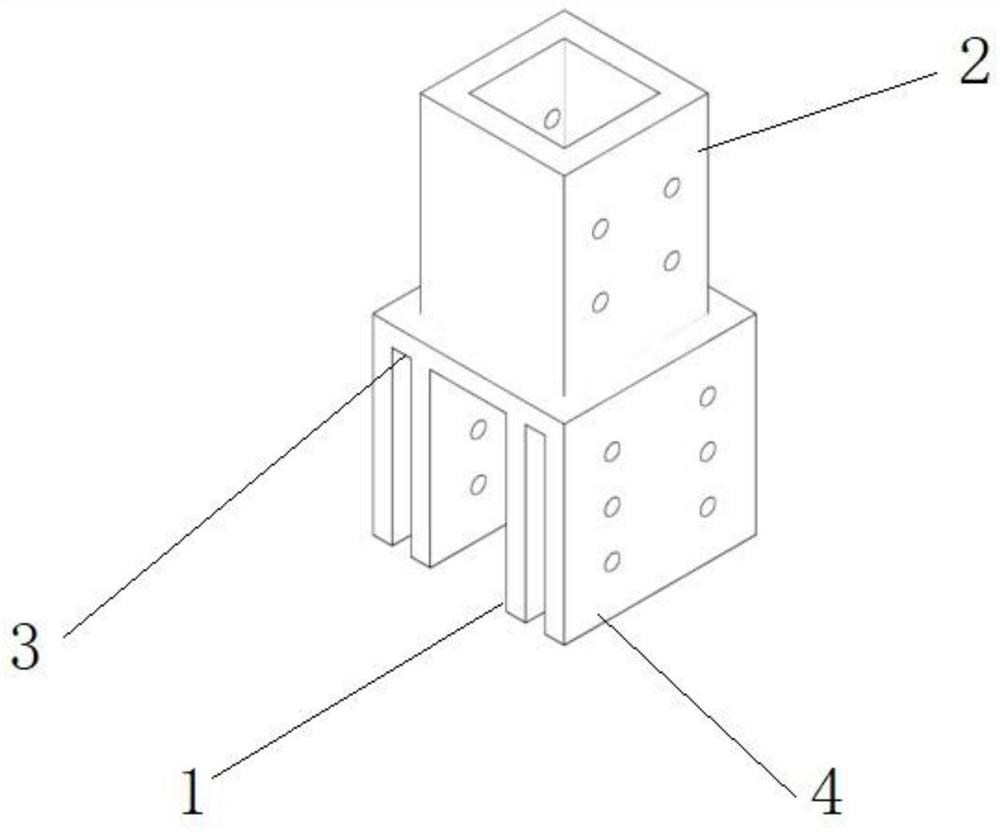

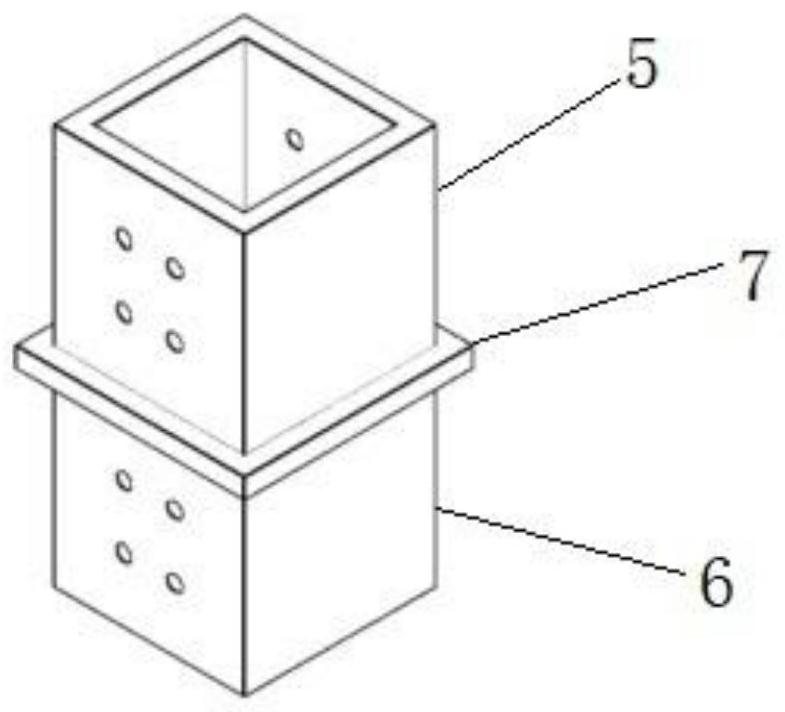

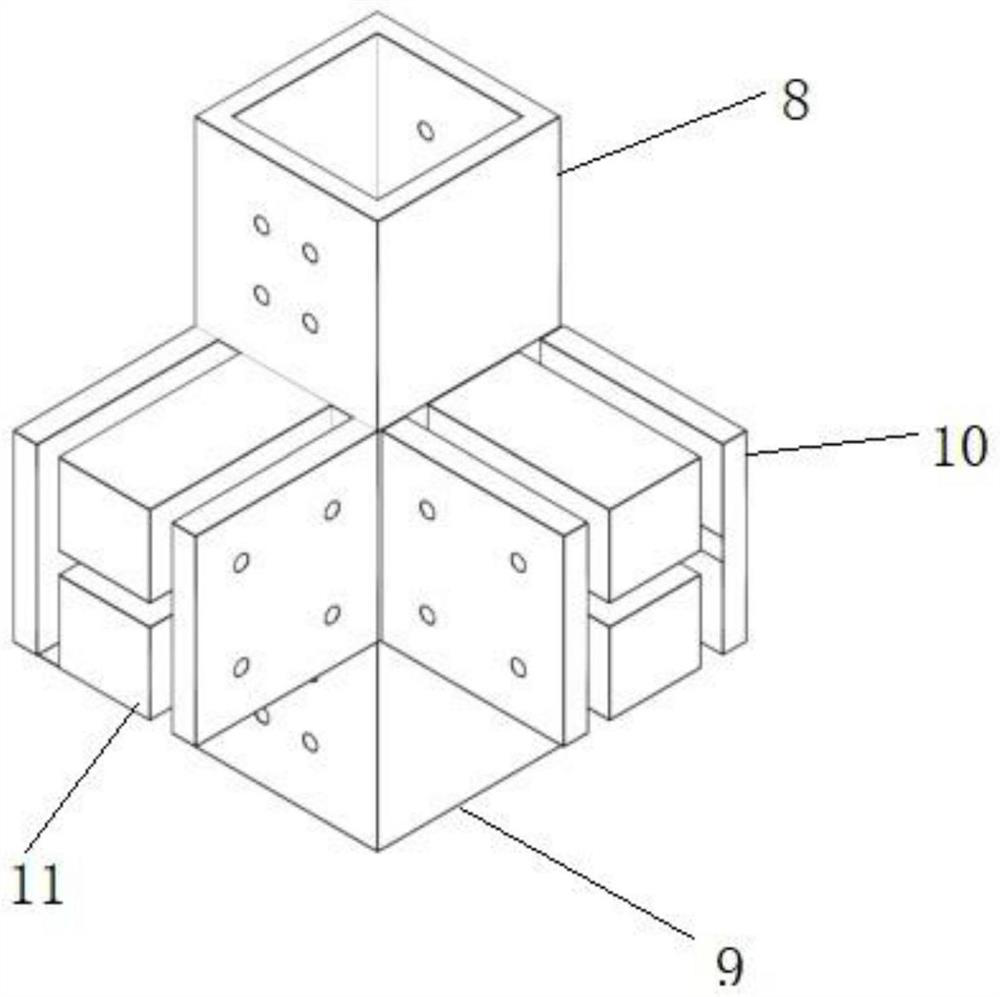

Modular design method of novel steel structure

ActiveCN111639371AMeet the mechanical requirementsLow costGeometric CADDesign optimisation/simulationFloor slabFinite element analysis software

The invention discloses a modular design method of a novel steel structure, which comprises the following steps of: 1) establishing a steel structure frame model according to the requirements of customer architectural styles and architectural specifications, and analyzing the stress conditions of all parts and connecting pieces of a steel structure frame after a wall body and a floor slab are established by applying finite element analysis software; 2) according to the steel structure frame model, automatically calculating and outputting an installation sequence of each part and each connecting piece of the steel structure frame by computer software, and labeling; 3) according to a stress condition analysis result, selecting materials meeting corresponding mechanical property requirementsfor industrialized production of all components and connecting pieces of the steel structure frame, and correspondingly marking the labels determined in the step (2) on all the components and the connecting pieces; and 4) transporting all components, connecting pieces, wallboards and floors of the steel structure frame which is produced in an industrialized mode to a construction site to constructa house of a steel structure. The method has the beneficial effects that installation is convenient and rapid, and the construction cost is saved.

Owner:CHINA NAT CHEM ENG HEAVY MECHANIZED CORP

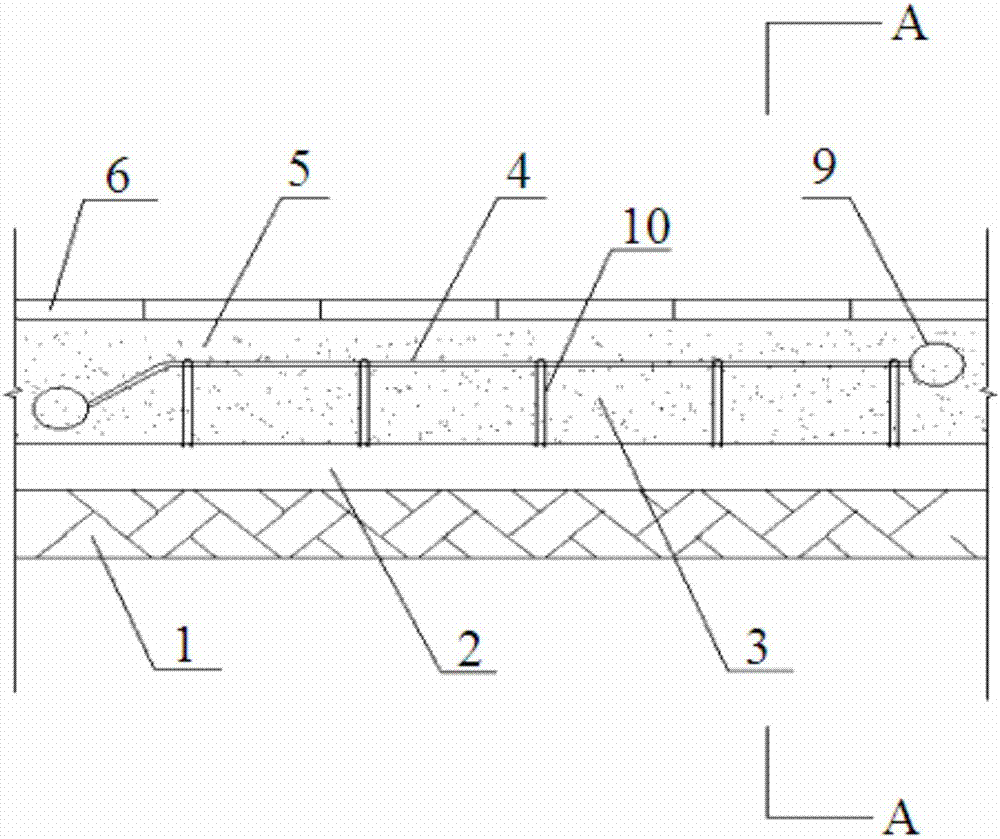

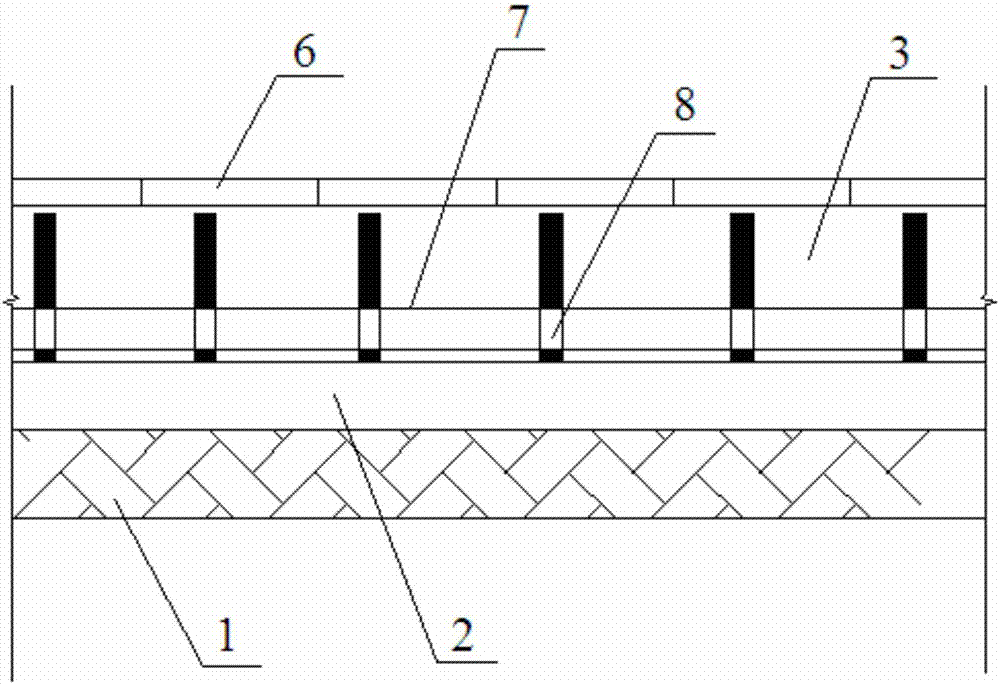

Composite phase change material, preparation method of composite phase change material, energy storage slurry and energy storage floor board

InactiveCN106867462AImprove thermal conductivityPrevent leakageCovering/liningsHeat-exchange elementsLiquid stateMass ratio

The invention relates to the technical field of a heating tail end device, in particular to a composite phase change material, a preparation method of the composite phase change material, energy storage slurry and an energy storage floor board. The composite phase change material comprises an organic phase change material and an inorganic carrier, wherein the organic phase change material is fully filled in pores of the inorganic carrier, and is polyethylene glycol; the inorganic carrier is expanded graphite; the mass ratio of the polyethylene glycol to the expanded graphite is 11.5:1. The composite phase change material provided by the invention uses the polyethylene glycol as the phase change material, and uses the expanded graphite as a support and enhancing heat transfer material. The polyethylene glycol and the expanded graphite are subjected to negative pressure adsorption for 10 min in a constant temperature drying box at the pressure being -0.05 Mpa and the temperature being 70 DEG C according to a mass ratio of 11.5:1 to obtain the composite phase change material. The expanded graphite has the advantages that the heat conduction coefficient is high; the developed reticular hole type structures are realized; through the capillary effects of the micropores, the phase change material of the polyethylene glycol is adsorbed into the micropores, so that the leakage of the liquid-state phase change material is effectively avoided; the heat conduction performance of the phase change material is improved; meanwhile, the volume is basically unchanged in the phase change process.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

High-power-density and high-efficiency permanent magnet synchronous motor for electric aircraft

ActiveCN112953150AShorten the lengthImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric aircraftElectric machine

A high-efficiency and high-power-density permanent magnet synchronous motor for an electric aircraft comprises a stator iron core, a stator winding, a permanent magnet, a rotor iron core, a rotor support, a rotating shaft, a front bearing, a rear bearing, a machine shell and a rear end cover; light weight of the motor is achieved by increasing the inner diameter of a motor stator and reducing the axial length; the motor stator winding adopts a fractional slot and concentrated double-layer winding structure, so that the winding end size is reduced; the stator iron core adopts an ultrathin silicon steel sheet; the rotating shaft adopts a hollow shaft structure to reduce weight; the rotor bracket adopts a spoke-shaped structure, so that the weight of the rotor is reduced; the rotating shaft, the rotor support and the rotor iron core are sequentially connected together in a key groove fit mode from inside to outside. The permanent magnets are axially segmented, so that eddy-current loss is reduced, and motor efficiency is improved; the outer side of the casing adopts a radiating fin structure, so that the weight is effectively reduced while the radiating capability of the motor is ensured; and the end cover and the components are packaged together, so the performance requirements of high power density and high efficiency of the driving motor of the electric aircraft are met.

Owner:BEIHANG UNIV

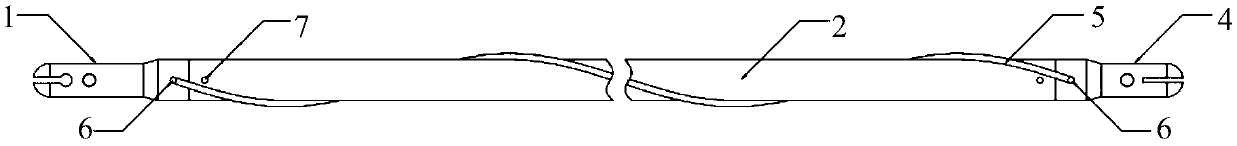

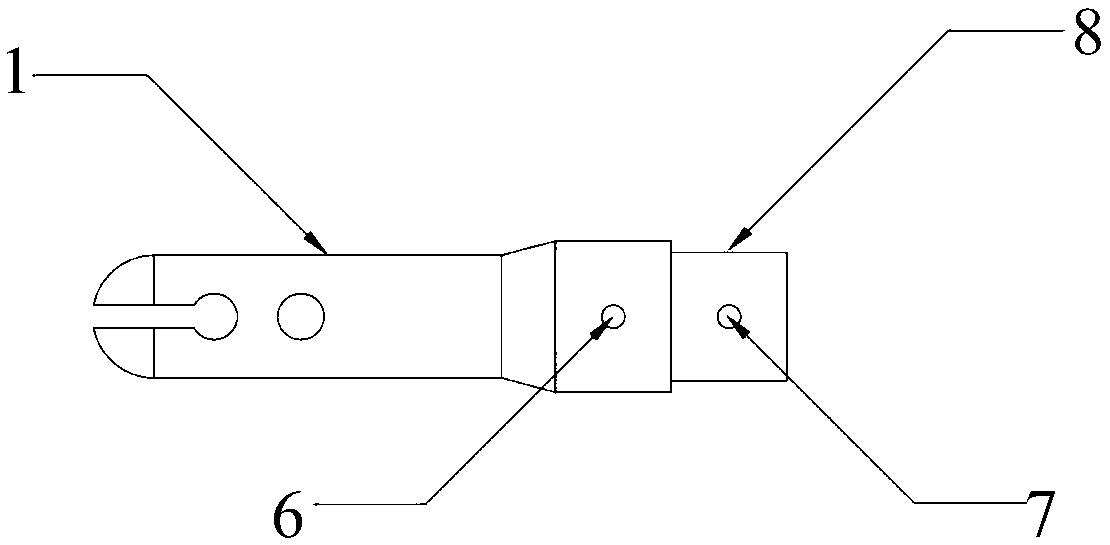

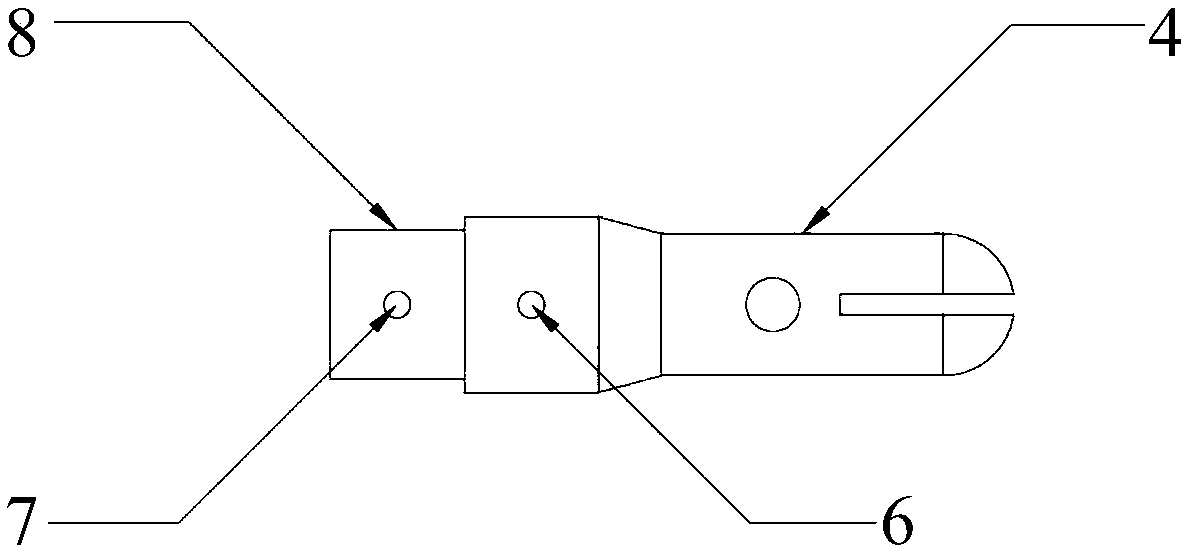

Visual fuel rod

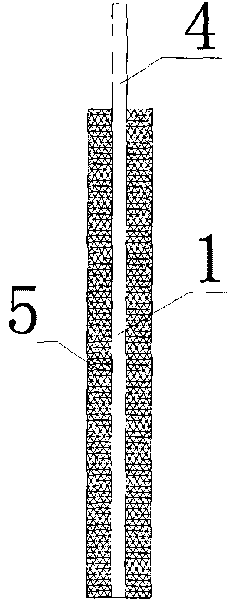

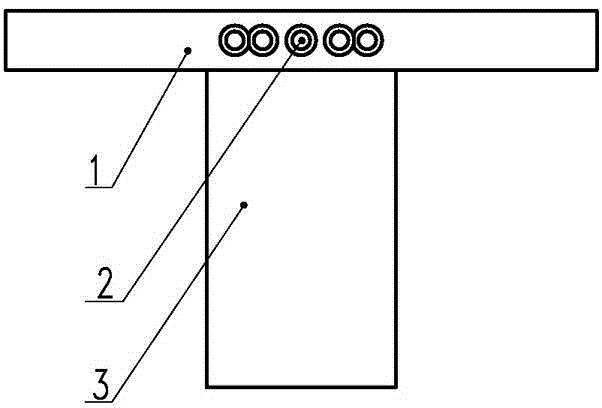

ActiveCN109659042AMeet the requirements of mechanical strengthEasy collimation installationOptical rangefindersFuel elementsAutomotive engineeringMeasuring equipment

The invention provides a visual fuel rod. The visual fuel rod is characterized in that the visual fuel rod includes a lower plug (1), a fuel shell (2), a liquid column (3), an upper plug (4) and a positioning winding wire (5). The liquid column (3) is arranged in the fuel shell (2). The refractive index deviation of the liquid column (3) and the fuel shell (2) is within a range of 1%. The lower plug (1) and the upper plug (4) are connected to the two ends of the fuel shell (2) so as to seal the liquid column (3) in the fuel shell (2). The positioning winding wire (5) wraps and is fixed to theouter surface of the fuel shell (2). Through the arrangement of liquid with the same or similar refractive index with the fuel shell (2) in the fuel shell (2), the requirements of optical velocity measuring equipment for refractive index matching and transmittance can be satisfied, and the requirements of mechanical strength can be satisfied. The visual fuel rod can be used for studying a velocityfield, a pressure field and the like inside a fuel assembly.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

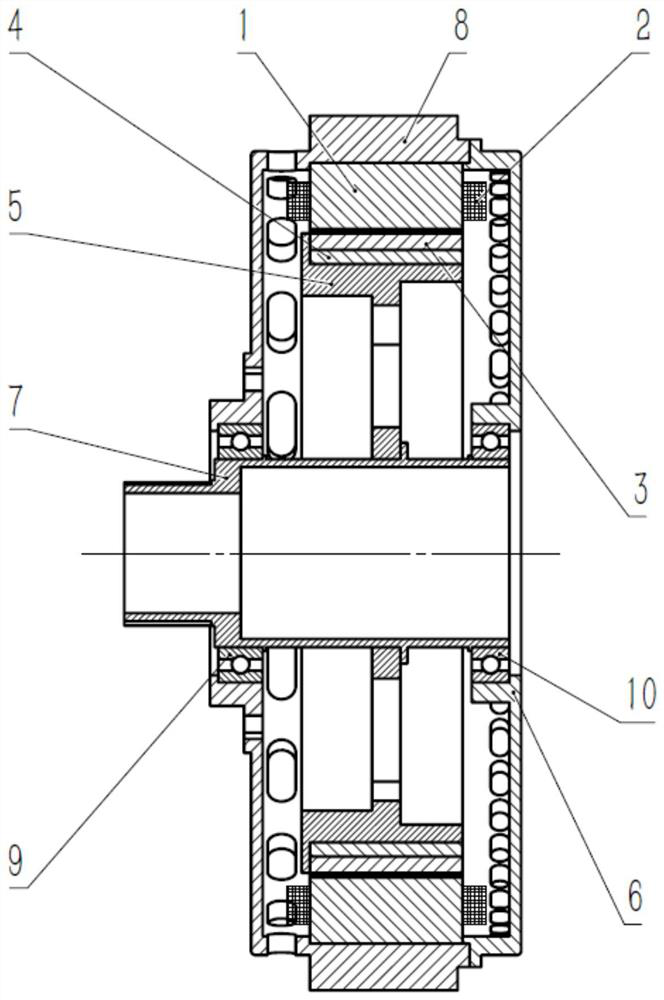

Lightweight high-power permanent magnet brushless DC motor rotor for airborne equipment

ActiveCN104079134AReduce volumeReduce weightMagnetic circuit rotating partsAirplaneThermal interference

The invention relates to a lightweight high-power permanent magnet brushless DC motor rotor for airborne equipment. The permanent magnet brushless DC motor rotor is characterized in that a rotating shaft is a solid shaft, thermal interference fit is adopted for the circumference where the rotating shaft is connected with a rotor iron core in an end-to-end mode, and the circumference located on one side of the rotor iron core is provided with a plurality of semicircular air grooves; a plurality of circular first hole grooves are evenly formed in the central circumference of the outer diameter and the inner diameter of a rotor yoke part, the number of the first hole grooves is equal to that of permanent magnet magnetic steel, and the circle center of each first hole groove is located on the central axis of the corresponding magnetic steel. As the permanent magnet brushless DC motor rotor is quite beneficial to weight reduction for aircraft power plants such as an airplane and a guided missile, the application prospects of the permanent magnet brushless DC motor rotor in the aerospace field are excellent, and the weight reduction of the optimized scheme can reach 40 percent compared with an original scheme.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Magnetomotive device and using method thereof

The invention relates to a magnetomotive device, which comprises a crankshaft, a main motor and at least two magnetomotive units, wherein an output shaft of the main motor is connected with a power output shaft sequentially through the camshaft and a flywheel; a sliding permanent magnet in each magnetomotive unit is connected with a rod journal on the crankshaft through a crankshaft connecting rod; a back permanent magnet which corresponds to each sliding permanent magnet is arranged right behind a leading channel where each sliding permanent magnet is located; and a top permanent magnet is correspondingly arranged above each sliding permanent magnet. When the magnetomotive device is used, the repulsive force exists between the sliding permanent magnets and the back permanent magnets to facilitate the sliding permanent magnets to drive the crankshaft to rotate in an accelerative manner through the crankshaft connecting rod. The magnetomotive device disclosed by the invention has the advantages of sufficient magnetomotive power, large output power, uniform and coherent power output and high stability.

Owner:SUIZHOU SHUANGYI LONGJI MACHINERY TECH

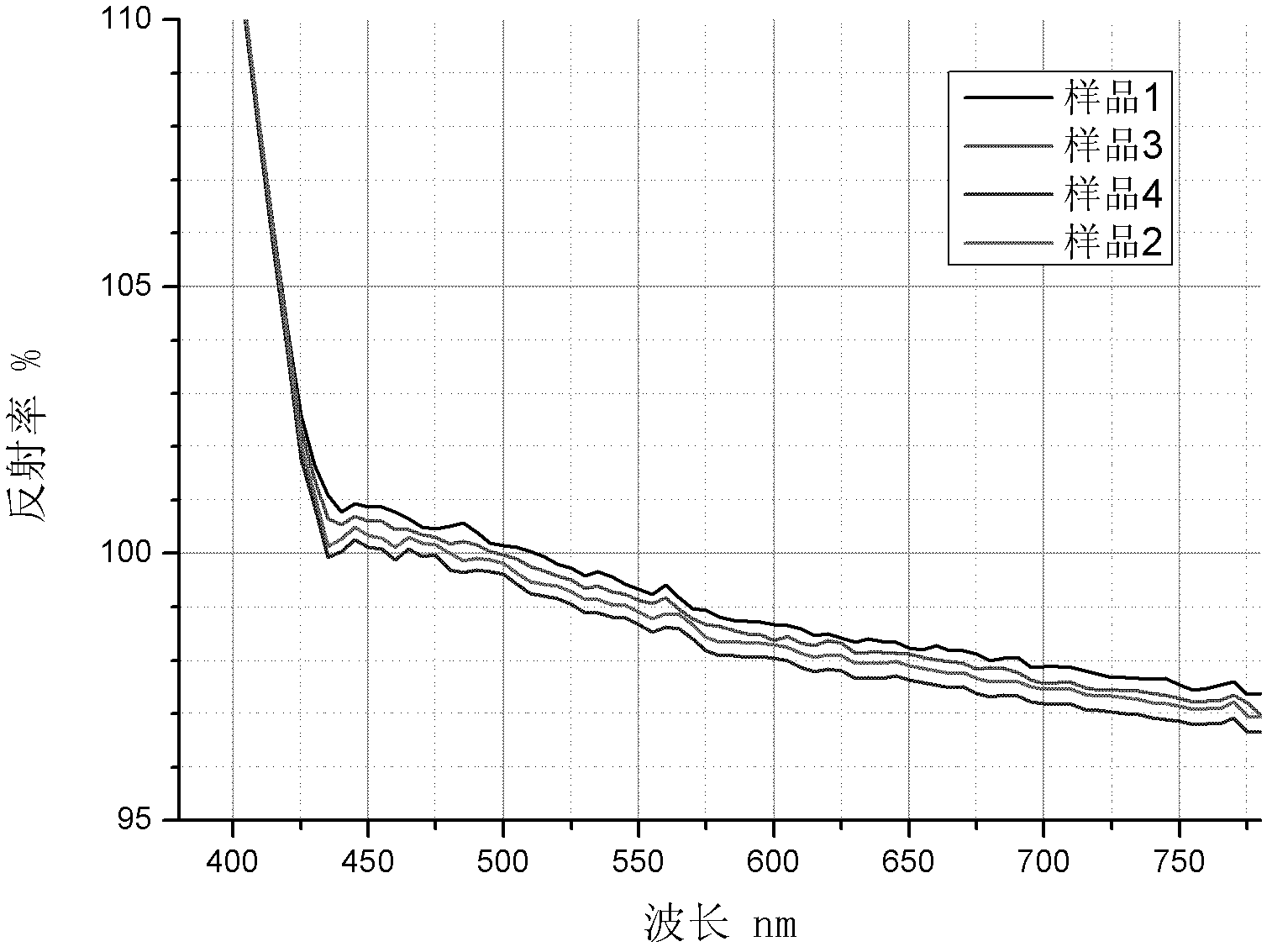

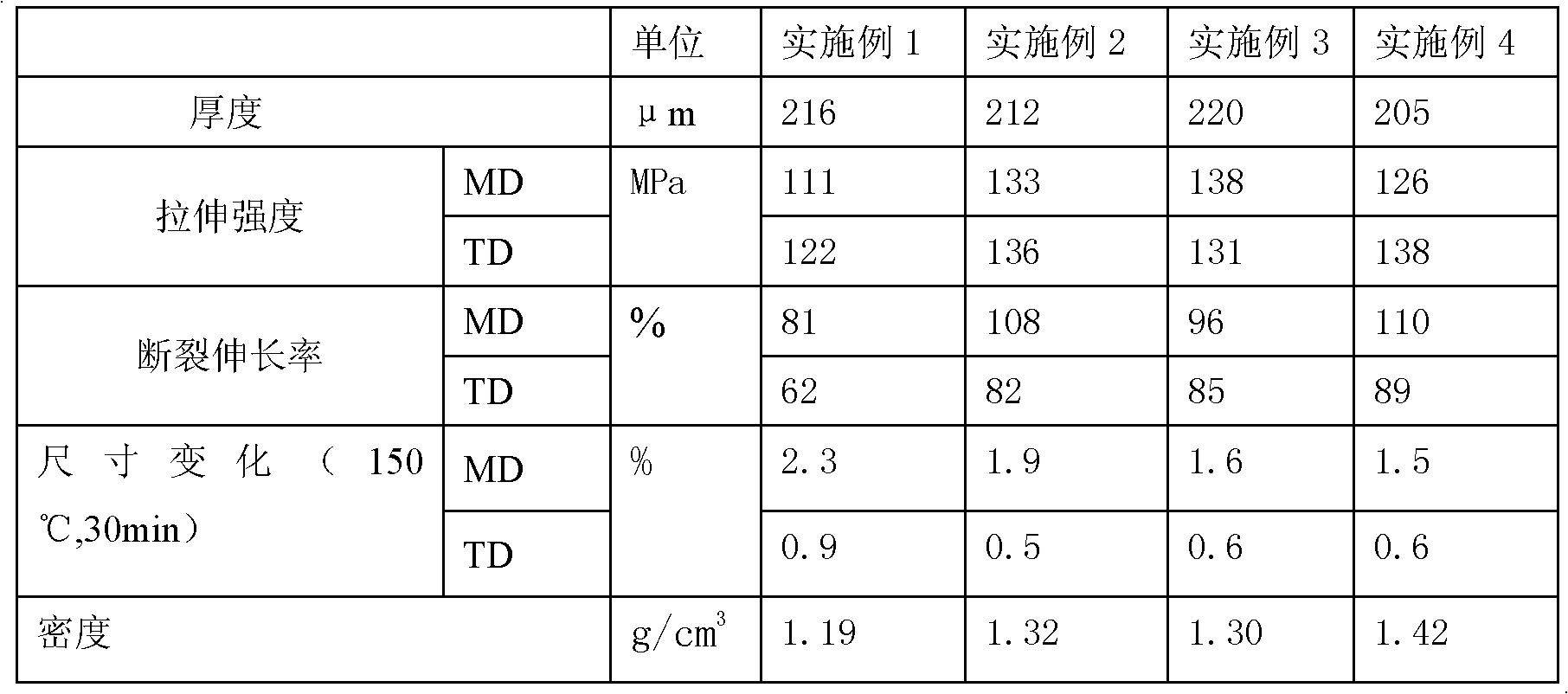

Method for preparing reflective film with light diffusion effect on surface

ActiveCN102848587AImprove reflectivityMeet mechanical strength requirementsPretreated surfacesFlat articlesManufacturing cost reductionPolyester

The invention relates to a method for preparing reflective film with light diffusion effect on surface. The method includes sending polyester chip subjected to fluidization treatment to drying tower for drying, sending the polyester chip to T-shaped die head via a fuse pipe, a rough filter, a metering pump and a fine filter to extrude slab, subjecting the prepared slab to longitudinal stretching to form polyester film, uniformly coating adhesive containing light diffusion agent on both surfaces of the polyester film, performing lateral stretching, then performing thermoforming, drying and curing the coating layer, wind-cooling, and rolling to obtain the reflective film. The invention can reduce manufacture cost, and the prepared reflective film has better mechanical strength and higher reflectivity.

Owner:JIANGSU YUXING FILM TECH

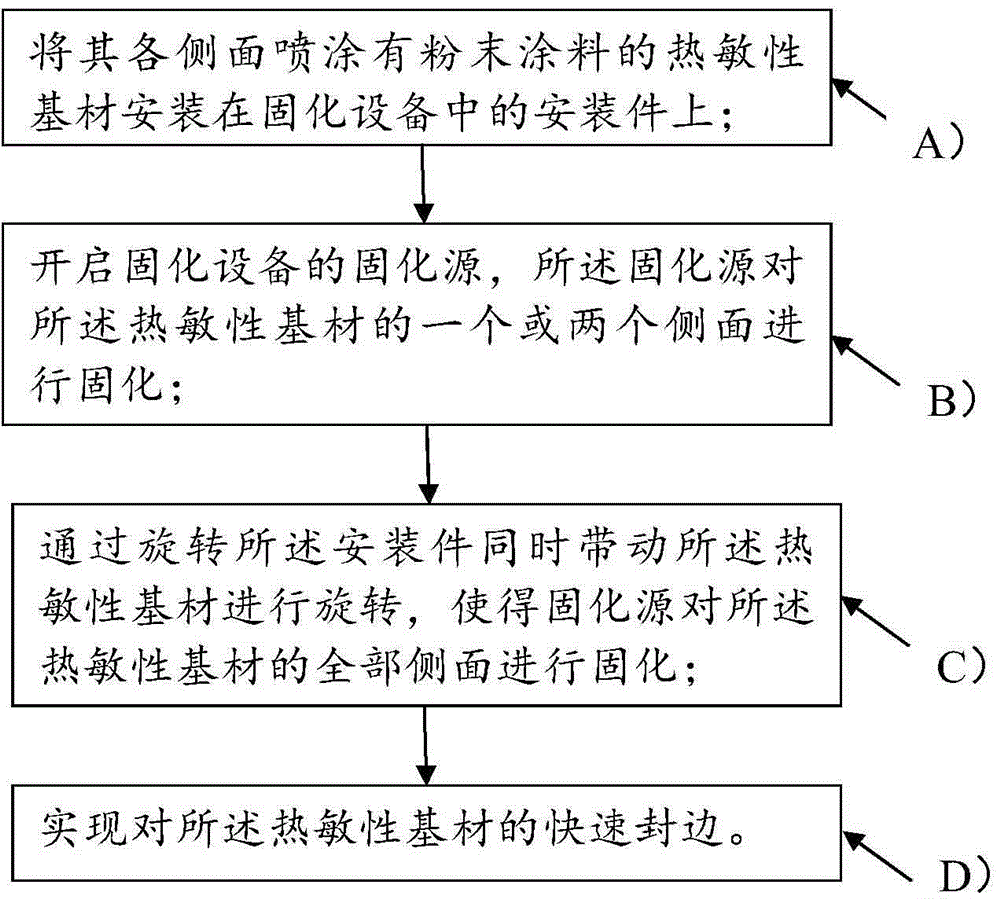

Method for solidifying edge seals of thermally sensitive base material

InactiveCN103817058AImprove edge banding efficiencySuitable for large-scale industrial applicationsPretreated surfacesPowdery paintsEngineeringMoisture

The invention relates to a method for solidifying edge seals of a thermally sensitive base material. The method includes: A) mounting the thermally sensitive base material with powder coating sprayed on every lateral side on a mounting piece of solidifying equipment; B) turning on the solidifying equipment so that a solidifying source can solidify one or two lateral sides of the thermally sensitive base material; C) rotating the mounting piece to drive the thermally sensitive base material to rotate so that the solidifying source can solidify all the laterals sides of the thermally sensitive base material; D) realizing quick edge sealing of the thermally sensitive base material. The method has the advantages that the problem that edge seal coating solidification may fail due to large impact in an edge seal coating solidification process since water moisture is evaporated from the interior of the thermally sensitive base material to the lateral sides of the thermally sensitive base material massively and quickly is avoided, edge sealing efficiency of the thermally sensitive base material is improved greatly, and the method is suitable for large-scale industrialized application.

Owner:TIGER DRYLAC TAICANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com