Calcium phosphate-based bone repair scaffold and preparation method thereof

A calcium phosphate-based bone and calcium phosphate bone technology, which can be used in coatings, medical science, prostheses, etc., can solve the problems of inability to manufacture bone repair scaffolds, inability to control pore size, toxic and side effects of pore-forming agents, etc. Effects on new bone formation, promotion of cell adhesion and proliferation, and enhancement of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

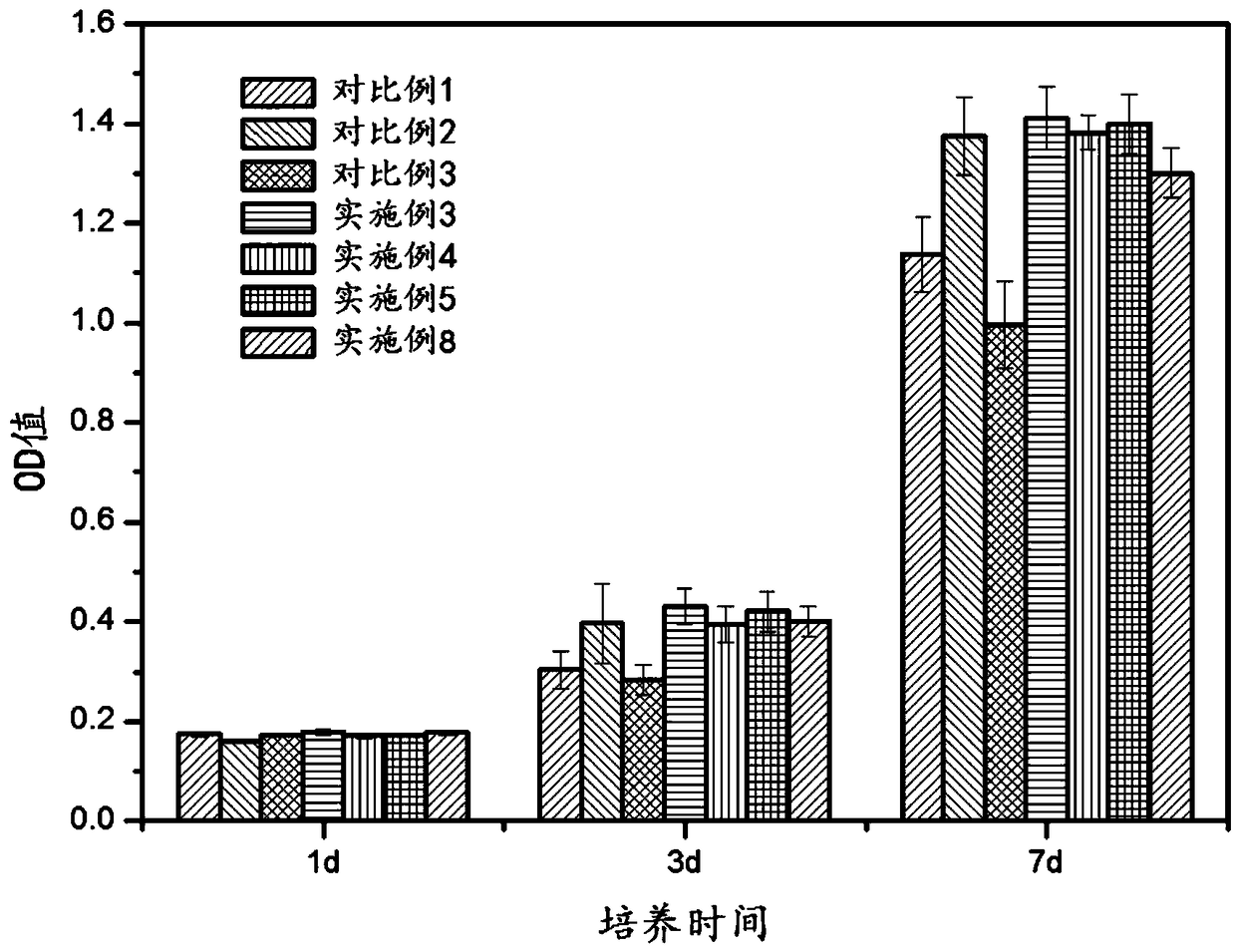

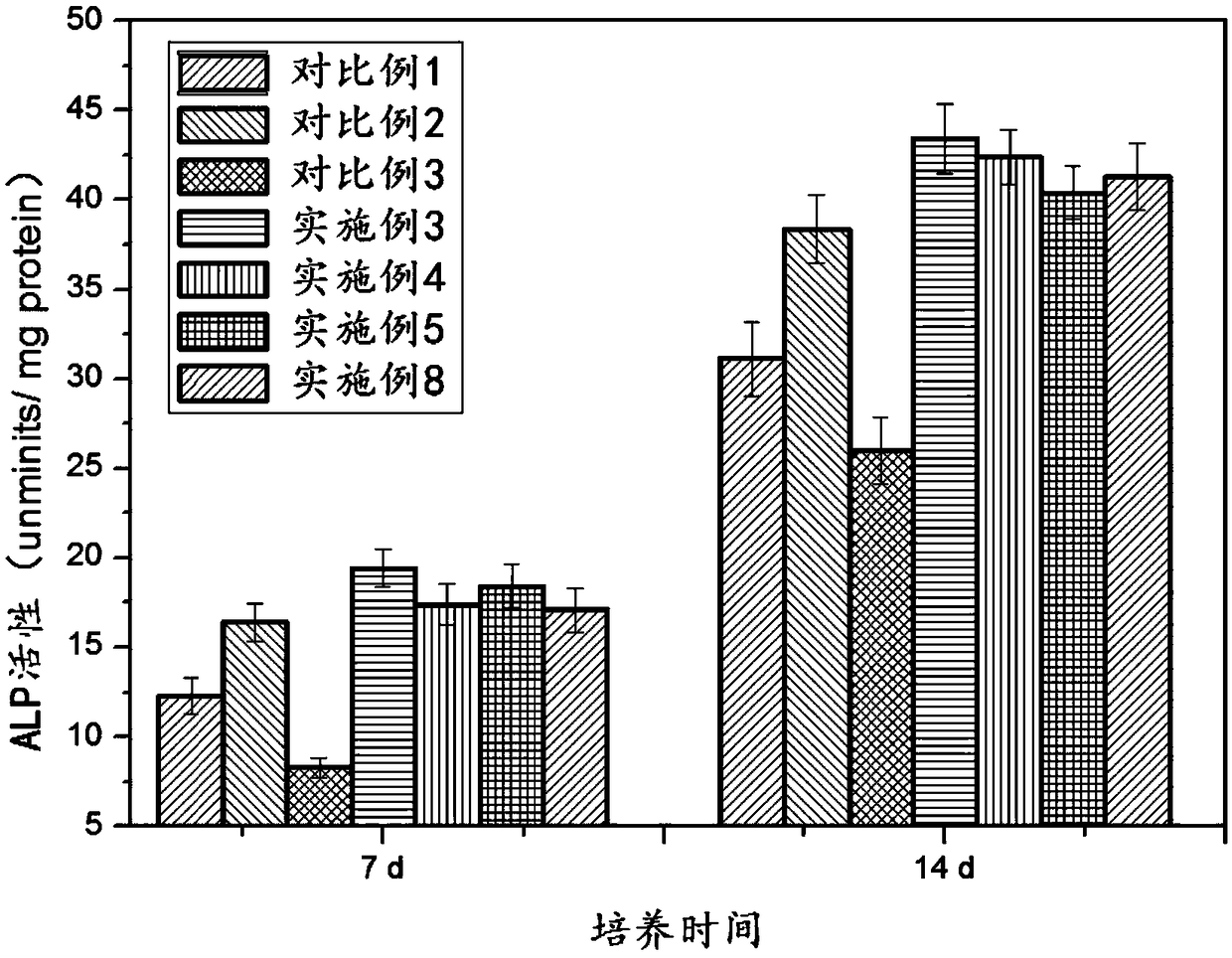

Examples

Embodiment 1

[0033] A preparation method of a calcium phosphate-based bone repair scaffold, characterized in that it comprises the following steps:

[0034] (1) The calcium phosphate bone cement solid phase powder is mixed with the solidified liquid, the solid phase ratio of the calcium phosphate bone cement solid phase powder and the solidified liquid is 1g:0.45mL, and the calcium phosphate bone cement slurry is obtained after stirring evenly, wherein, the The solid phase powder includes polyethylene glycol, α-tricalcium phosphate, strontium-doped octacalcium phosphate and / or strontium-doped amorphous calcium phosphate; in the solid phase powder, the molar ratio of strontium to calcium is: strontium: calcium = 0.1:1; the molar ratio of the sum of calcium and strontium to phosphorus is: calcium+strontium:phosphorus=1.1:1; the mass fraction of polyethylene glycol in the solid phase powder is 0.5%;

[0035] Hydroxypropyl methylcellulose and carboxymethyl chitosan are dissolved in the citric ...

Embodiment 2

[0044] A preparation method of a calcium phosphate-based bone repair scaffold, characterized in that it comprises the following steps:

[0045] (1) The calcium phosphate bone cement solid phase powder is mixed with the solidified liquid, the solid phase ratio of the calcium phosphate bone cement solid phase powder and the solidified liquid is 1g:0.45mL, and the calcium phosphate bone cement slurry is obtained after stirring evenly, wherein, the The solid phase powder includes polyethylene glycol, α-tricalcium phosphate, strontium-doped octacalcium phosphate and / or strontium-doped amorphous calcium phosphate; in the solid phase powder, the molar ratio of strontium to calcium is: strontium: calcium = 0.7:1; the molar ratio of the sum of calcium and strontium to phosphorus is: calcium+strontium:phosphorus=1.3:1; the mass fraction of polyethylene glycol in the solid phase powder is 0.6%;

[0046] Hydroxypropyl methylcellulose and carboxymethyl chitosan are dissolved in the citric ...

Embodiment 3

[0055] A preparation method of a calcium phosphate-based bone repair scaffold, characterized in that it comprises the following steps:

[0056] (1) The calcium phosphate bone cement solid phase powder is mixed with the solidification liquid, the solid phase ratio of the calcium phosphate bone cement solid phase powder and the solid phase liquid is 1g:0.5mL, and the calcium phosphate bone cement slurry is obtained after stirring evenly, wherein, the The solid phase powder includes polyethylene glycol, α-tricalcium phosphate, strontium-doped octacalcium phosphate and / or strontium-doped amorphous calcium phosphate; in the solid phase powder, the molar ratio of strontium to calcium is: strontium: calcium = 0.7:1; the molar ratio of the sum of calcium and strontium to phosphorus is: calcium+strontium:phosphorus=1.3:1; the mass fraction of polyethylene glycol in the solid phase powder is 0.7%;

[0057] Hydroxypropyl methylcellulose and carboxymethyl chitosan are dissolved in the cit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com