High-power-density and high-efficiency permanent magnet synchronous motor for electric aircraft

A high power density, permanent magnet synchronous technology, applied in synchronous motors with stationary armatures and rotating magnets, electric components, magnetic circuits featuring magnetic materials, etc. , Affect the performance of the electric aircraft drive motor, restrict the efficiency of the motor, etc., to meet the requirements of mechanical strength, reduce mechanical strength, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A specific embodiment of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

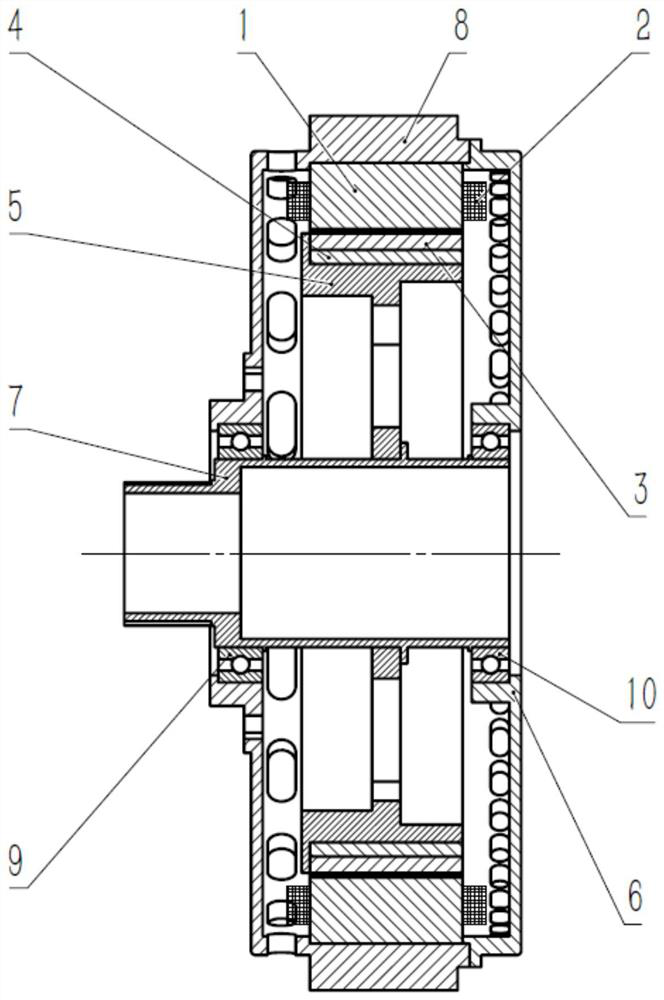

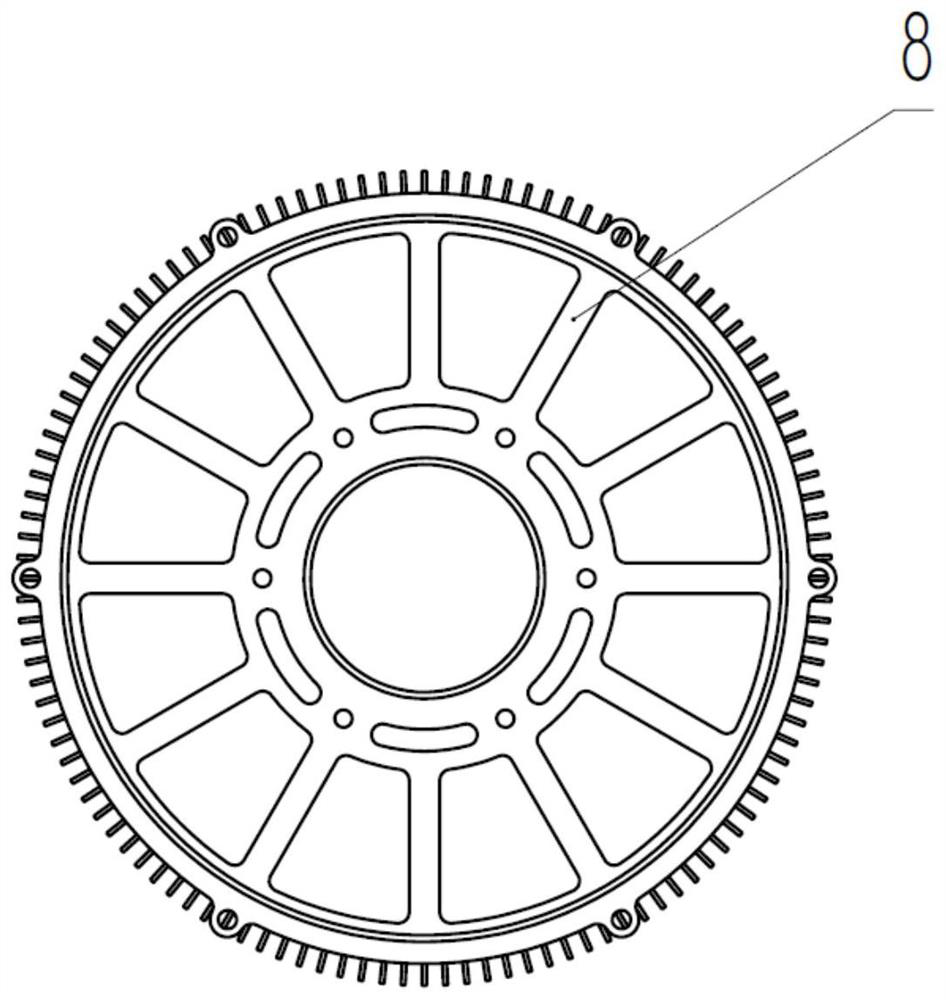

[0039] Specific embodiment 1 of the technical solution of the present invention provides a permanent magnet synchronous motor with high efficiency and high power density for electric aircraft, such as figure 2 As shown, it includes: stator core 1, stator winding 2, permanent magnet 3, rotor core 4, rotor bracket 5, rotating shaft 7, front bearing 9, rear bearing 10, casing 8 and rear end cover 6.

[0040] like figure 2 As shown, the stator part is composed of stator core 1 and stator winding 2. The stator core 1 is made of high magnetic saturation ultra-thin silicon steel sheet 10JNEX900; the stator winding 2 is made of high temperature resistant enameled wire QY-2 / 220, and the winding is wound in a centralized double-layer winding method.

[0041] like figure 2 As shown, the rotor part is composed of a permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com