Modular design method of novel steel structure

A modular design and steel structure technology, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as installation requiring professional construction personnel, limiting the promotion and application of steel structures, and increasing construction costs, so as to reduce material costs, Effects of saving cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

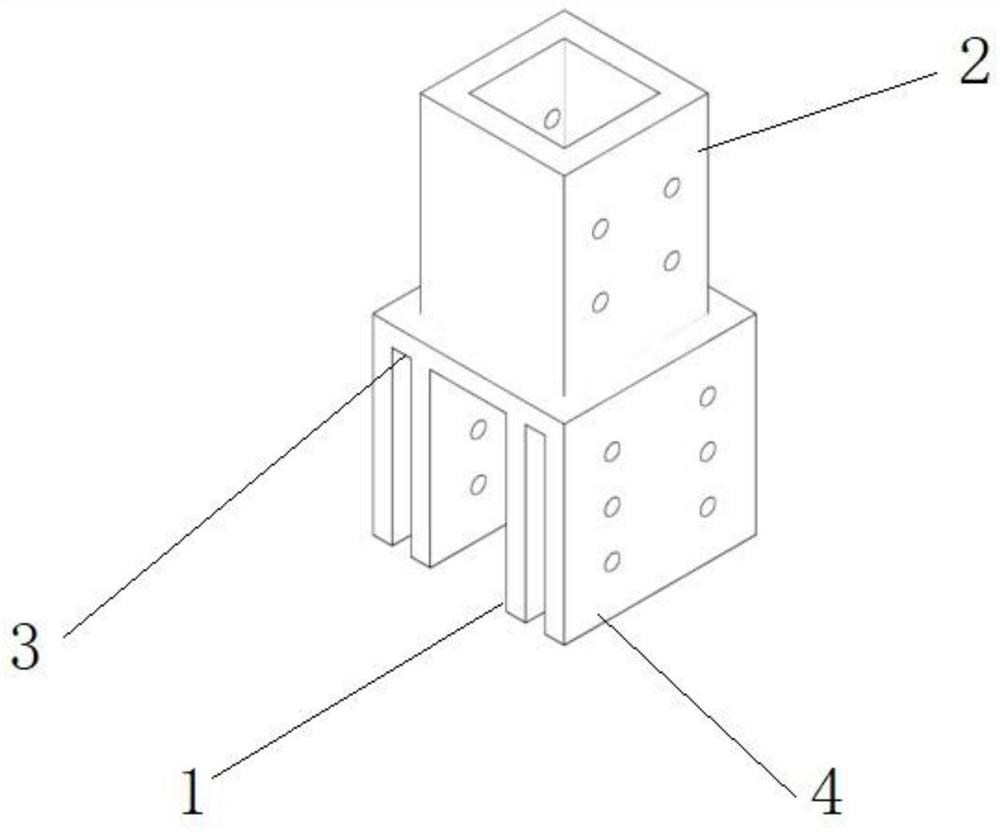

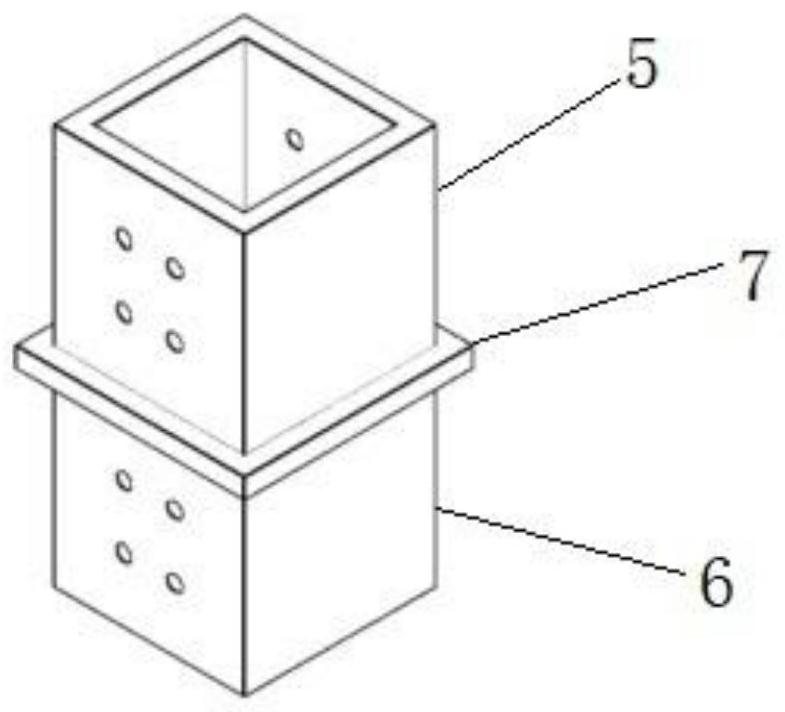

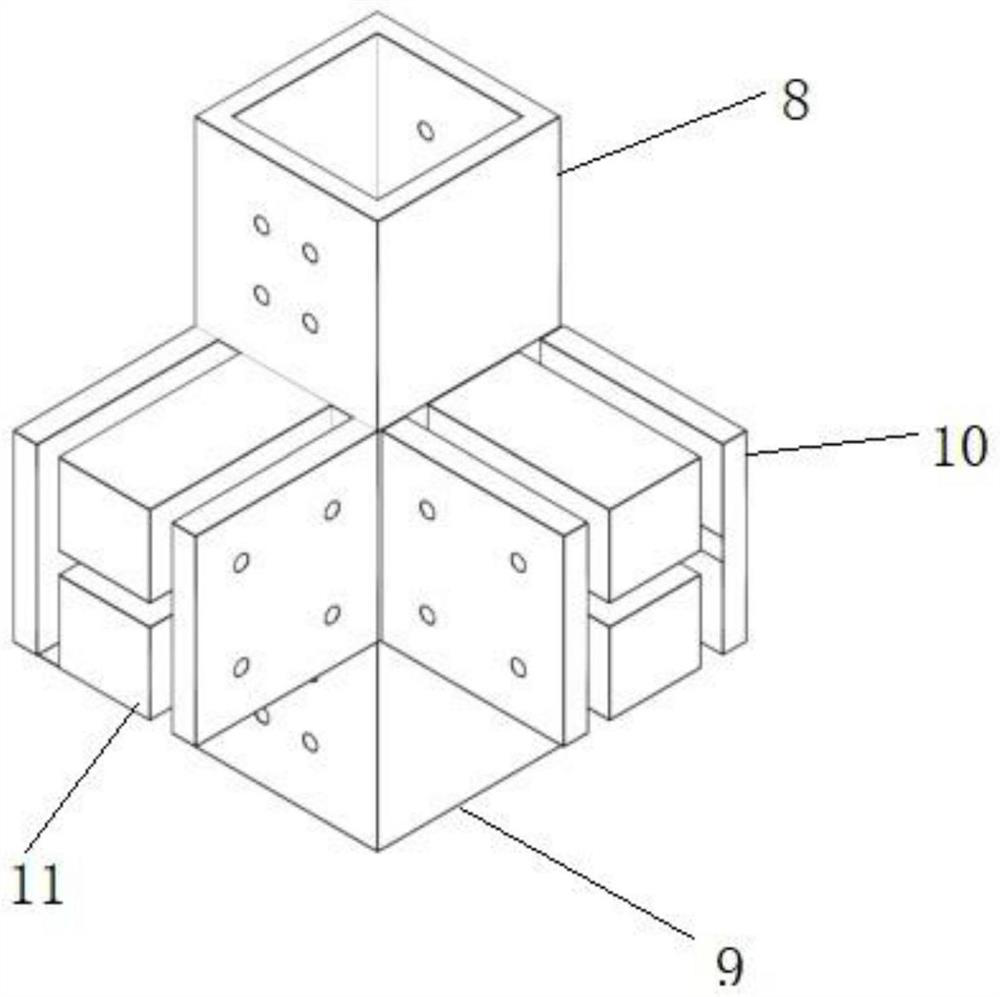

[0074] A modular design method for a novel steel structure, comprising the following steps:

[0075] 1) Establish a steel structure frame model according to the customer's architectural style requirements and building code requirements, create walls, floors and roof slabs 32 according to the customer's requirements for wall materials, floor materials and roof materials, and apply finite elements The analysis software analyzes the force status of the components and connectors of the steel structure frame after the walls and floors are created;

[0076] 2) According to the steel structure frame model in step 1), the computer software automatically calculates and outputs the installation sequence of the components and connectors of the steel structure frame, and labels the components and connectors of the steel frame structure according to the installation sequence;

[0077] 3) According to the analysis results of the stress status in step 1), select materials that meet the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com