Sensor mounting base with cooling function

A sensor and mounting seat technology, applied in the field of sensor mounting seats, can solve problems such as high temperature and excessive compensation wires, and achieve the effects of reducing surface temperature, reducing measurement accuracy out of tolerance, and reducing weight burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

[0013] The invention innovatively proposes a mounting seat with a cooling function, that is to cool the part inserted into the casing itself, so that it can maintain a certain mechanical strength at high temperature, and at the same time, the thermocouple compensation wire part above it is cooled. cool down.

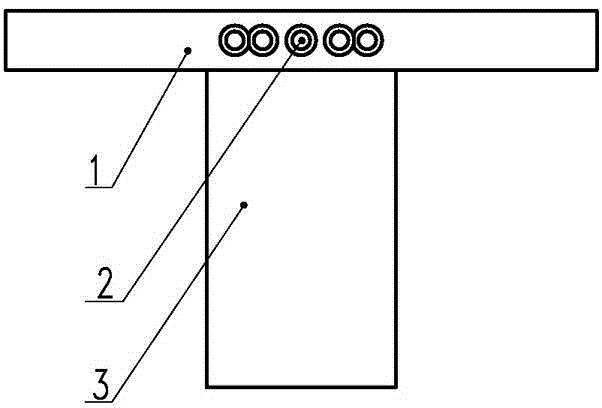

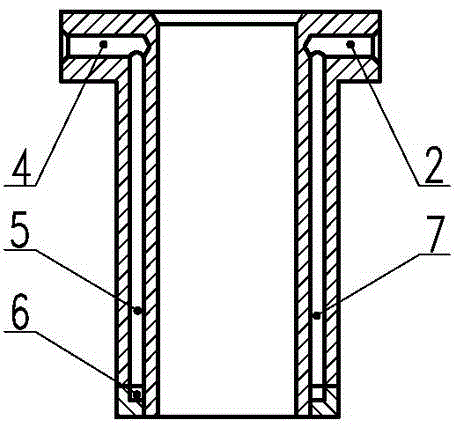

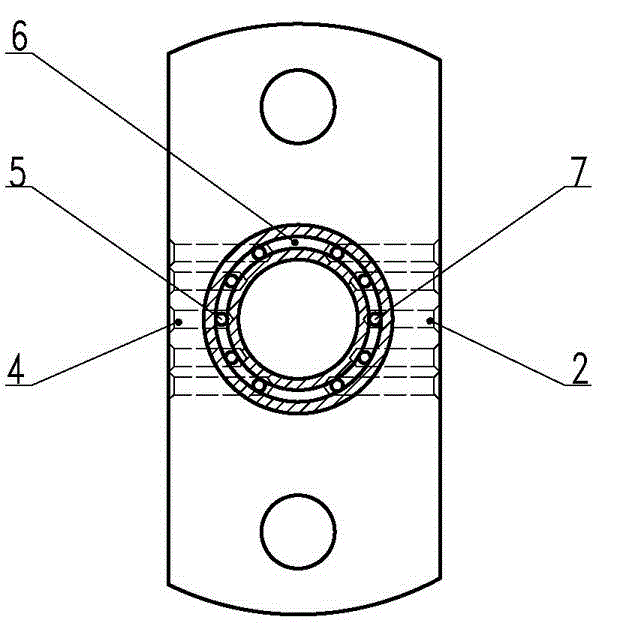

[0014] Such as Figure 1 to Figure 3 The sensor mounting seat with cooling function shown in the present invention is generally viewed as follows: a platform 1 made of nickel-based superalloy, a cylindrical boss 3 and a sealing ring (not marked) are integrally assembled and welded together coaxially, wherein the cylindrical The boss 3 is hollow (for assembling sensor structures such as therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com