Reliability design optimization method for avionic device

A technology of avionics equipment and optimization methods, which is applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problem that design methods and control methods are difficult to guarantee, reliability indicators cannot be met, and reliability optimization cannot be completed in the design stage. Complete and other issues to achieve the effect of reducing the probability of modifying the physical prototype, shortening the development cycle, and improving reliability indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

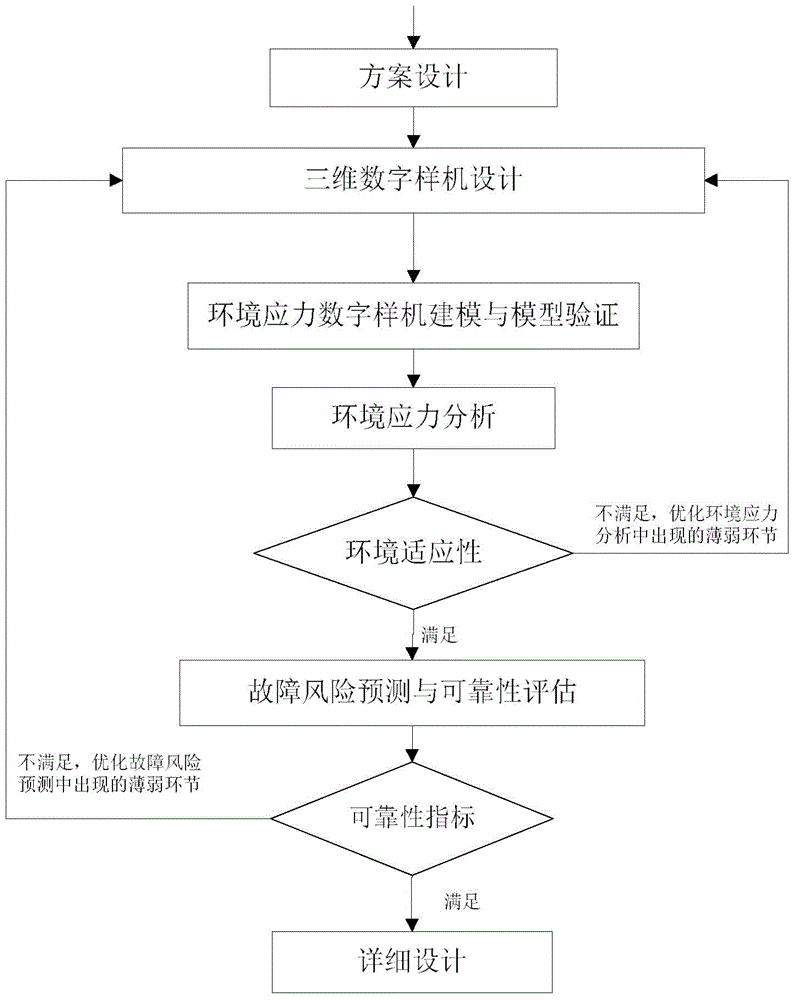

[0012] refer to figure 1 . In the following embodiments, the realization of design optimization for improving reliability of avionics equipment is realized by integrating reliability analysis and optimization into performance design. In the design stage, 3D digital prototype modeling is carried out according to the design plan of avionics equipment; based on the 3D digital prototype, according to the temperature, temperature cycle, vibration, impact environmental load, power consumption, current, voltage and frequency in the equipment life cycle Carry out environmental stress digital prototype modeling and model verification of thermal characteristics and mechanical characteristics; refer to the environmental adaptability requirements of avionics equipment, and carry out Environmental stress analysis of equipment thermal characteristics, mechanics, etc., locating the weak link of environmental stress of the equipment, comparing and according to the design criteria stipulated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com