Concrete delivery tube and preparation method thereof

A technology for a concrete conveying pipe and an outer pipe, which is applied in the field of concrete conveying pipe and its preparation, can solve the problems of large flow channel resistance, easy to cause pipe blockage, changes in chemical composition and performance of surfacing alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] According to the present invention, when preparing the delivery tube, various methods can be used for preparation, wherein, the first embodiment of the delivery tube preparation method provided by the present invention includes:

[0039] provide an inner tube;

[0040] A first part of the outer tube and a second part of the outer tube are provided, and the first part of the outer tube and the second part of the outer tube are attached to the outside of the inner tube and connected to obtain an outer tube compounded on the outside of the inner tube.

[0041] Wherein, when connecting the first part of the outer tube and the second part of the outer tube, welding is preferably adopted. As for the components of the outer tube, it may include a plurality of outer tube parts whose cross-sections are arc-shaped, and the cross-sections of the plurality of outer tube parts enclose a circle as the outer tube. According to the present invention, after the multiple components of t...

Embodiment 1

[0048] Wear-resistant cast iron is selected as the inner tube material, and the inner tube is obtained by one-time casting. The composition of the inner tube is calculated by weight percentage: 3.1% of C, 1.2% of Si, 1.9% of Mn, 0.035% of S, 0.036 of P, 2.8% Mo, 1.9% Cu, 2.4% Ni, and the balance is Fe.

[0049] Low-alloy steel is selected as the outer tube material, and its composition is calculated by weight percentage: 0.375% C, 0.35% Si, 0.65% Mn, 0.9% Cr, 0.035% S, 0.036 P, and the balance is Fe .

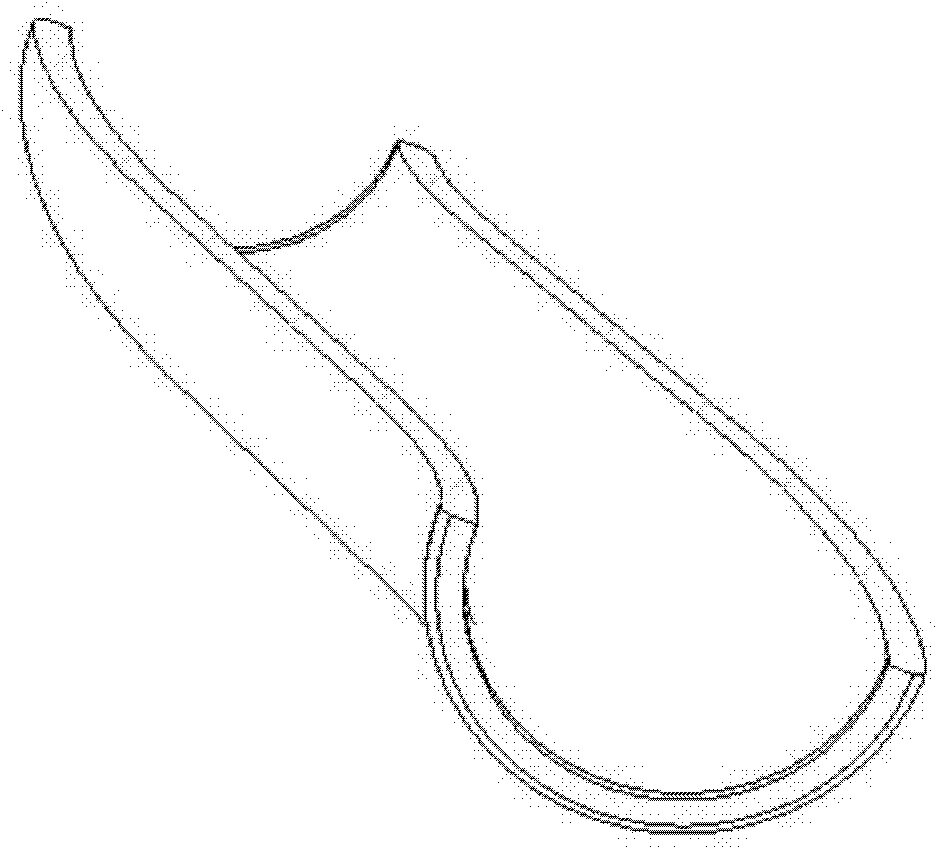

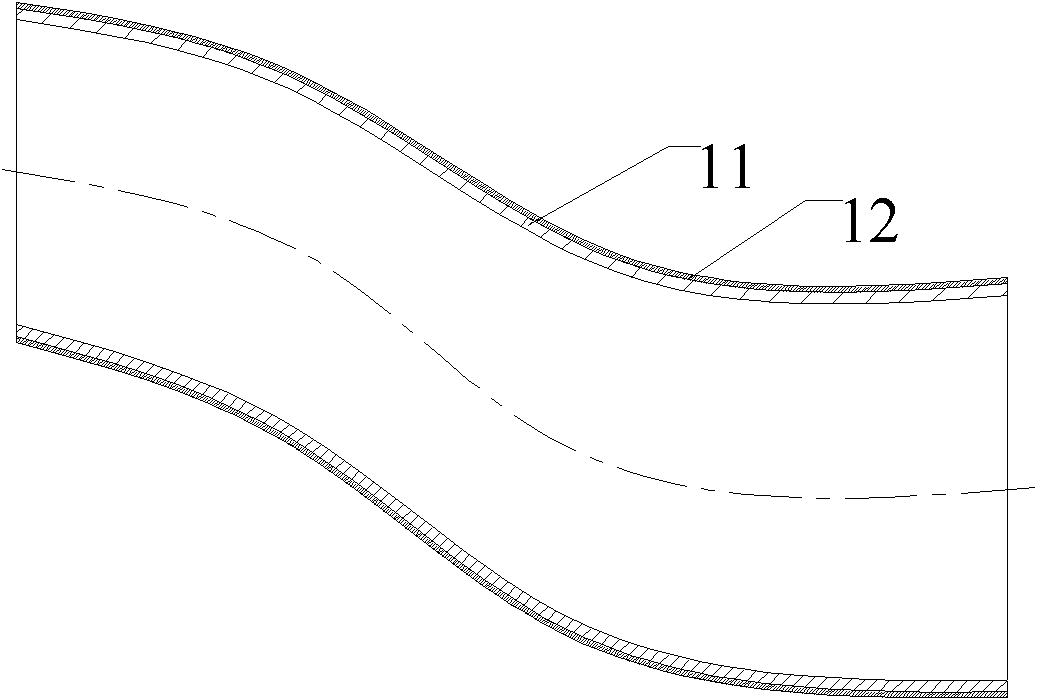

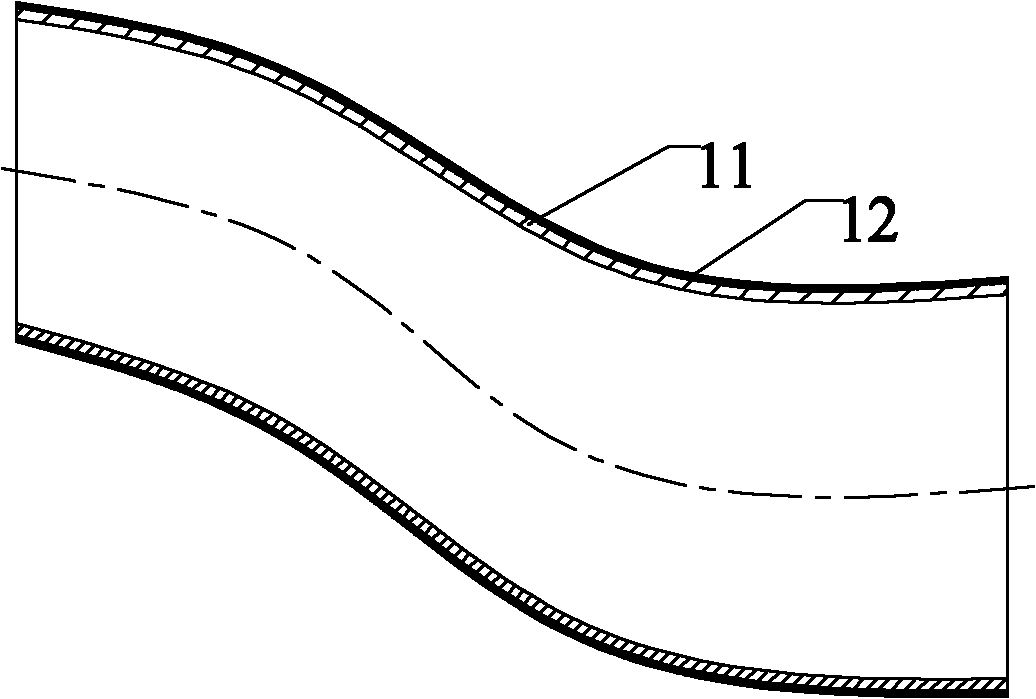

[0050] The half-pipes of the two outer tubes are prepared by molding, such as figure 1 Shown is a schematic diagram of one of the half-pipes. Then the two half-pipes are clad on the outside of the inner pipe and welded together to form a variable-section S pipe, such as figure 2 As shown, the variable-section S-tube includes an inner tube 11 and an outer tube 12 compounded outside the inner tube.

[0051] The heat treatment process is: 980℃×3h normalizing treatment. Then ...

Embodiment 2

[0054] High-speed steel is selected as the inner tube material, and its composition is: 0.98% of C, 0.30% of Si, 0.16% of Mn, 8.5% of Mo, 3.7% of Cr, 1.9% of V, 1.5% of W, 0.025% of S, 0.028% of P, and the balance is Fe. The material of the inner tube is molded out of the desired arc of the S tube by a hydraulic press to form two inner tube half-pipes, both of which have an inner diameter of 20 mm.

[0055] Carbon steel is selected as the material of the outer tube, and its composition is calculated by weight percentage: 0.5% C, 0.6% Si, 0.9% Mn, 0.035% S, 0.036 P, and the balance is Fe. The material of the outer tube is molded out of the arc required by the variable-section S tube through a hydraulic press to form two outer tube half-pipes,

[0056] The two inner tube half-pipes and the two outer tube half-pipes are welded together to form an inner tube and an outer tube surrounding the inner tube.

[0057] The heat treatment process is: quenching 1190. ℃ × 2 hours, temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com