Patents

Literature

108results about How to "Meet wear resistance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

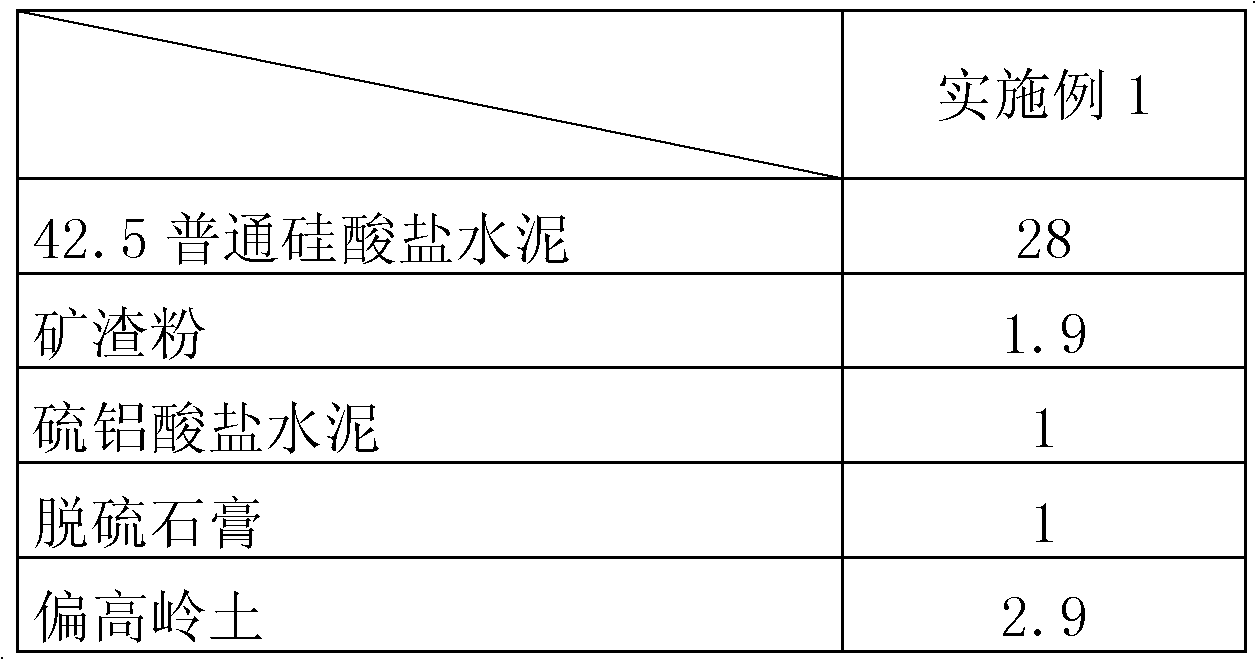

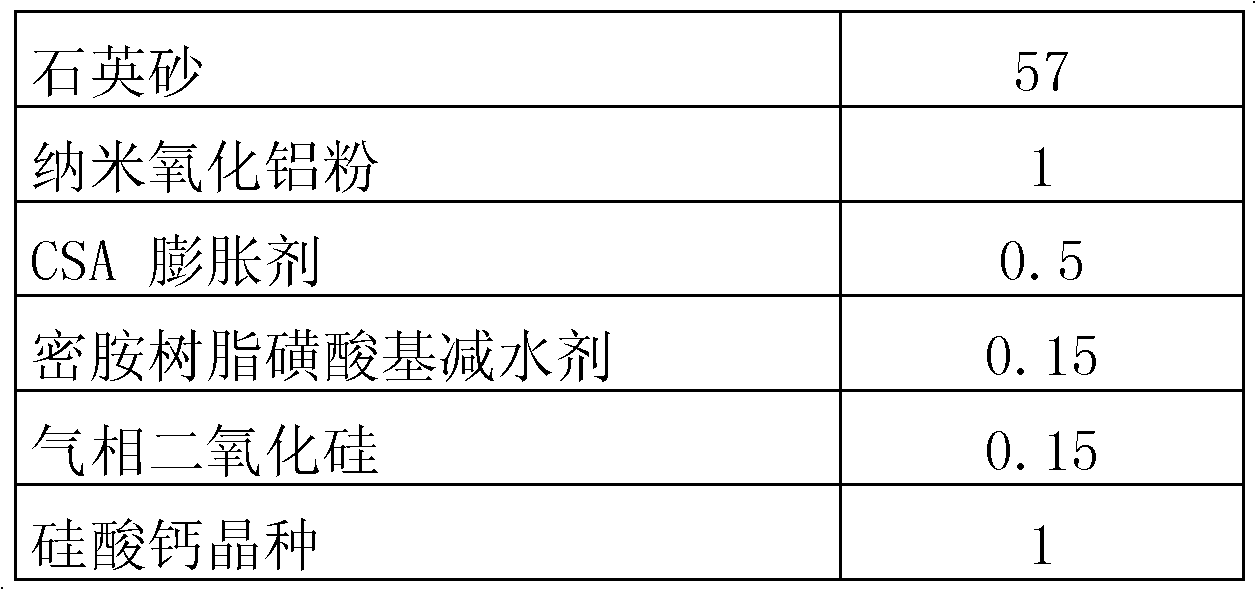

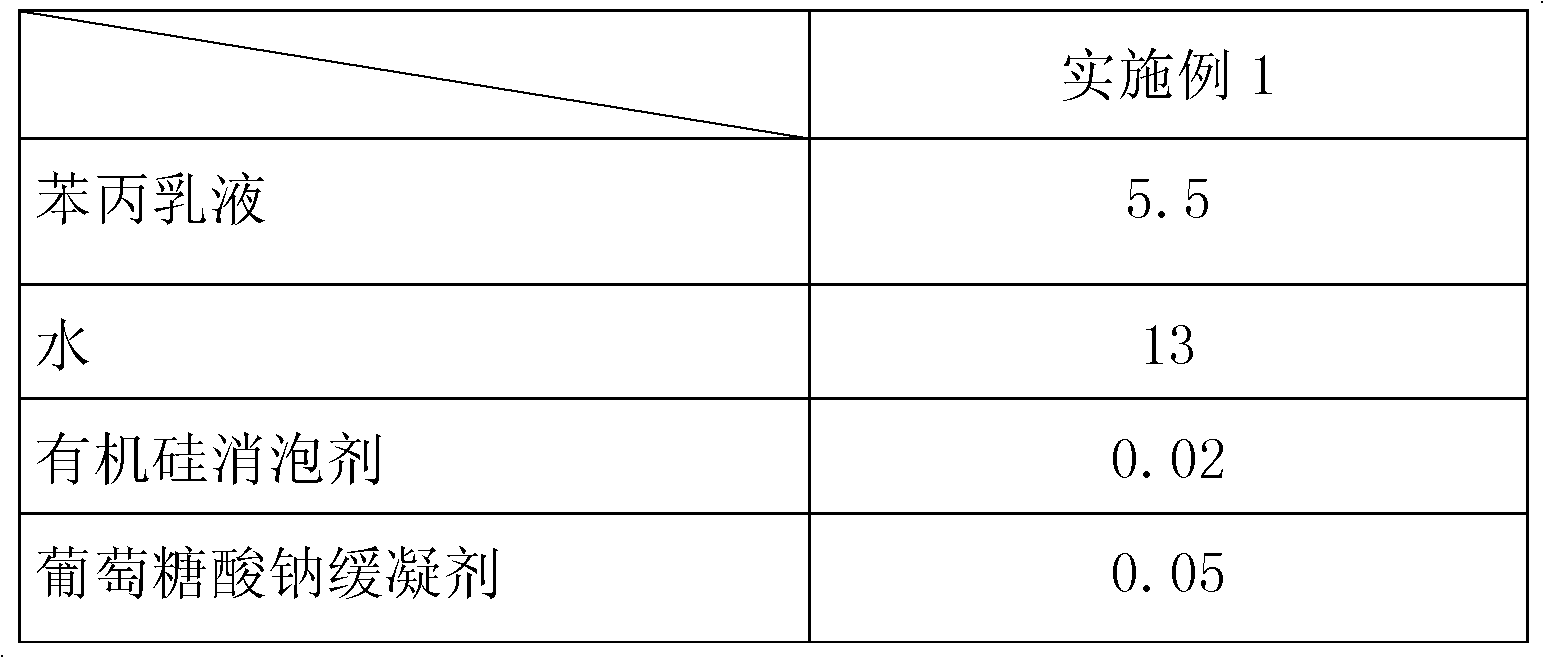

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

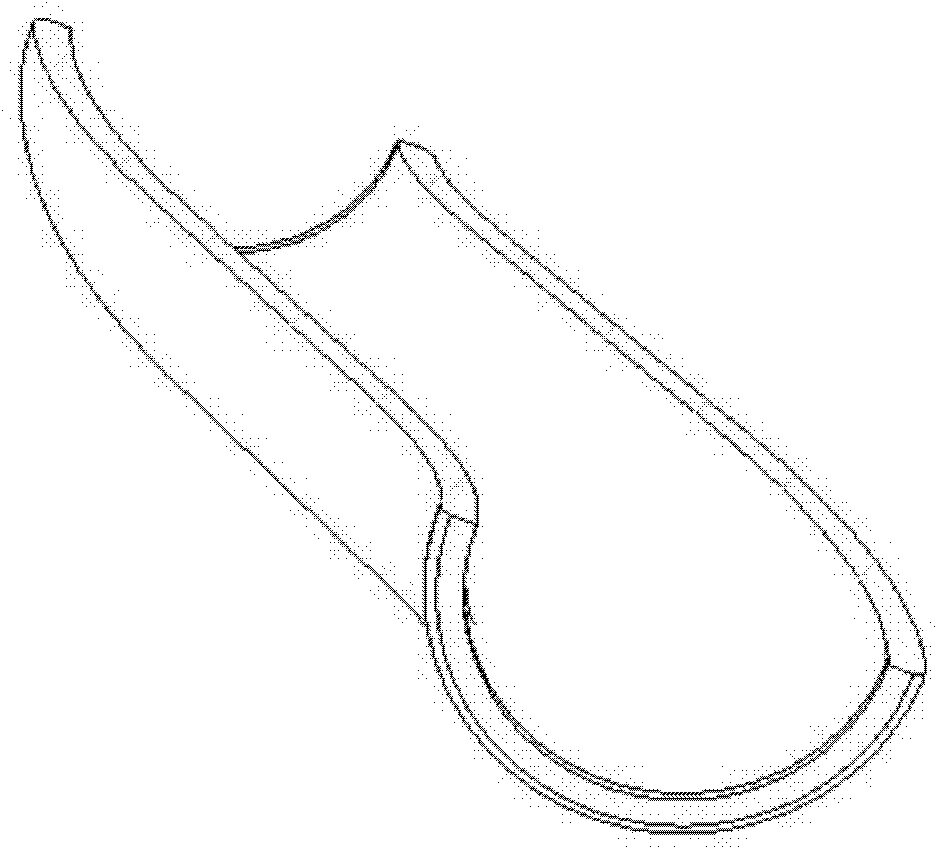

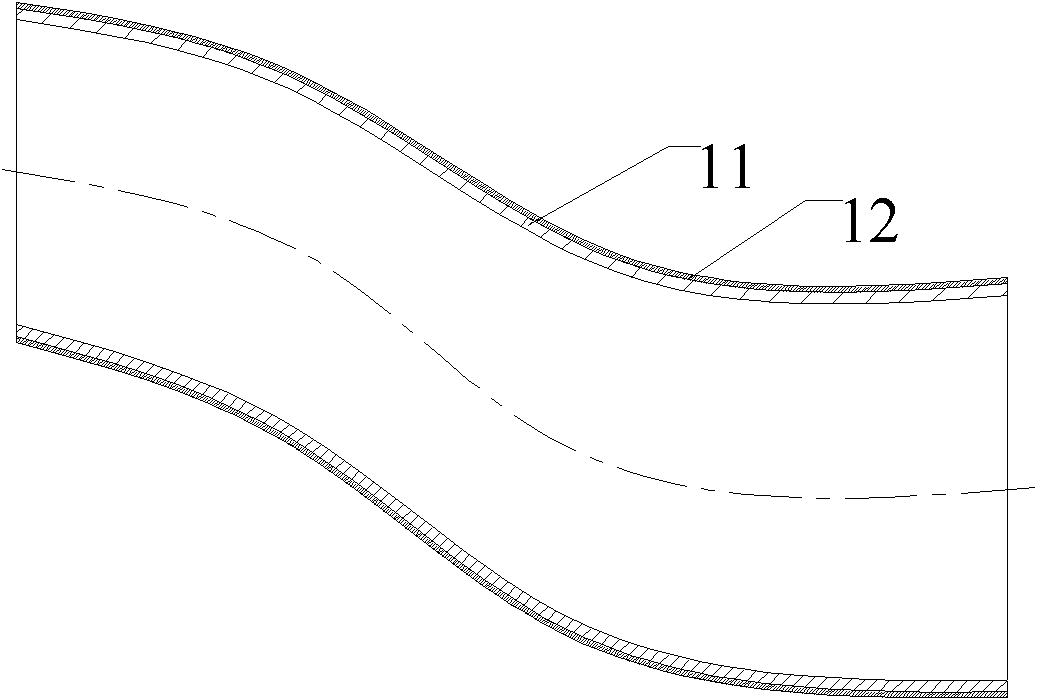

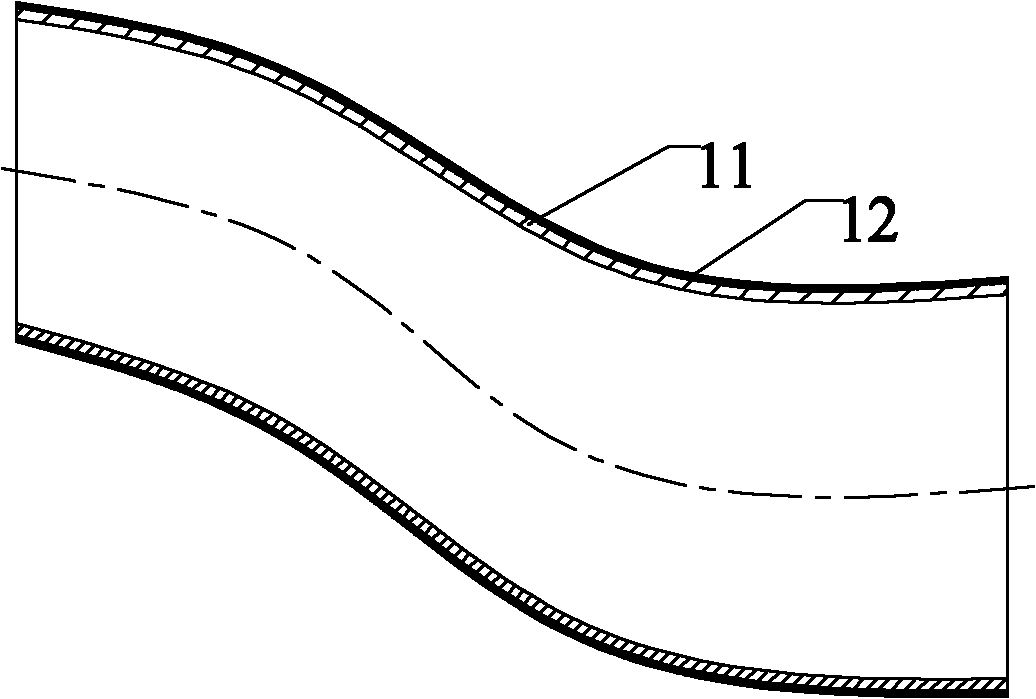

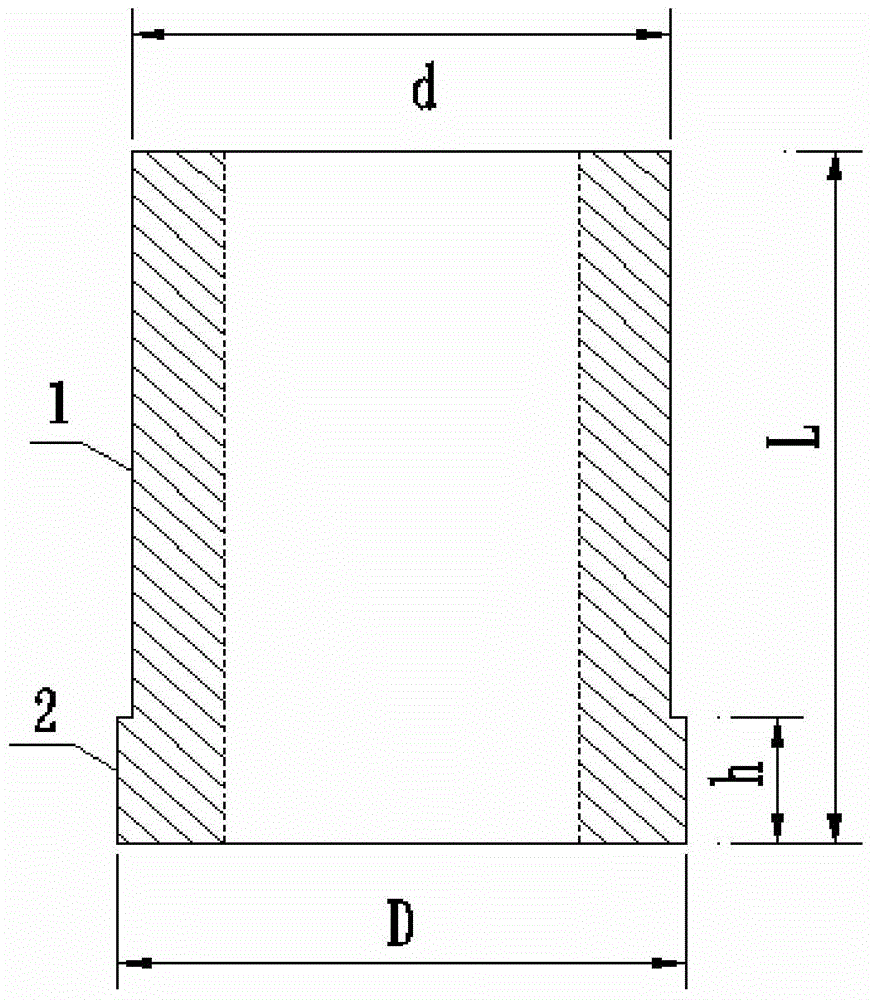

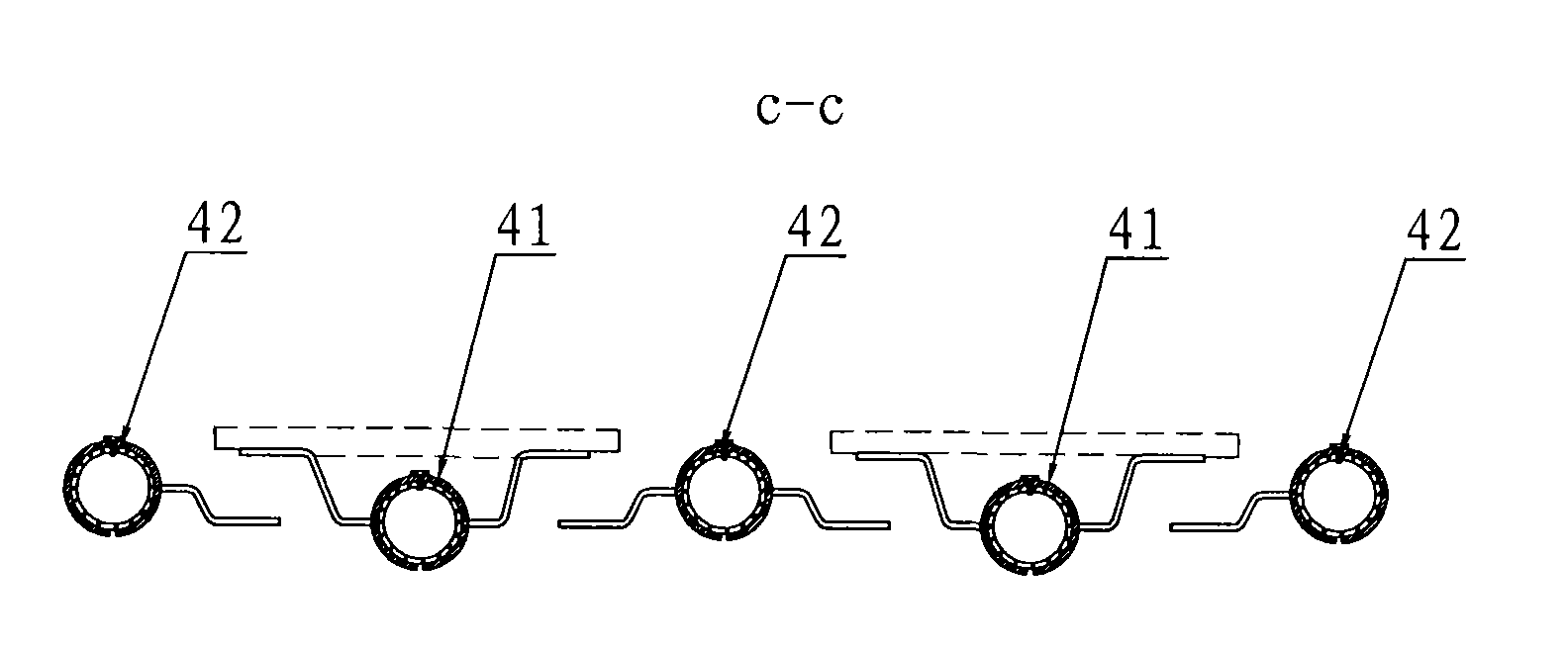

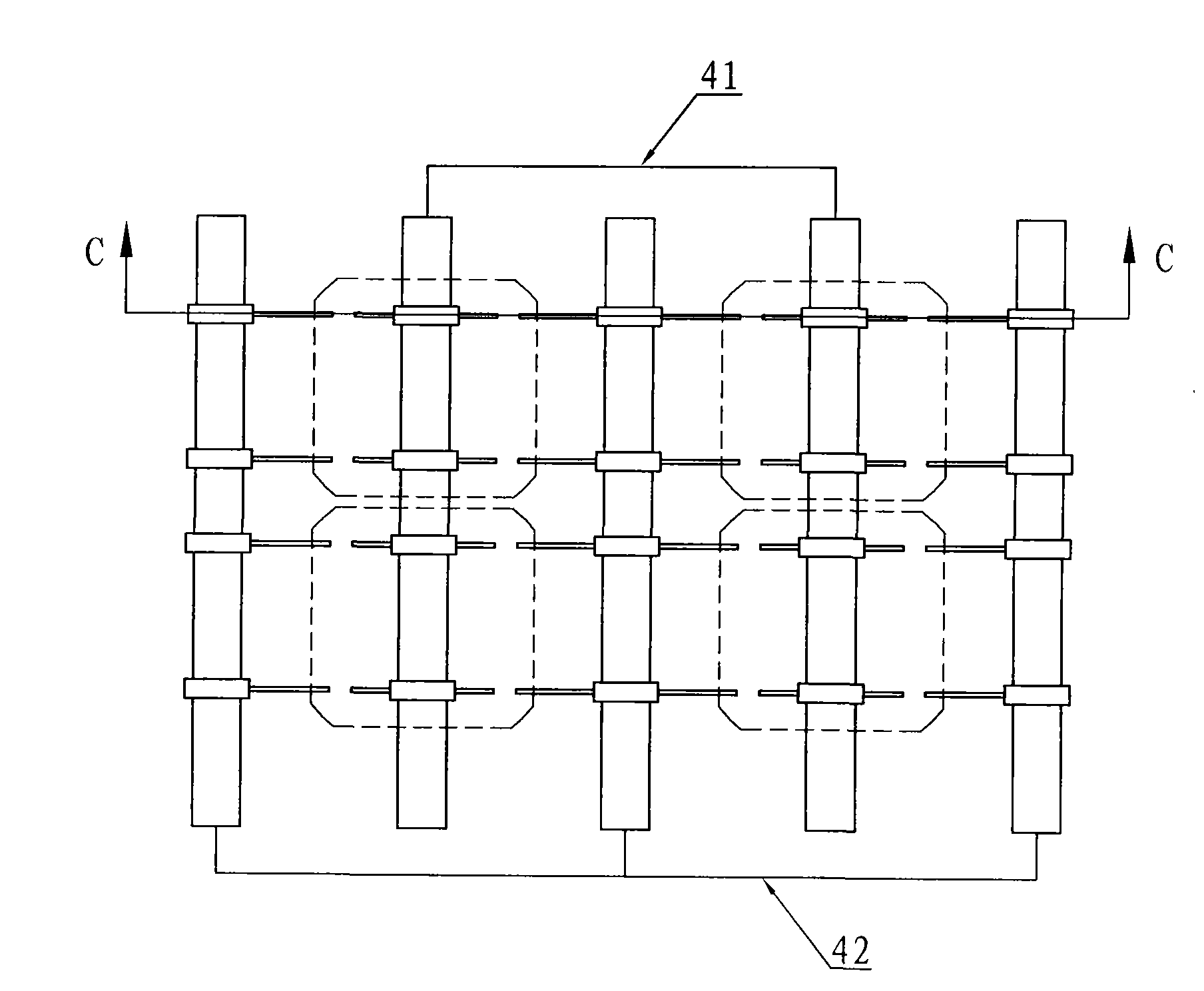

Concrete delivery tube and preparation method thereof

InactiveCN102032397AImprove wear resistanceImprove toughnessBuilding material handlingRigid pipesEngineeringHigh wear resistance

The invention provides a concrete delivery tube, which has at least two bent parts and comprises an inner tube and an outer tube compounded outside the inner tube, wherein the outer tube at least consists of an outer tube first part and an outer tube second part; the shapes of cross sections of the outer tube first part and the outer tube second tube are circular arcs; the outer tube is formed by connecting the outer tube first part and the outer tube second part; and the wear resistance of the inner tube is higher than that of the outer tube, and the roughness of the outer tube is higher than that of the inner tube. Compared with the prior art, a high-priced surfacing welding process is not required to improve the wear resistance of the inner surface of the delivery tube, and with the composite tube having the inner tube with high wear resistance and the outer tube which is compounded outside the inner tube and has high roughness, the concrete delivery tube meet the requirements on wear resistance and mechanical strength.

Owner:湖南三一中阳机械有限公司

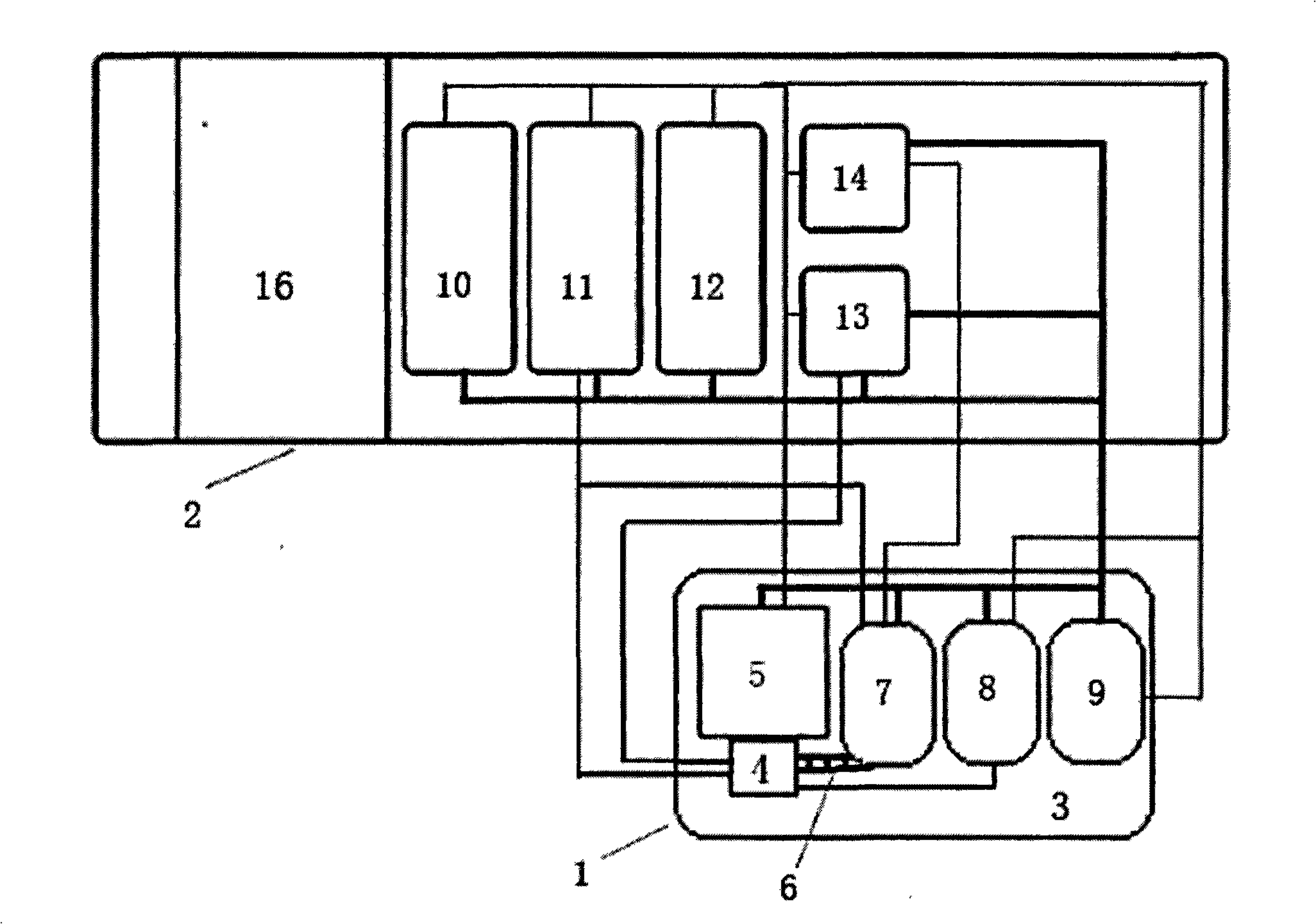

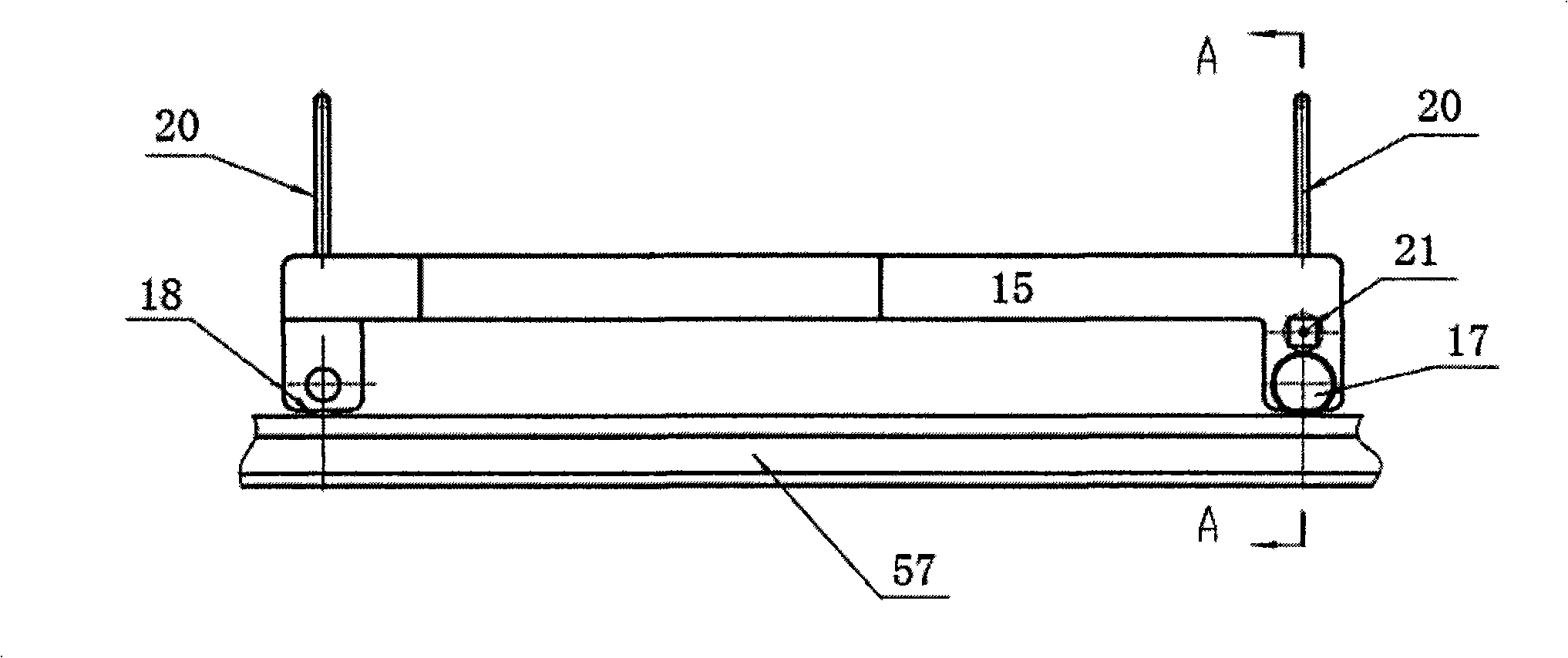

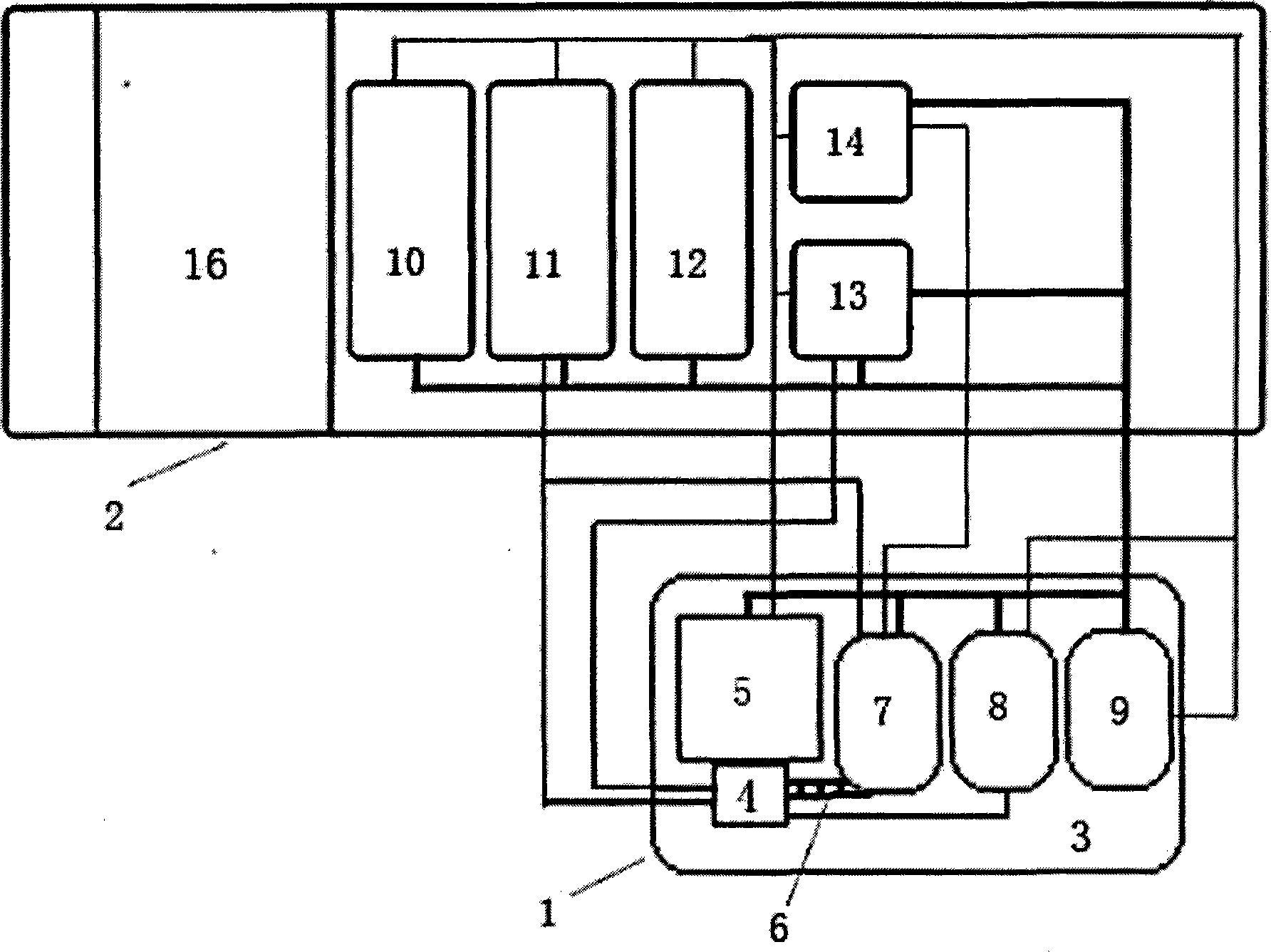

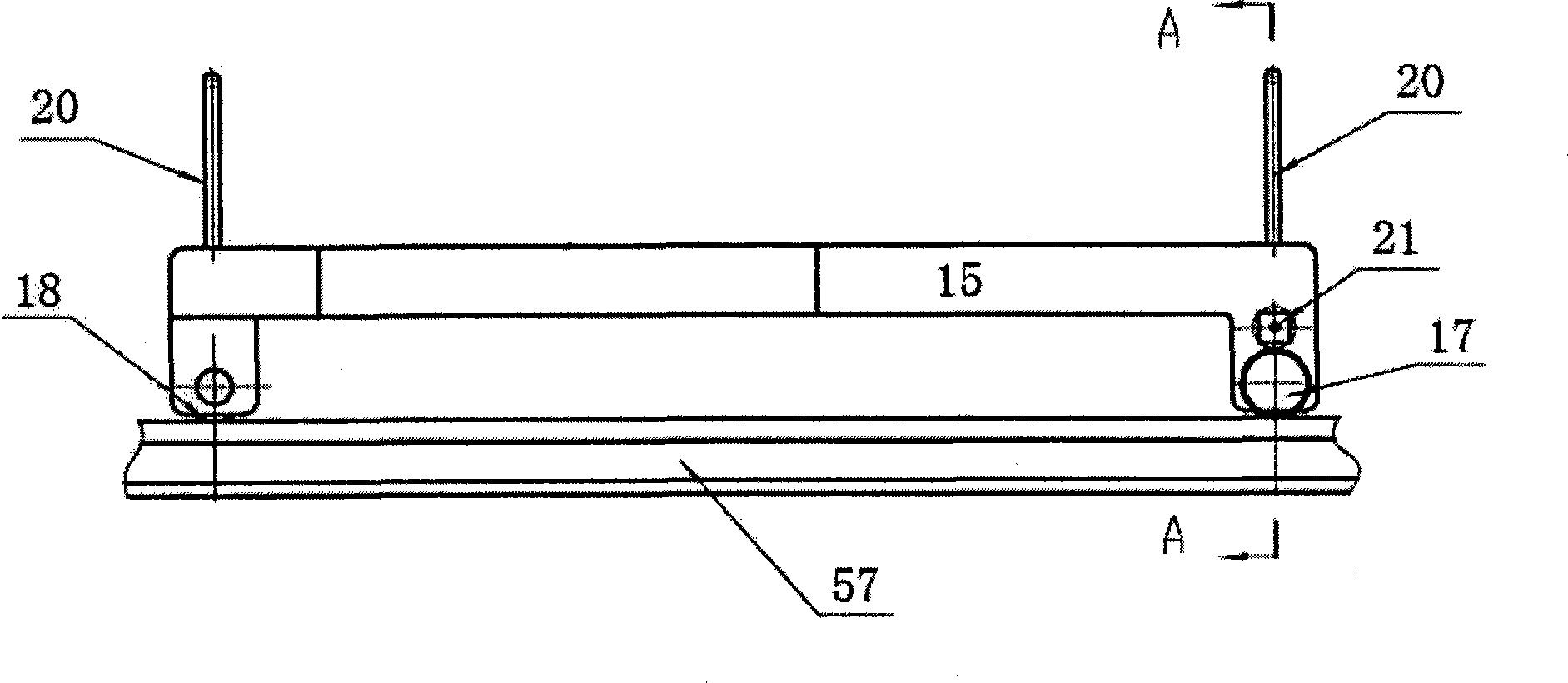

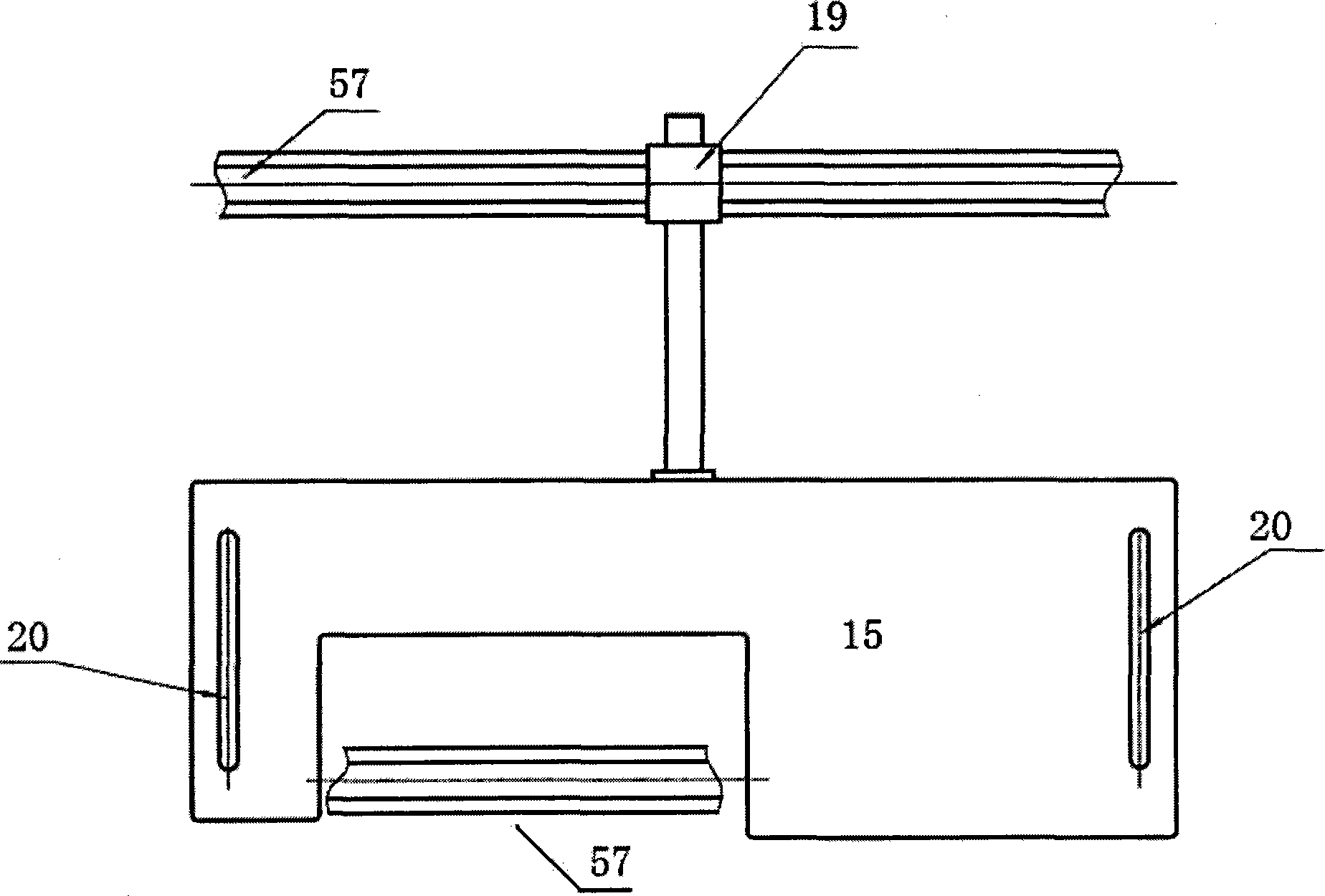

On-line laser machining apparatus for strengthening and toughening treatment of steel rail surface

ActiveCN101403030AImprove wear resistanceExtend the life cycleFurnace typesHeat treatment furnacesEngineeringHigh pressure

The invention discloses an on-line laser processing equipment used for strengthening and toughening of the surface of a steel rail, comprising a laser processing lathe and a power system container. The laser processing lathe comprises a motion actuating mechanism, a laser processing head and / or a control system and a powder feeder which are arranged on a moving cart; and the power system container comprises a power generator, a refrigerator, an air compressor, a cool drying machine and a high-voltage power supply of a laser which are arranged in the container. The laser processing head can be arranged on the motion actuating mechanism and is directly connected with the laser or connected with the laser by a light-guiding system. The invention can complete the laser surface quenching, fused quenching, alloying and cladding treatment of various steel rails which comprises a stock rail, a curve, a guide rail, a switch and the like under the premise that the steel rail is not dismounted and the normal running of trains, thus leading the wear resistance of the processed steel rail to be improved greatly and having the characteristics of simple assembly and disassembly, high processing precision and simple operation and control.

Owner:HUAZHONG UNIV OF SCI & TECH +1

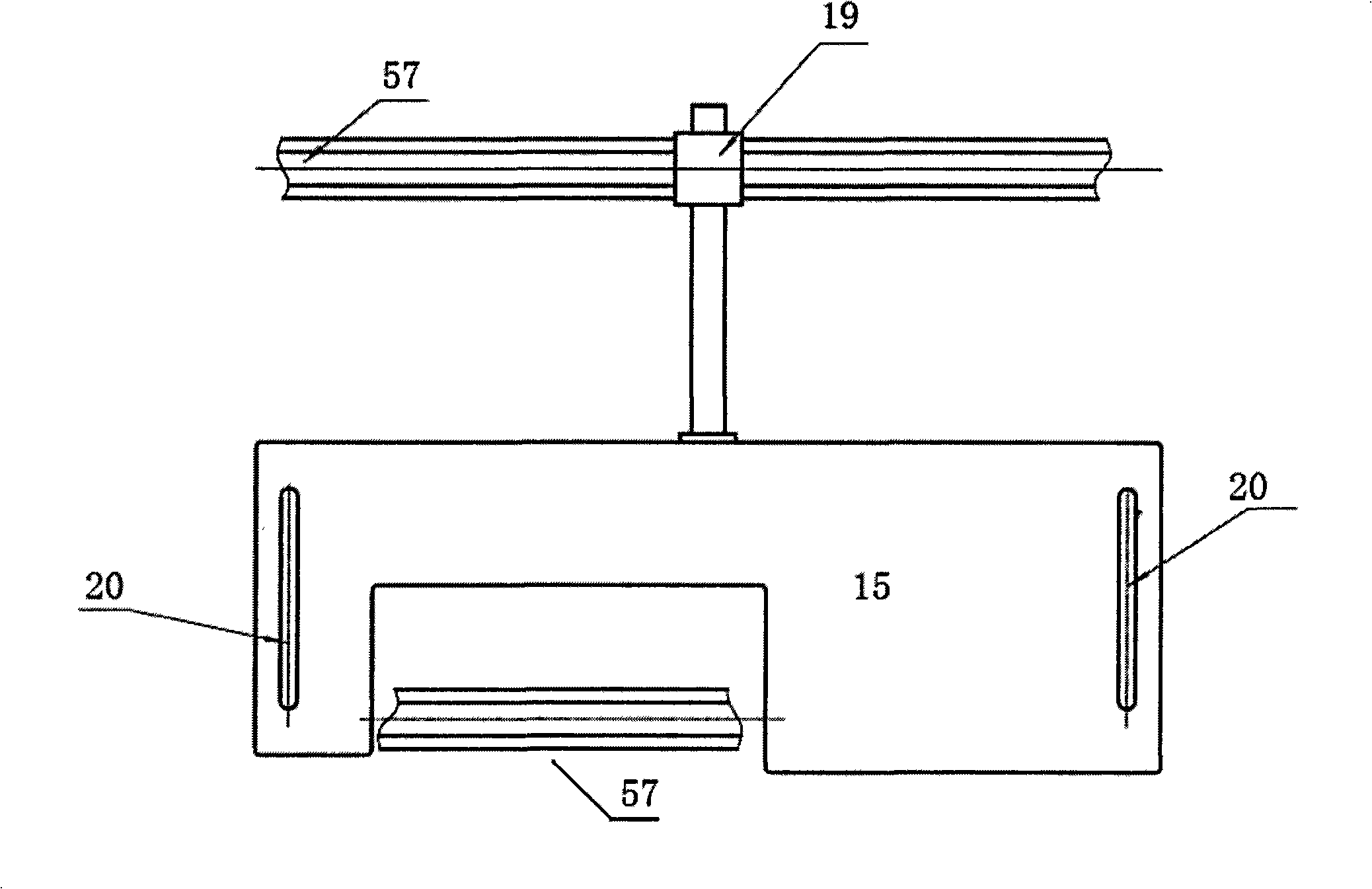

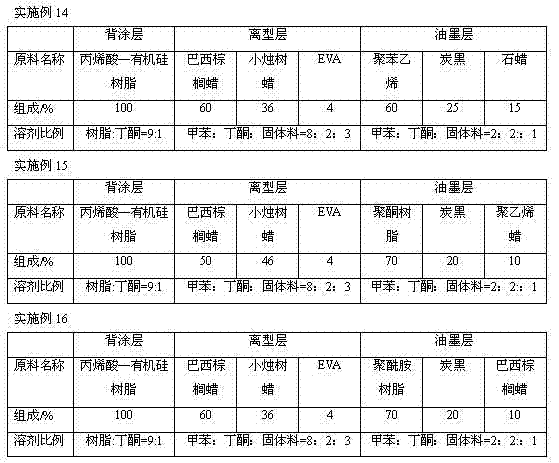

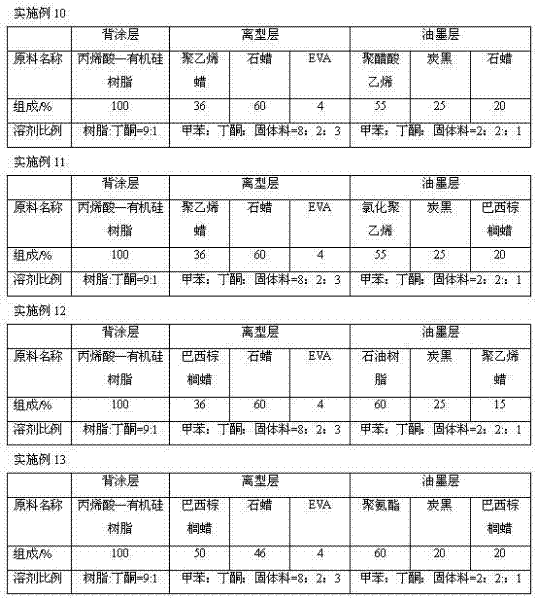

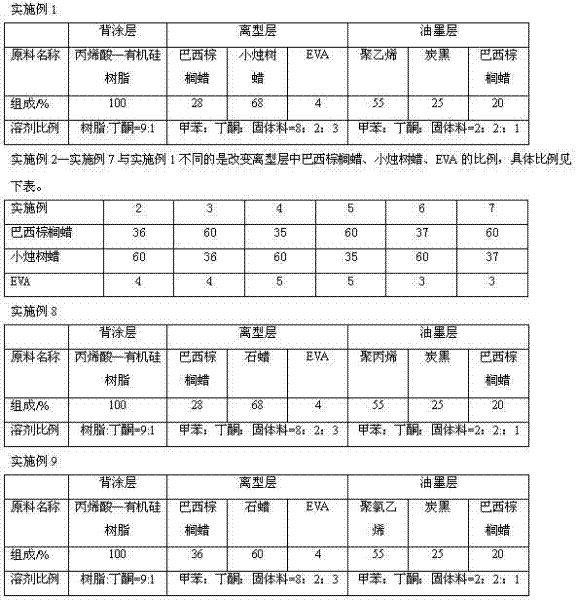

Thermal transfer ribbon used for edge crush type printer and preparation method thereof

ActiveCN102653189AReduce solubilityMeet the requirements of wear resistanceInk ribbonsPolyesterPolymer science

The invention relates to a thermal transfer ribbon, in particular to a thermal transfer ribbon used for an edge crush type printer and a preparation method thereof. The thermal transfer ribbon comprises an ink layer, a release layer, a base film and a back coating from top to bottom in sequence, wherein the release layer is composed of wax and an adhesive in a mass ratio of (10-40):1; the base film is a polyester film; the back coating is prepared from acrylic acid-organic silicon resin; and the ink layer is composed of 10-20% of wax, 15-30% of carbon black and 40-70% of adhesive by mass. The thermal transfer ribbon can not only achieve the effect of quick transfer but also simultaneously meet the requirement of abrasion resistance of printed matters and realize high-speed printing.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

On-line laser processing device used for railway steel rail surface toughening treatment

The invention discloses an online laser process device for railway rail surface tenacious treatment, which includes a laser processing vehicle and a power mobile machinery shop. The laser processing vehicle includes a motion actuator, a laser processing head, a control system and / or automatic powder feeder equipped on a moving trolley; the power mobile machinery shop includes a dynamo, a freezer, an air compressor, a refrigerated air dryer and a laser high voltage source equipped on a lorry. The laser processing head is equipped on the motion actuator; the laser processing head is connected to the laser directly or by a light guiding system. The invention can finish laser surface quenching, fused quenching, alloying and cladding on various rails, including rail, bend, guard rail, turnout, etc., without dismantling rail and affecting the normal operation of a train, the processed rail has greatly lengthened its wearability, and has characteristics of easy dismantling, high processing precision and easy operating.

Owner:HUAZHONG UNIV OF SCI & TECH +1

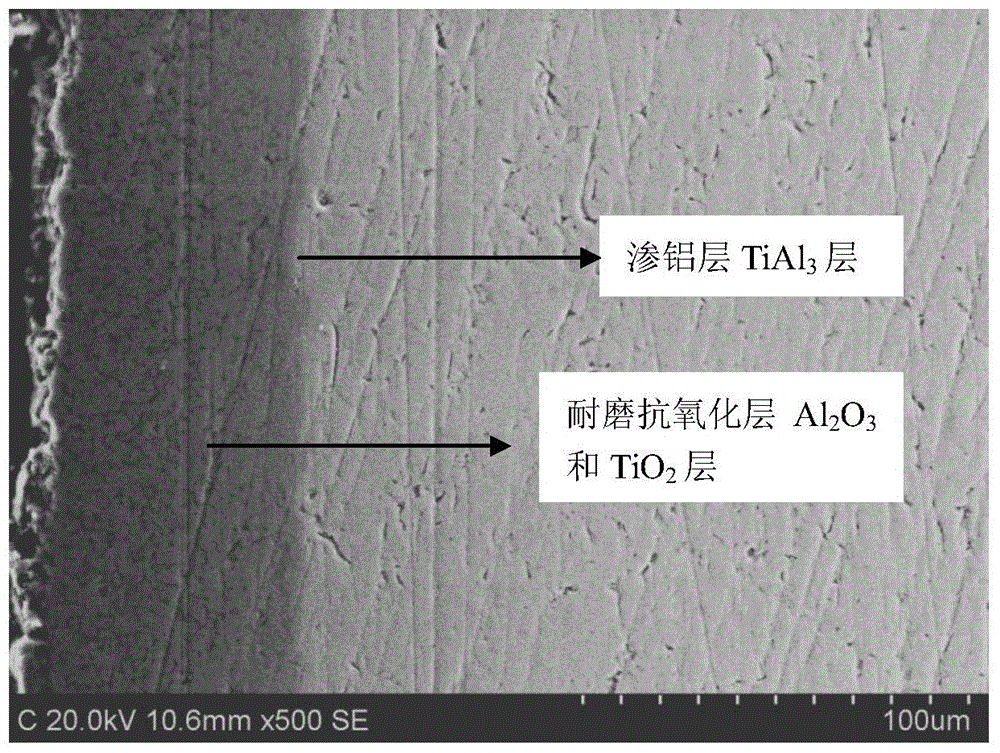

Titanium and titanium alloy surface antioxidant wear-resistant composite coating and manufacturing method thereof

ActiveCN104947107AImprove bindingImprove antioxidant capacityAnodisationSolid state diffusion coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides a titanium and titanium alloy surface antioxidant wear-resistant composite coating and a manufacturing method thereof and belongs to the technical field of surface treatment. The titanium and titanium alloy surface antioxidant wear-resistant composite coating and the manufacturing method thereof are used for solving the problems of a protective layer used for achieving high-temperature oxidation resistance of the surface of titanium alloy and improving the abrasion resistance of the surface of the titanium alloy in the prior art. The composite coating is composed of an inner oxygen isolating layer and an outer abrasion-resistant anti-oxidation layer. The oxygen isolating layer is an aluminized coating rich in aluminum, and the main component of the oxygen isolating layer is Til3. The abrasion-resistant anti-oxidation layer is made of high-hardness ceramic containing Al2O3 and TiO2. The manufacturing method comprises the steps that 1, pretreatment of the surface of titanium or titanium alloy; 2, aluminizing treatment of the surface of the titanium or titanium alloy; 3, micro-arc oxidation treatment of the surface of the titanium or titanium alloy. The method is simple and suitable for industrial use. The composite coating is better in high-temperature oxidation resistance compared with an existing protective coating, the problems that through cracks are caused and the bonding force of a painting layer is poor during ordinary aluminizing are solved, the problems that the titanium alloy subjected to ordinary micro-arc oxidation is insufficient in hardness, and nitrided modified coating is thin are also solved, and the requirements of most titanium alloy parts for abrasion resistance are met.

Owner:SHENYANG LIGONG UNIV

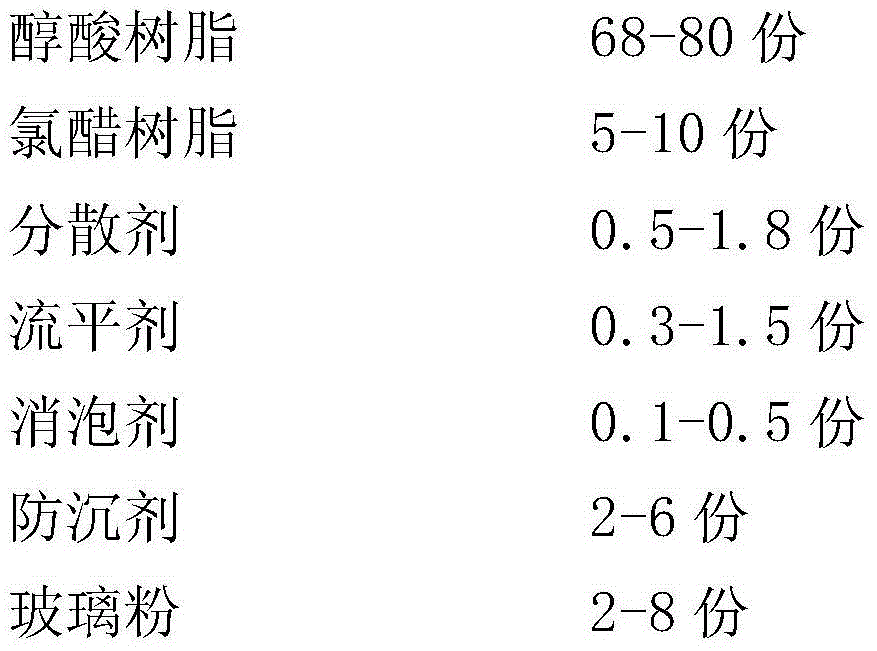

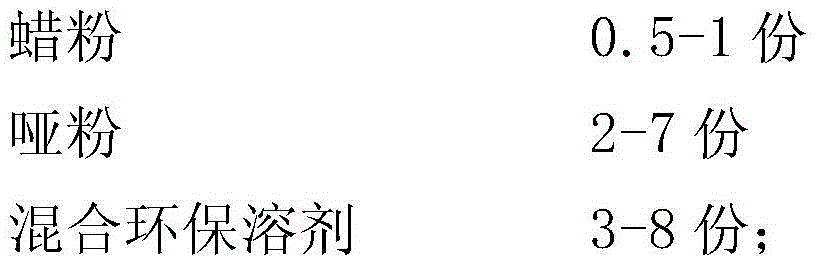

Polyurethane matt wearable top-coat paint for removing odor and preparation method thereof

The invention relates to a polyurethane top-coat paint and a preparation method thereof, and particularly relates to a polyurethane matt wearable top-coat paint for removing an odor and a preparation method thereof. The polyurethane matt wearable top-coat paint can be applied to office suite furniture, and belongs to the field of a household decorative coating. The polyurethane matt wearable top-coat paint for removing the odor is prepared from a primary agent, a curing agent and a diluent according to the ratio of (1-1.4):(0.5-0.7):(0.7-1.2), wherein the primary agent comprises the following components in parts by weight: 68-80 parts of alkyd resin, 5-10 parts of vinyl chloride-acetate copolymer, 0.5-1.8 parts of dispersant, 0.3-1.5 parts of flatting agent, 0.1-0.5 parts of defoamer, 2-6 parts of anti-settling agent, 2-8 parts of glass powder, 0.5-1 part of wax powder, 2-7 parts of matte powder and 3-8 parts of mixed environment-friendly solvent. The prepared polyurethane matt wearable top-coat paint for removing the odor is not only low in odor after construction, but also good in scratch resistance performance of the film, good in abrasive resistance, and good in environmental performance.

Owner:SKSHU PAINT

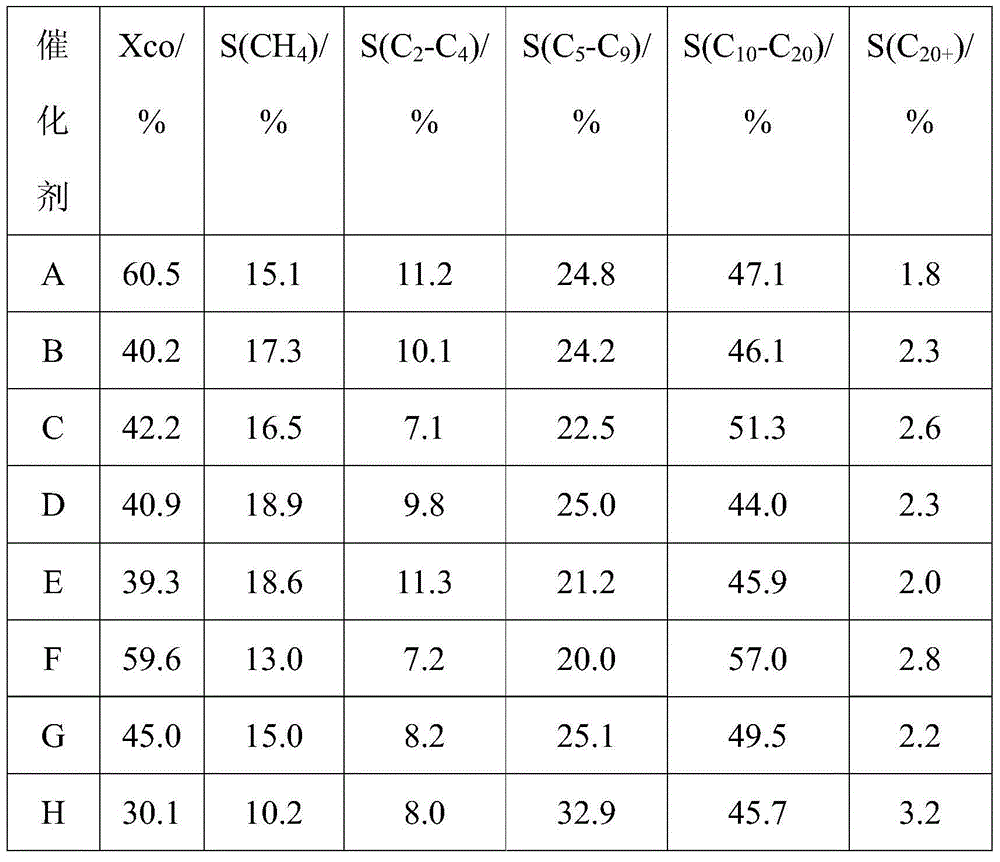

Cobalt-base Fischer-Tropsch synthesis catalyst and preparation method and application thereof

ActiveCN104368344AUniform size distributionFine particleLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsFischer–Tropsch processSol-gel

The invention discloses a cobalt-base Fischer-Tropsch synthesis catalyst and a preparation method and application thereof. The catalyst comprises a mesoporous carbon carrier and an active component cobalt, wherein the active component cobalt is confined in the mesoporous carbon carrier. The catalyst has specific surface area of 220-400 m<2> / g and particle diameter of 50-150 um. The preparation method employs phenolic resin solution as an organic precursor, and then a sol-gel method is employed to embed the active component Co into the mesoporous carbon carrier. The catalyst prepared by the invention before usage only requires introduction of inert gas into at a certain temperature without hydrogen reduction, so as to obtain the catalyst containing cobalt. The catalyst of the invention has the advantages of high reduction degree, high dispersity, good stability, uniform size of active component, controllable carrier aperture and high selectivity on diesel, and can meet the requirements of a slurry bed reactor on the wear resistance of the catalyst.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Copper base particle reinforced friction material

InactiveCN100467659CHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

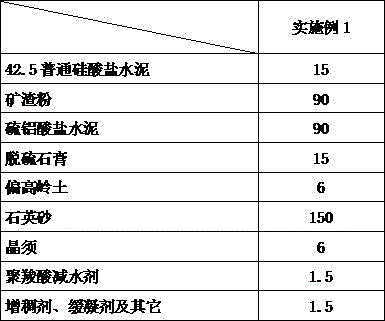

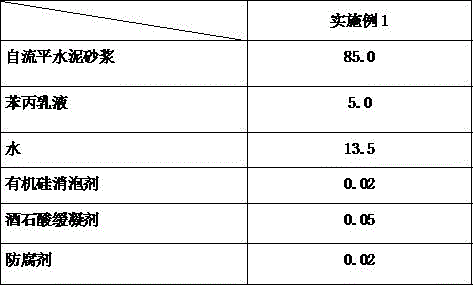

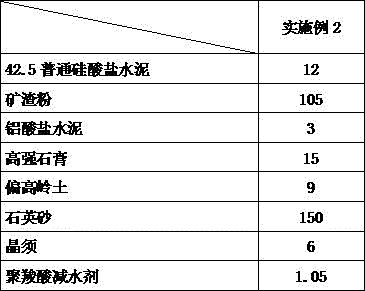

Whisker reinforcement-based self-leveling cement mortar and application thereof

The invention discloses whisker reinforcement-based self-leveling cement mortar. The whisker reinforcement-based self-leveling cement mortar comprises the following components in parts by weight: 10 to 20 parts of ordinary Portland cement, 50 to 150 parts of slag powder, 3 to 20 parts of special cement, 10 to 20 parts of gypsum, 5 to 10 parts of metakaolin, 100 to 160 parts of quartz sand, 1 to 10 parts of a crystal whisker and 1 to 1.5 parts of a water-reducing agent, wherein the special cement adopts sulphoaluminate cement or aluminate cement; the gypsum adopts one of or a mixture of more than two of high-strength gypsum, fluorgypsum, desulfurized gypsum and citric acid gypsum; and the crystal whisker adopts one of or a mixture of more than two of gypsum crystal whiskers, a magnesium hydroxide crystal whisker, a magnesium oxide crystal whisker, an ettringite crystal whisker and a calcium carbonate crystal whisker. A terrace prepared from the whisker reinforcement-based self-leveling cement mortar has high surface hardness and high anti-compression and anti-bending strength, and can meet the wear-resistant requirement of most occasions.

Owner:江苏蓝圈新材料股份有限公司

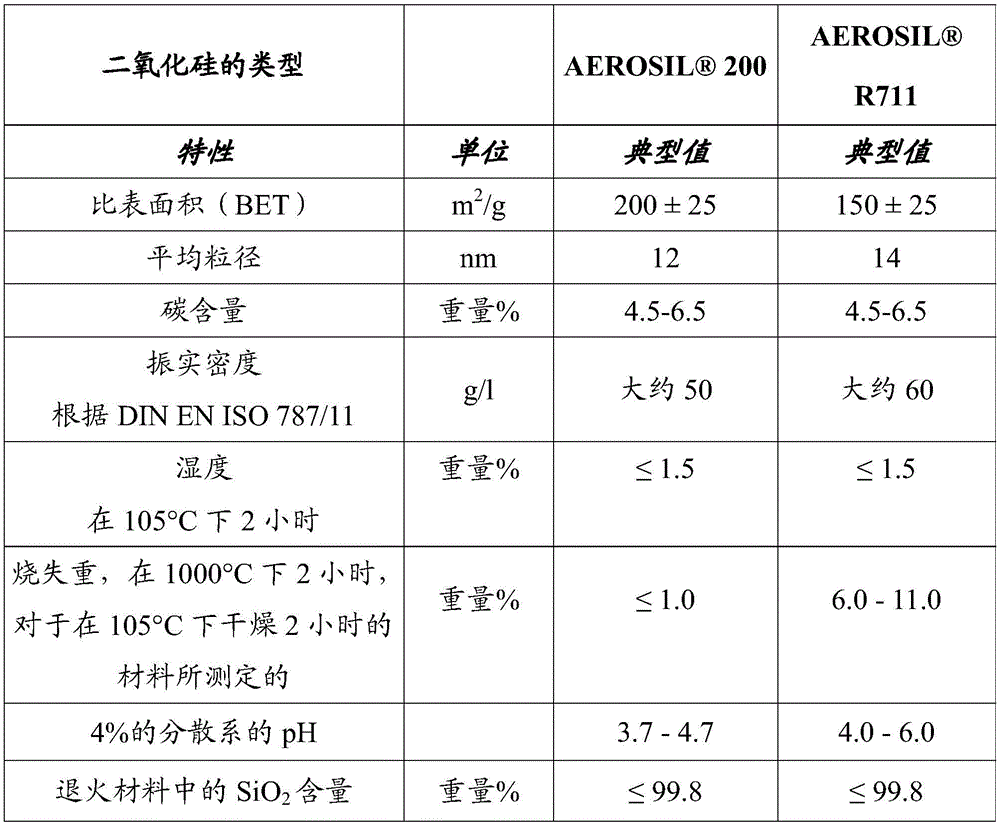

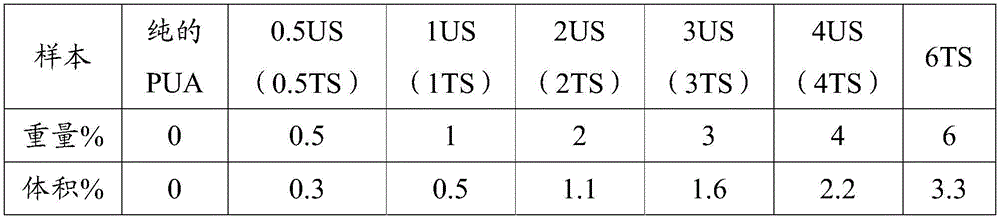

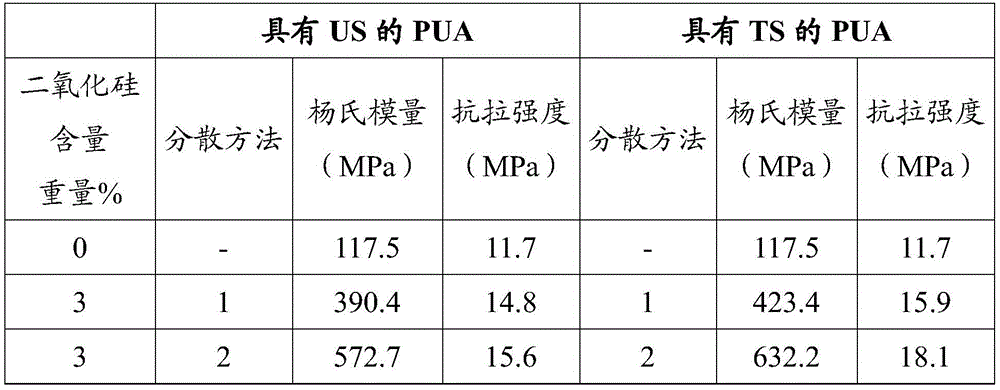

Abrasion-resistant materials

The invention provides an abrasion resistant material which comprises a polymeric matrix composite, preferably selected from the group comprising amorphous thermoplastics and resins, containing homogenously dispersed nanoparticles ranging in size from 1 to 50 nm, further combined with clusters of the said nanoparticles, or a combination of nanoparticles of different sizes within the above stated range. Furthermore, the invention provides a method of preparation of this material and automotive parts containing these materials.

Owner:VYSOKE UCENI TECHNICKE V BRNE

Low-alloy white cast iron

ActiveCN101463446ASolve the difficulties of too high hardness, large crack tendency and difficult processingModerate hardnessFoundryWear resistant

The invention relates to a low alloy white cast iron, which can meet the special requirements of wearing pieces of cereals processing machines. The cast iron comprises the following chemical compositions according to the weight percentage: 3.5-3.8% of carbon, 1.5-1.9% of silicon, more than 0 and less than or equal to 1.0% of Mn, less than 0.05% of phosphorus, 0.02% of sulfur, more than 0 and less than or equal to 1.0% of chromium; the rest is Fe and unavoidable trace impurity elements. The white cast iron is in line with the performance provision of the wearing pieces of the cereals processing machines and has better mechanical work and casting combination property compared with the high hardness wear-resistant white cast iron (Patent CN1019029B). The white cast iron has the advantages of easy controllable components, little alloy, low production cost and fine foundry processing property, thus better in favor of industrialization application, etc.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

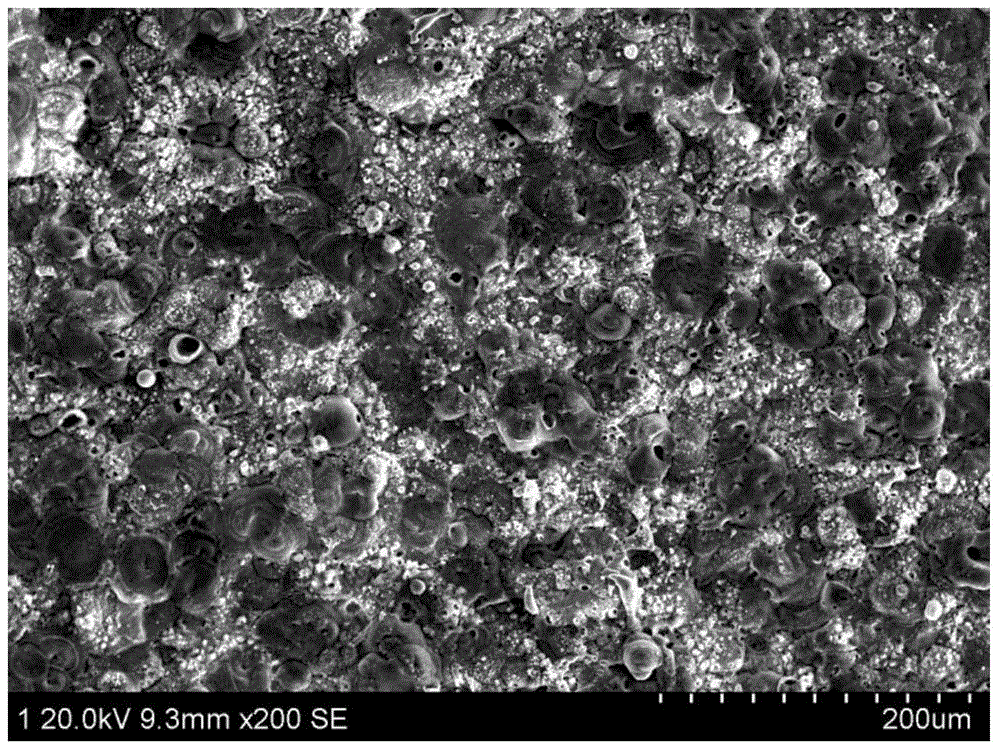

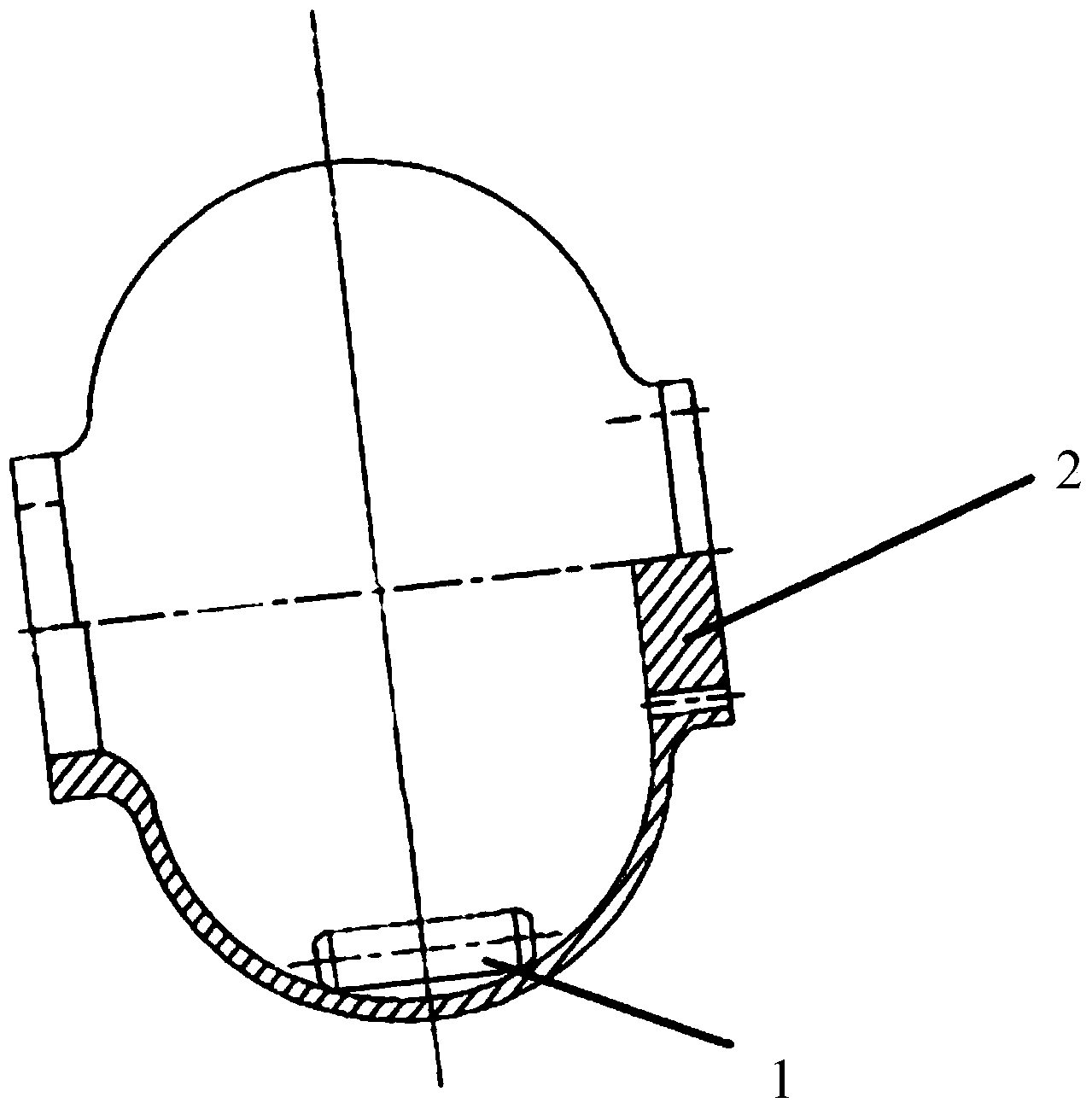

Ceramic preform, preparation method thereof, ceramic wear-resistant structure and wear-resistant part

InactiveCN110615672AImprove wettabilityInfiltration playsAdditive manufacturing apparatusCeramic shaping apparatusWear resistantWear resistance

The invention relates to a ceramic preform, a preparation method thereof, a ceramic wear-resistant structure and a wear-resistant part. The preparation method comprises the following steps: sinteringa ceramic biscuit prepared on the basis of a photocuring 3D printing process, and carrying out nickel plating treatment to obtain the ceramic preform; the obtained ceramic preform is a hemispheroid ora sphere with a foam structure. Through arrangement of the semispherical or spherical structure, when the ceramic preform is subjected to external force action, the base body can provide the maximumsupporting effect for the outer surface; and because of nickel plating treatment, the preform has good wettability on casting molten metal, the molten metal can conveniently permeate into a cavity ofthe ceramic preform in a casting process to be compounded with the preform into a whole to play a supporting role, the overall wear resistance and toughness are improved, and the preform is firm in combination and not prone to damage and stripping. The ceramic preform or the ceramic wear-resistant structure is configured according to different wear degrees and strengths of different parts of the wear-resistant part, so that the wear-resistant requirements of special parts of the wear-resistant part are met, the overall wear-resistant toughness is improved, the service lifetime is prolonged, and the maintenance period is shortened.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Method for making diamond string beads

ActiveCN104439255AImprove sharpnessMeet wear resistance requirementsUltimate tensile strengthEnergy consumption

The invention discloses a method for making diamond string beads. The method comprises the steps that firstly Fe-based submicron alloy powder, auxiliary material and granular-making additive are used for making granules, the granules are evenly mixed with diamond grains, and carcass materials are obtained, wherein the Fe-based submicron alloy powder is composed of Fe (45+x)Co(17+y) Cu (38+z), -2 <= x, y and z<=2, and x+ y+ z=0; secondly the carcass materials are made unto carcass rings, bead core steel is sleeved with the carcass rings, then the bead core steel sleeved with the carcass rings are freely sintered in a uniform atmosphere, and the diamond string beads are obtained. The Fe-based submicron alloy powder composed of specific ingredients is used for making the diamond string beads through free sintering, the carcass linear shrinkage is made to be 13%-18%, the carcass can not crack and deform after being shrunk, and composition segregation can not happen in the carcass after sintering is completed; by means of the powder, the sharpness of the obtained string beads can be improved, and the abrasion resistance requirement of a string bead rope saw is met; in addition, labor intensity, energy consumption and unit cost are all lowered to a certain extent.

Owner:GUILIN TEBON SUPERHARD MATERIAL

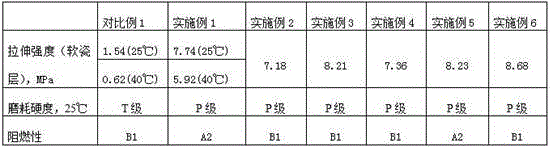

Integrated floor-heating flexible ceramic tile and production method thereof

ActiveCN106433096AHigh hardnessImprove heat resistanceHeating fuelNon-macromolecular adhesive additivesElastomerEpoxy

The invention relates to an integrated floor-heating flexible ceramic tile and a production method thereof. The integrated floor-heating flexible ceramic tile combined by a flexible ceramic layer and a polymer composite electric-heating film is good in flexibility, high in tear resistance, high in elongation at break, high in heat resistance, high in heat efficiency, fast in heating, and the like. The flexible ceramic layer is produced by inorganic powder and polymer materials, and the polymer materials are water-borne epoxy resin emulsion, water-soluble epoxy resin curing agent, rubber elastomer and fluorine-containing polyacrylate elastic emulsion. The polymer composite electric-heating film comprises a polyurethane resin heat-conducting insulating layer, a carbon nanotube polyurethane resin heating layer, a polyurethane resin insulating layer and electrodes. The polymer composite electric-heating film is formed by the heat-conducting insulating layer semi-cured by polyurethane resin, the heating layer semi-cured by carbon nanotube polyurethane resin and the insulating layer semi-cured by polyurethane resin through hot pressing. The soft ceramic layer is integrally connected with the polymer composite electric-heating film through the polyurethane resin heat-conducting insulating layer to form the integrated floor-heating flexible ceramic tile.

Owner:万卓(江苏)新材料有限公司

Machining method for spherical surface roller pin free of edge angles

ActiveCN103659562ANot easy to scratchAvoid breakingEdge grinding machinesPolishing machinesPulp and paper industryLantern

The invention discloses a machining method for a spherical surface roller pin free of edge angles. The method includes the following steps of A roll polishing, B heat treating and C modified line machining and further includes the following step of edge angle removal machining, wherein after roll polishing in the step A, an arc lantern-shaped rolling barrel is manufactured according to the size and the shape of a roller pin, the rolling barrel is horizontally arranged on a support with an adjustable dip angle, the roller pin after roll polishing is thrown into a barrel body of the rolling barrel through a throwing opening, the two ends of a roller pin blank make contact with the barrel wall in the barrel body, the rolling barrel rotates in the circumferential direction around the axis of the barrel body through an external power source, and in the rotating process, the roller pin blank is grinded in a 360-degree rolling-polishing mode along the barrel wall in the barrel body, so that the edge angles at the two ends of the roller pin are machined to be arc angles. The method solves the problem that the edge angles exist in the connecting positions of the two ends of the outer side wall and the semicircular ends of the roller pin, and the roughness of the semicircular ends at the two ends of the roller pin is small.

Owner:NINGBO ZHONGHE AUTO PATS

Low-cost hard-face build-up welding flux-cored wire with high adaptability

ActiveCN105108370ALow costEasy to useWelding/cutting media/materialsSoldering mediaHigh carbonHardness

The invention discloses a low-cost hard-face build-up welding flux-cored wire with high adaptability and relates to the technical field of welding. The low-cost hard-face build-up welding flux-cored wire with high adaptability is composed of a flux core and a low-carbon steel sheath, wherein the flux core is composed of 4-10% of high-carbon ferromanganese, 3-7% of low-carbon ferromanganese, 5-15% of high-carbon ferro-aluminum, 20-40% of micro-carbon ferro chrome, 10-30% of other alloy and the balance iron, and the low-carbon steel sheath comprises, by weight, 0.01-0.10% of C, 0.1-0.4% of Mn, 0.01-0.03% of Si, 0.005-0.010% of S, and 0.005-0.015% of P. By the adoption of the low-cost hard-face build-up welding flux-cored wire with high adaptability, cost can be effectively reduced, and abrasion resistance is guaranteed. The low-cost hard-face build-up welding flux-cored wire with high adaptability has the advantages of being excellent in processing property and physical and chemical property, high in adaptability, free of cracks and the like. The harness of the low-cost hard-face build-up welding flux-cored wire is over HRC50.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

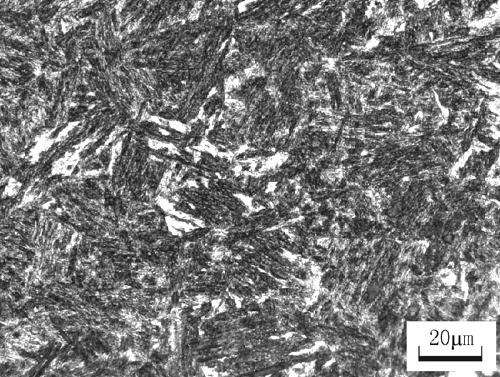

Low-temperature semi-quenched and wear-resistant steel with brinell hardness of 400 HB and production method thereof

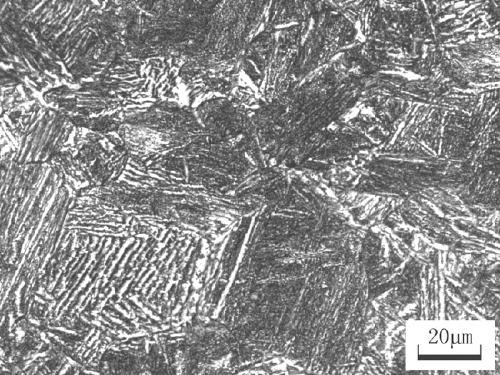

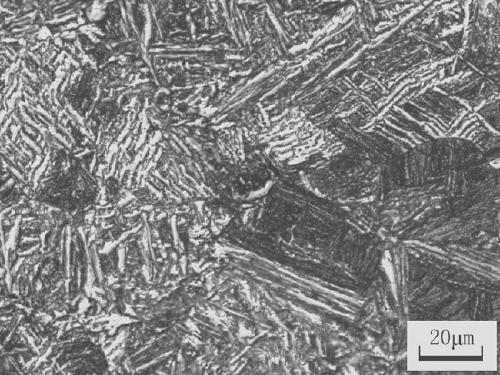

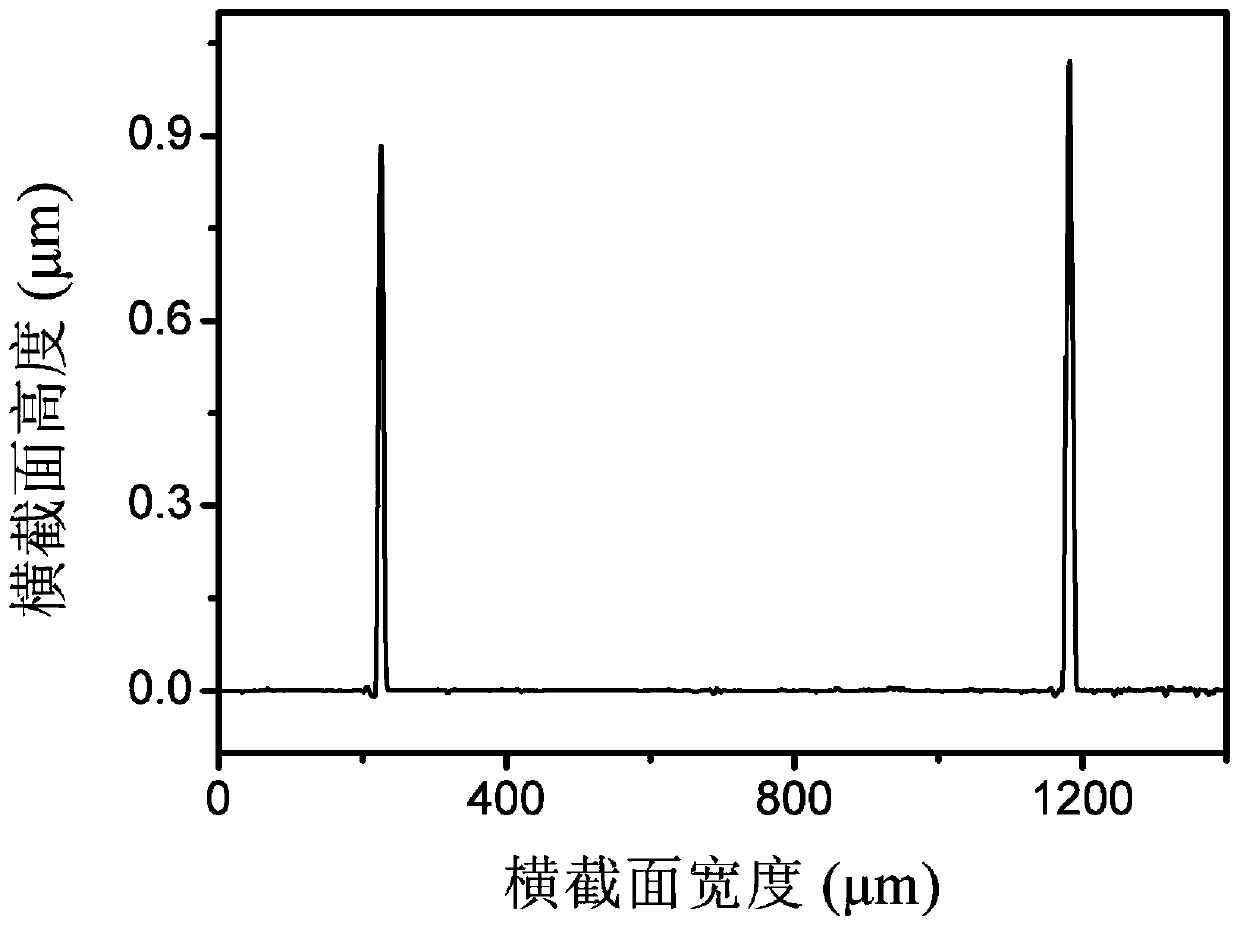

The invention discloses a low-temperature semi-quenched and wear-resistant steel with the brinell hardness of 400 HB. The low-temperature semi-quenched and wear-resistant steel with the brinell hardness of 400 HB is prepared from the following components of, in percentage by weight, 0.08%-0.25% of C, 0.30%-0.50% of Si, 0.5%-1.0% of Mn, less than or equal to 0.01% of P, less than or equal to 0.005%of S, 0.60%-0.80% of Cr, 0.03%-0.05% of Al, 0.01%-0.02% of Ti, 0.02%-0.03% of Nb and 0.001%-0.004% of B; the production method comprises the following steps of performing RH vacuum treatment after conventional converter combined blowing and LHF furnace treatment; heating a casting blank; performing rough rolling; carrying out finish rolling; quenching; tempering at low temperature; and finishingfor later use. On the premise of ensuring the hardness value, a relatively soft bainite or sorbite metallographic structure is obtained at the core part of the steel plate, the surface of the steel plate is tempered martensite metallographic structure, so that the brinell hardness of the surface of the steel plate is greater than 400HBW, and the production cost is reduced by at least 10% comparedwith that of the prior art due to the addition of the alloy elements.

Owner:武汉钢铁有限公司

Super wear-resistant novel two-dimensional composite material and preparation method thereof

ActiveCN109777352AGood wear resistanceImprove wear resistanceOther chemical processesSolventWear resistant

The invention discloses a preparation method of a super wear-resistant novel two-dimensional composite material. The preparation method is a coating method, and comprises the following steps: scattering a novel two-dimensional composite material on the surface of a substrate, scattering a zero-dimensional material B and / or a two-dimensional material C on the surface of the novel two-dimensional material A, adding a solvent to the surface of the novel two-dimensional material A and the surface of the zero-dimensional material B and / or the two-dimensional material C, performing coating by usinga scarper plate until the novel two-dimensional material A, the zero-dimensional material B and / or the two-dimensional material C and the solvent are uniformly mixed, and volatilizing the solvent to obtain the super wear-resistant novel two-dimensional composite material supported on the substrate. The super wear-resistant novel two-dimensional composite material prepared by the method can meet the wear resistance demands of materials or parts with high wear resistance demand.

Owner:TSINGHUA UNIV

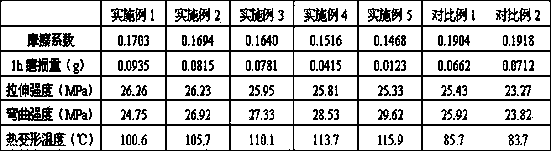

Anti-friction polypropylene material and preparation method thereof

The invention discloses an anti-friction polypropylene material and a preparation method thereof, belonging to the technical field of the anti-friction polypropylene materials. An anti-friction polypropylene composite material with relatively good wear resistance, rigidity and heat resistance is prepared by compounding a calcium carbonate crystal whisker with a certain length-diameter ratio and aramid pulp. According to the anti-friction polypropylene material disclosed by the invention, a high-anti-shock polypropylene copolymer is adopted as base resin, and the calcium carbonate crystal whisker and the aramid pulp which are helpful for improving the anti-friction performance of the material are adopted for increasing the rigidity of the material so as to ensure that the material can obtain good anti-friction performance and rigidity at the same time. By compounding the calcium carbonate crystal whisker and the aramid pulp, the anti-friction polypropylene material ensures that the rigidity, wear resistance and heat resistance of the material can be improved to a certain extent, and the comprehensive performance of the material can be more balanced.

Owner:CHANGZHOU UNIV

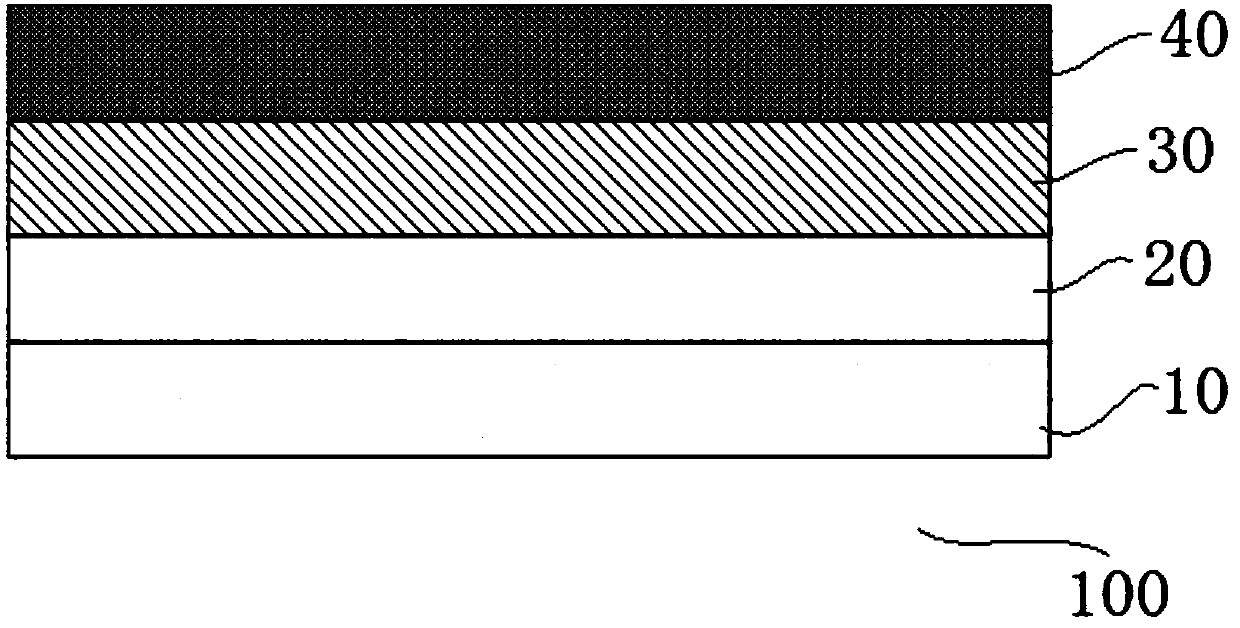

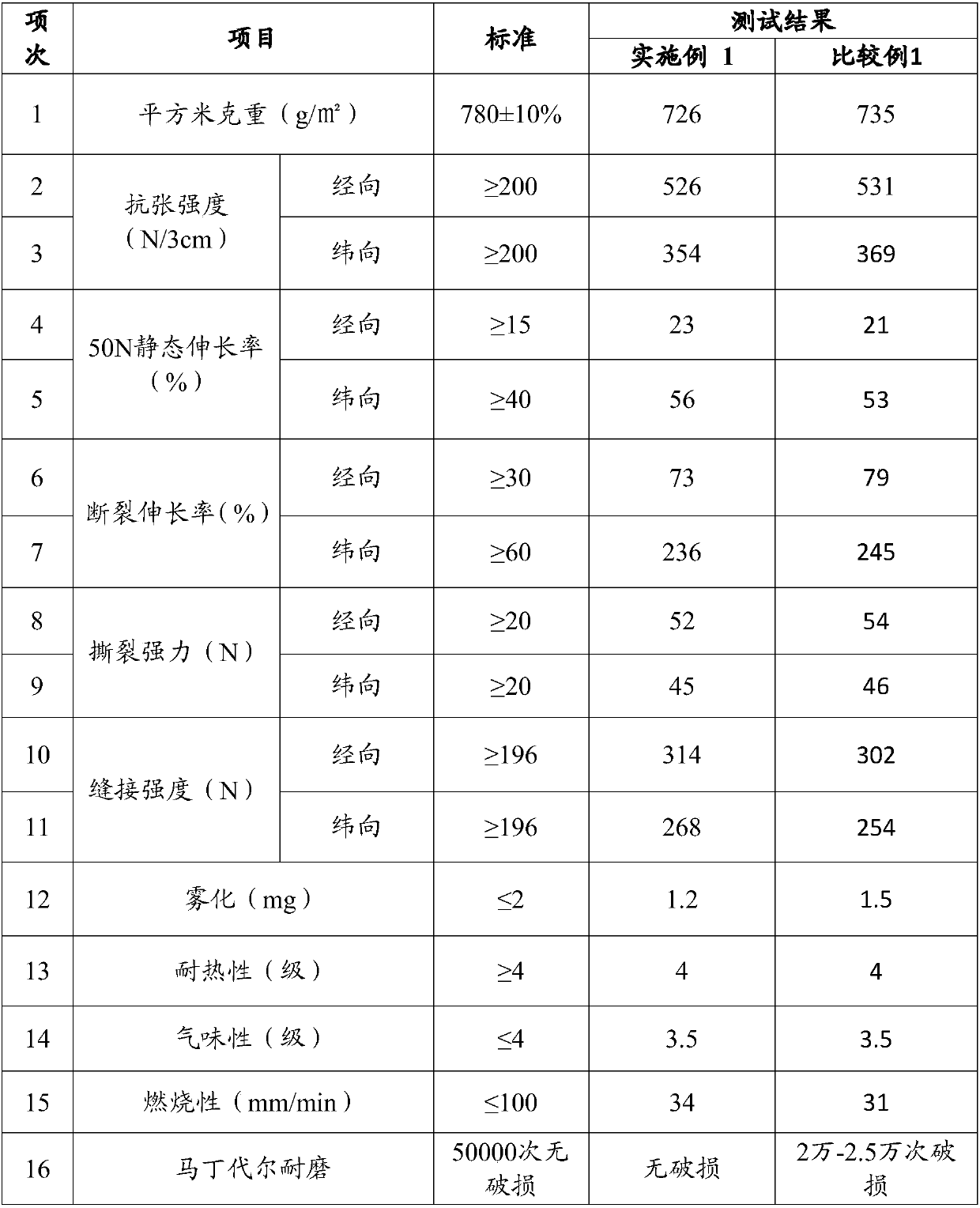

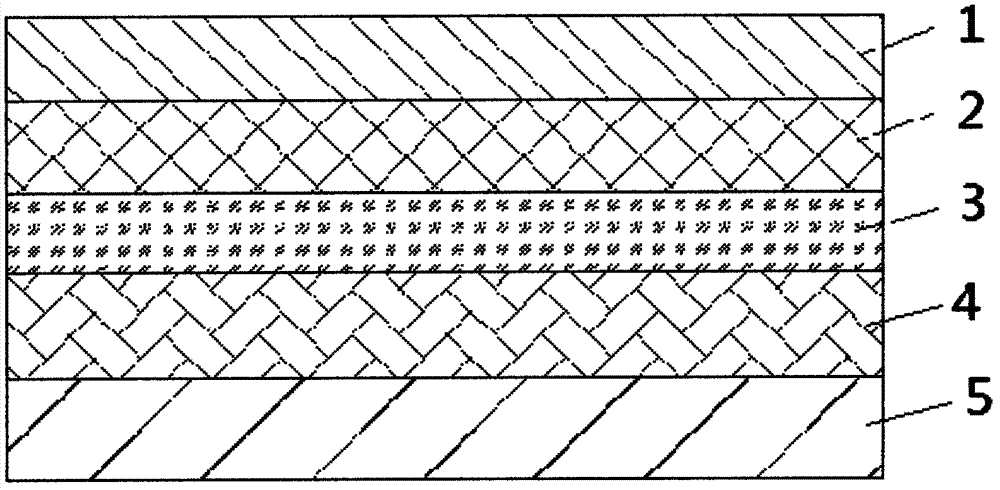

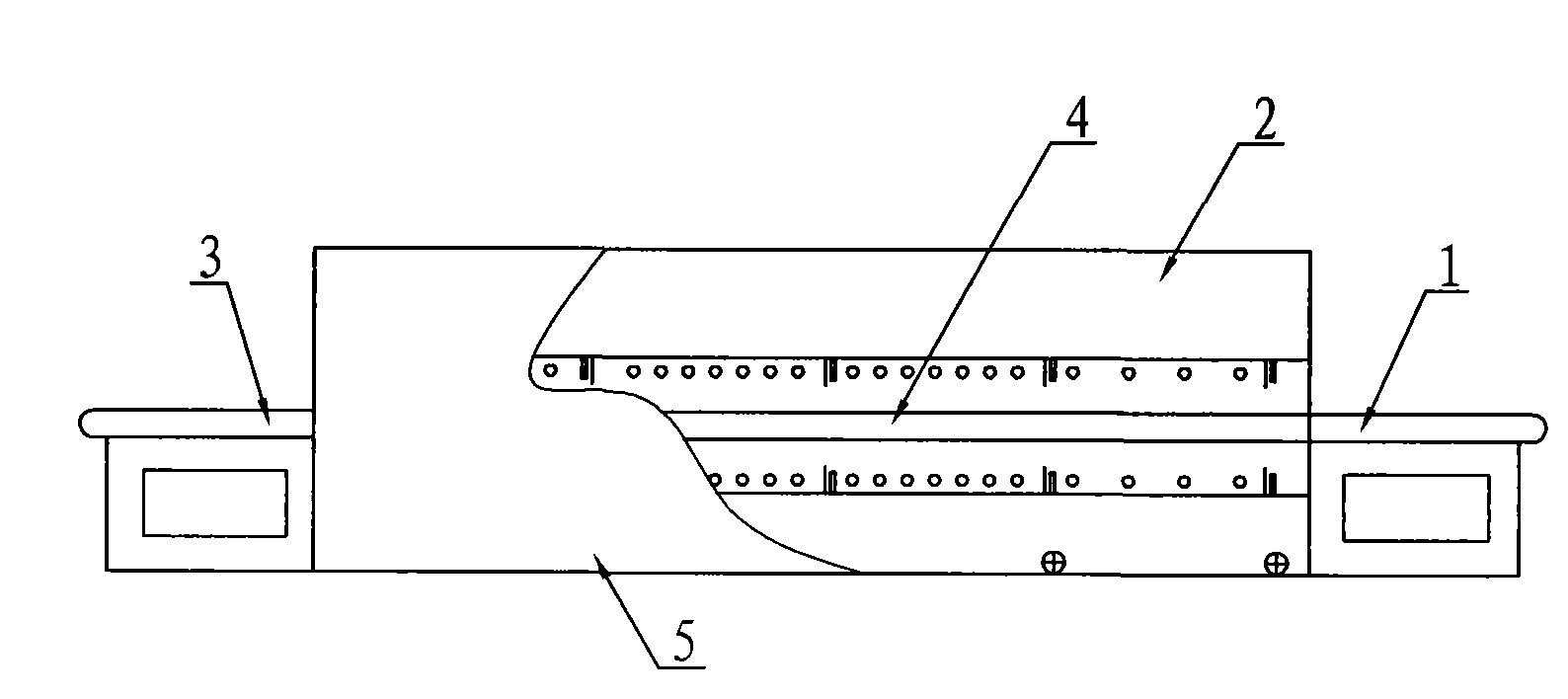

Artificial leather treating agent, artificial leather and preparation method thereof, as well as vehicle provided with artificial leather

InactiveCN108049198AImprove wear resistanceEasy to prepareTextiles and paperPolycarbonate coatingsEmulsionFoaming agent

The invention provides an artificial leather treating agent, artificial leather and a preparation method thereof, as well as a vehicle provided with the artificial leather. The artificial leather treating agent comprises 90-110 parts by weight of polycarbonate resin emulsion and 8-9 parts by weight of an auxiliary, wherein the auxiliary comprises 4-6 pats by weight of a curing agent, 0.05-0.15 part by weight of a de-foaming agent, 1-2 parts by weight of a flatting agent and 1-3 parts by weight of a hand feeling agent. The artificial leather treating agent provided by the embodiment of the invention has the characteristics of being resistant to illuminate, low in atomization, low in odor and excellent in low temperature torsion resistance; the artificial leather prepared by the artificial leather treating agent has high wear resistance and meets the requirements for wear resistance of vehicle interior products; the preparation method of the artificial leather is simple, easy to controland suitable for large-scale popularization and application.

Owner:BAIC GRP ORV CO LTD

Environmentally-friendly holographic anti-counterfeiting printing film

The invention provides an environmentally-friendly holographic anti-counterfeiting printing film having the advantages of simple use, high production efficiency and high yield. The holographic anti-counterfeiting printing film comprises an antistatic layer, a wear-resistant protection layer, a PET film, an activation connecting layer and a printing effect improvement layer. The environmentally-friendly holographic anti-counterfeiting printing film has a reasonable structure, and can be applied to holographic anti-counterfeiting printing materials for legal certificates. Multiple functions comprising bonding, printing, beauty and counterfeiting inhibition of the PET material can be realized because of the structure of the material, and the reasonable structure is a base for the integration and non-interference of the multiple functions. If an information layer and a bonding layer are in a same side surface, loose attachment is formed, and bonded film separation must appear under a strong force because of the material characteristic of the information layer; and if the information is at the other side of the printing bonding layer, the wear resistance use requirements of the certificates cannot be satisfied without reliable protection measures.

Owner:中安防伪技术有限公司

Quartz glass tube silicon chip bracket component

ActiveCN102032777AHigh strengthMeet the intensityFinal product manufactureFurnace typesCeramic coatingTemperature resistance

The invention provides a quartz glass tube silicon chip bracket component for a mesh belt-free silicon chip sintering furnace. The component comprises a quartz glass tube, metal sleeves, support legs and limiting screws, wherein the support legs are fixed on the metal sleeves; the metal sleeves are provided with threaded holes and are fixed on the quartz glass tube at equal intervals through the limiting screws; the support legs are made of steel wires; and the surfaces of the steel wires are coated with ceramic coatings. The quartz glass tube has the advantages of high intensity, high temperature resistance, low expansion coefficient, thermal shock resistance, acid resistance, chemical stability, high electrical insulating property, small heat absorption capacity and the like and is very suitable to be taken as a silicon chip bracket. The support legs are made of steel wires and the surfaces of the steel wires are coated with ceramic coatings, so that the requirements on intensity, high temperature resistance and wearing resistance of the support leg are met and metal ion pollution of a silicon chip caused by metal contact in a sintering process is reduced. Each metal sleeve is provided with an opening and a threaded hole, so that the metal sleeve is convenient to fix on the quartz glass tube.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

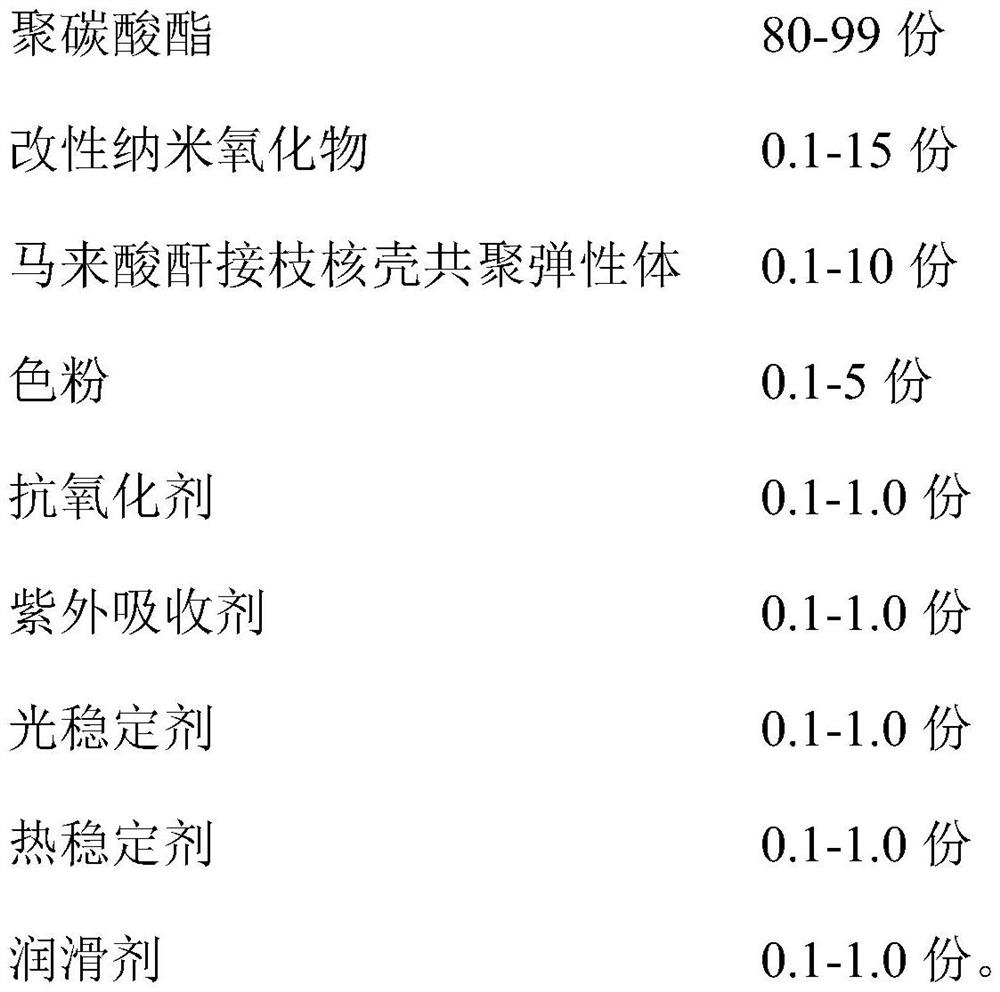

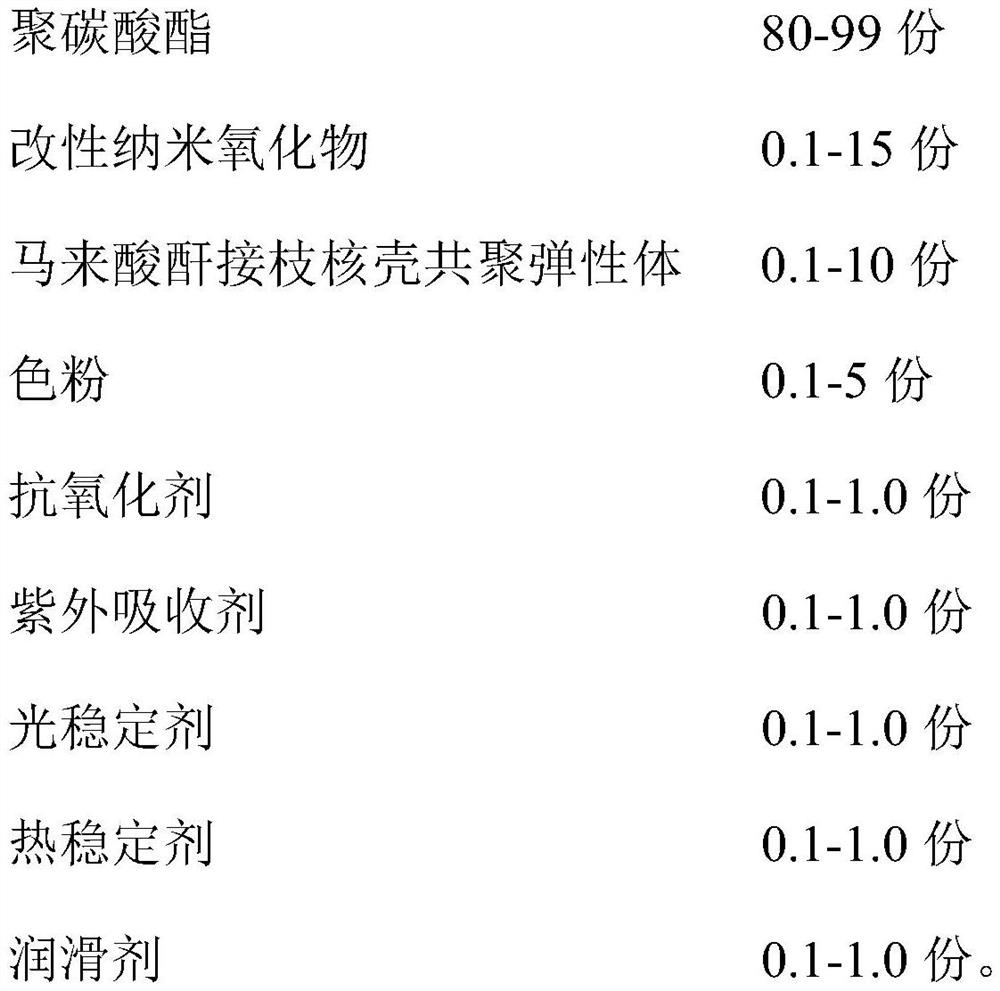

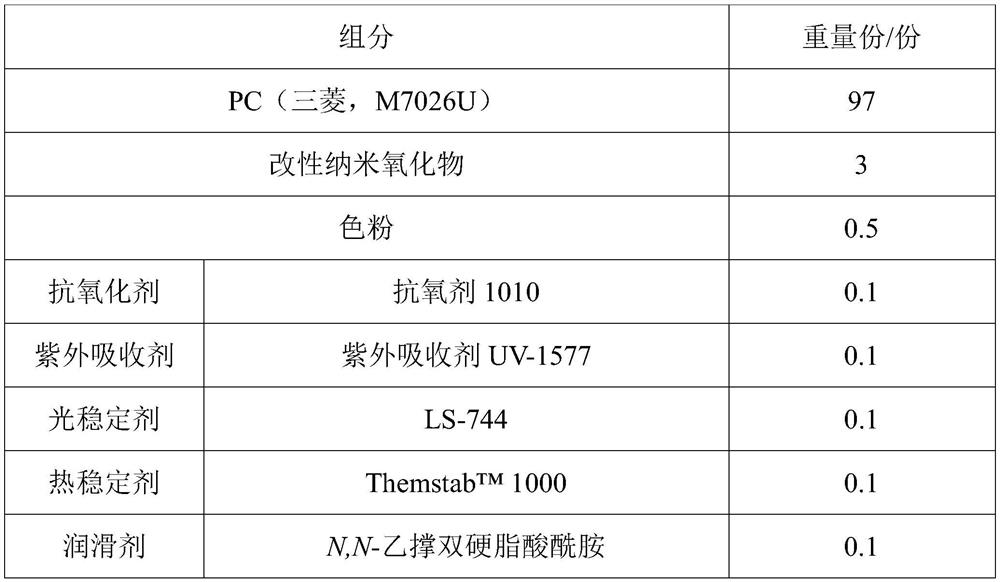

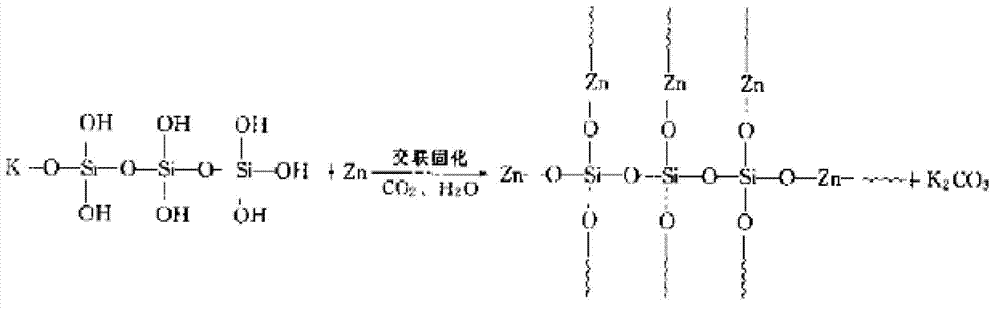

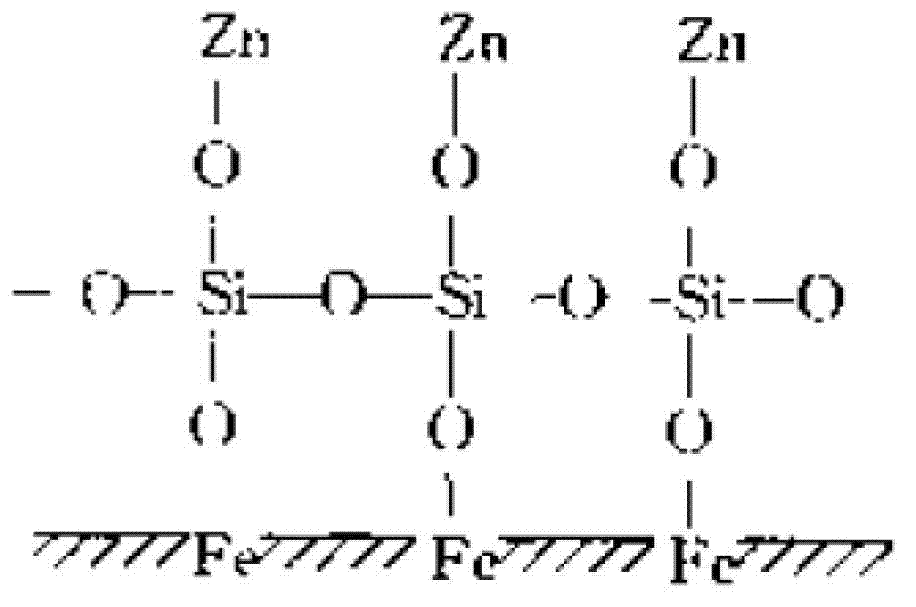

Polycarbonate material as well as preparation method and application thereof

ActiveCN111607213AImprove gloss retentionImprove scratch resistancePolymer scienceHyperbranched polyester

The invention provides a polycarbonate material as well as a preparation method and application thereof. The polycarbonate material is prepared from the following components in parts by weight: 80 to99 parts of polycarbonate and 0.1 to 15 parts of a modified nano oxide. Wherein the modified nano oxide is modified by a coupling agent, a hyperbranched polyester and a rare earth ion together; the modified nano oxide has good dispersibility in a polycarbonate matrix material, not only can the scratch resistance and tensile strength of the polycarbonate material be improved, but also the influenceof the modified nano oxide on the impact toughness, blackness and surface gloss of the obtained material is small through a reasonable proportion and a scientific preparation method. The polycarbonate material provided by the invention is relatively good in scratch resistance, high in gloss retention rate, relatively good in tensile strength, and relatively excellent in physical properties such as surface gloss, blackness and impact toughness.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

Preparation method of concocted diesel oil

ActiveCN101007969AImprove wear resistanceGood emissionLiquid carbonaceous fuelsFuel additivesAromatic hydrocarbonViscosity

The inventon relates to a method for blending diesel, comprising following steps: (1) choosing two or more kinds of diesel, (2) blending with a certain ratio and getting blending diesel, testing the kinematic viscosity at 40 Deg. C for this blending diesel, testing or counting the sulfur content, total aromatic hydrocarbons content, polycyclic aromatics content and end point; (3) counting HFRR grinded spot diameter according to formula (1)- (5) in the instruction manual; (4) if the counted HFRR grinded spot diameter is in the intended range, the blending diesel will be needed diesel, and if not, repeating step (2)- (4) until the HFRR grinded spot diameter is in the intended range. The invention can conveniently blend diesel that meets II kind diesel standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wind generating set flange and wear-resistant coating technology of flange

InactiveCN102808744AMeet wear resistance requirementsIncrease coefficient of frictionWind energy generationSpecial surfacesElectricitySand blasting

The invention discloses a wind generating set flange, which includes a flange body, wherein water inorganic zinc rich paint is sprayed on the surface of the flange body to form a wear-resistant protective coating after solidification, and the surface of the flange body requires sand blasting before spraying the water inorganic zinc rich paint. The invention aims to provide the wind generating set flange taking the water inorganic zinc rich paint as the wear-resistant coating and the wear-resistant coating technology of the flange, and the water inorganic zinc rich paint sprayed on the surface of the flange body not only can satisfy the requirement for the twenty-year anticorrosion service life of the wind generating set flange, but also can satisfy the technical performance requirements for the wear resistance and the engaging force of the mutually-connected flange surfaces.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

RPUC high-performance die-pressed sole material

InactiveCN106916366AUniform foamingImprove structural stabilitySolesDomestic footwearRubber materialMaterials science

The invention discloses a RPUC high-performance die-pressed sole material, wherein a formula comprises the following components: 100 parts of a rubber material, 0.6-1 part of a bridging agent, 6.2-17.8 parts of an auxiliary gent, and 2-5 parts of a color material. A specific use method is improved. A sole produced by the RPUC high-performance sole formula with the specifically selected materials and proportion meets the requirements of slip stopping, abrasion resistance, light weight, high elasticity and the like, the sole comfort degree and practical degree are improved, and the development tendency of the sole is met.

Owner:DONGGUAN XINGTENG FOOTWARE MATERIAL

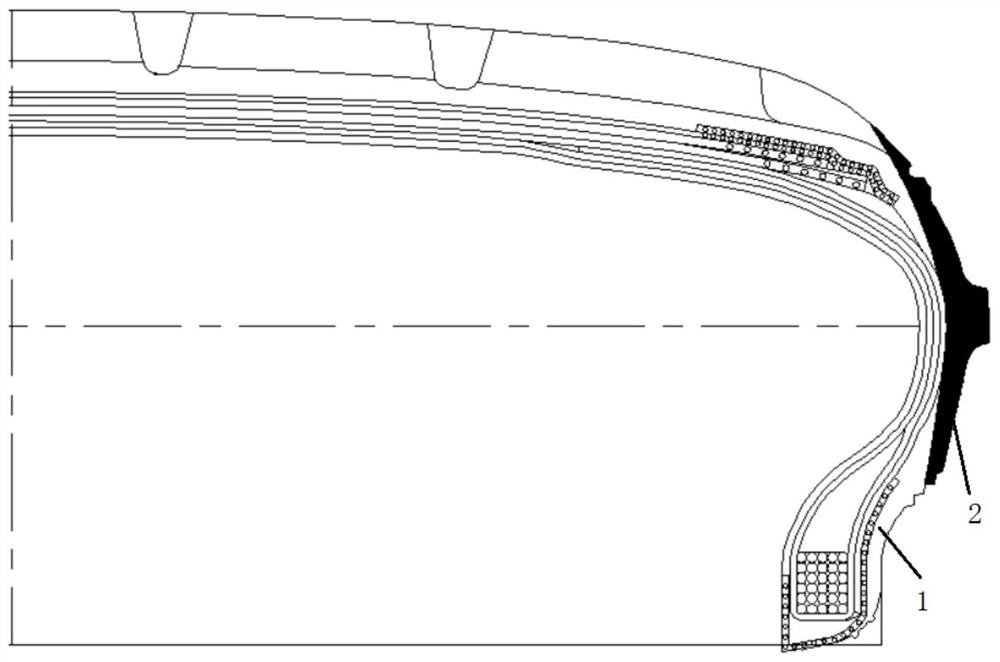

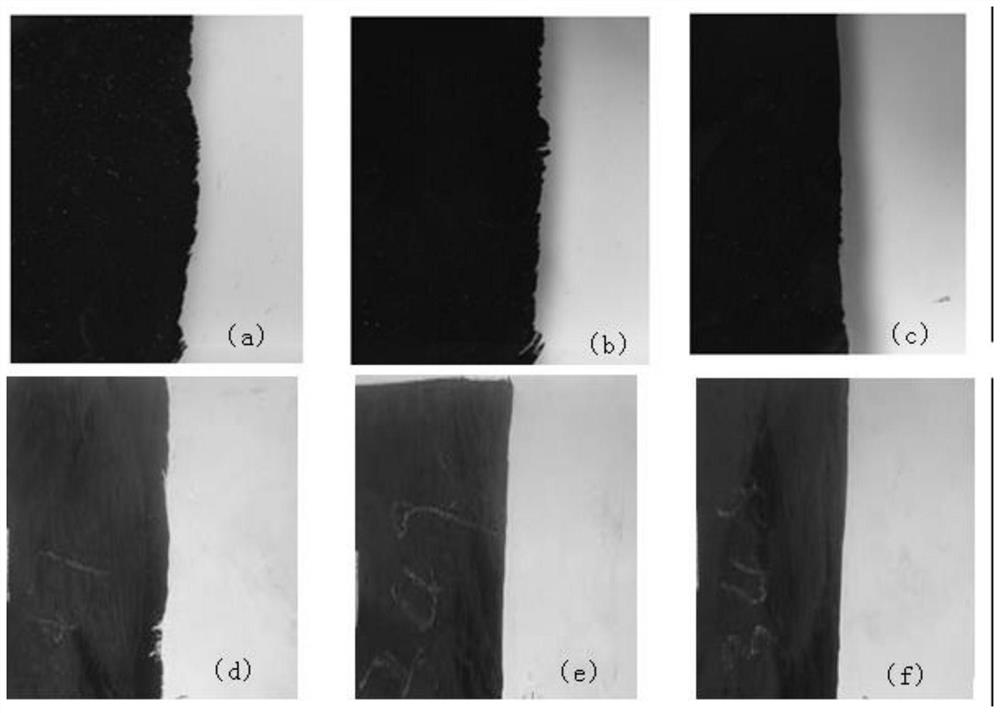

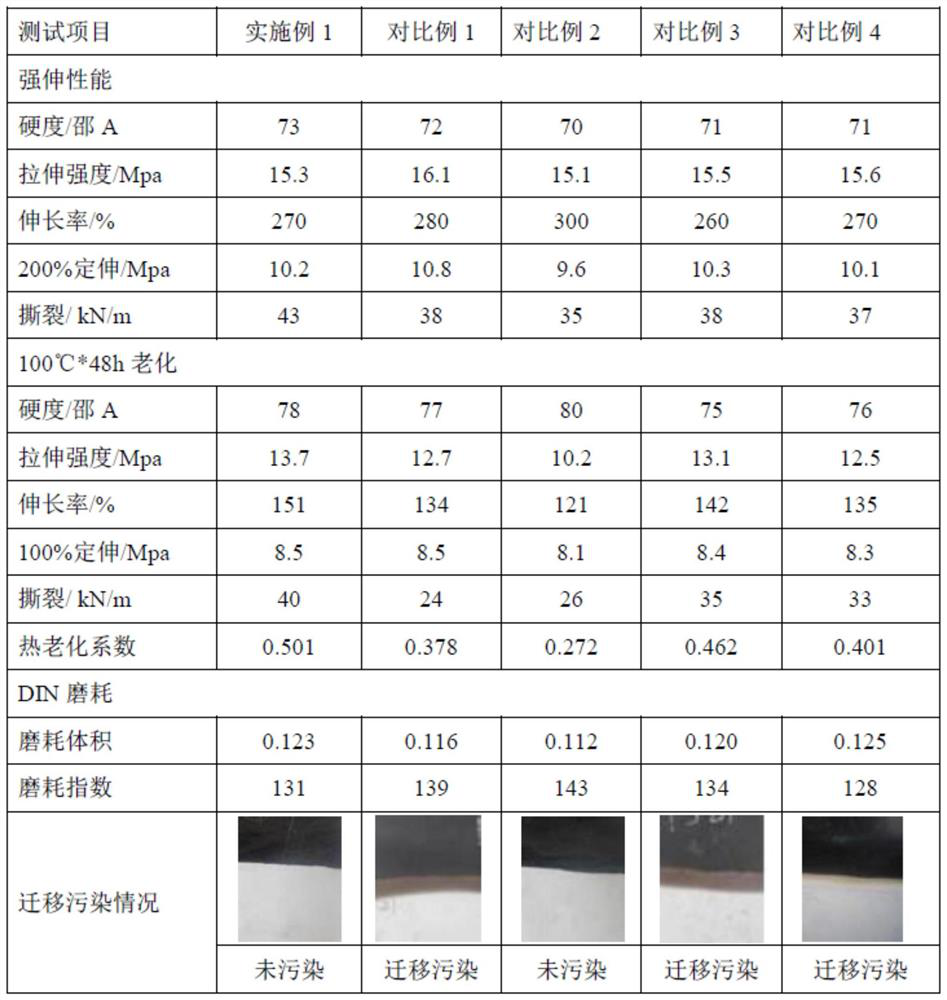

Non-polluting wear-resistant seam allowance rubber material and preparation method thereof

ActiveCN111732764AGood weather resistanceImprove the protective effectRubber materialPolymer science

The invention discloses a non-polluting wear-resistant seam allowance rubber material and a preparation method thereof. The rubber material comprises the following components in percentage by weight,20-50 phr of natural rubber, 15-35 phr of butadiene styrene rubber, 10-30 phr of butadiene rubber, 15-35 phr of ethylene propylene rubber, 50-80 phr of carbon black, 1-10 phr of a softening agent, 2.0-5.0 phr of zinc oxide, 1.0-3.0 phr of stearic acid, 1.0-4.0 phr of a triazine anti-aging agent, 0.5-3.0 phr of a phenolic antioxidant, 1.0-2.5 phr of sulfur, 0.3-1.0 phr of alkylphenol disulfide, 1.0-3.0 phr of an accelerant and 4-8 phr of other components. The non-polluting wear-resistant seam allowance rubber material solves the problem of migration pollution of a seam allowance part of a new generation of color tire on the premise of meeting the key performances of wear resistance, protection and the like of the seam allowance rubber material.

Owner:SAILUN GRP CO LTD

Transparent paste beautification sealer curing agent for tiles and preparation method thereof

InactiveCN110563928AMeet environmental protection requirementsImprove anti-yellowing effectWeather resistanceFirming agent

The invention relates to a transparent paste beautification sealer curing agent for tiles and a preparation method thereof. A component B of the curing agent adopts a cycloamine curing agent 1.3bis(aminomethyl)cyclohexane for modification reaction to reduce the number of contained active bonds and lower the reaction activity of the curing agent, thus reaching the effects of controlling the curingspeed and eliminating a matte surface on the surface of a cured product. Epoxy resin is used as a chain extender of the curing agent to improve the compatibility between the curing agent and resin, and at the same time, D400 polyetheramine, D2000 polyetheramine and T5000 polyetheramine are mixed with epoxy resin for modification under certain operation conditions, thus obtaining a raw material ofbeautification sealer curing agent for tiles with moderate viscosity, good weather resistance, good water resistance, fast curing speed, high glossiness and moderate rigidity and softness.

Owner:周林凡

Preparation equipment and method of ball-point pen wear-resistant metal bead

InactiveCN107900371AHigh shapePrecise screeningTransportation and packagingMetal-working apparatusWear resistantMetal powder

Preparation equipment of a ball-point pen wear-resistant metal bead comprises a plasma rotary electrode centrifugal atomizing device, and a spherical metal powder box is arranged on the lower portionof a conical head at the bottom of the plasma rotary electrode centrifugal atomizing device; the middle of the plasma rotary electrode centrifugal atomizing device is provided with a feed inlet for installing a rod material; a first round hole metal plate screen and a second round hole metal plate screen are arranged in the spherical metal powder box; an above-screen powder outlet pipe is arrangedat the position, on one side of the spherical metal powder box, on the upper side of the first round hole metal plate screen; a target powder outlet pipe is arranged at the position, on one side of the spherical metal powder box, on the upper side of the second round hole metal plate screen. A preparation method includes the steps that firstly, the pulverizing and atomizing atmosphere proportionof a rotary electrode atomizing device 1 is adjusted, and Ar / He / N2 ternary mixed gas is used; secondly, an electrode bar made of stainless steel or other metal materials is used for plasma rotary electrode atomizing, wherein the particle size of spherical metal powder is 0.55-1 mm; thirdly, lasers are used for punching the first round hole metal plate screen and the second round hole metal plate screen for screening the collected powder. The preparation equipment has the advantages of being simple in structure, high in productivity and low in cost.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com