On-line laser processing device used for railway steel rail surface toughening treatment

A laser processing and laser processing head technology, applied in the field of railway track surface strengthening and repair, can solve problems such as heavy weight, inability to appear martensite, increase laser processing procedures, etc., to extend the life cycle and reduce the number of replacements , the effect of prolonged wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

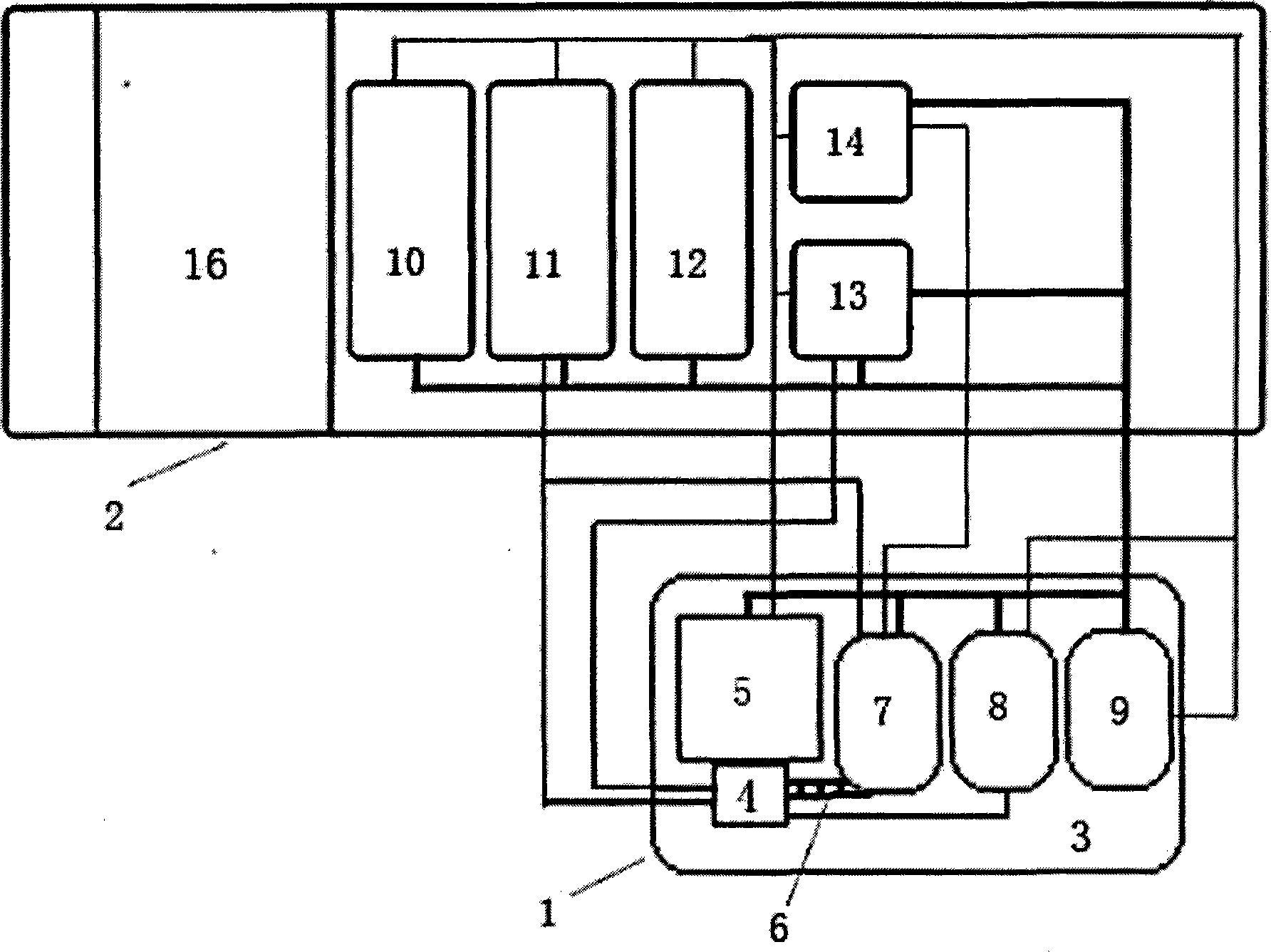

[0048] The laser processing equipment involved in the present invention consists of two parts: a laser processing vehicle and a power engineering vehicle.

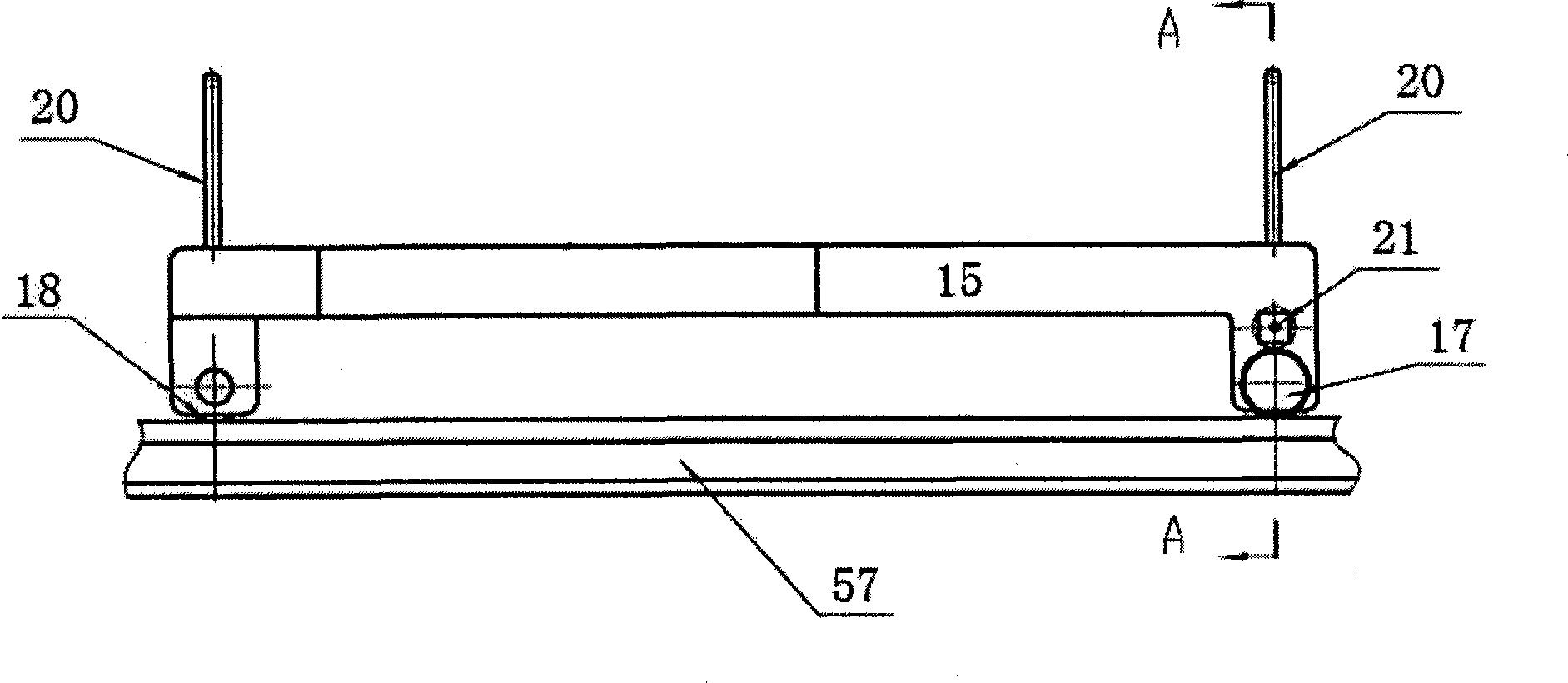

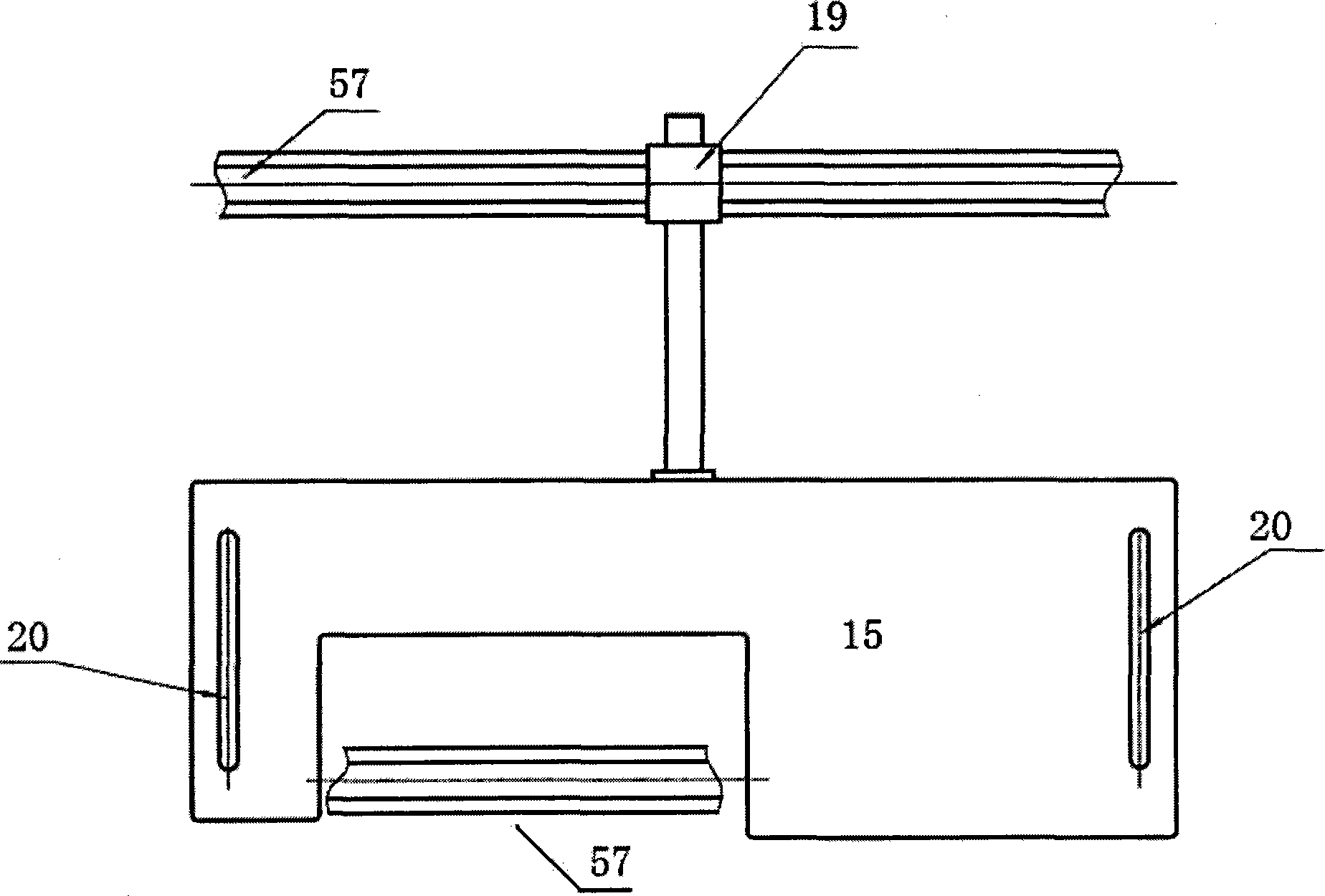

[0049] The laser used in the present invention may be a high-power semiconductor laser, a fiber laser, a diode-pumped solid-state laser or a lamp-pumped solid-state laser. When the laser uses a high-power semiconductor laser, it is best to install the laser on the laser processing vehicle. This is because the semiconductor laser is small in size and light in weight, and it can be directly installed on the laser processing vehicle without significantly increasing the weight of the processing vehicle. Reduce the distance between the laser and the laser processing head, reduce the length of the optical fiber or the complexity of the light guide system, reduce the energy loss of the laser beam during transmission, and improve the performance / price ratio of the equipment. When using other solid-state lasers, due to the relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com