Super wear-resistant novel two-dimensional composite material and preparation method thereof

A two-dimensional material and composite material technology, which is applied in the field of super wear-resistant new two-dimensional composite materials and their preparation, can solve the problems of poor wear resistance of the new two-dimensional composite materials, cannot meet wear resistance requirements, etc., and achieve excellent wear resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

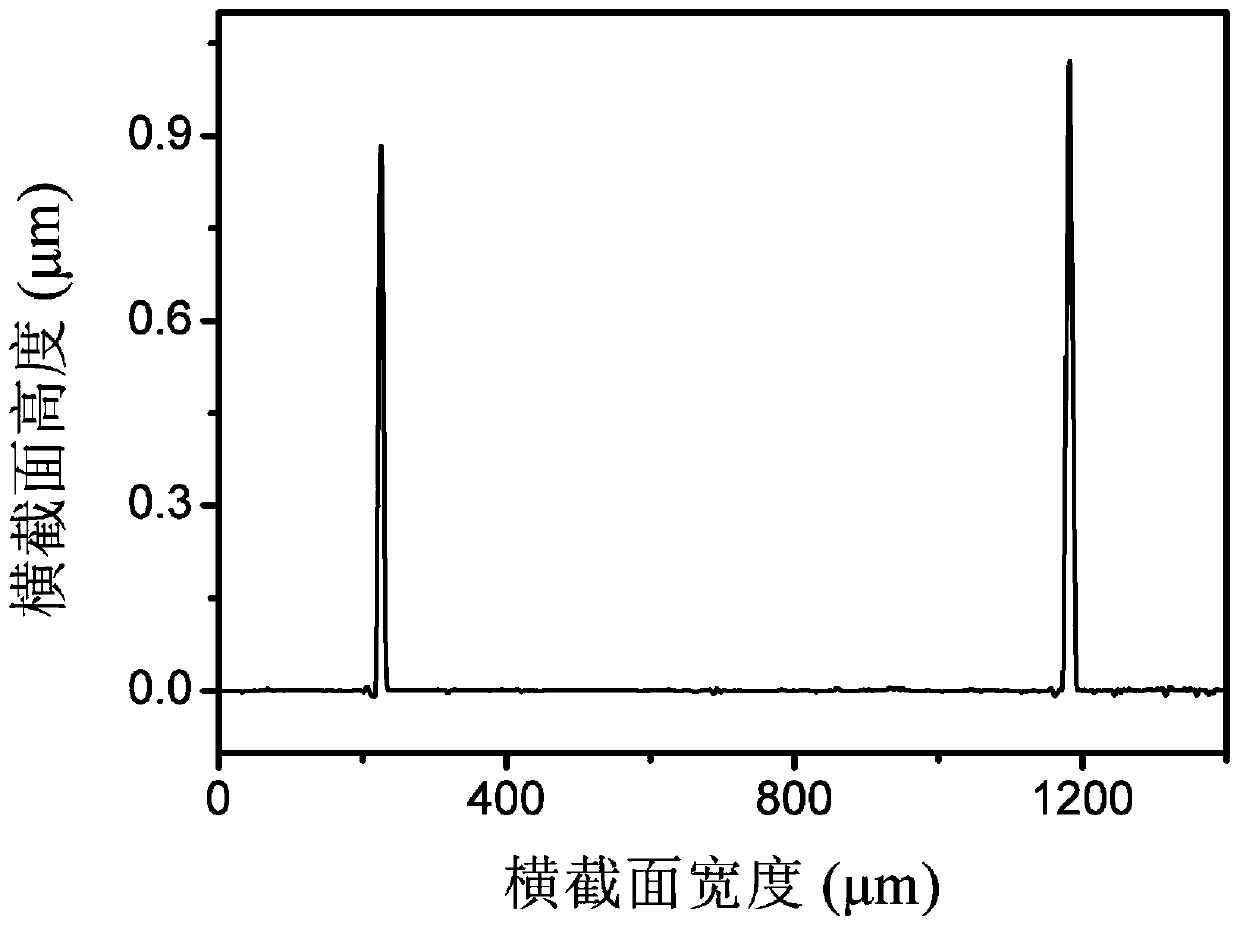

Embodiment 1

[0036] First, 30 mg of two-dimensional trititanium carbide (Ti 3 C 2 ) powder was evenly sprinkled on the surface of the silicon wafer, and then 30mg of nano-diamond powder (Shanghai Aladdin Biochemical Technology Co., Ltd., N140011) was evenly sprinkled on the two-dimensional Ti 3 C 2 Slowly add 0.2mL of absolute ethanol dropwise to the surface of the powdered silicon wafer until it is covered with two-dimensional Ti 3 C 2 powder and nano-diamond powder on the surface of a silicon wafer, and coated with a scraper so that the two powders and absolute ethanol are evenly mixed, placed in a room temperature environment, until the absolute ethanol volatilizes completely, and a new super wear-resistant two-dimensional composite material is obtained.

Embodiment 2

[0038] First, 30 mg of two-dimensional trititanium carbide (Ti 3 C 2 ) powder was evenly sprinkled on the surface of the silicon wafer, and then 30 mg of single-layer graphene powder (Shanghai Aladdin Biochemical Technology Co., Ltd., G139804) was evenly sprinkled on the two-dimensional Ti 3 C 2 Powder the surface of the silicon wafer, slowly drop 0.2mL of absolute ethanol to sprinkle the 2D Ti 3 C 2 Powder and graphene powder on the surface of silicon wafers, and use a scraper to mix the two powders and absolute ethanol evenly, place them at room temperature, and wait for the absolute alcohol to volatilize completely to obtain a new super wear-resistant two-dimensional composite material.

Embodiment 3

[0040] First place the silicon wafer gently on the bottom of the glass beaker, add 10mL of absolute ethanol to the glass beaker; then add 30mg of two-dimensional trititanium carbide (Ti 3 C 2 ) powder and 30 mg of nano-diamond powder were slowly added to a beaker filled with absolute ethanol; after the beaker was sealed, ultrasonically vibrated for 1 hour at room temperature (ultrasonic power was 200W, frequency was 40kHz), and then left to stand in room temperature environment For 24 hours, all the materials in the beaker were deposited on the surface of the silicon wafer to obtain a semi-finished product of a super wear-resistant two-dimensional composite material; gently clamp the semi-finished product of a new super wear-resistant two-dimensional composite material from the beaker with tweezers, and place it on the At room temperature, after the absolute ethanol volatilizes completely, a new super wear-resistant two-dimensional composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com