Low-temperature semi-quenched and wear-resistant steel with brinell hardness of 400 HB and production method thereof

A technology of Brinell hardness and wear-resistant steel, which is applied in the field of low-temperature semi-hardened wear-resistant steel and its production, and can solve problems such as waste, excessive energy consumption, alloys, and wear-resistant steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

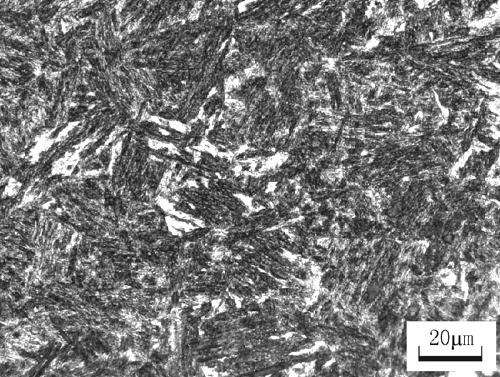

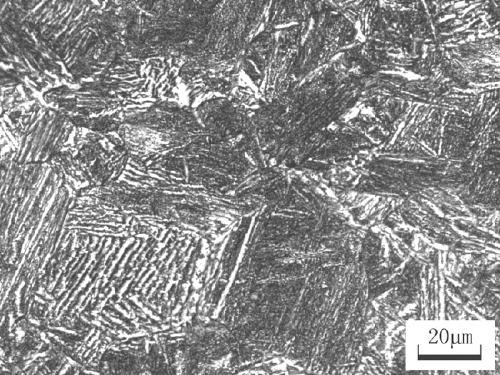

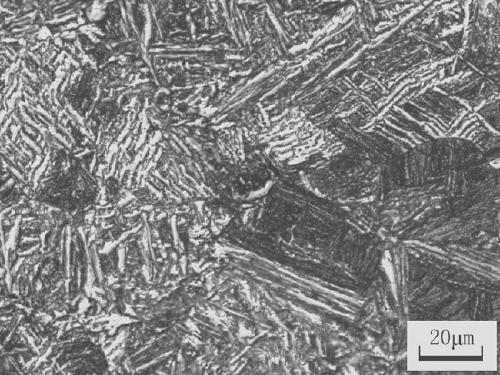

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below:

[0051] Table 1 is the value list of each embodiment of the present invention and comparative example;

[0052] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0053] Table 3 is a list of various embodiments of the present invention and comparative performance detection situations;

[0054] Table 4 is a table of residual stress conditions of various embodiments of the present invention and comparative examples.

[0055] Each embodiment of the present invention is produced according to the following production process:

[0056] 1) After conventional converter compound blowing and LHF furnace treatment, RH vacuum treatment is carried out, during which, 500-800g / ton steel is fed into Si-Ca wire;

[0057] 2) Heating the billet after casting, the heating temperature is controlled at 1200°C-1280°C, and the heating rate is controlled at 8-12min / cm;

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com