Preparation equipment and method of ball-point pen wear-resistant metal bead

A wear-resistant metal and ballpoint pen technology, which is applied in metal processing equipment, metal material coating technology, coating, etc., can solve the problems of production efficiency and investment relative cost difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

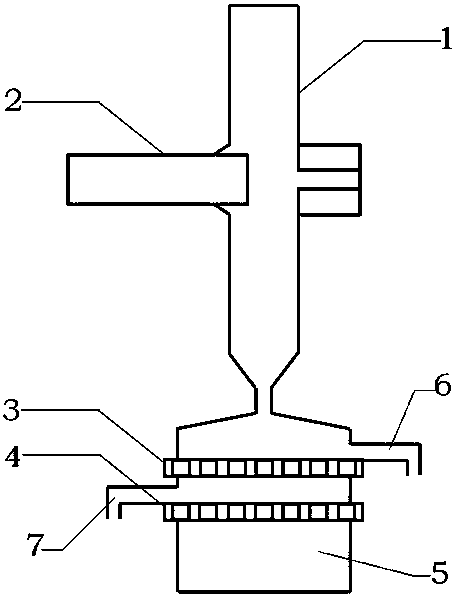

[0028] The method for preparing the wear-resistant metal ball of a ballpoint pen by utilizing the above-mentioned equipment comprises the following steps:

[0029] Step 1, adjust the proportion of the atomization atmosphere in the rotary electrode atomization device 1, using Ar / He / N 2 Ternary mixed gas, the He content is controlled at 50%; for stainless steel materials, N 2 The content of 10%, for other metal materials, N 2 It can be controlled at 18%; the rest of the atmosphere is Ar, and the total filling pressure is kept at 1bar;

[0030] Step 2, use the electrode rod 2 of 17-4PH steel for plasma rotary electrode atomization, adjust the rotation speed of the electrode rod 2 to 1000rpm, use a rod with a diameter of 50mm, and obtain a spherical metal powder with a main particle size of 1mm;

[0031] Step 3, use laser punching round hole metal plate sieve 1 3, round hole metal plate sieve 2 4 to sieve the collected powder; the hole diameter difference between round hole meta...

Embodiment 2

[0035] The method for preparing the wear-resistant metal ball of a ballpoint pen by utilizing the above-mentioned equipment comprises the following steps:

[0036] Step 1, adjust the proportion of the atomization atmosphere in the rotary electrode atomization device 1, using Ar / He / N 2 For ternary mixed gas, the content of He is controlled at 70%; for stainless steel, N 2 The content is 30%, for other metal materials, N 2 It can be controlled at 10%; the rest of the atmosphere is Ar, and the total filling pressure is kept at 3bar;

[0037] Step 2, use the electrode rod 2 of 304 steel for plasma rotary electrode atomization, adjust the rotation speed of the electrode rod 2 to 5000rpm, use a rod with a diameter of 50mm, and obtain a spherical metal powder with a main particle size of 0.55mm;

[0038] Step 3, use laser punching round hole metal sieve 1 3 and round hole metal sieve 2 4 to sieve the collected powder; the hole diameter difference between round hole metal sieve 1 3 ...

Embodiment 3

[0042] The method for preparing the wear-resistant metal ball of a ballpoint pen by utilizing the above-mentioned equipment comprises the following steps:

[0043] Step 1, adjust the proportion of the atomization atmosphere in the rotary electrode atomization device 1, using Ar / He / N 2 For ternary mixed gas, the content of He is controlled at 60%; for stainless steel, N 2 The content of 20%, for other metal materials, N 2 It can be controlled at 15%; the rest of the atmosphere is Ar, and the total filling pressure is kept at 2bar;

[0044] Step 2, use the electrode rod 2 of 316L steel for plasma rotary electrode atomization, adjust the rotation speed of the electrode rod 2 to 2500rpm, and use a rod with a diameter of 50mm, so that the main particle size range of the collected powder is concentrated at 0.85mm;

[0045] Step 3, use laser punching round hole metal plate sieve 1 3, round hole metal plate sieve 2 4 to sieve the collected powder; the hole diameter difference betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com