3D-printing metal powder material preparation method capable of reducing hollow powder

A 3D printing and metal powder technology, applied in the field of 3D printing, can solve the problems of low density of parts, warping of parts, low bonding strength of sintered area, etc., achieve high powder sphericity, reduce shrinkage cavity, and low oxygen content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

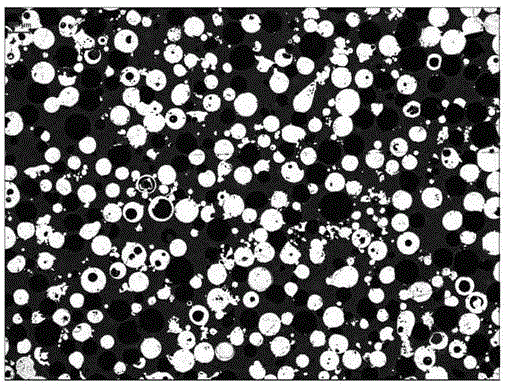

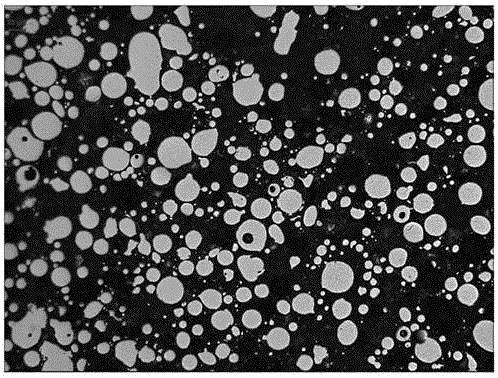

Image

Examples

preparation example Construction

[0017] A method for preparing a metal powder material for 3D printing for reducing hollow powder, comprising the following steps:

[0018] A. The raw material stainless steel or aluminum alloy is melted under the protection of slightly positive pressure nitrogen, and melted into stainless steel or aluminum alloy liquid;

[0019] B. Use nitrogen as the atomizing gas, control the atomization pressure to 1.5-2Mpa when aluminum alloy is used as raw material, and control the atomization pressure to 3-4Mpa when stainless steel is used as raw material, and carry out gas atomization on molten stainless steel or aluminum alloy liquid , the liquid is crushed and cooled into spherical or quasi-spherical particles of stainless steel or aluminum alloy;

[0020] C. The spherical or quasi-spherical particles obtained in the collecting step B are processed to obtain metal powder for 3D printing.

[0021] In the preparation method of the metal powder material for 3D printing used to reduce th...

Embodiment 1

[0024] Embodiment 1, a kind of preparation method for the 3D printing metal powder material that is used to reduce hollow powder, comprises the following steps:

[0025] A. The raw material stainless steel or aluminum alloy is melted under the protection of slightly positive pressure nitrogen, and melted into stainless steel or aluminum alloy liquid;

[0026] Specifically: the raw material stainless steel (316L stainless steel) is placed in a closed melting furnace body, the atomization chamber and the melting furnace body are evacuated and filled with nitrogen to form a slight positive pressure state, the power of the melting furnace body and the holding furnace is adjusted to 90kw, The holding time is 30 minutes, and the melting furnace body is heated to a preset temperature of 1650° C., so that the raw stainless steel in the melting furnace body melts into stainless steel liquid.

[0027] B. Nitrogen is used as the atomizing gas, the atomizing pressure is controlled to 3Mpa...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method for the 3D printing metal powder material that is used to reduce hollow powder, comprises the following steps:

[0031] A. The raw material stainless steel is smelted under the protection of slight positive pressure nitrogen, and smelted into stainless steel liquid;

[0032] Specifically: put the raw material stainless steel (304 stainless steel) in a closed smelting furnace, vacuumize the atomization chamber and smelting furnace and fill it with nitrogen to form a slight positive pressure state, adjust the power of the smelting furnace and the holding furnace to 80kw, The holding time is 50 minutes, and the melting furnace body is heated to a preset temperature of 1650° C., so that the raw stainless steel in the melting furnace body is melted into stainless steel liquid.

[0033] B. Nitrogen is used as the atomizing gas, and the atomizing pressure is controlled to be 3.5Mpa, and the molten stainless steel is gas-atomized, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com