Non-polluting wear-resistant seam allowance rubber material and preparation method thereof

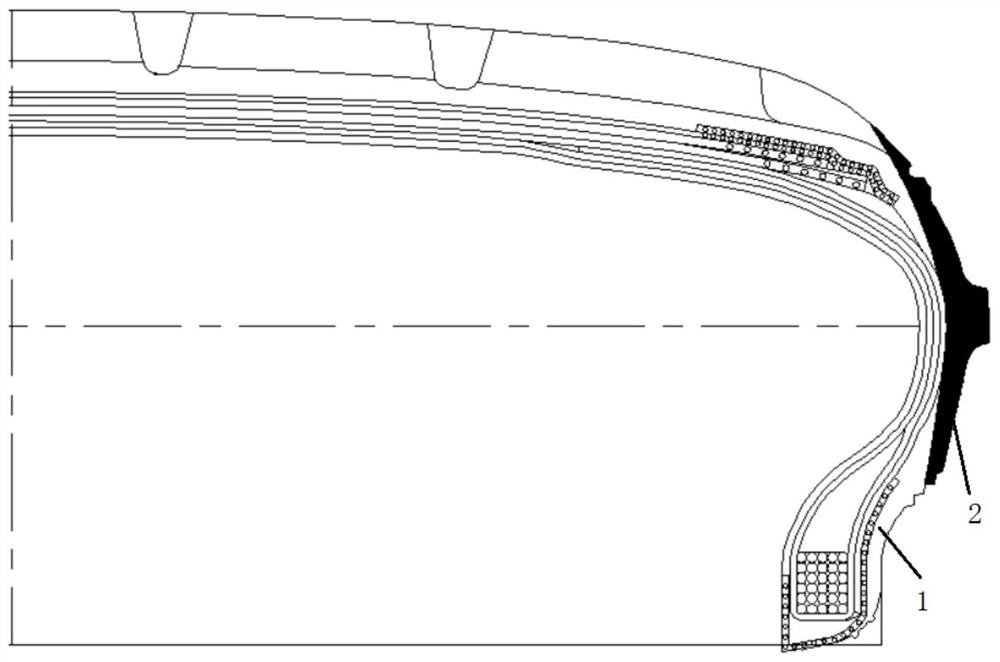

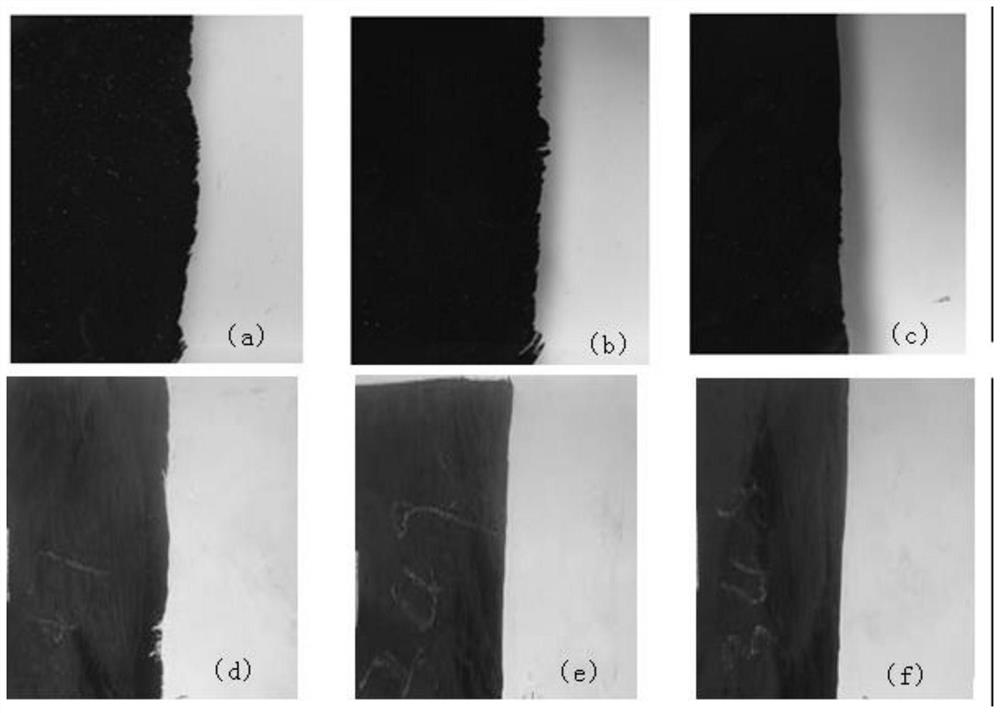

A non-polluting, wear-resistant rubber technology, which is applied in the field of automobile tire materials, can solve the problems of migration and pollution at the rim of colored tires, and achieve the effect of improving protection performance, excellent ozone resistance, and protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

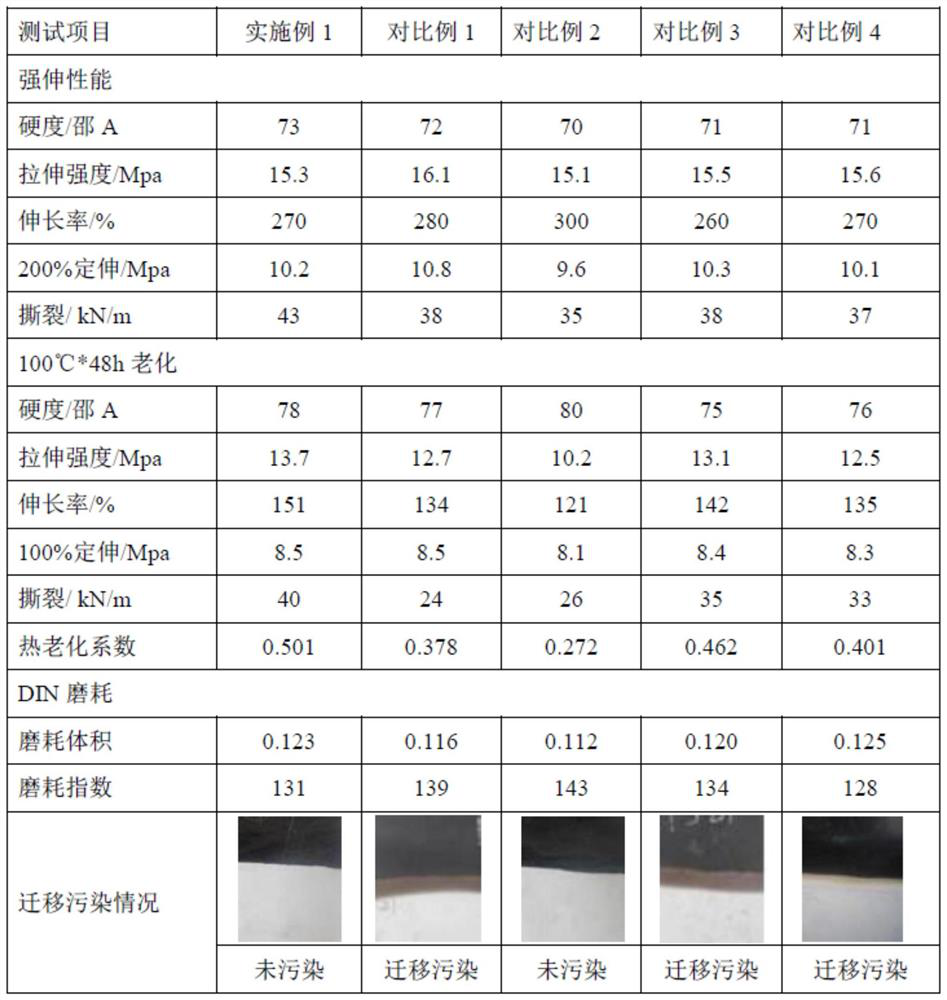

Embodiment 1

[0043] The non-polluting slit wear-resistant rubber compound of the present embodiment includes the following components in weight percentage:

[0044]

Embodiment 2

[0076] The non-polluting slit wear-resistant rubber compound of the present embodiment includes the following components in weight percentage:

[0077]

[0078]

[0079] The preparation method of the non-polluting slit wear-resistant rubber compound of the present embodiment comprises the following steps:

[0080] (1) Rubber pre-mixing: Mixing is carried out in the internal mixer, add raw rubber system, press the top bolt for 40 seconds, lift the weight, press the top bolt for 40 seconds, lift the weight, and press the top bolt for 40 seconds; the speed of the internal mixer is 30rpm ; 155 ℃ deglue, get pre-mixed rubber;

[0081] (2) One-stage mixing: mixing is carried out in an internal mixer, and the premixed rubber obtained in step (1), carbon black, zinc oxide, stearic acid, triazine antioxidant, phenolic antioxidant, sulfur , alkylphenol disulfide, accelerator and other components, press the top bolt for 40s, lift the weight, add softener, press the top bolt for 35...

Embodiment 3

[0086] The non-polluting slit wear-resistant rubber compound of the present embodiment includes the following components in weight percentage:

[0087]

[0088]

[0089] The preparation method of the non-polluting slit wear-resistant rubber compound of the present embodiment comprises the following steps:

[0090] (1) Rubber pre-mixing: Mixing is carried out in the internal mixer, add raw rubber system, press the top bolt for 35 seconds, lift the weight, press the top bolt for 35 seconds, lift the weight, press the top bolt for 35 seconds; the speed of the internal mixer is 40rpm ; 155 ℃ deglue, get pre-mixed rubber;

[0091] (2) One-stage mixing: mixing is carried out in an internal mixer, and the premixed rubber obtained in step (1), carbon black, zinc oxide, stearic acid, triazine antioxidant, phenolic antioxidant, sulfur , alkylphenol disulfide, accelerator and other components, press the top bolt for 35s, lift the weight, add softener, press the top bolt for 20s, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com