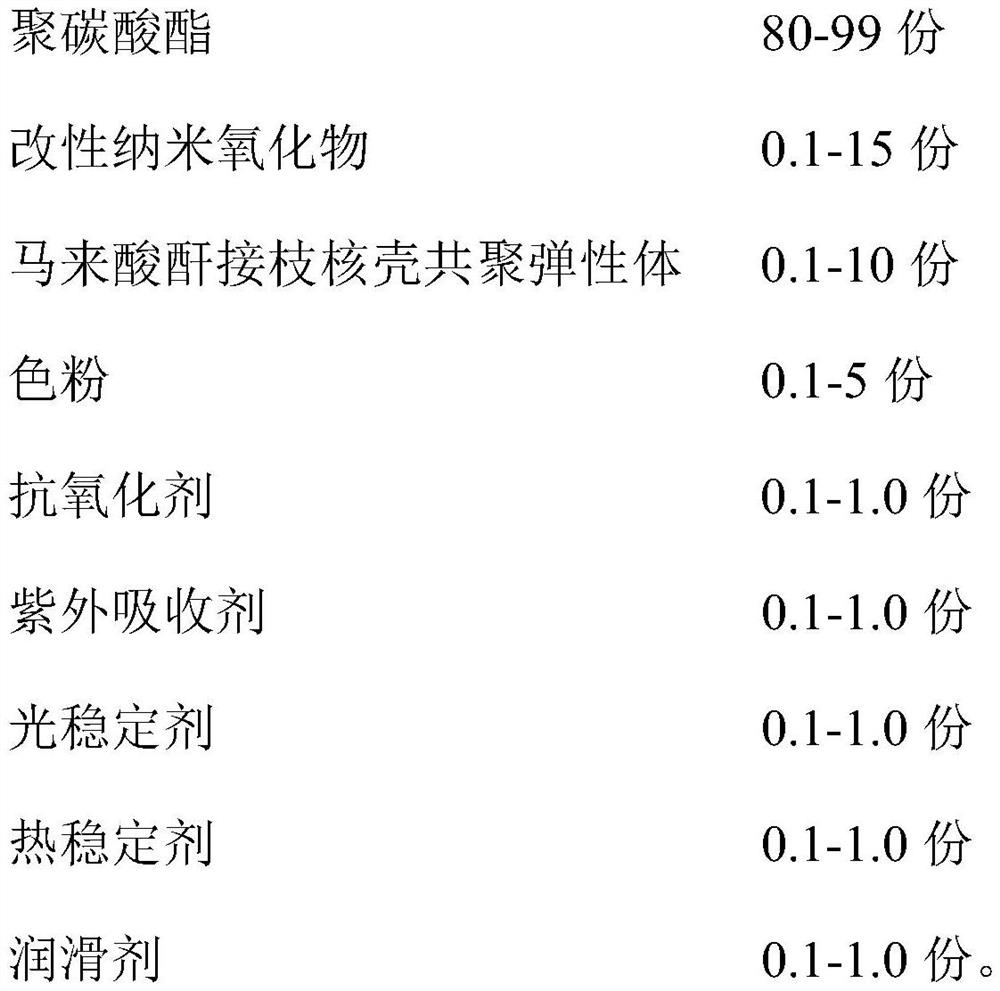

Polycarbonate material as well as preparation method and application thereof

A polycarbonate and hyperbranched polyester technology, applied in the field of polymer materials, can solve the problems of poor impact toughness of materials, and achieve the effects of improving high and low temperature impact toughness, improving gloss retention rate and increasing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

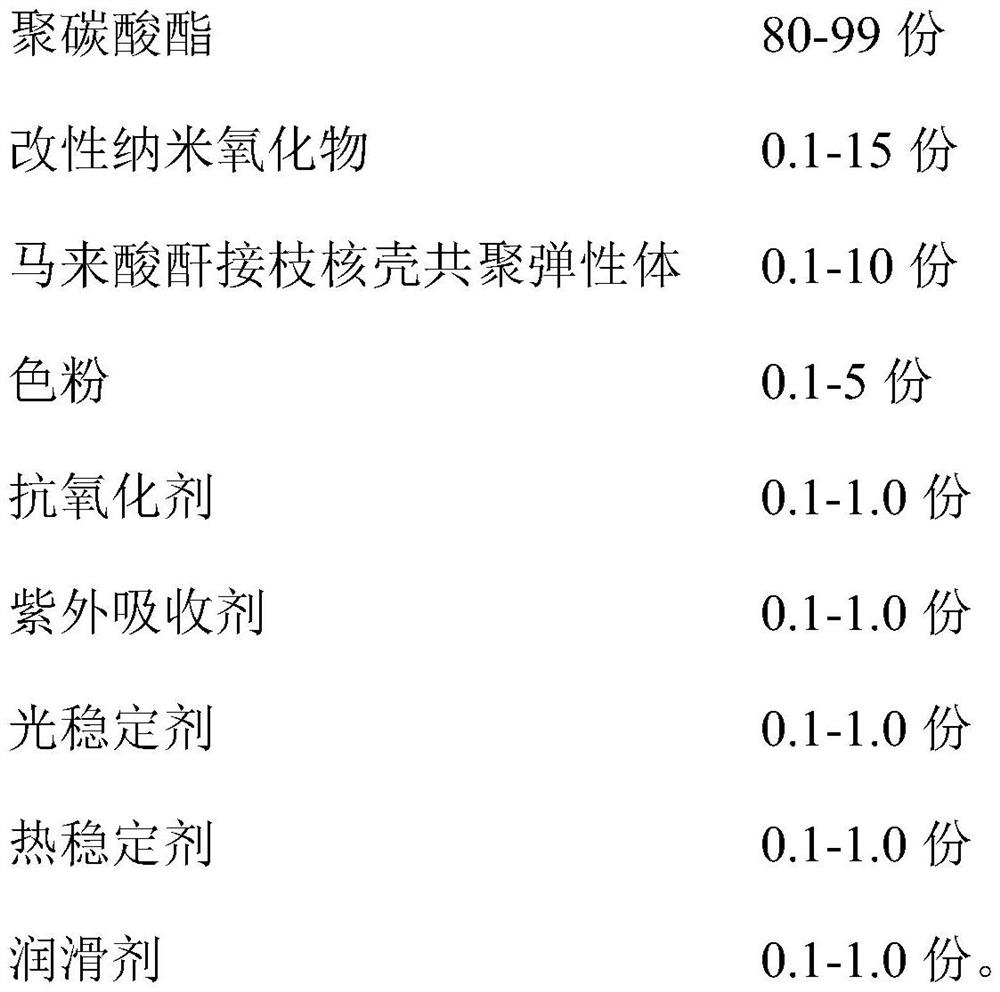

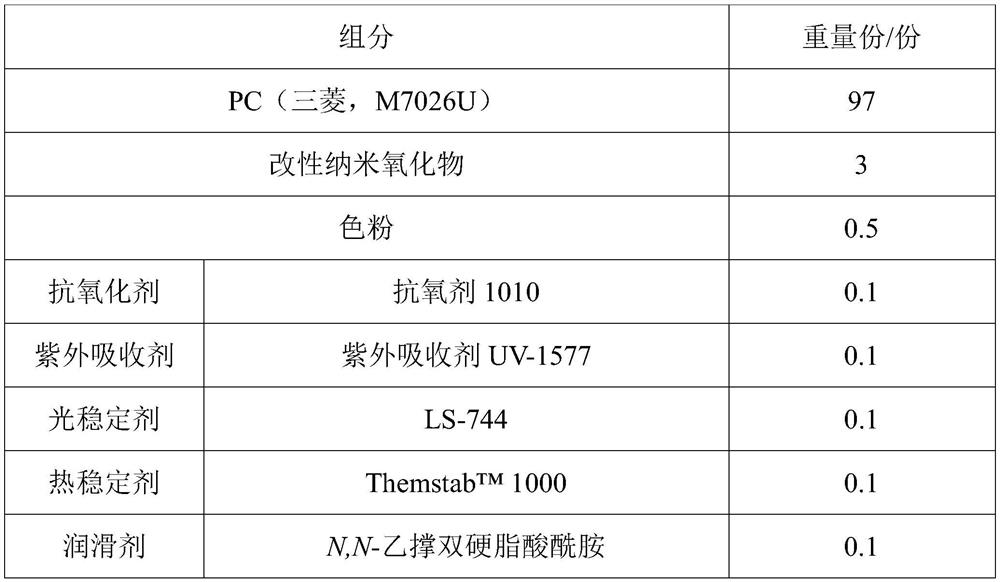

[0073] This embodiment provides a high-gloss black scratch-resistant polycarbonate material, which includes the following components by weight:

[0074]

[0075] The components in the above formula are uniformly mixed with a high-speed mixer for 8 minutes, and then the mixture is added to the twin-screw extruder for melt blending. The working parameters of the extruder are as follows: the temperature in the first zone is 250℃, and the temperature in the second zone is 260℃, the temperature in zone three is 270℃, zone four is 270℃, zone five is 270℃, zone six is 270℃, zone seven is 270℃, zone eight is 270℃, zone nine is 270 ℃, the temperature in the ten zones is 270℃, the temperature in the eleven zones is 265℃, the screw speed is 500 rpm, and the residence time is 2 min. After extrusion, it is cooled, dried, and pelletized to obtain the high-gloss black scratch-resistant polymer Carbonate material.

[0076] Wherein, the preparation method of the modified nano oxide includes the ...

Embodiment 2

[0082] This embodiment provides a high-gloss black scratch-resistant polycarbonate material, which includes the following components by weight:

[0083] Component Weight parts / parts PC (Mitsubishi, M7026U)99 Modified nano oxide1 Toner 0.5

[0084] The components in the above formula are uniformly mixed with a high-speed mixer for 10 minutes, and then the mixture is added to the twin-screw extruder for melt blending. The working parameters of the extruder are as follows: the temperature in the first zone is 230℃, and the temperature in the second zone is 240℃, the temperature in zone three is 250℃, zone four is 250℃, zone five is 250℃, zone six is 250℃, zone seven is 250℃, zone eight is 250℃, zone nine is 250 ℃, temperature in ten zones is 250℃, temperature in eleven zones is 245℃, screw speed is 350 rpm, residence time is 3 min, cooling, drying and pelletizing after extrusion to obtain the high-gloss black scratch-resistant polycarbonate Ester material.

[0085] Wherein, t...

Embodiment 3

[0091] This embodiment provides a high-gloss black scratch-resistant polycarbonate material, which includes the following components by weight:

[0092]

[0093] The components in the above formula are uniformly mixed with a high-speed mixer for 5 minutes, and then the mixture is added to the twin-screw extruder for melt blending. The working parameters of the extruder are as follows: the temperature in the first zone is 270℃, and the temperature in the second zone is 280℃, the temperature in zone three is 290℃, zone four is 290℃, zone five is 290℃, zone six is 290℃, zone seven is 290℃, zone eight is 290℃, zone nine is 290 ℃, the temperature in the ten zones is 290℃, the temperature in the eleven zones is 285℃, the screw speed is 850 revolutions / min, the residence time is 1 min, cooling, drying, and pelletizing after extrusion to obtain the high-gloss black scratch-resistant polycarbonate Ester material.

[0094] Wherein, the preparation method of the modified nano oxide include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com