Transparent gasoline resistant PMMA alloy material and preparation method thereof

An alloy material and gasoline-resistant technology, which is applied in the field of transparent gasoline-resistant PMMA alloy materials and its preparation, can solve the problems of low elongation, fragility, and cracking of ordinary PMMA resins, and achieve the best effect of improving gloss retention Effect

Inactive Publication Date: 2019-10-22

广东奇德新材料股份有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, ordinary PMMA resins are easy to crack and brittle due to their low elongation, which limits their further applications.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 6

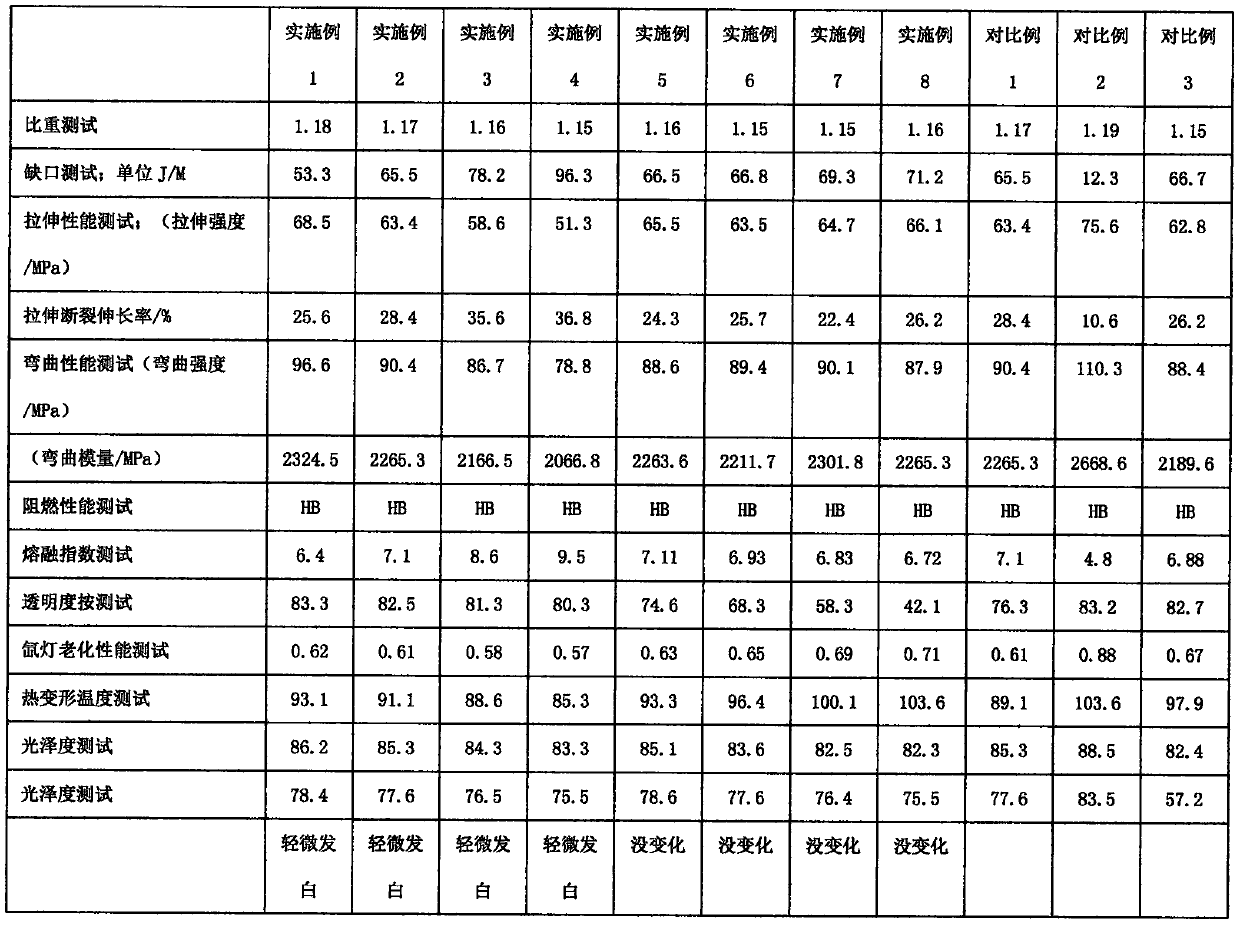

[0054] It can be seen from Example 6 and Comparative Example 1 / 2 / 3 that the addition of compatibilizer can effectively improve the compatibility of PMMA, SAN-coated cross-linked acrylic rubber, and PA, and improve the mechanical properties and transparency of the material.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a transparent gasoline-resistant PMMA alloy material and a preparation method thereof, which are characterized by comprising the following components in percentage by weight: 43.3 to 75.3 percent of polymethyl methacrylate, 15 to 30 percent of SAN-coated crosslinked acrylic rubber, 3 to 5 percent of styrene-anhydrous maleic anhydride polymer, 5 to 30 percent of polyamide, 0.2 percent of phenolic antioxidant, 0.2 percent of phosphate antioxidant, 0.1 percent of thioester antioxidant, 0.3 percent of benzotriazole ultraviolet absorber, 0.6 percent of hindered amine light stabilizer and 0.3 percent of pentaerythritol tetrastearate. The transparent gasoline-resistant PMMA alloy material and the preparation method thereof adopt SAN-coated acrylic rubber to toughen PMMA, the acrylic rubber has excellent weather resistance, and the compatibility of the acrylic rubber and PMMA can be improved by adopting SAN coating.

Description

technical field [0001] The invention belongs to the technical field of alloy materials, in particular to a transparent gasoline-resistant PMMA alloy material and a preparation method thereof. Background technique [0002] Polymethyl methacrylate (PMMA, commonly known as plexiglass, acrylic or acrylic), has crystal-like transparency, with a light transmittance of over 92%, and has a good color development effect when dyed with dyes. In addition, PMMA has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance. PMMA is widely used in aviation, automobile, electronics, medical, chemical, building materials, sanitary ware and advertising signs and other industries. [0003] However, the common PMMA resin is easy to crack and brittle due to its low extensibility, which limits its further application. Contents of the invention [0004] Aiming at the problems existing in the prior art, the object of the present invention is t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L33/12C08L51/04C08L35/06C08L77/02C08K5/134C08K5/526C08K5/103

CPCC08L33/12C08L2201/10C08L2205/035C08L51/04C08L35/06C08L77/02C08K5/1345C08K5/526C08K5/103

Inventor 李小辉饶德生廖登雄

Owner 广东奇德新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com