Cold-resistant acrylic emulsion leather auxiliary agent and preparation method thereof

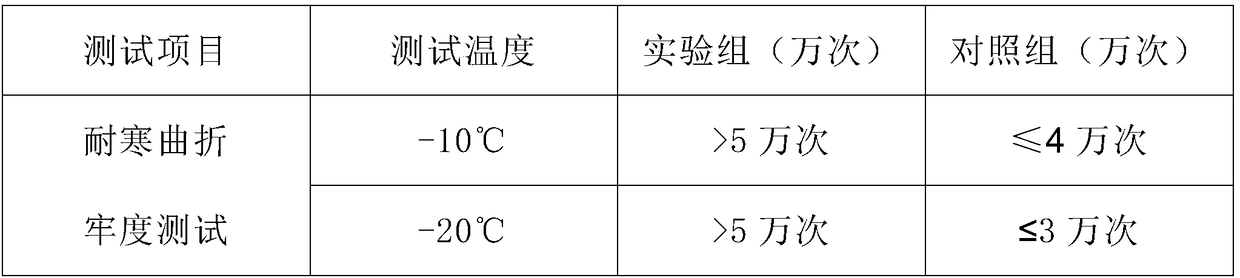

An acrylic emulsion and leather technology, which is applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc. To solve problems such as twists and turns, to achieve the effect of improving gloss, good cold resistance, twists and turns, and excellent hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of cold-resistant acrylic emulsion leather auxiliary agent, the components of the leather auxiliary agent and the parts by weight of each component are: 1000 parts of butyl acrylate, 1 part of isooctyl acrylate, 1 part of methyl methacrylate, ethyl acrylate 120 parts, 2400 parts of water, 20 parts of ammonia water, 20 parts of lauryl sulfate, 1 part of preservative, 0.1 part of persulfate, 0.1 part of sodium hydrosulfite, 0.1 part of tert-butyl hydroperoxide, 20 parts of zinc oxide. Zinc oxide is nanoscale. Preservatives are commonly used preservatives, for example: kathon LX150 and the like.

Embodiment 2

[0028] A cold-resistant acrylic emulsion leather auxiliary, the components of the leather auxiliary and the parts by weight of each component are: 1300 parts of butyl acrylate, 150 parts of isooctyl acrylate, 1 part of acrylic acid, 50 parts of ethyl acrylate, water 2800 parts, 30 parts of sodium hydroxide solution, 30 parts of sodium dodecylbenzenesulfonate, 10 parts of preservatives, 5 parts of azobisisobutyronitrile, 2 parts of sodium hydroxide, 2 parts of tert-butyl hydroperoxide, oxidation 30 parts of zinc.

Embodiment 3

[0030] A cold-resistant acrylic emulsion leather auxiliary agent, the components of the leather auxiliary agent and the parts by weight of each component are: 1500 parts of butyl acrylate, 150 parts of methyl methacrylate, 50 parts of acrylic acid, 10 parts of ethyl acrylate, 3500 parts of water, 50 parts of ammonia water, 60 parts of lauryl sulfate, 25 parts of preservatives, 10 parts of persulfate, 0.1-10 parts of sodium hydrosulfite, 8 parts of tert-butyl hydroperoxide, and 35 parts of zinc oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com