A kind of leather finishing agent and preparation method thereof

A leather finishing agent and monomer technology, which is used in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, coating, etc., can solve the problem of limiting the wide application of leather finishing agent, and achieve a soft and supple hand. properties and water resistance, and the effect of improving flexibility and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

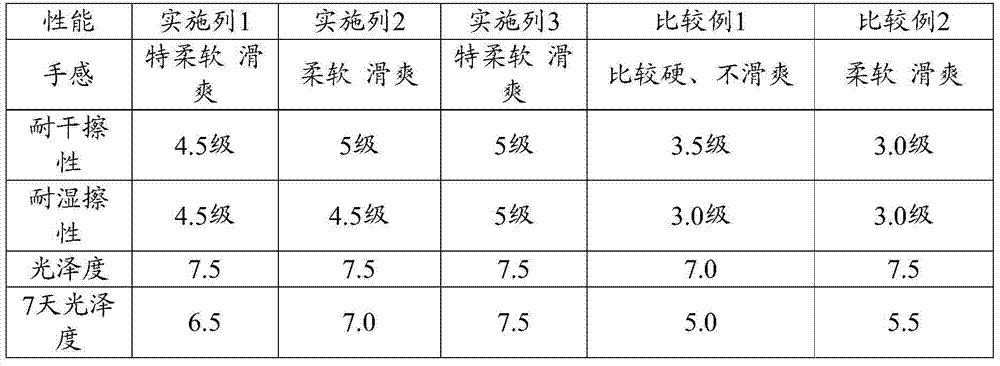

Examples

preparation example Construction

[0039] The present invention has no special limitation on the preparation method of the acrylate monomer, and the three substances in butyl acrylate, ethyl acrylate, styrene and acrylonitrile are mixed; or butyl acrylate, ethyl acrylate, styrene Ethylene and acrylonitrile can be mixed. In an embodiment of the present invention, the mixing may be performed under stirring. In an embodiment of the present invention, the mixing time may be 8 minutes to 12 minutes.

[0040] In an embodiment of the present invention, based on the parts by weight of the γ-glycidyl etheroxypropyl trimethoxysilane, the parts by weight of the persulfate can be 0.1 part to 1 part; in other In an embodiment, the weight part of the persulfate may be 0.5-0.8 parts. In an embodiment of the present invention, the persulfate may be selected from one or more of ammonium persulfate, potassium persulfate and sodium persulfate. In a preferred embodiment of the present invention, the persulfate is a persulfate s...

Embodiment 1

[0079] Add 550g of deionized water to the reaction kettle, add 100g of casein to the reaction kettle under stirring conditions and heat up to 75°C, stir for 1 hour to fully expand the casein to obtain a casein solution; Next, in described casein solution, add the triethanolamine of 20g and carry out the hydrolysis reaction of 2 hours, obtain hydrolyzed casein solution;

[0080] Adjust the temperature of the water bath to 75°C, add 5g of γ-glycidyloxypropyltrimethoxysilane to the hydrolyzed casein solution for 2 hours of heat preservation reaction, and obtain the modified casein solution;

[0081] The butyl acrylate of 22.5g, the ethyl acrylate of 15g and the mixture of the styrene of 7.5g are formed as acrylate monomer, under the condition of stirring, join in the reactor, add in the reactor by 0.8g Ammonium persulfate aqueous solution composed of ammonium persulfate and 25g deionized water, sodium bisulfite aqueous solution composed of 0.5g sodium bisulfite and 25g deionized ...

Embodiment 2

[0087] Add 730g of deionized water to the reaction kettle, add 130g of casein to the reaction kettle under stirring conditions and heat up to 75°C, stir for 1 hour to fully expand the casein to obtain a casein solution; Next, in described casein solution, add the triethanolamine of 26g and carry out the hydrolysis reaction of 2 hours, obtain hydrolyzed casein solution;

[0088] Adjust the temperature of the water bath to 75°C, add 7g of γ-glycidyloxypropyltrimethoxysilane to the above hydrolyzed casein solution for 2 hours of heat preservation reaction, and obtain the modified casein solution;

[0089] The mixture that the butyl acrylate of 20g, the acrylonitrile of 25g and the styrene of 20g are formed as acrylate monomer, under the condition of stirring, join in the reaction kettle, add the ammonium persulfate by 1g in the reaction kettle And the ammonium persulfate aqueous solution that 25g deionized water forms, the sodium bisulfite aqueous solution that is made up of 0.8g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com