Copper base particle reinforced friction material

A friction material and particle technology, applied in friction linings, mechanical equipment, etc., to achieve the effect of saving manufacturing costs, being environmentally friendly, and shortening sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

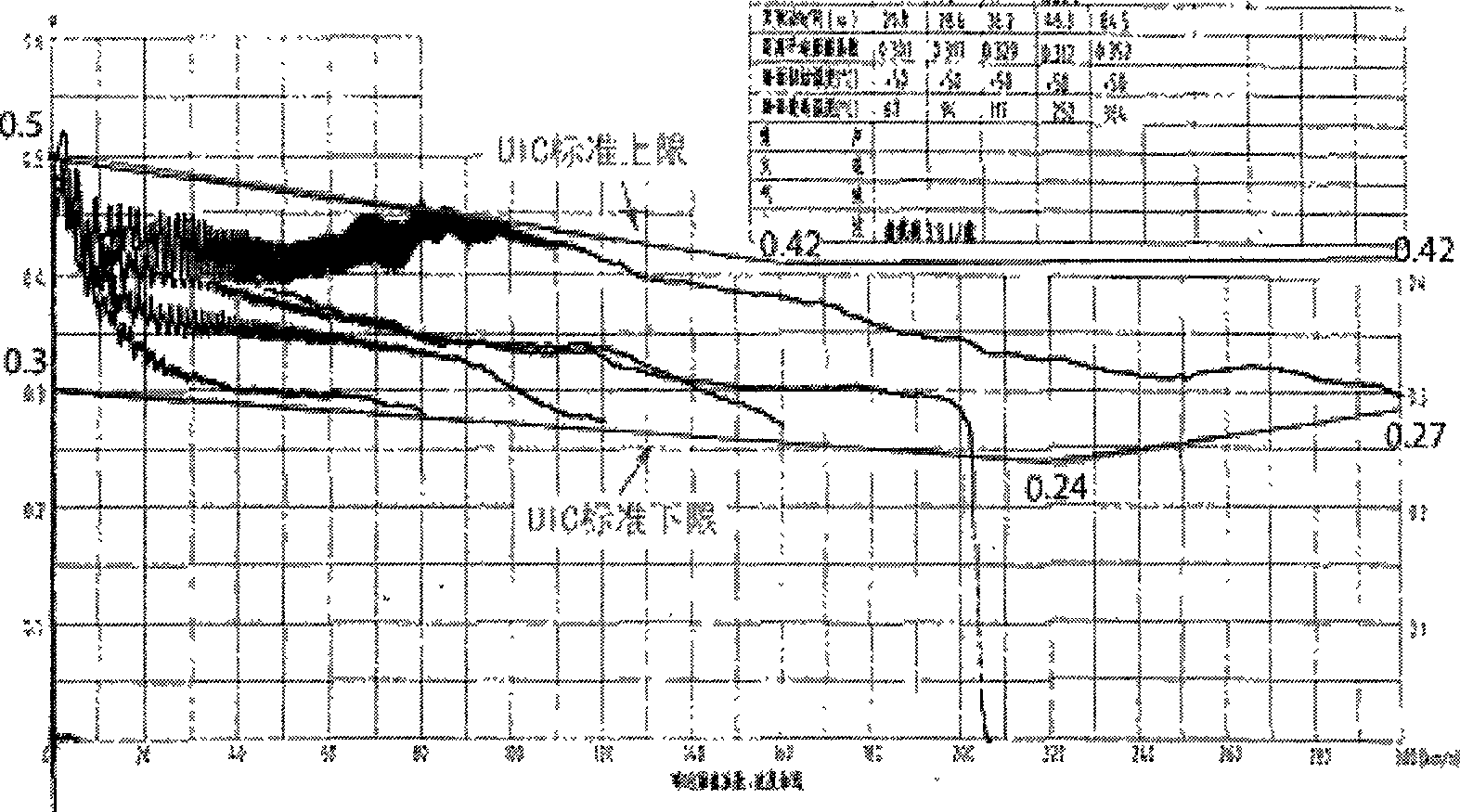

Image

Examples

Embodiment 1

[0019] Copper-based particle reinforced friction material, the weight percentage of each component is as follows: copper powder 54%, tin powder 6%, aluminum powder 3%, iron powder 12%, Al 2 o 3 6%, SiO 2 9%, graphite 10%.

[0020] To manufacture a brake block from the above friction material, firstly weigh the above raw materials in proportion and mix them, add 0.2% kerosene by weight of the mixed powder, and mix until uniform. Put the mixed powder with suitable weight into the mold, press it under the pressure of 500MPa for 5-10 seconds, and take it out to become a cold pressed blank. Put the cold-pressed blank into the hot-pressing mold, start the vacuum system, when the vacuum reaches 70mmHg, apply a pressure of 3MPa to the blank, and at the same time, start the heating current, when the temperature of the blank reaches 800°C, apply a pressure of 50MPa to the blank, and keep it warm for 2 minutes , with the furnace cooling to 100 ℃ out of the furnace, made of brake blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com