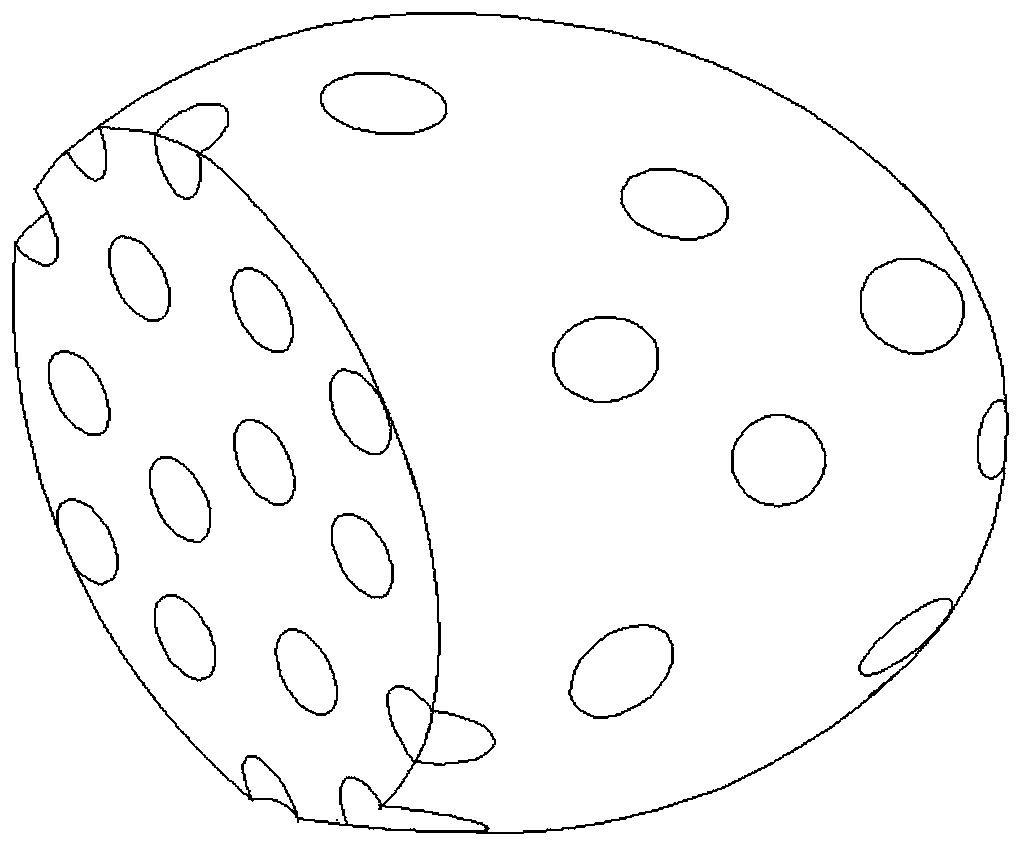

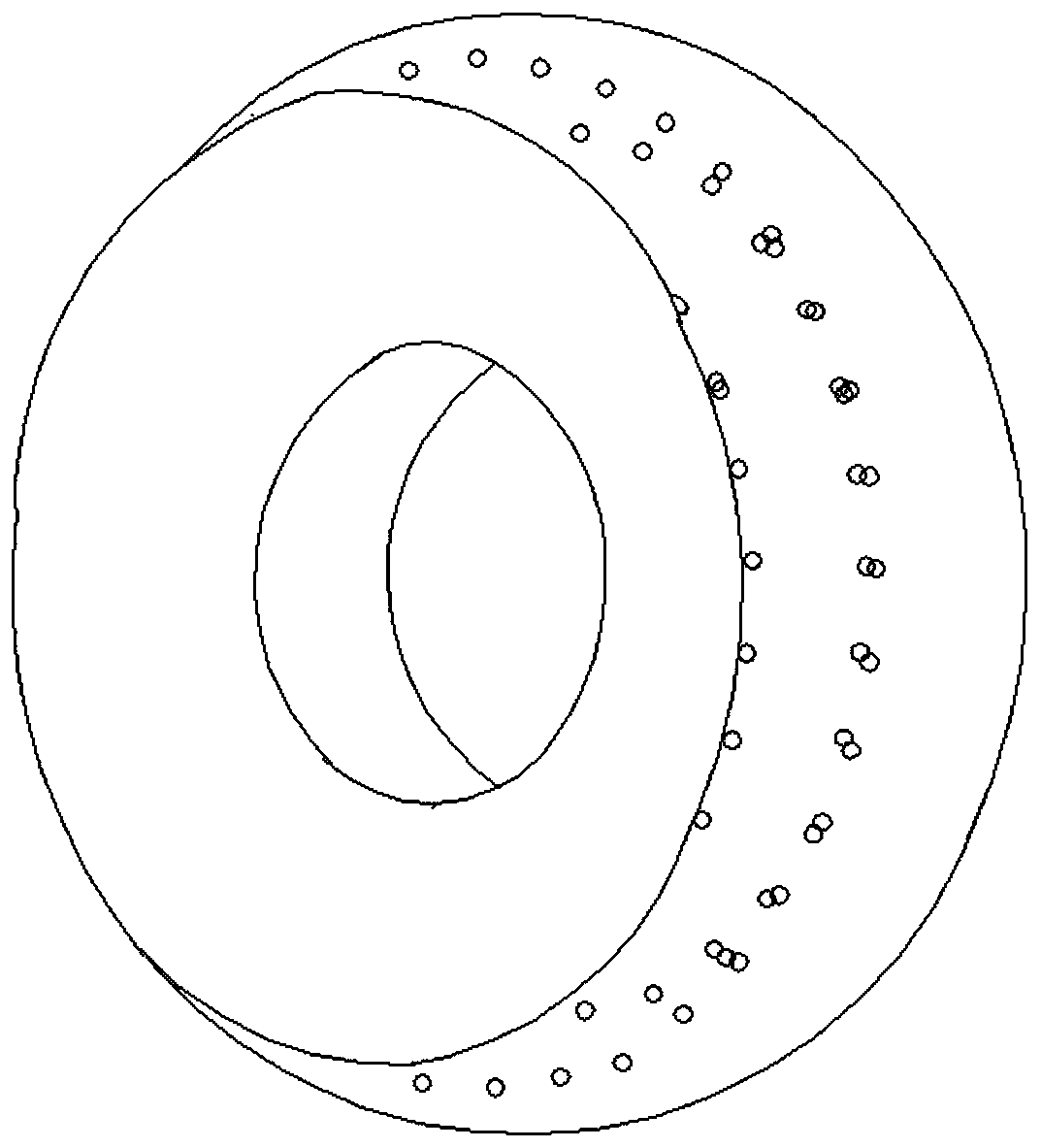

Ceramic preform, preparation method thereof, ceramic wear-resistant structure and wear-resistant part

A technology of prefabricated body and wear-resistant parts is applied in the field of composite wear-resistant materials, which can solve the problems of inability to prepare to meet the wear-resistant requirements of special parts, and the degree of wear and strength are not equal, so as to improve wear-resistant toughness, not easily damaged or peeled off. , good wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation process of the ceramic preform of the present embodiment is:

[0035] S1, a certain amount of photoinitiator TPO (2,4,6-trimethylbenzoyl-diphenylphosphine oxide) is added in the dipropylene glycol acrylate in the darkroom, wherein, acrylic resin and photoinitiator The weight ratio is 70:0.2, fully stirred for about 20-30 minutes to completely dissolve the photoinitiator, and obtain a uniform and stable photocurable resin system;

[0036] S2, 9 parts by weight of dispersant ammonium polyacrylate, 1 part by weight of auxiliary agent (the weight ratio of leveling agent, defoamer and polymerization inhibitor is 1:1:1), 10 parts by weight of zirconia powder and 25 parts by weight Alumina powder is mixed with 55 parts by weight of a uniform and stable photocurable resin system, and then placed in a stirring mill or a ball mill for uniform mixing to obtain a photocurable 3D printing ceramic slurry with high solid content and low viscosity. Among them, Al 2 o3...

Embodiment 2

[0045] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0046] The preparation process of the ceramic preform of the present embodiment is:

[0047] S1, a certain amount of photoinitiator 1173 (2-hydroxyl-2-methyl-1-phenyl-1-acetone) is added to tripropylene glycol diacrylate in a dark room, wherein the acrylic resin and photoinitiator The weight ratio is 95:5, fully stir for about 20-30 minutes to completely dissolve the photoinitiator, and obtain a uniform and stable photocurable resin system;

[0048] S2, 10 parts by weight of dispersant triethyl phosphate, 1 part by weight of auxiliary agent (the weight ratio of leveling agent, defoamer and polymerization inhibitor is 1:1:2), 9 parts by weight of zirconia powder and 45 parts by weight Mix 35 parts by weight of alumina powder with 35 parts by weight of a uniform and stable photocurable resi...

Embodiment 3

[0057] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0058] The preparation process of the ceramic preform of the present embodiment is:

[0059] S1. Add a certain amount of photoinitiator 819 [bis(2,4,6-trimethylbenzoyl) phenylphosphorus oxide] to bisphenol A epoxy acrylate in a dark room, wherein acrylic resin and light The weight ratio of the initiator is 80:2, fully stir for about 20-30 minutes to completely dissolve the photoinitiator, and obtain a uniform and stable photocurable resin system;

[0060] S2, 1 part by weight of dispersant castor oil, 0.1 part by weight of auxiliary agent (the weight ratio of leveling agent, defoamer and polymerization inhibitor is 1:1:1), 6 parts by weight of zirconia powder and 25 parts by weight of oxidation The aluminum powder is mixed with 35 parts by weight of a uniform and stable photocurable resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com