Machining method for spherical surface roller pin free of edge angles

A processing method and needle rolling technology, which is applied in metal processing equipment, manufacturing tools, surface polishing machine tools, etc., can solve the problems of small roughness, needle roller corners, etc., reduce heat generation, reduce working noise, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through specific examples; but the present invention is not limited to these examples.

[0026] All equipment and materials used in the following examples are commercially available. The operation process of centerless grinder and drum is conventional process. HRC hardness is obtained by Rockwell hardness tester.

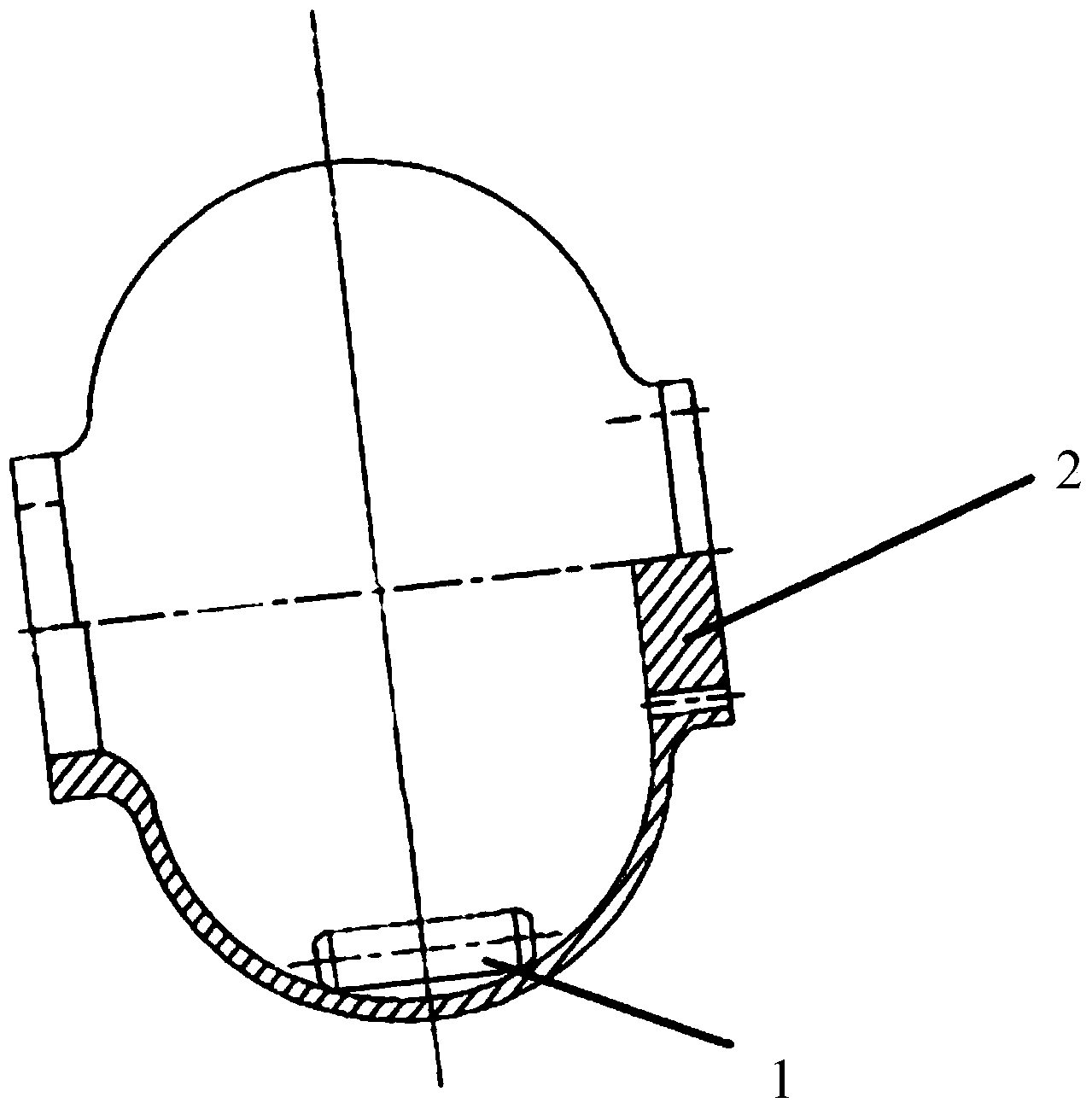

[0027] Such as figure 1 Shown: a schematic diagram of the processing of the needle roller 1 in the drum 2.

[0028] The non-angular spherical needle roller processing method of the present invention comprises the following steps: A, rolling and polishing: select GCr15 steel to form a rolling needle blank after cutting, and then use a barrel polishing machine to roll and polish the two ends of the needle roller It is a spherical surface, wherein the barrel polisher can process 200-280 kg of needles per batch, the speed of the barrel polisher is 300-350 rpm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com