Lifting tool for mounting large-size machine tools

A technology for machine tool installation and spreader, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of easily scratching the surface of the object to be lifted, poor flexibility of the spreader, and inconvenient use, etc. Simple, easy-to-adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

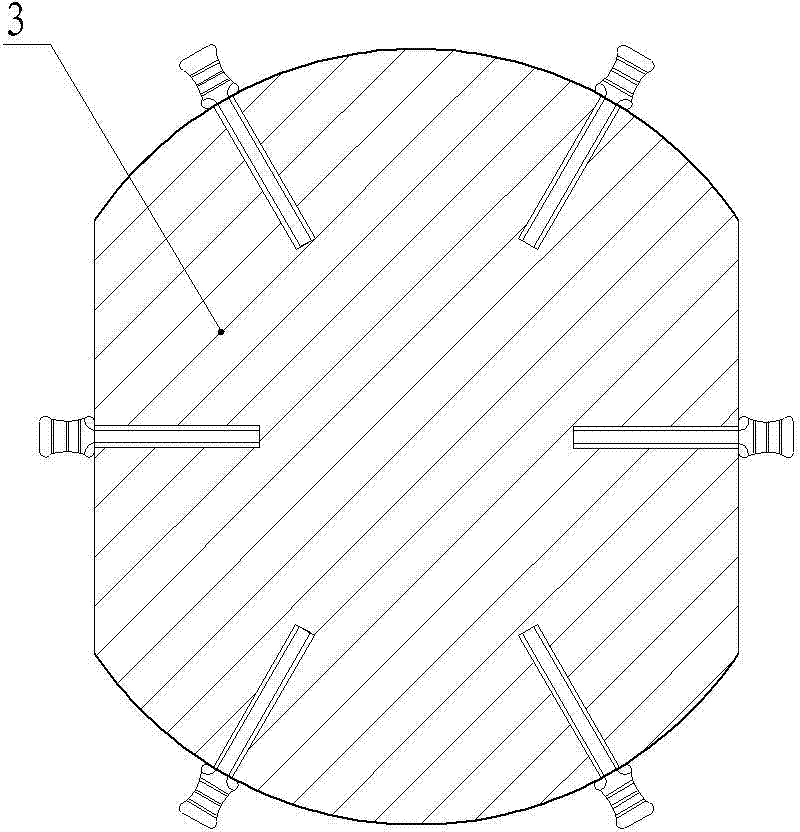

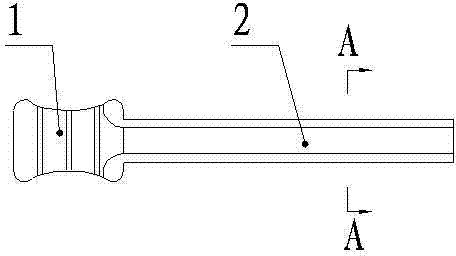

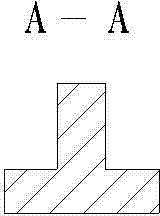

[0019] figure 1 with figure 2 The large-scale machine tool installation sling includes a lifting part 1 used to connect with the lifting wire rope and an insertion part 2 inserted into the lifting object groove or hole; the lifting part 1 and the insertion part 2 are the same whole rod body; the insertion part 2 The cross-sectional shape is designed according to the cross-sectional shape of the slot or hole in the lifting object. In order to facilitate positioning, the cross-section of the lifting part 1 is larger than that of the insertion part 2; the lifting part 2 is provided with three ring grooves for the positioning of the lifting wire. Preferably, the lifting part 1 is a revolving body with a recess, and the ring groove in the middle is arranged at the lowest point of the recess. This embodiment is used for hoisting the machine tool workbench 3 with T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com