Silicone rubber with permanent hydrophilic property on surface, preparing method and use thereof

A silicone rubber and hydrophilic technology, applied in optics, optical components, instruments, etc., can solve the problems of weakened optical transparency and high price, and achieve the effects of perfect biocompatibility, low cost, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1. the preparation that contains the addition type two-component silicone rubber of Si-H bond

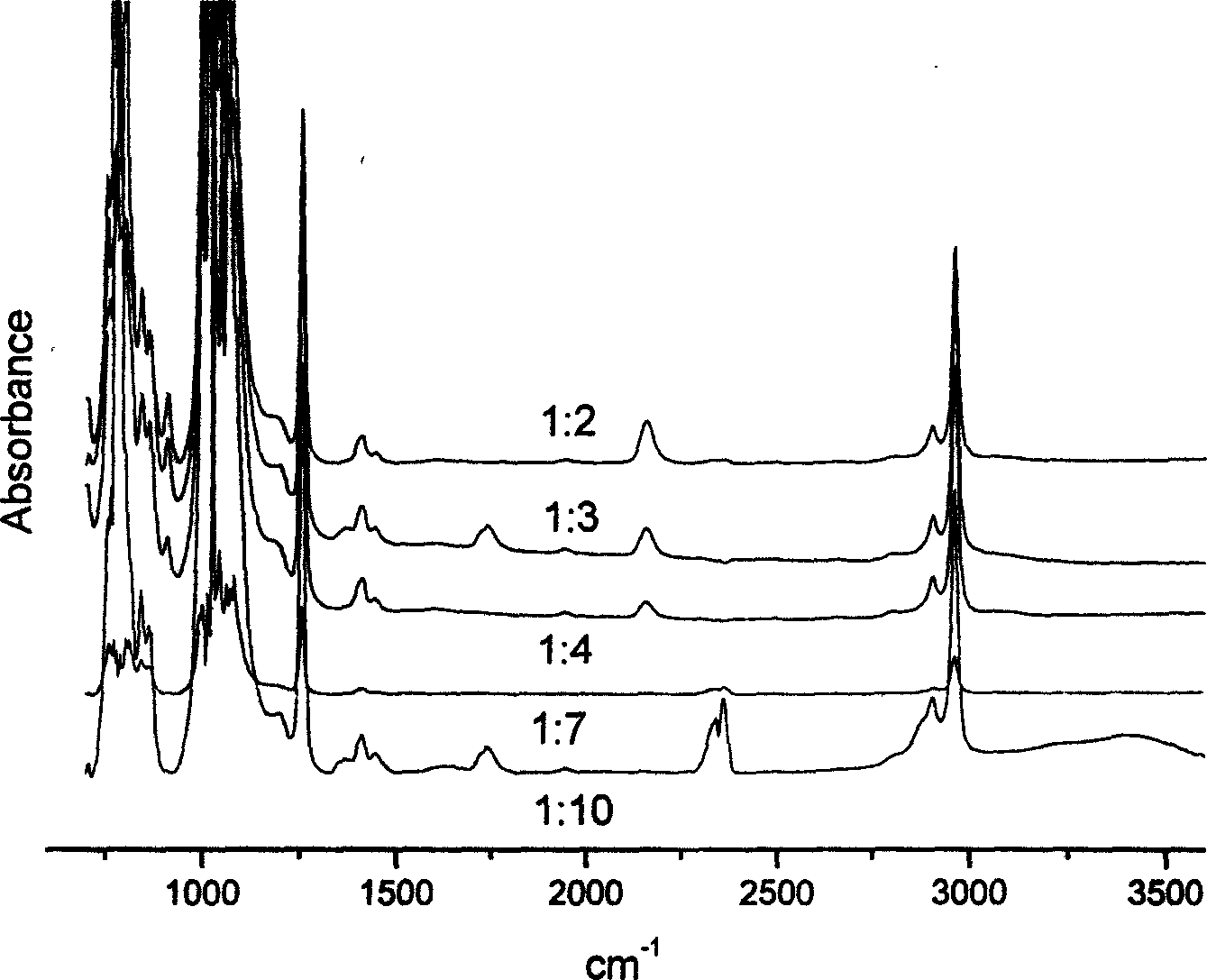

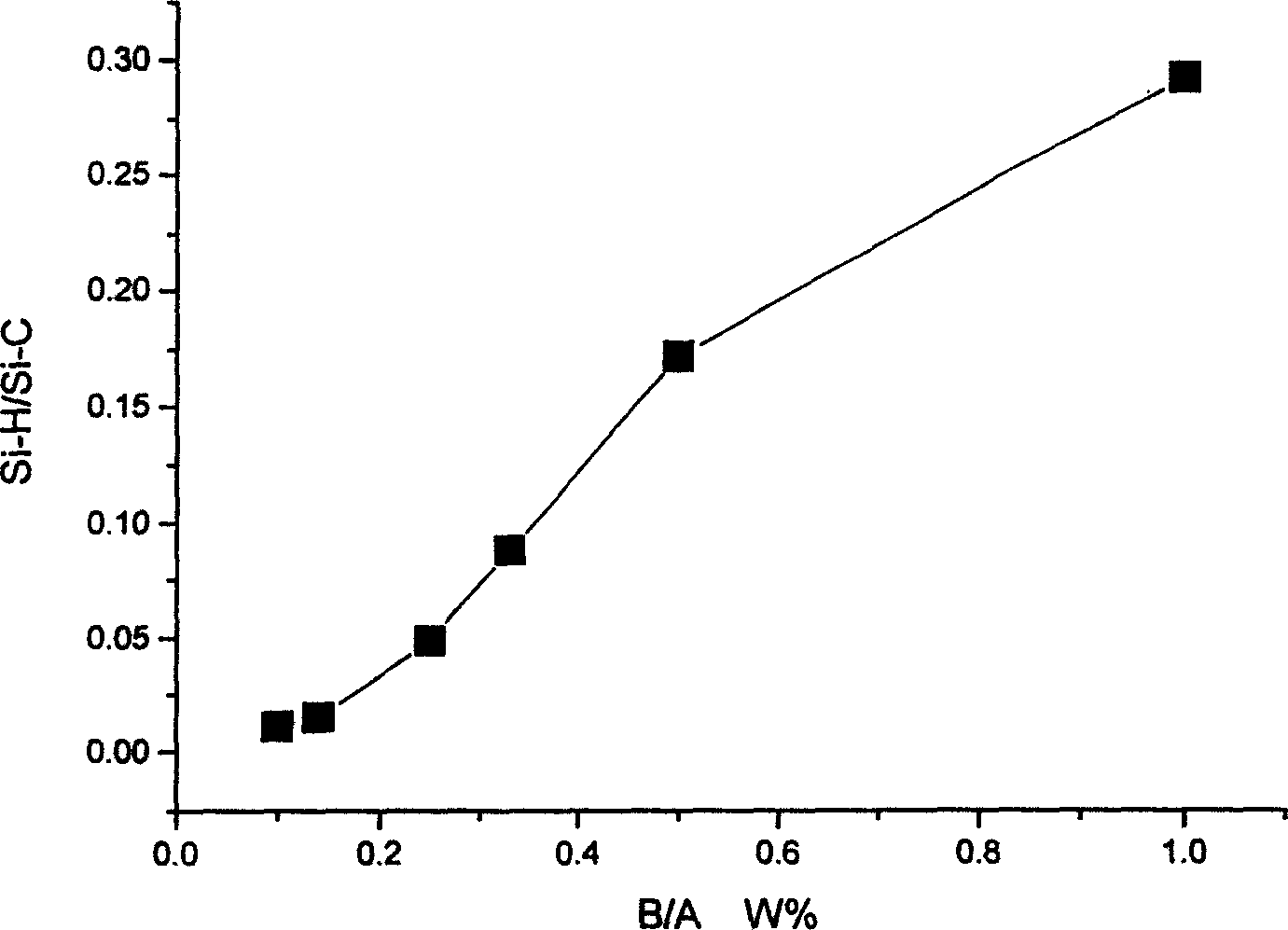

[0055] Taking Dow Corning Sylgard 184 silicone rubber as an example, component A (mainly composed of vinyl-containing polydimethylsiloxane) and B component (mainly composed of silicon hydrogen-containing polymethylsiloxane) Take out 30g of the two components according to the mass ratio of 10:1; 7:1; 4:1; 3:1; 2:1, mix together and stir, so that the two parts are fully mixed. Pour it into a container with a horizontal surface (such as a glass Petri dish), and vacuum to remove air bubbles until it is transparent and free of air bubbles. React at 100°C for 0.5 hour to obtain a colorless and transparent cured silicone rubber. Carefully peel off the silicone rubber, cut into small pieces, and set aside. ATR-FTIR spectroscopy studies (see figure 1 , 2): at 1110-1000cm -1 The vibration peak of Si-O-Si bond appeared between 1255 and 800cm -1 The vibration peak of Si-C...

Embodiment 2

[0056] Embodiment 2. the preparation that contains the addition type two-component silicone rubber of Si-H bond

[0057] Mix the two components A and B according to the ratio of 3:1, follow the operation steps of Example 1, and keep at 150° C. for 0.2 hours to obtain a transparent cured silicone rubber. Take out a small amount of cured silicone rubber and do ATR-FTIR spectrum. ATR-FTIR infrared spectrum at 1110-1000cm -1 The vibration peak of Si-O-Si bond appeared between 1255 and 800cm -1 The vibration peak of Si-C bond appeared at 2160cm -1 The Si-H bond vibration peak appeared at , indicating that there were still Si-H bonds not involved in the reaction.

Embodiment 3

[0058] Embodiment 3. the preparation that contains the addition type two-component silicone rubber of Si-H bond

[0059] Mix the two components A and B at a ratio of 2:1, and react at 80° C. for 0.5 hour according to the operation steps of Example 1 to obtain a transparent cured silicone rubber. Do ATR-FTIR spectroscopy. ATR-FTIR infrared spectrum at 1110-1000cm -1 The vibration peak of Si-O-Si bond appears between them. at 1255 and 800cm -1 The vibration peak of the Si-C bond appears at . 2160cm -1 There is a strong Si-H bond vibration peak. Indicating that the existing Si-H bond did not participate in the reaction at this time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com