Polyurethane matt wearable top-coat paint for removing odor and preparation method thereof

A technology of polyurethane and clear topcoat, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor paint surface adhesion, easy scratching of paint film, low hardness, etc., to meet the requirements of scratch resistance and wear resistance. Sexual requirements, good leveling, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] The specific implementation method is as follows: a polyurethane clean odor matte wear-resistant varnish, it is formulated by the weight ratio of 1-1.4:0.5-0.7:0.7-1.2 by main agent, curing agent and diluent; Wherein,

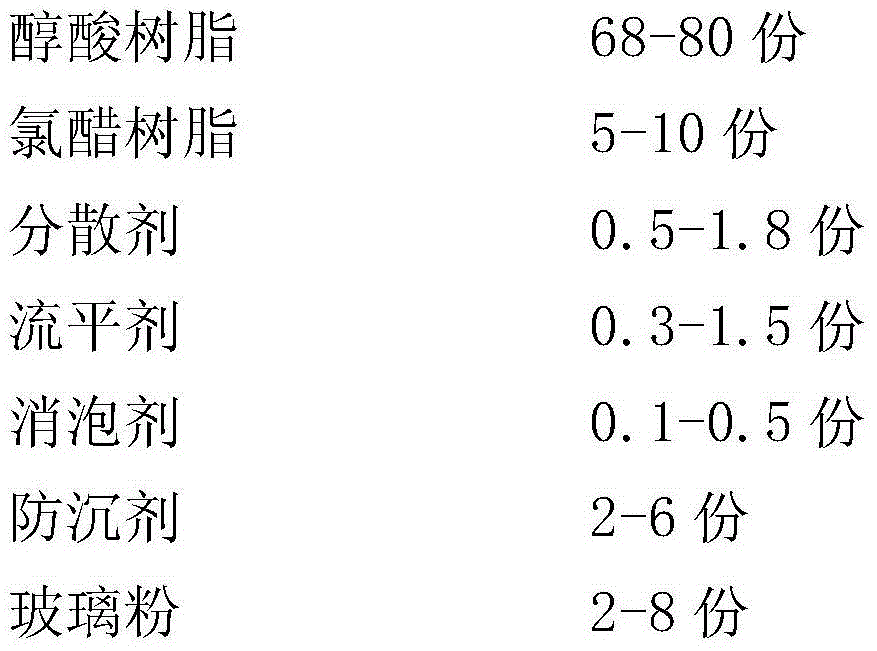

[0038] The main agent components and parts by weight ratio are as follows:

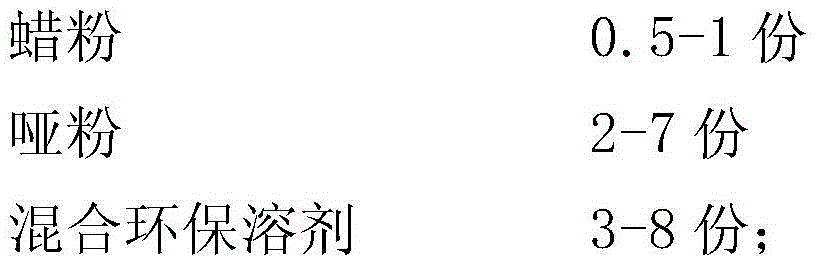

[0039]

[0040]

[0041] The mixed environment-friendly solvent is prepared by mixing butyl acetate, xylene and propylene glycol methyl ether acetate, wherein 0.5-2 parts of butyl acetate, 1-6 parts of xylene, and 1-5 parts of propylene glycol methyl ether acetate;

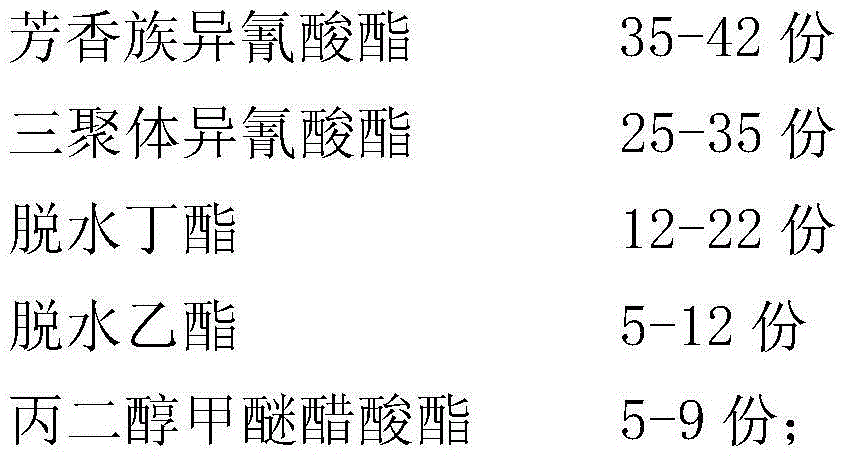

[0042] The curing agent is formed by mixing aromatic isocyanate, trimer isocyanate, dehydrated butyl ester, dehydrated ethyl ester and propylene glycol methyl ether acetate, wherein,

[0043]

[0044] Described diluent component and parts by weight ratio are as follows:

[0045]

[0046] A preparation method of a polyurethane odor-free matt wear-resistant clear finish:

[0047] The main ingredient is p...

Embodiment 1

[0053] A polyurethane odor-free matt wear-resistant clear finish, which is prepared from a main agent, a curing agent, and a thinner in a weight ratio of 1:0.5:0.7;

[0054] The main ingredient is prepared according to the following preparation method: butyl acetate, xylene, and propylene glycol methyl ether acetate are mixed according to the weight ratio of 2:5:5 to make an environmentally friendly solvent;

[0055] After mixing 72 parts of alkyd resin, 4 parts of mixed environmentally friendly solvent, 0.7 part of dispersant and 0.2 part of defoamer, disperse at 600 rpm for 5 minutes until the mixture is uniform; slowly add glass powder 3 in the dispersed state After 0.7 parts of wax powder and 2.5 parts of matte powder, disperse at 1200 rpm for 10 minutes until the fineness is less than 30 μm; then stop the dispersion, add 7 parts of vinyl acetate resin, 3 parts of anti-settling agent and 1 part of leveling agent After the portion, disperse at 800 rpm for 8 minutes until th...

Embodiment 2

[0060] A polyurethane odor-free matt wear-resistant clear finish, which is prepared from a main agent, a curing agent, and a diluent in a weight ratio of 1.1:0.55:0.8;

[0061] The main ingredient is prepared according to the following preparation method: 1 part of butyl acetate, 3 parts of xylene, and 3 parts of propylene glycol methyl ether acetate are mixed into an environmentally friendly solvent, and 3 parts of the mixed environmentally friendly solvent are taken out for use;

[0062] After mixing 68 parts of alkyd resin, 3 parts of mixed environmentally friendly solvent, 1 part of dispersant and 0.1 part of defoamer, disperse at 600 rpm for 5 minutes until the mixture is uniform; slowly add glass powder 5 in the dispersed state After 1 part of wax powder and 5 parts of matte powder, disperse at 1200 rpm for 10 minutes until the fineness is less than 30 μm; then stop the dispersion, add 8 parts of vinyl acetate resin, 5 parts of anti-settling agent and 1.5 parts of levelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com