Integrated floor-heating flexible ceramic tile and production method thereof

A soft porcelain and floor heating technology, which is applied in the field of building decoration materials, can solve the problems of low heat transfer efficiency, no flame-retardant components in conductive media, and low safety, and achieve high application safety performance, excellent water and oil repellency, and excellent preparation technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

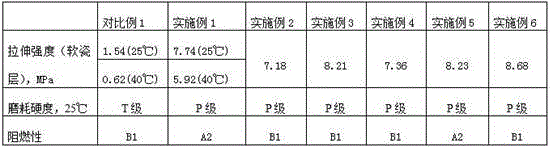

Examples

Embodiment 1

[0055] An integrated floor heating soft porcelain, the preparation method of which comprises the following steps:

[0056] (1) Preparation of soft porcelain layer:

[0057] 1) Weigh 25 parts of Portland white cement with the label of 325, 15 parts of 80-mesh stone powder and 50 parts of 300-mesh quartz sand by weight, add them to the kneader, mix evenly, and obtain the mixed powder;

[0058] 2) Weigh 10 parts by weight of water-based epoxy resin emulsion (viscosity at 25°C is 500mPa.s, epoxy equivalent is 200g / mol), 2 parts of fluorine-containing polyacrylate elastic emulsion, 10 parts of flame retardant tripolyphosphoric acid 1 part, 1 part of inorganic pigment titanium dioxide and 10 parts of water are added to the stirring tank, and stirred evenly to obtain a mixed emulsion;

[0059] 3) Add the mixed powder obtained in step 2) to the mixed emulsion obtained in step 1), stir well, mix evenly, add 3 parts of rubber elastic body, stir, react for 0.5 hours, then add curing age...

Embodiment 2

[0066] An integrated floor heating soft porcelain, the preparation method of which comprises the following steps:

[0067] (1) Preparation of soft porcelain layer:

[0068] 1) Weigh 20 parts of Portland white cement labeled 425, 20 parts of 100-mesh stone powder and 40 parts of 150-mesh quartz sand, add them to a kneader, mix evenly, and obtain a mixed powder;

[0069] 2) Weigh 15 parts of water-based epoxy resin emulsion (viscosity at 25°C is 6,000mPa.s, epoxy equivalent is 1,400g / mol), 5 parts of fluorine-containing polyacrylate elastic emulsion, 3 parts of flame retardant melamine, poly Add 5 parts of ammonium phosphate, 2 parts of inorganic pigment carbon black and 15 parts of water into a stirring tank, and stir evenly to obtain a mixed emulsion;

[0070] 3) Add the mixed powder obtained in step 2) to the mixed emulsion obtained in step 1), stir well, and after mixing evenly, add 5 parts of rubber elastomer, stir, and react for 2 hours, then add curing agent polyamide 3...

Embodiment 3

[0077] An integrated floor heating soft porcelain, the preparation method of which comprises the following steps:

[0078] (1) Preparation of soft porcelain layer:

[0079] 1) Weigh 15 parts of Portland white cement labeled 525, 25 parts of 300-mesh stone powder and 30 parts of 80-mesh quartz sand, add them to a kneader, mix evenly, and obtain a mixed powder;

[0080] 2) Weigh 20 parts of water-based epoxy resin emulsion (viscosity at 25°C is 2,000mPa.s, epoxy equivalent is 800g / mol), 2 parts of fluorine-containing polyacrylate elastic emulsion, and 5 parts of flame retardant melamine ammonium polyphosphate , 7 parts of ammonium polyphosphate, 1 part of inorganic pigment carbon black, 1 part of cadmium red and 10 parts of water are added to the stirring tank and stirred evenly to obtain a mixed emulsion;

[0081] 3) Add the mixed powder obtained in step 2) to the mixed emulsion obtained in step 1), stir well, mix evenly, add 3 parts of rubber elastic body, stir, react for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com