On-line laser machining apparatus for strengthening and toughening treatment of steel rail surface

A technology of laser processing and laser processing head, used in the surface strengthening and toughening treatment of rails in subways and light rails, online laser processing equipment, and railway fields, which can solve the problems of heavy weight, inability to appear martensite, and high energy consumption, etc. Achieve the effect of extending the life cycle, reducing the number of replacements, and improving the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

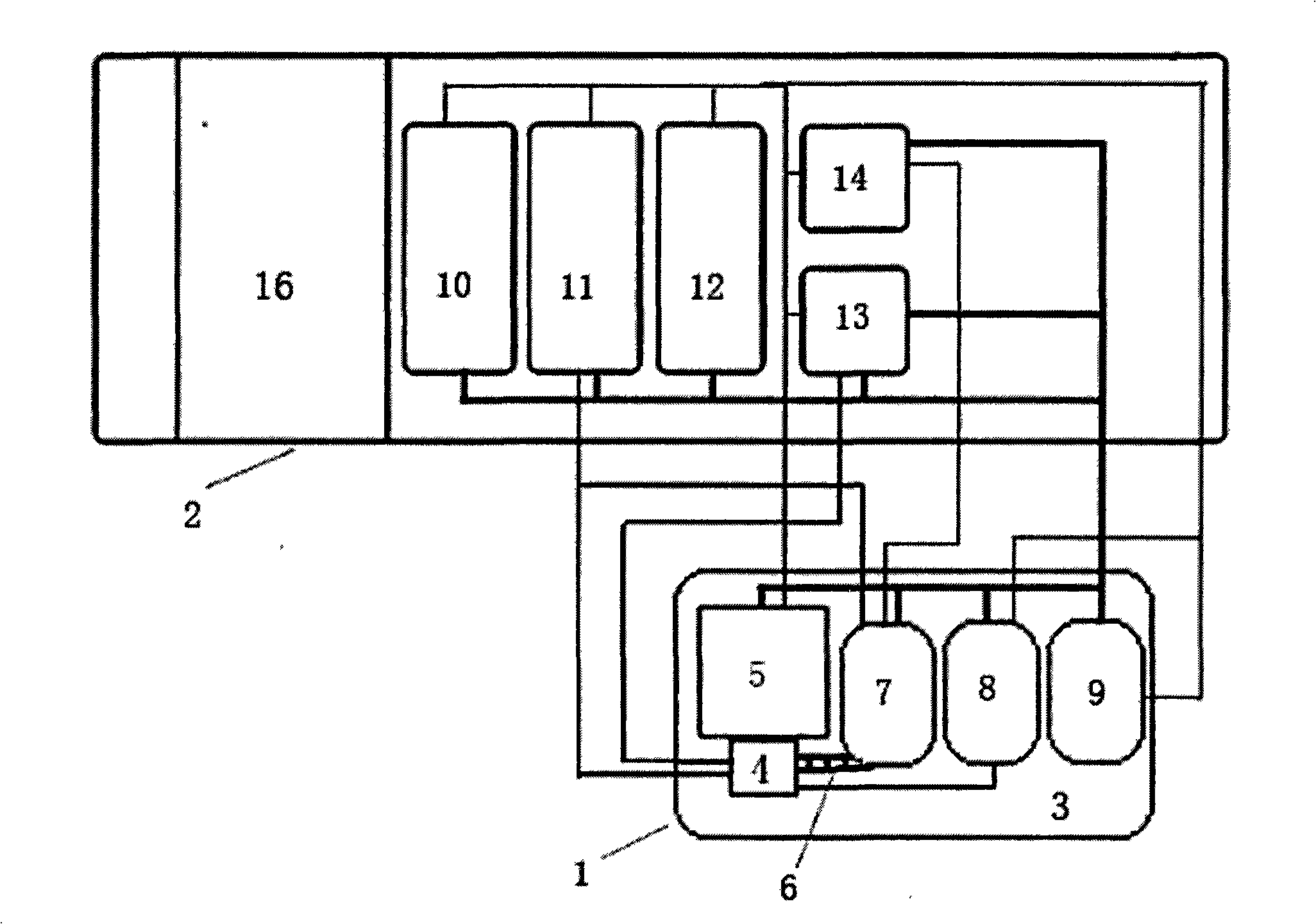

[0054] The laser processing equipment involved in the present invention consists of two parts: a laser processing vehicle and a power system container. The laser processing vehicle is small in size and light in weight. There are many ways to realize it. It can complete various strengthening and toughening treatment tasks on the surface of the rail without dismantling the rail. The relatively large volume and weight of equipment such as generators, refrigerators, air compressors, cold dryers, and laser high-voltage power supplies are integrated to form a power system. In order to ensure the high mobility of the laser processing vehicle and meet the processing needs of rails in different environments, the power system is installed in the container body to form a power system container. The container is installed on a truck to form a power engineering vehicle, which can meet the requirements of online laser processing of railroad rails in the field; it can also be installed on a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com