Abrasion-resistant materials

A wear-resistant material and thermoplastic technology, applied in the field of wear-resistant materials, can solve the problems of lack of wear resistance of resin, exposed base surface, non-uniform wear, etc., to achieve the effect of increasing the overall price, maintaining production technology, and simplifying maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A reaction mixture was prepared by dissolving the following initiators in the urethane-acrylate monomer while stirring at room temperature for 30 minutes: 0.3 wt% camphorquinone and 0.2 wt% DMAEMA. Perform this process in the dark to prevent premature polymerization.

[0022] Unmodified fumed silica nanoparticles (Aerosil200) or fumed silica nanoparticles surface-modified by methacryloylsilane (AerosilR711) were subsequently vacuum-dried at 120 °C for 1 h, and then added to In the mixture, disperse using one of the following steps:

[0023] 1) The nanoparticles were stirred into the mixture at laboratory temperature for 3 hours.

[0024] 2) The nanoparticles were stirred into the mixture at laboratory temperature for 3 hours, followed by exposure to an ultrasonic bath (K5, Kraintek) at 30°C.

[0025] The mixture is then poured into rubber molds and cured using UV radiation.

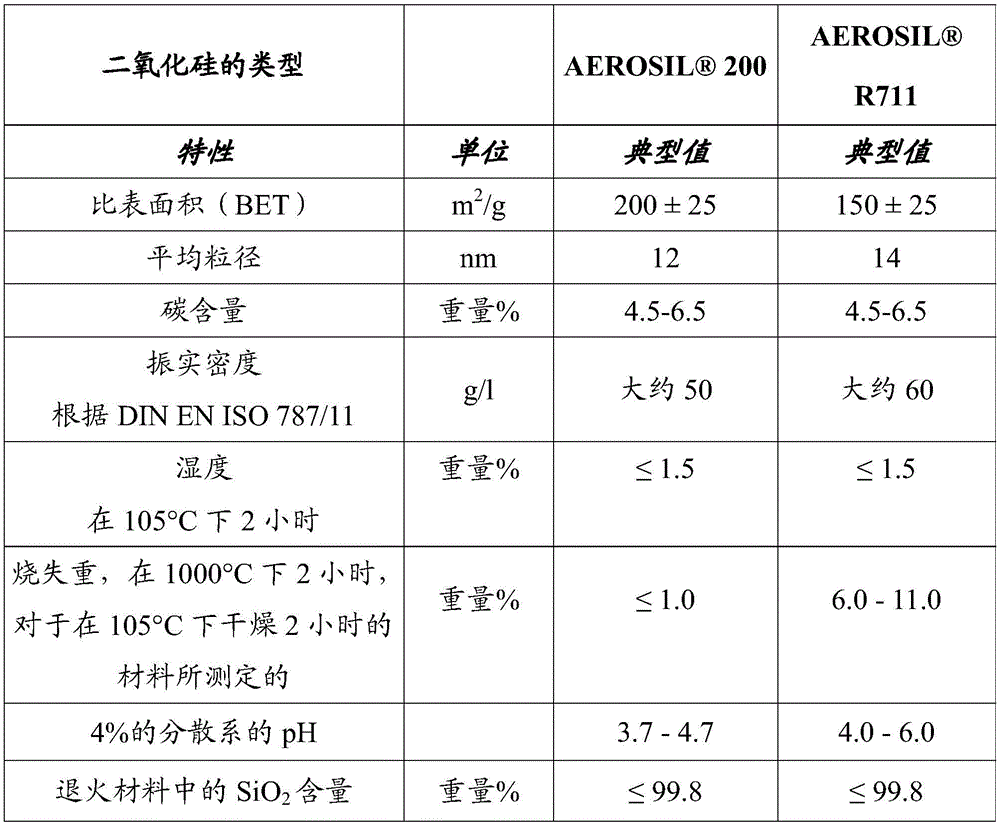

[0026] Table 1 shows the physicochemical data of Aerosil200 and AerosilR711.

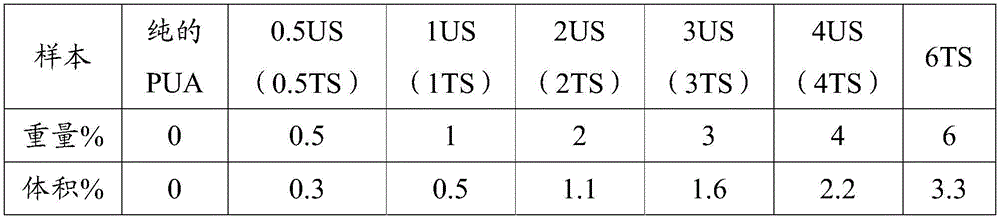

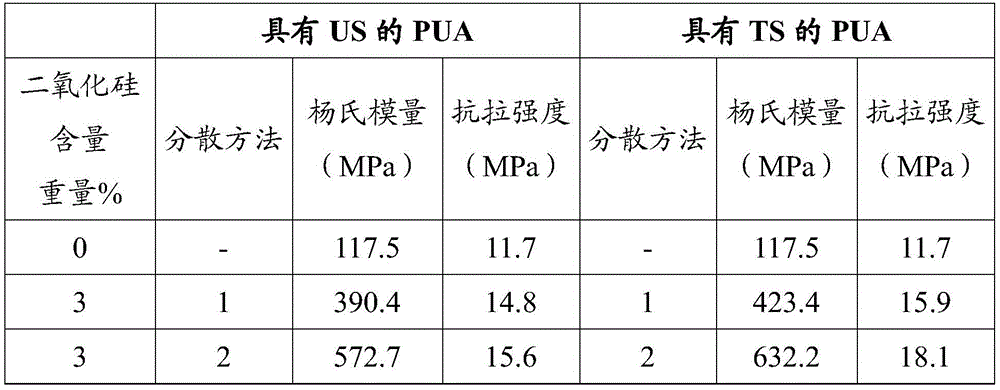

[0027] Table...

Embodiment 2

[0040] Silica nanoparticles (silica-unmodified surface Sigma-Aldrich-specific surface area 390m 2 / g, particle size 7nm; silica coated with Cab-O-SilTS-530 - surface area 220m2 / g) of PMMA (PlexiglasFormmaseTransparent8N) or PC (Makrolon) based polymer nanocomposites:

[0041] 1) Dry the thermoplastic particles at 90°C.

[0042] 2) The particles were then dissolved in various organic solvents (acetone, toluene, acetone / toluene 1:1, dichloromethane, methyl ethyl ketone).

[0043] 3) The nanoparticles were vacuum dried at 120° C. for 24 hours.

[0044] 4) The nanoparticles were then dispersed by ultrasound and then stirred into the same solvent at 50 °C for 1 hour.

[0045] 5) The mixture of nanoparticles and solvent was added to the dissolved particles, followed by stirring for 3 hours.

[0046] 6) Using a mechanical stirrer to remove the organic solvent by gradient drying under stirring. The dried thermoplastic nanocomposites were then pulverized (dried at 140°C for 2 hour...

Embodiment 3

[0052] Silica nanoparticles (silica-unmodified surface Sigma-Aldrich-specific surface area 390m 2 / g, particle size 7nm; silica coated with Cab-O-SilTS-530 - surface area 220m 2 / g) of PC (Makrolon) based polymer nanocomposites:

[0053] 1) Dry the thermoplastic particles at 90°C.

[0054] 2) The particles were then dissolved in various organic solvents (acetone, toluene, acetone / toluene 1:1, dichloromethane, methyl ethyl ketone).

[0055] 3) The nanoparticles were vacuum dried at 120° C. for 24 hours.

[0056] 4) The nanoparticles were then dispersed by ultrasound and then stirred into the same solvent at 50 °C for 1 hour.

[0057] 5) The mixture of nanoparticles and solvent was added to the dissolved particles, followed by stirring for 3 hours.

[0058] 6) Using a mechanical stirrer to remove the organic solvent by gradient drying under stirring. The dried thermoplastic nanocomposites were then pulverized (dried at 140°C for 2 hours, ground, dried at 145°C for 3 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com