Nanoscale double-cylindrical-bore filter membrane

A double-cylindrical, nano-scale technology, applied in membranes, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor permeability, filter pore size can not be used to filter extremely fine substances, and cannot withstand high pressure, etc., to achieve excellent filtration. Membrane performance, excellent permeability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

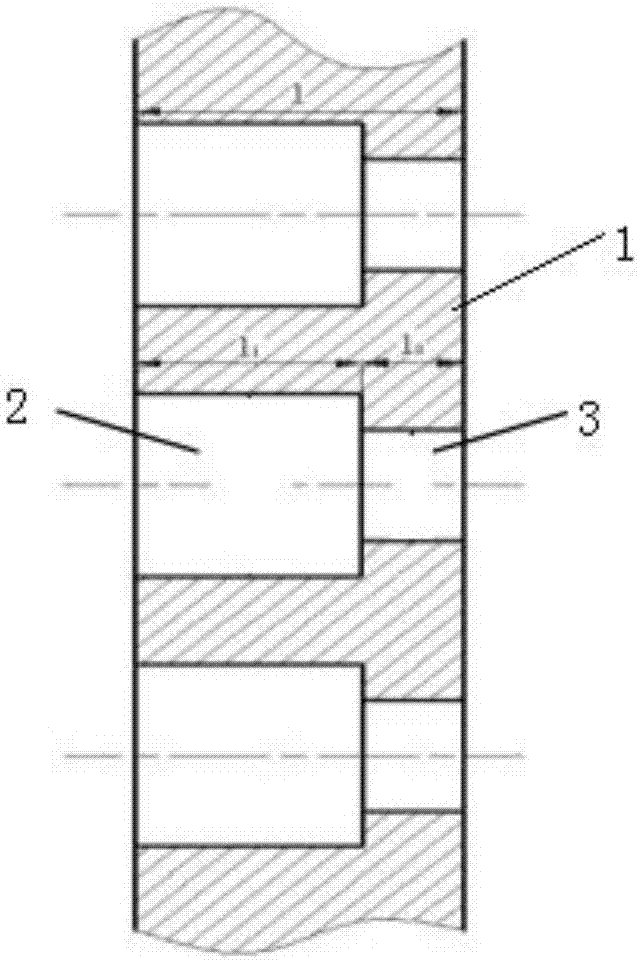

[0037] The nanoscale double-cylindrical hole filter membrane of the embodiment has two diameters on a thin layer of solid material 1 that are often different cylindrical holes, and these cylindrical holes are evenly distributed on the surface of the thin solid material 1, such as figure 1 shown. This layer of solid material 1 is the filter membrane, and the thickness of the filter membrane is equal everywhere, but the thickness of the filter membrane in the present invention is not limited to be equal everywhere. figure 1 The filter membrane shown is planar, but the filter membrane of the present invention is not limited to planar, and can also be curved and flexible.

[0038] Two cylindrical holes with different diameters but better concentricity are manufactured in the thickness direction of the filter membrane. The hole with a smaller diameter is filter hole 3, and its diameter is on the order of nanometers, so it can be used to filter out extremely fine substances such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com