Lightweight high-power permanent magnet brushless DC motor rotor for airborne equipment

A permanent magnet brushless DC and motor rotor technology, which is applied in the direction of electromechanical devices, magnetic circuit rotating parts, electrical components, etc., can solve the problems of late start of research and application, small size and weight, and high technical difficulty. Vibration ability, high efficiency, high reliability, high power density, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

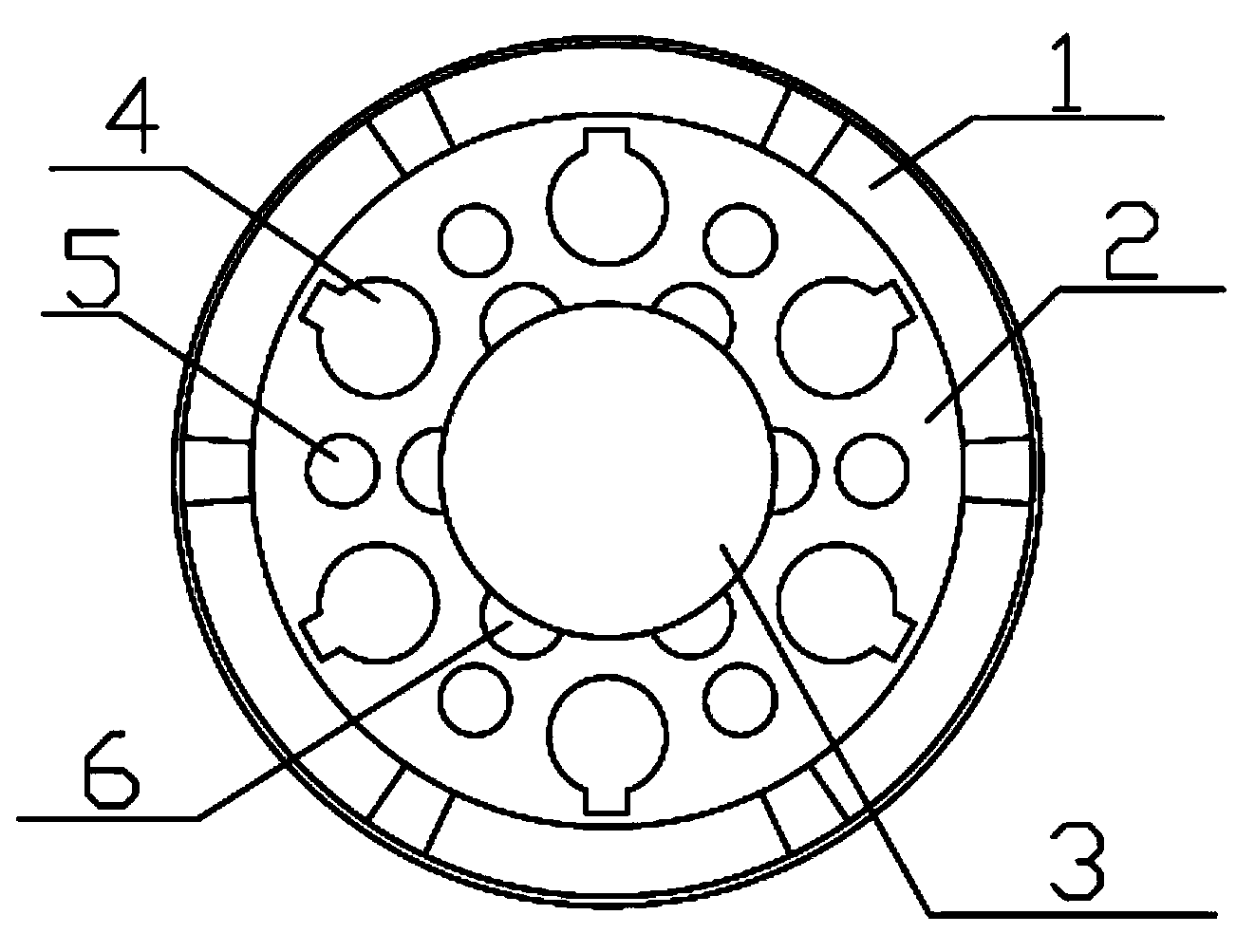

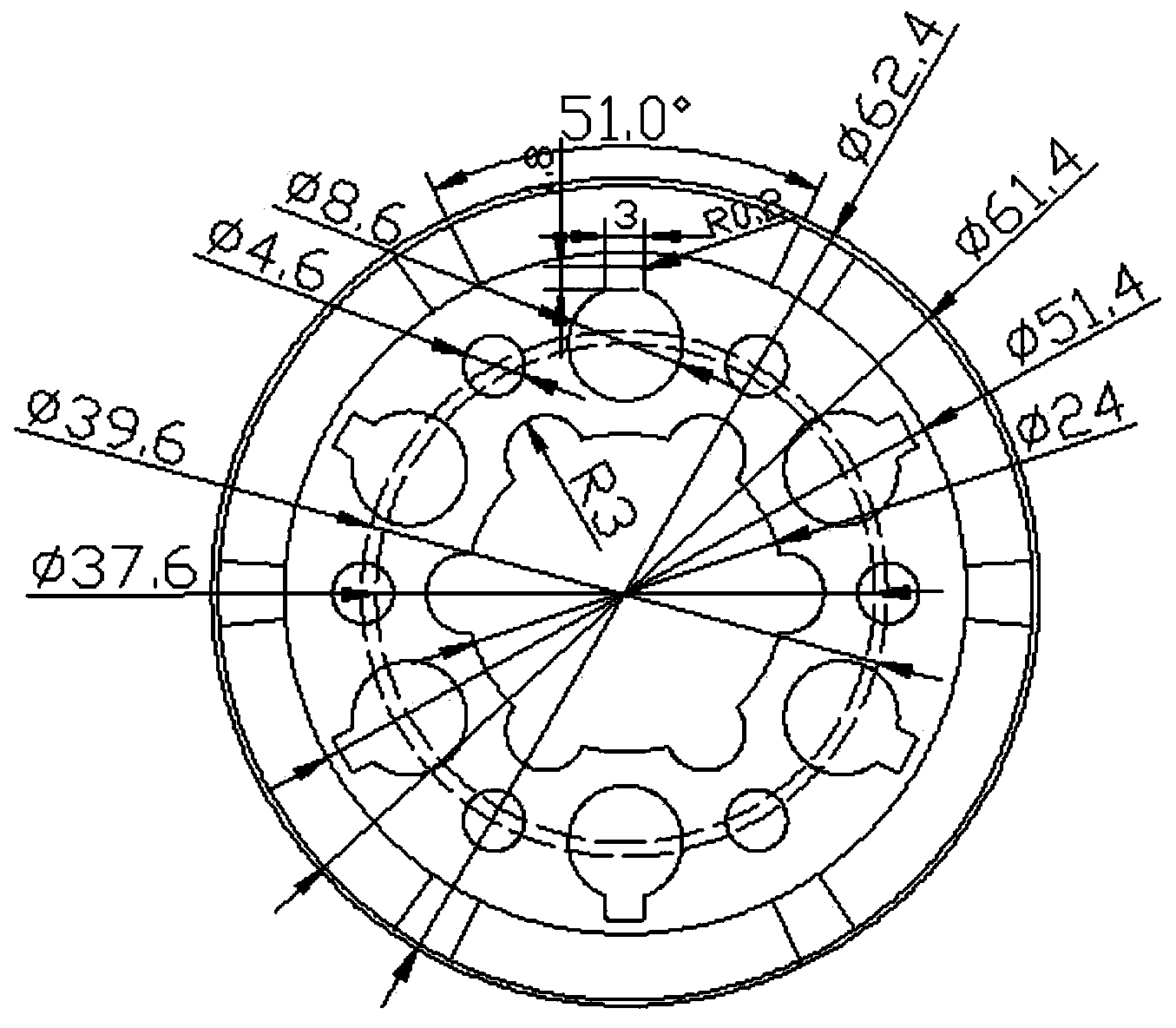

[0033] Concrete embodiment: [embodiment one] the rotor structure on the 2kW permanent magnet brushless DC motor of aircraft fan:

[0034] The aircraft operates at an altitude of about 10,000, and the external atmospheric pressure is about 1 / 4 of the ground pressure. Fans need to be used to ensure the air pressure in the cabin while maintaining the circulation of the air in the cabin. This project designs a 2kW permanent magnet brushless DC motor as the power source of the environmental control fan.

[0035] Aircraft have strict requirements on volume, weight and reliability. Compared with brushed DC motors, permanent magnet brushless DC motors use electronic commutation instead of mechanical commutation, which solves the problems of brushed DC motors such as commutation sparks, easy wear of commutator segments, and maintenance of commutator segments; The magnetic brushless DC motor is excited by rare earth permanent magnets. Compared with asynchronous motors, it has the chara...

Embodiment 2

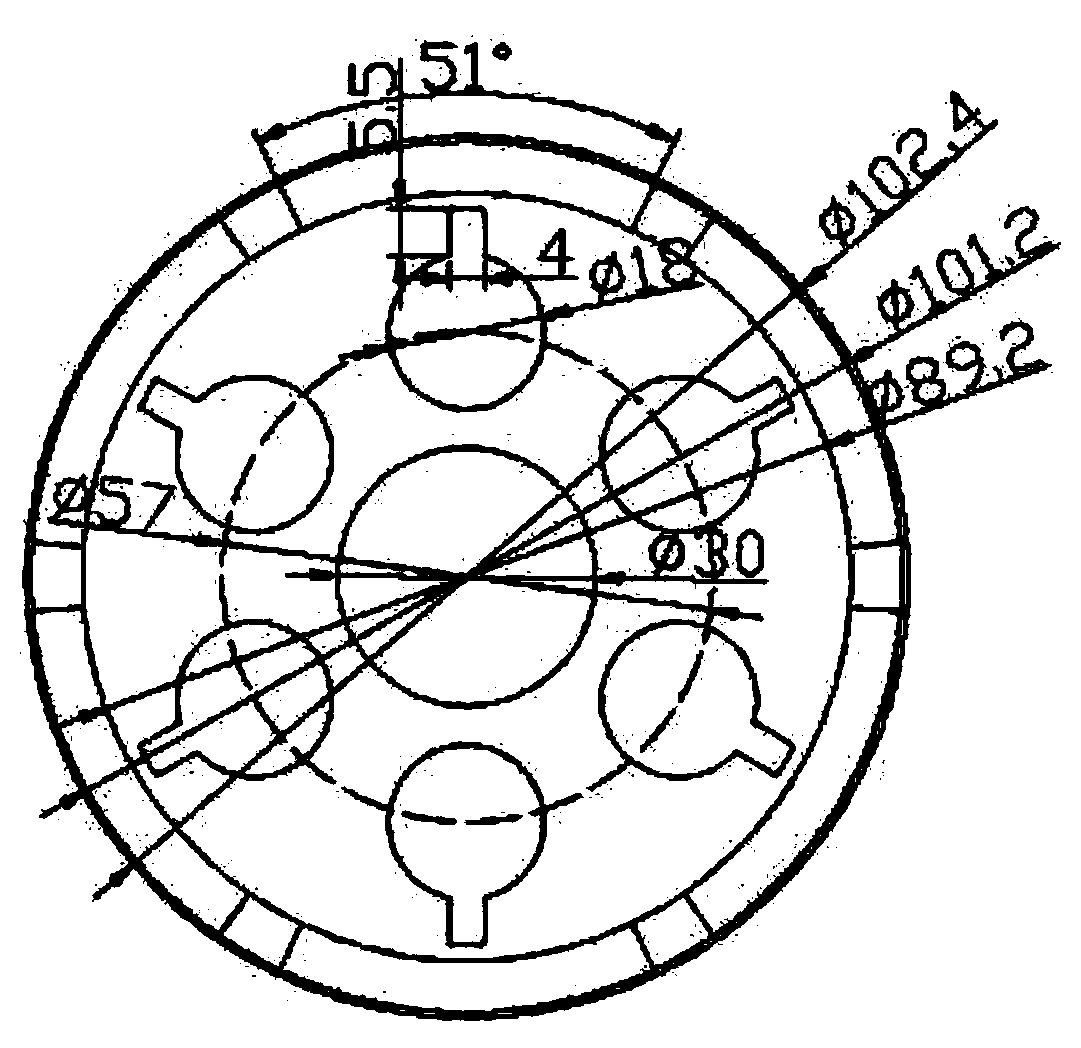

[0041] [Example 2] The 18kW permanent magnet brushless DC motor project is now combined with the aircraft fan:

[0042] Such as image 3 Shown is the appearance and size of the rotor of the permanent magnet brushless DC motor, including 1. the magnetic steel of the permanent magnet; 2. the rotor core; 3. the rotating shaft; 4. the first slot.

[0043] Such as image 3 Shown is the appearance and size of the rotor of the permanent magnet brushless DC motor. The rotor magnetic pole is surface-mounted tile type, and six permanent magnets are evenly distributed to form a six-pole motor. This rotor magnetic circuit structure is relatively simple, easy to process and manufacture, and easy to achieve optimal design. It is suitable for permanent magnet brushless DC The motor and the rotor tighten the ring to prevent the magnetic steel from being thrown out at high speed. The rotor core 2 is made of laminated cold-rolled silicon steel sheets, and the weight reduction is optimized wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com