High-voltage bushing and processing technology thereof

A high-voltage bushing and processing technology, which is applied in the direction of lead-in/through-type insulators, insulators, electrical components, etc., can solve the problem that the capacitor electrode and the insulating layer cannot be well fused, so as to improve the insulation performance and improve the high resistance Low temperature performance, effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

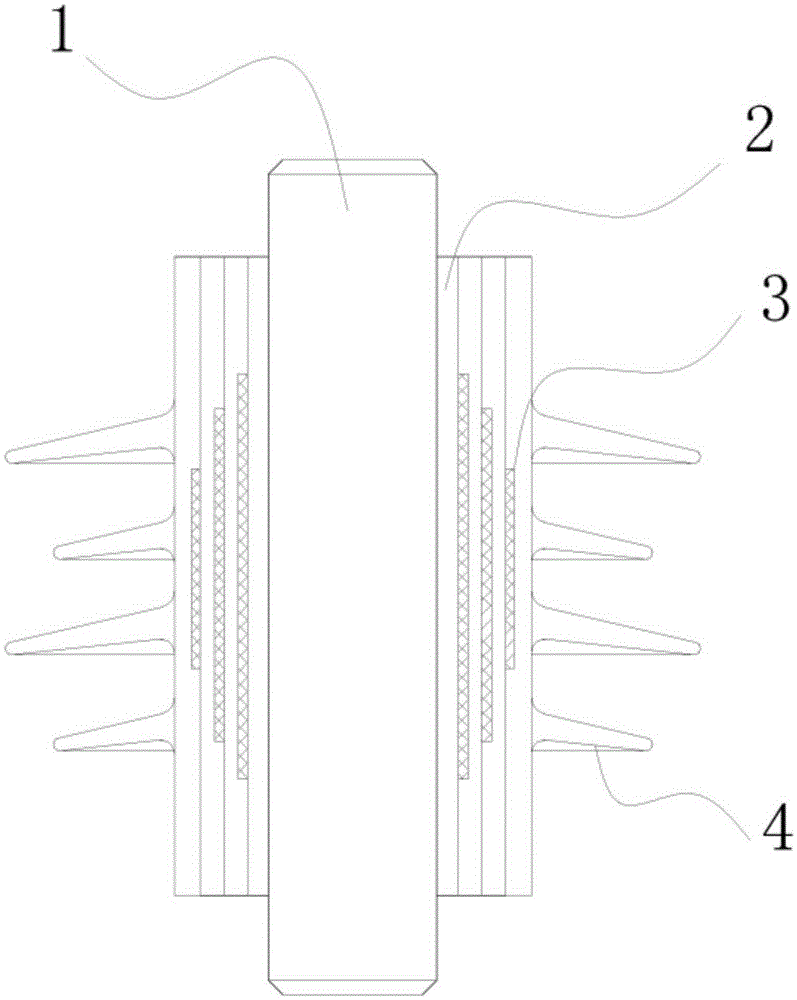

[0056] see figure 1 , The high-voltage bushing of the present invention includes a conductive rod, a capacitor electrode and an insulating layer between the capacitor electrodes, and the capacitor electrode is one or more of conductive cloth, conductive mesh or conductive yarn. If necessary, an insulating jacket provided on the outermost layer may also be included.

[0057] Conductive cloth, conductive mesh or conductive yarn after dewaxing, degreasing, pre-impregnation or coating coupling agent treatment; water absorption rate is less than 0.1%; thickness is 0.01mm ~ 1mm; material is non-woven fabric or fiber cloth dip-plating or brush-plating Metal conductive materials such as copper and tin or other non-metallic conductive materials such as carbon black can also be made of metal wires, metal strips or mixed with metal wires and plant fiber wires. Metal wires and metal strips include copper, tin, stainless steel or aluminum, etc.; plant fiber wires are cotton fibers or soyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com