An ultra-low dielectric loss polyimide film

A technology of polyimide film and dielectric loss factor, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems that it is difficult to meet the requirements of the dielectric properties of materials, and achieve low dielectric loss , Excellent dielectric loss, improved bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

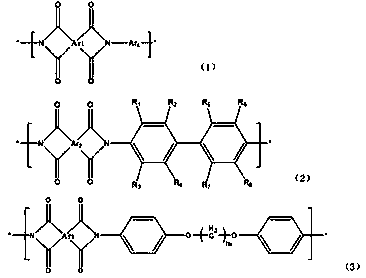

[0040] Preparation method of ultra-low dielectric loss multilayer polyimide film

[0041] 1. Preparation of core polyimide film

Embodiment 11

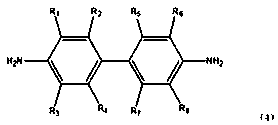

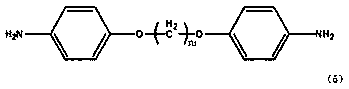

[0043]In a 500ml four-necked flask equipped with heating, cooling and internal stirring devices, nitrogen gas was continuously passed through, 220g of N-methylpyrrolidone was added and heated to 60°C, and 0.02mol of 1,3-bis(3-trifluoro Methyl-4-aminophenoxy)benzene, 0.06mol of 4,4'-diaminooctafluorobiphenyl and 0.02mol of 1,3-bis(4-aminophenoxy)neopentane were stirred to make the above The diamine is completely dissolved. 0.0995 mol of 2,3,3',4'-biphenyltetracarboxylic dianhydride was added step by step, kept in a nitrogen atmosphere, stirred and reacted at a constant temperature of 60°C for 6 hours, and then the resin synthesis reaction was completed to obtain a polyamic acid resin. After finishing the reaction, the polyamic acid resin is defoamed and then coated under a vacuum condition of vacuum degree -0.1 MPa. According to the coating process, the heating rate is 10 ℃ / min, rising from 60 ℃ to 390 ℃, and keeping it for 5 minutes after reaching the temperature, completing ...

Embodiment 12

[0045] According to the method of embodiment 1.1, wherein 2,3,3',4'-biphenyltetracarboxylic dianhydride is changed to 4,4'-(hexafluoroisopropene)tetracarboxylic dianhydride (6FDA), and other conditions remain unchanged , to obtain polyamic acid resin. In the coating process, the heating rate is 10°C / min, from 60°C to 330°C. After reaching the temperature, keep it for 5 minutes to complete thermal imidization, and then slowly cool to room temperature to obtain a core polyimide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com