Barium calcium zirconate titanate leadless piezoelectric ceramic material and preparation method thereof

A barium calcium zirconate titanate and lead-free piezoelectric technology, which is applied in the field of barium calcium zirconate titanate lead-free piezoelectric ceramic materials, can solve the problems of high sintering temperature of piezoelectric ceramics and difficult application of lead-free piezoelectric ceramics, etc. Achieve the effect of good performance stability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

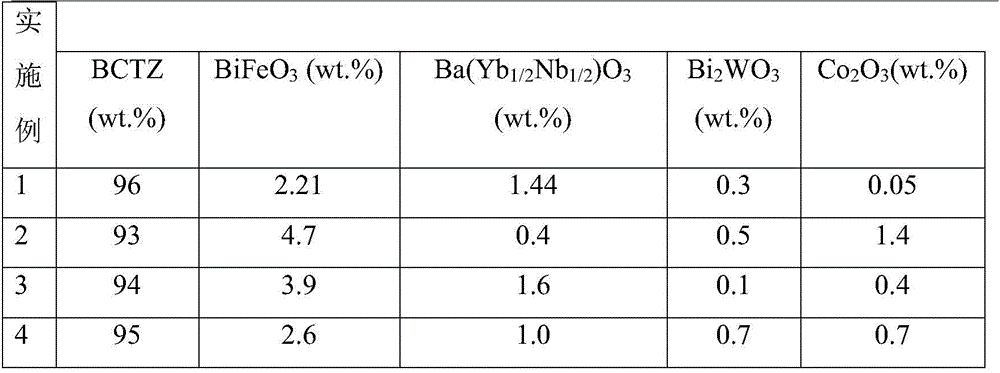

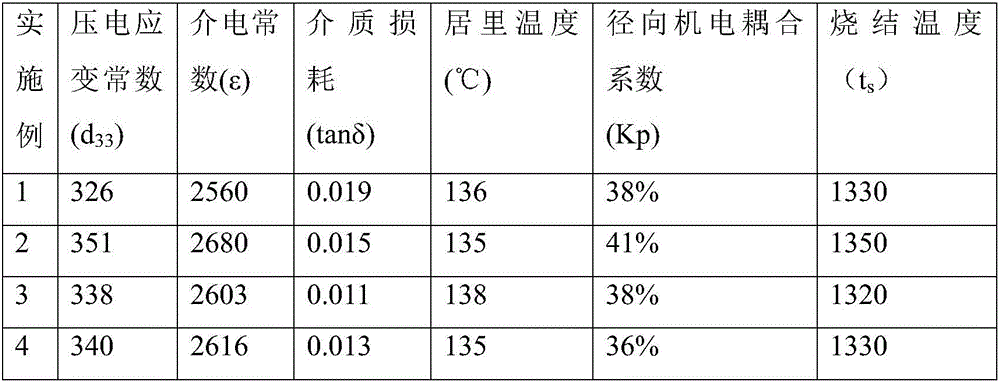

[0018]The present invention will be further described in conjunction with embodiment now. Table 1 provides the formulas of a total of 4 samples of the embodiment of the present invention.

[0019] The main raw material of the formula of totally 4 samples of the embodiment of the present invention adopts piezoelectric ceramic raw material, at first adopts conventional chemical raw material to synthesize respectively with solid-phase method during preparation (Ba 0.85 Ca 0.15 )(Ti 0.9 Zr 0.1 )O 3 、BiFeO 3 、 Bi 2 WO 3 , Ba(Yb 1 / 2 Nb 1 / 2 )O 3 , and then according to the above formula ingredients, the prepared material is mixed with dehydrated alcohol by planetary ball mill ball mill, material: ball: dehydrated alcohol=1:3: (0.6~1.0) (mass ratio), after ball milling for 4~8 hours , dry to obtain dry powder, add the polyvinyl alcohol solution that accounts for its weight 8~10% concentration and be 10% (percentage by weight) in the dry powder, carry out granulation, pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com