Method for prefabricating wrapping joint

A joint method and wrapping technology, which is applied in connection, assembly/disassembly of contact pieces, connection and connection through deformation, etc., can solve problems such as many faults, easy to generate heat, and increased dielectric loss, so as to achieve safe and reliable operation and not easy to break Good wear and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

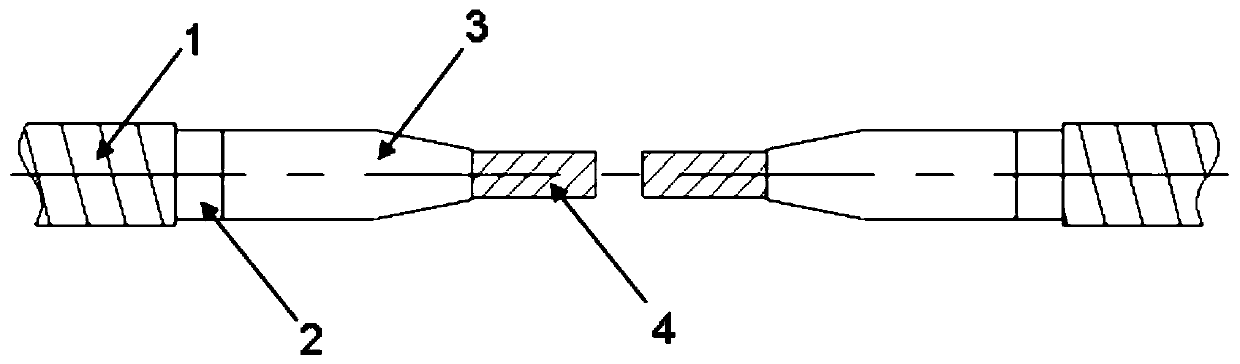

[0039] see figure 1 , The cable is copper shielding layer 1, insulating outer shielding layer 2, main insulating layer 3 and wire core 4 from outside to inside. According to the process requirements, the copper shielding layer 1 and the insulating outer shielding layer 2 are peeled off, and the main insulating layer 3 is peeled off to expose the wire core 4. Wherein the end of the stripped section of the main insulating layer 3 is stripped to form a tapered structure, and the length of the tapered structure is 50 cm.

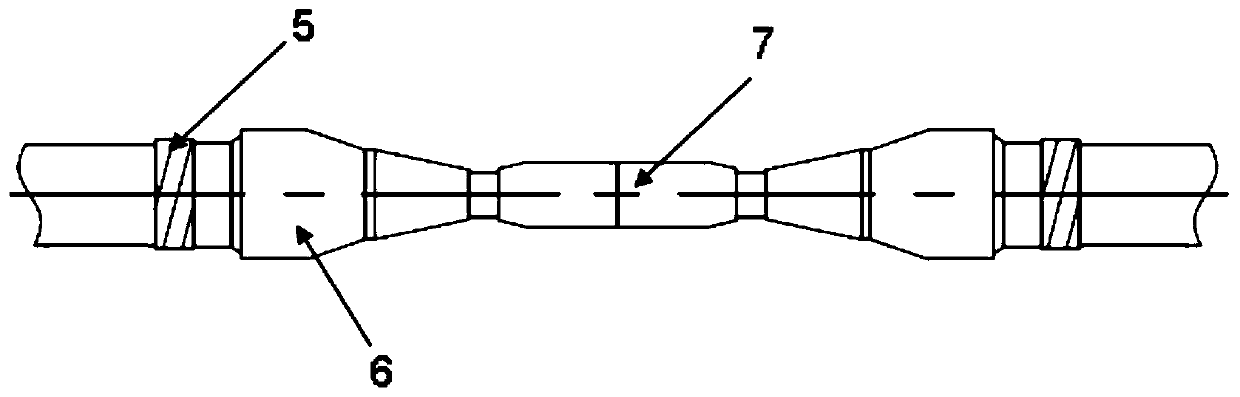

[0040] see figure 2 , on the copper shielding layer 1 and insulating shielding layer 2 of the cable, a semi-conductive tape is wrapped to form a limit step 5, a prefabricated stress cone 6 is placed outside the main insulating layer, and a copper connecting pipe 7 is connected to the outer core of the wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com