Patents

Literature

65results about How to "Increase the starting voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High voltage direct current cable insulation material

InactiveCN103665525AGood physical propertiesExcellent overall performancePlastic/resin/waxes insulatorsPartial dischargePower flow

The invention provides a high voltage direct current cable insulation material, which comprises the following components in parts by weight: 100 parts of LDPE (Low-density Polyethylene), 1-2 parts of CPE (Chlorinated Polyethylene), 0.5-1.5 parts of BaTiO3, 0.6-1.5 parts of conductive potassium titanate whisker, 1-2.5 parts of a cross-linking agent, and 0.1-0.5 part of an antioxygen. A semiconductive polyolefin shielding material prepared from the high voltage direct current cable insulation material has the advantages of ultra-smooth surface feature, good physical property and excellent overall performance; electric current is effectively output to form a favorable uniform electric field, and partial discharge or insulation breakdown caused by severe electric field concentration due to surface defects of a semiconductive shielding layer is prevented; ionized charge and injected charge are absorbed in a deep trap, so that charge accumulating in a local area is avoided, space charge accumulation in a cable insulation material is restrained, and electrical conductivity of the cable insulation material is reduced.

Owner:WUXI JIANGNAN CABLE

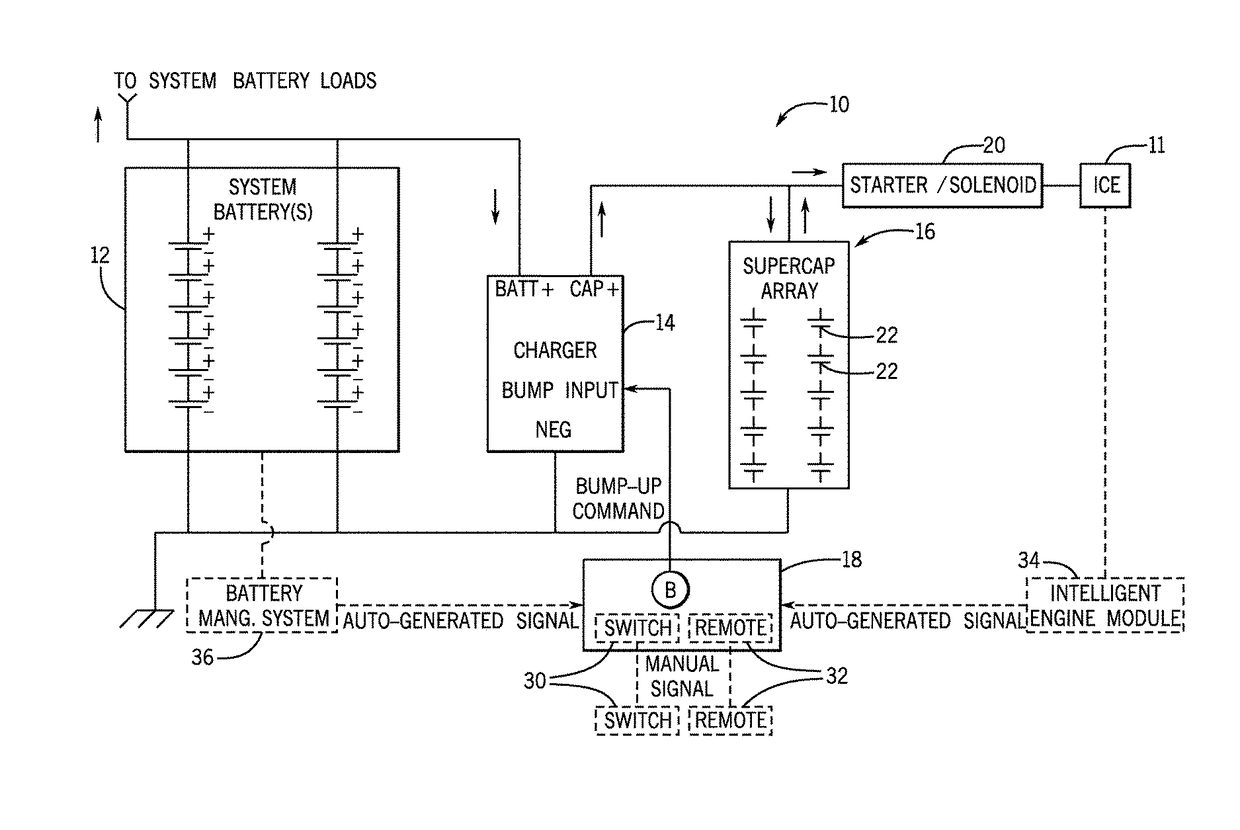

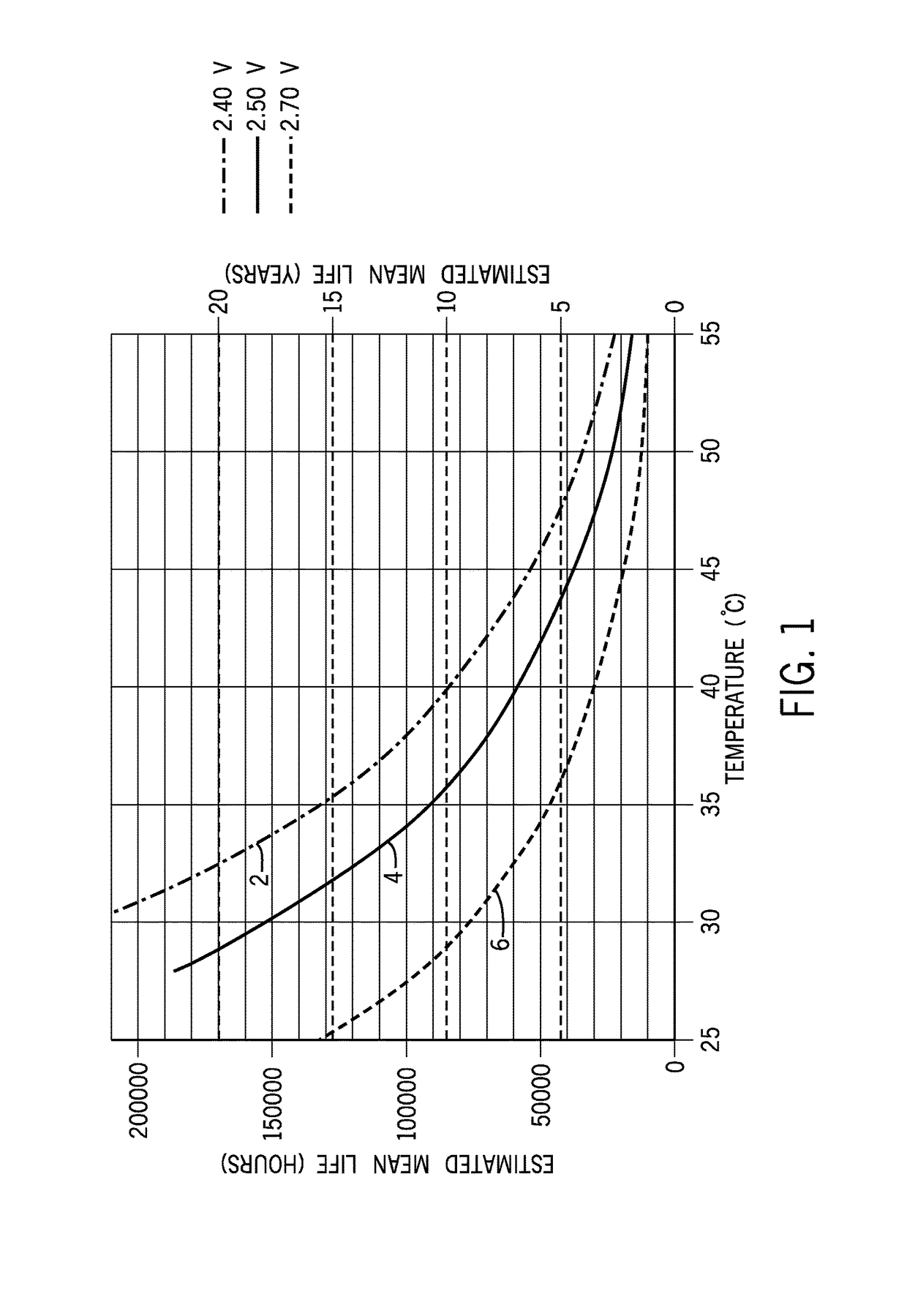

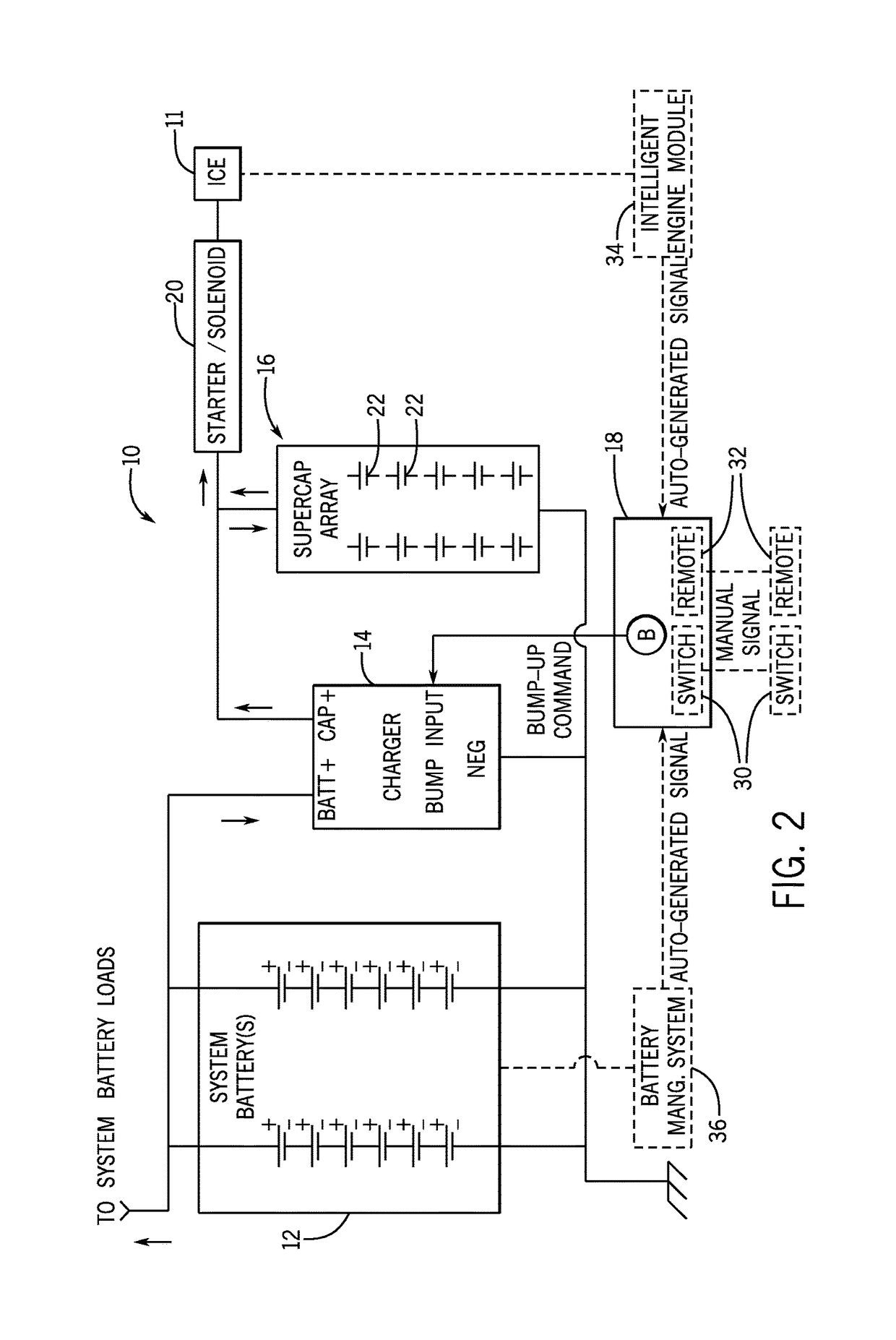

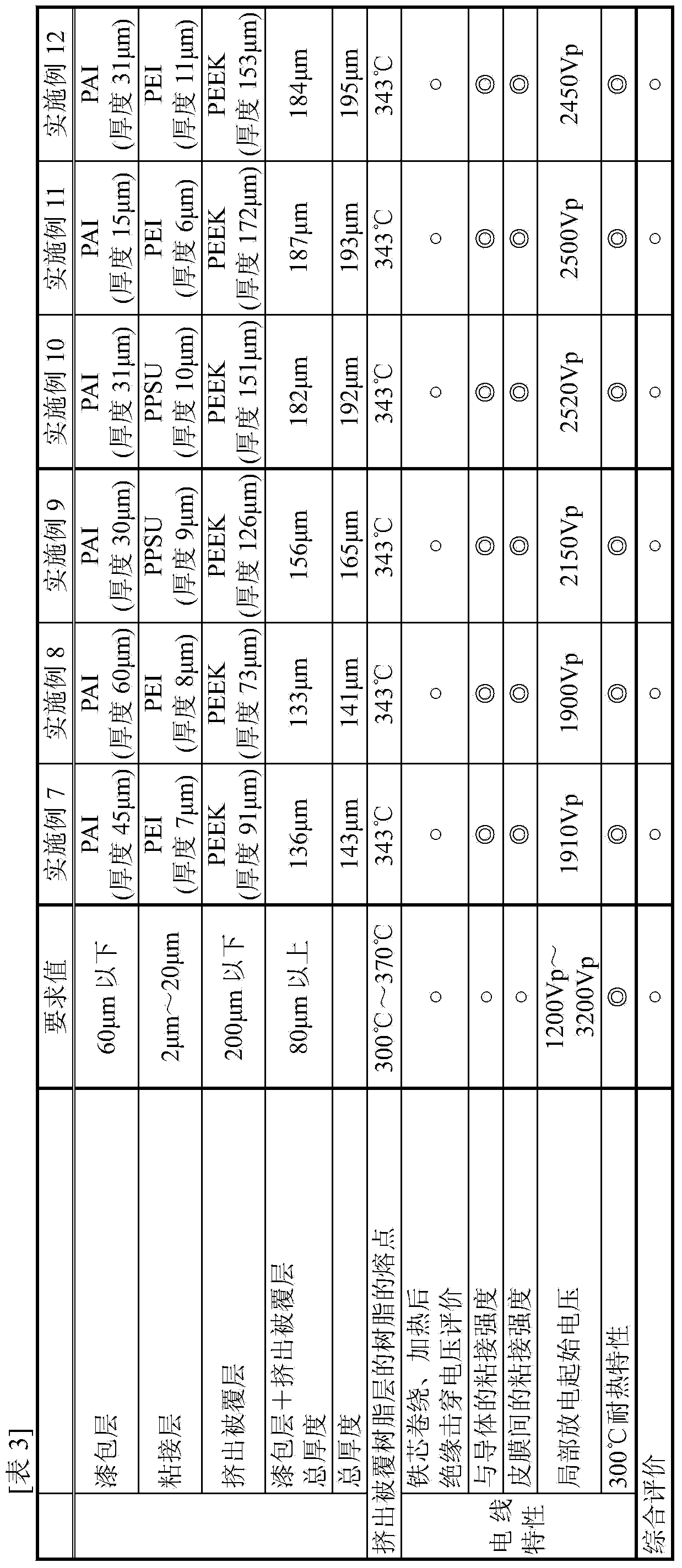

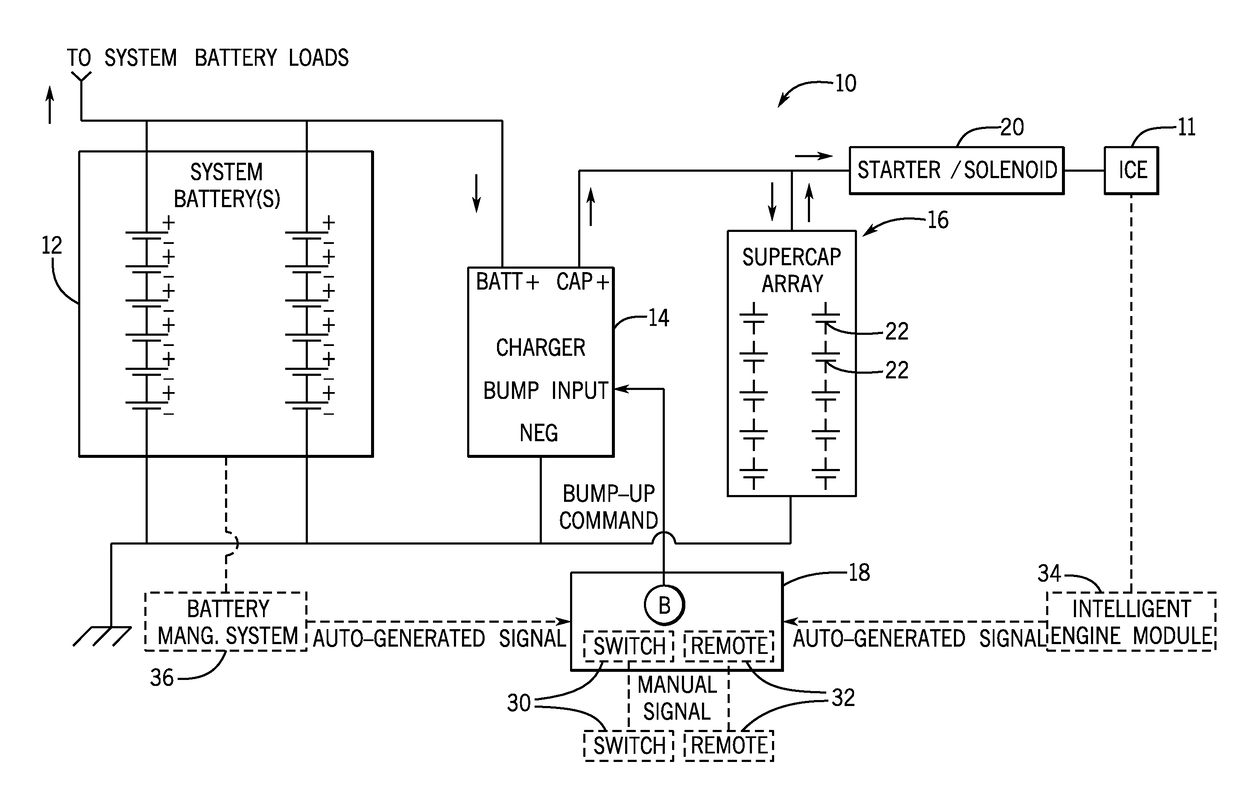

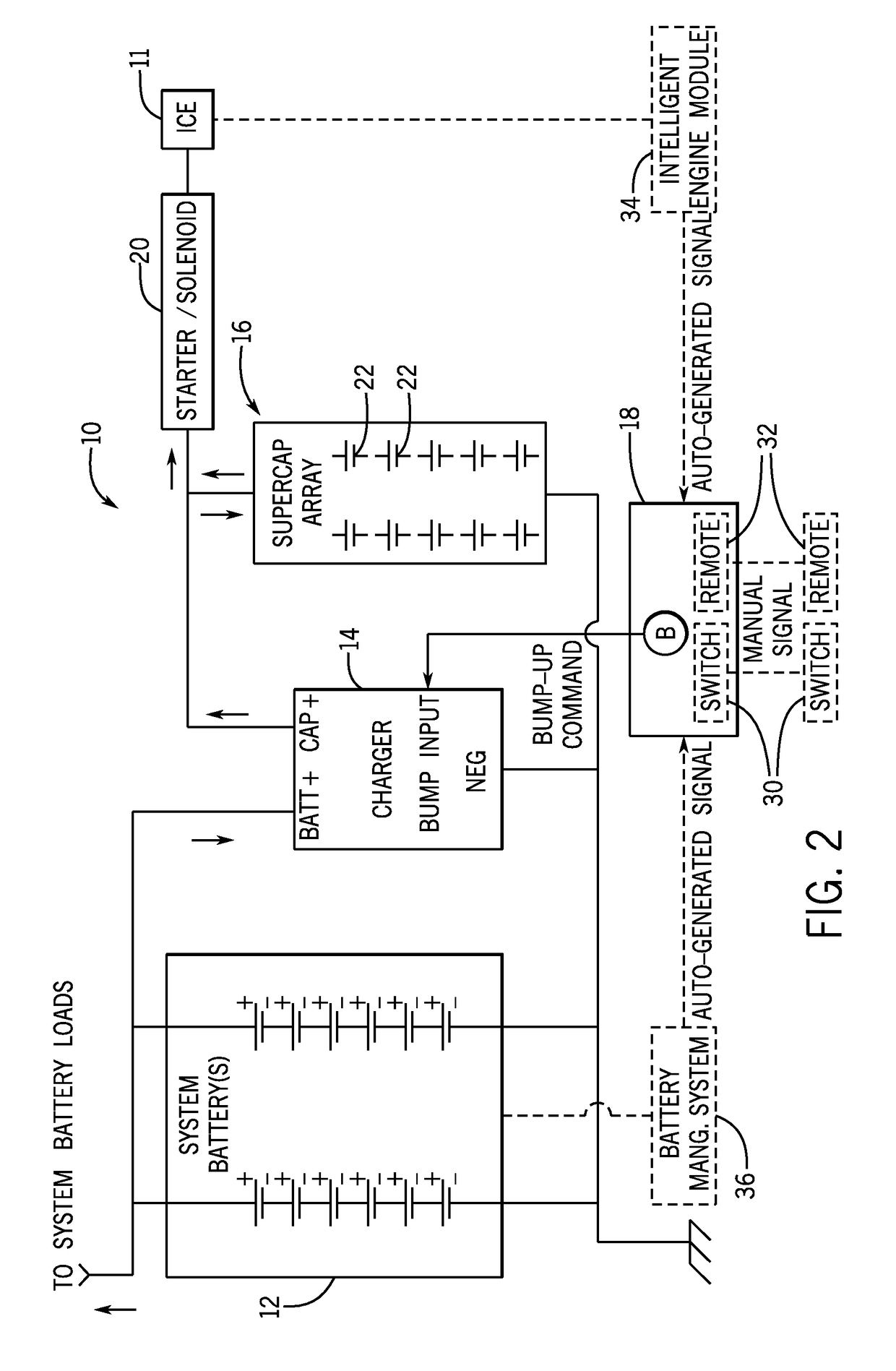

System and method for maximizing short-term energy storage in a supercapacitor array for engine start applications

ActiveUS9816475B1Increase the starting voltageHigh voltageBatteries circuit arrangementsElectric motor startersThermal energy storageElectrical battery

A system for starting an internal combustion engine includes a battery system, a charger to receive DC battery power from the battery system and convert the power to a DC charging current, a supercapacitor array having a plurality of supercapacitor cells connected to the charger to receive the DC charging current therefrom, and a motor starter to start the internal combustion engine responsive to a DC input from the supercapacitor array. The charger modifies a voltage of the supercapacitor cells in an on-demand fashion, with the charger programmed to provide DC charging current to the supercapacitor array to hold the supercapacitor cells at a first voltage, receive a bump-up command indicative of an upcoming engine start and, responsive to receiving the bump-up command, provide DC charging current to the supercapacitor array to increase a voltage of the supercapacitor cells temporarily to a second voltage higher than the first voltage.

Owner:EATON INTELLIGENT POWER LIMITED

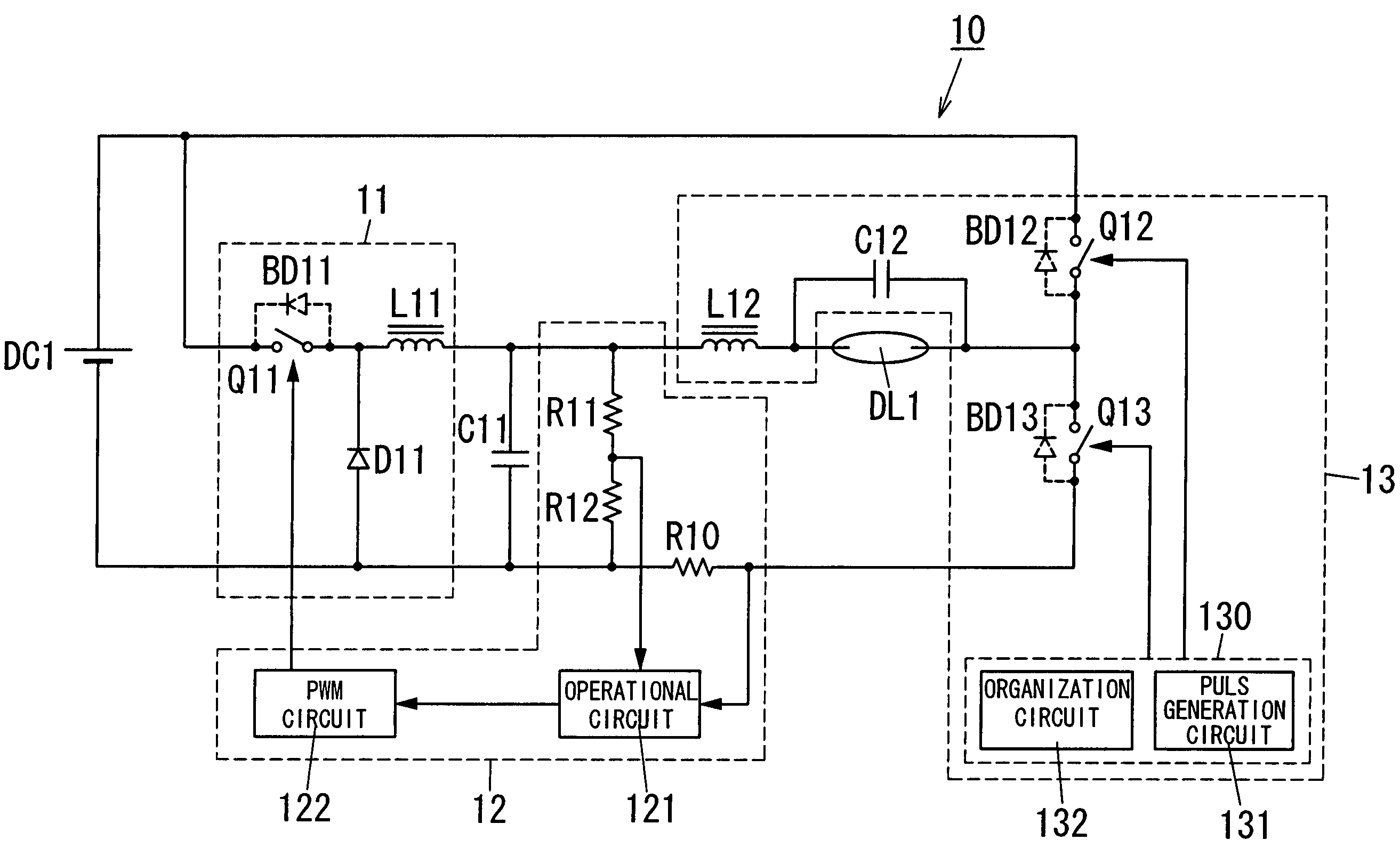

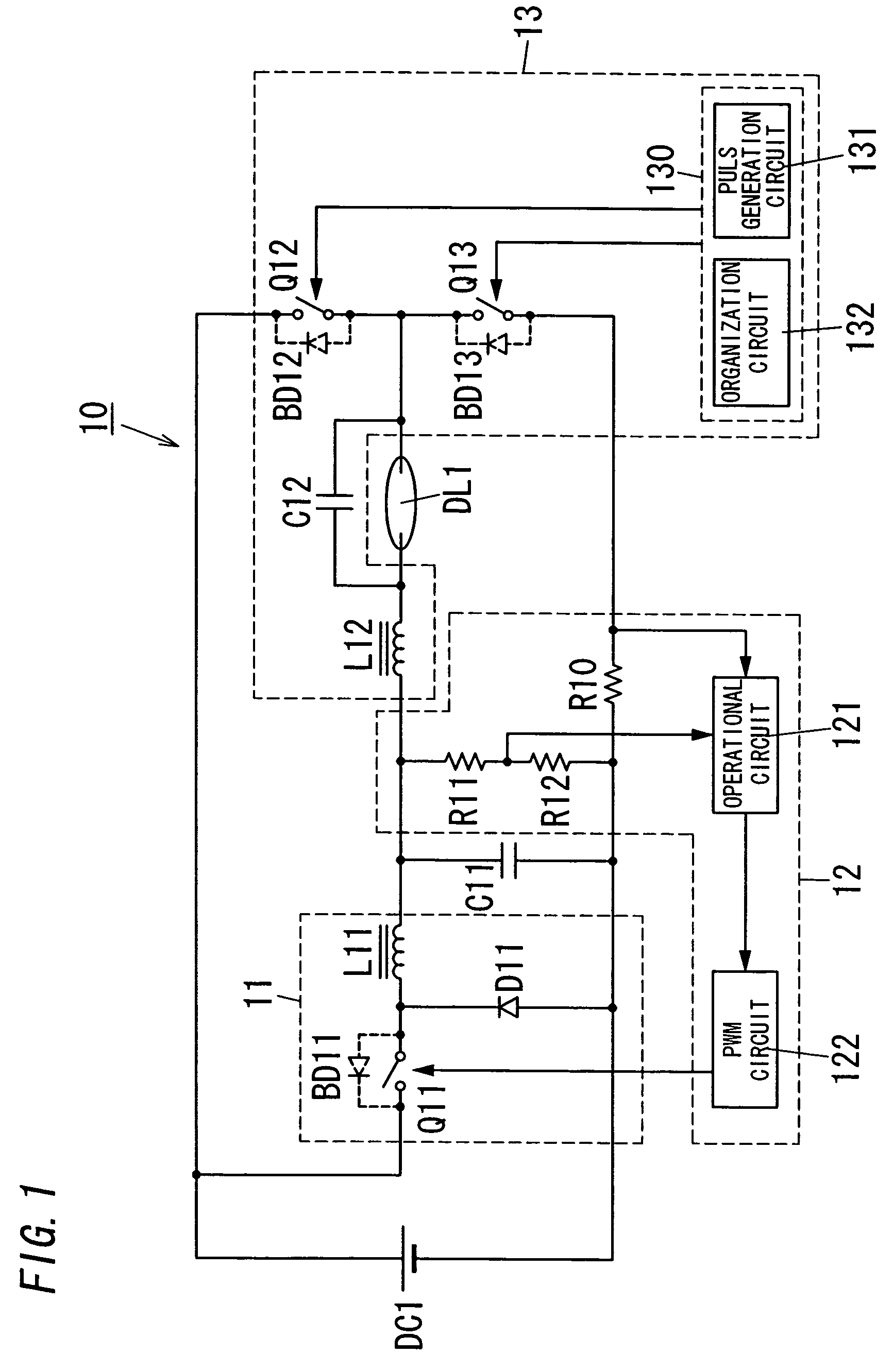

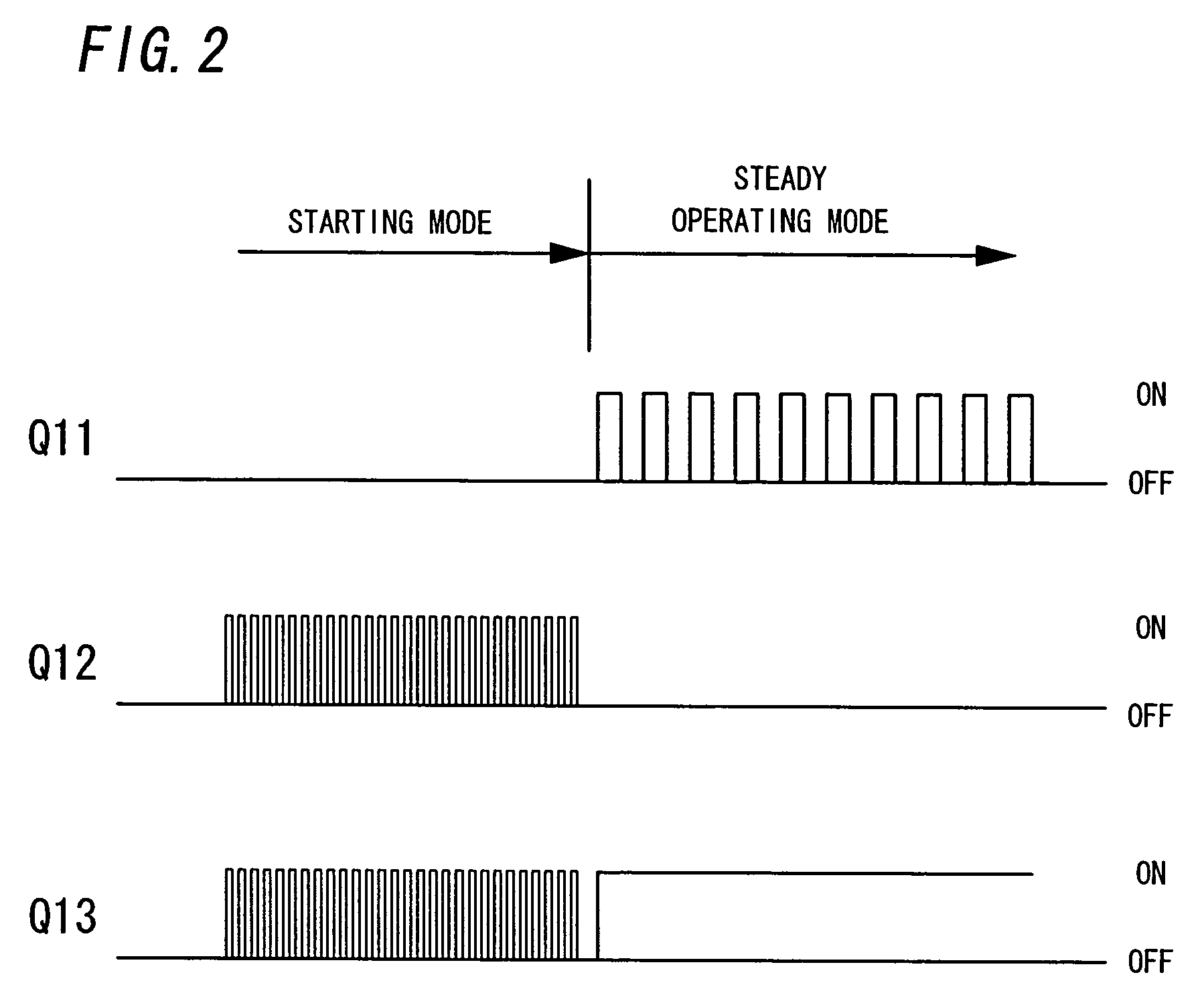

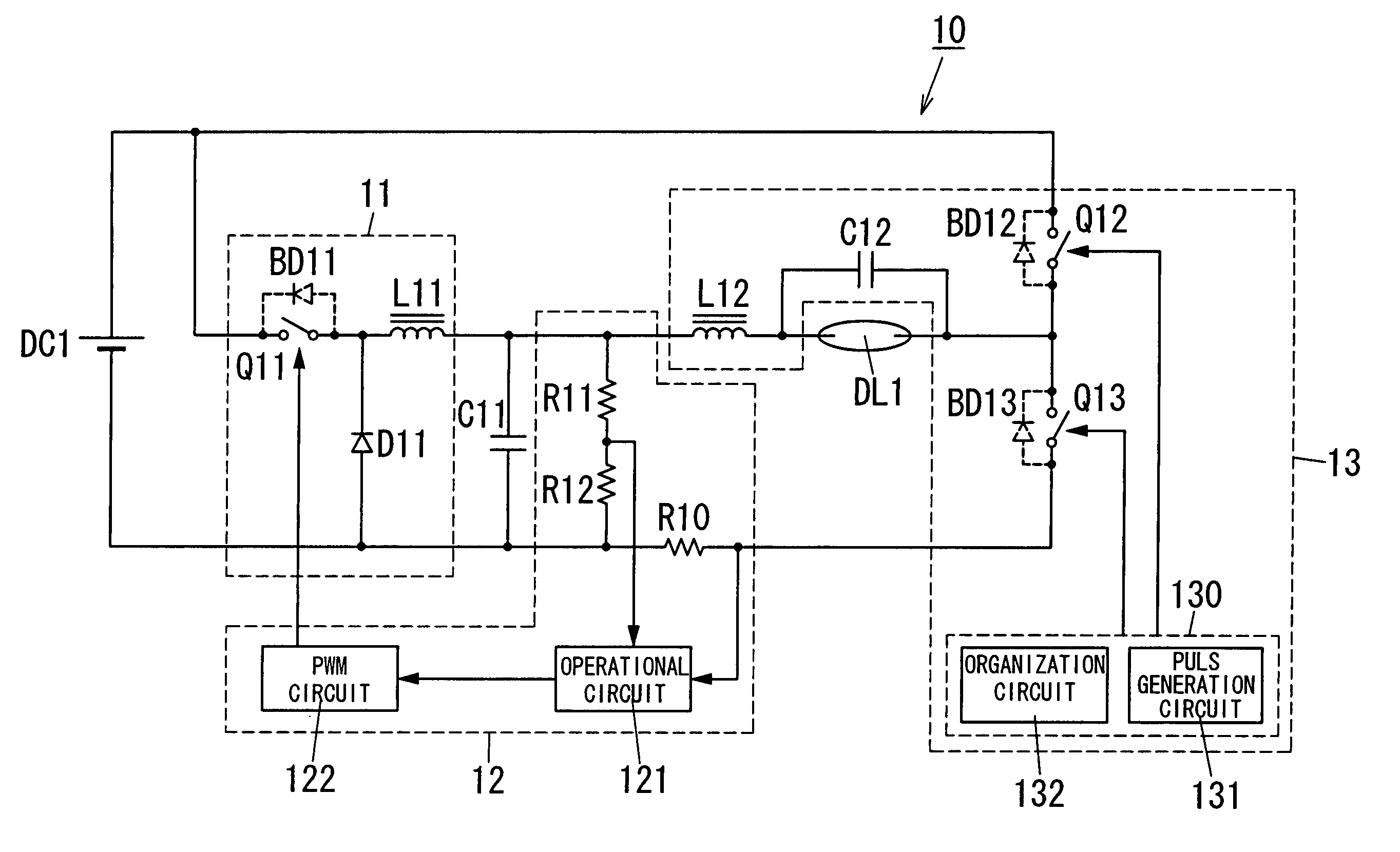

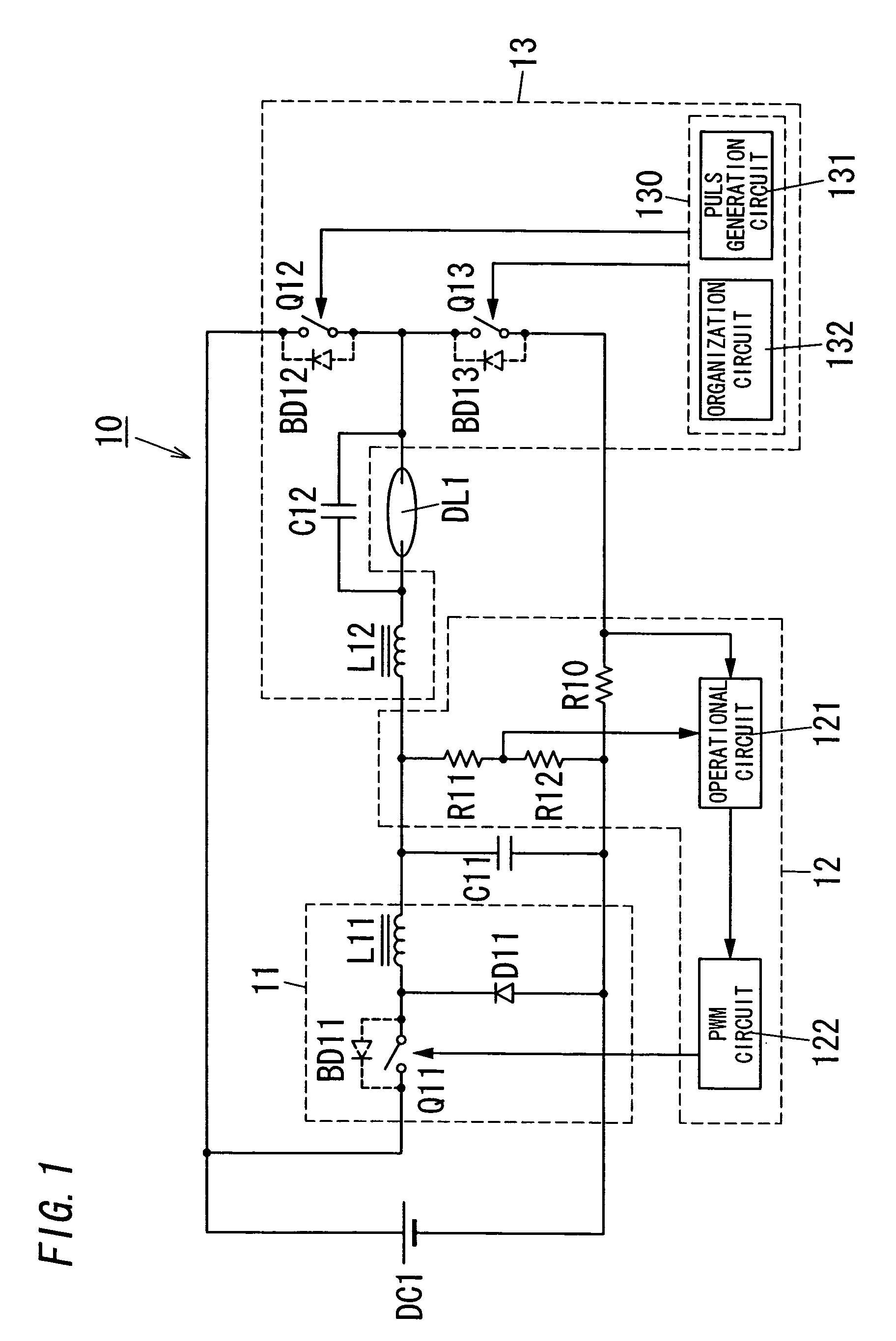

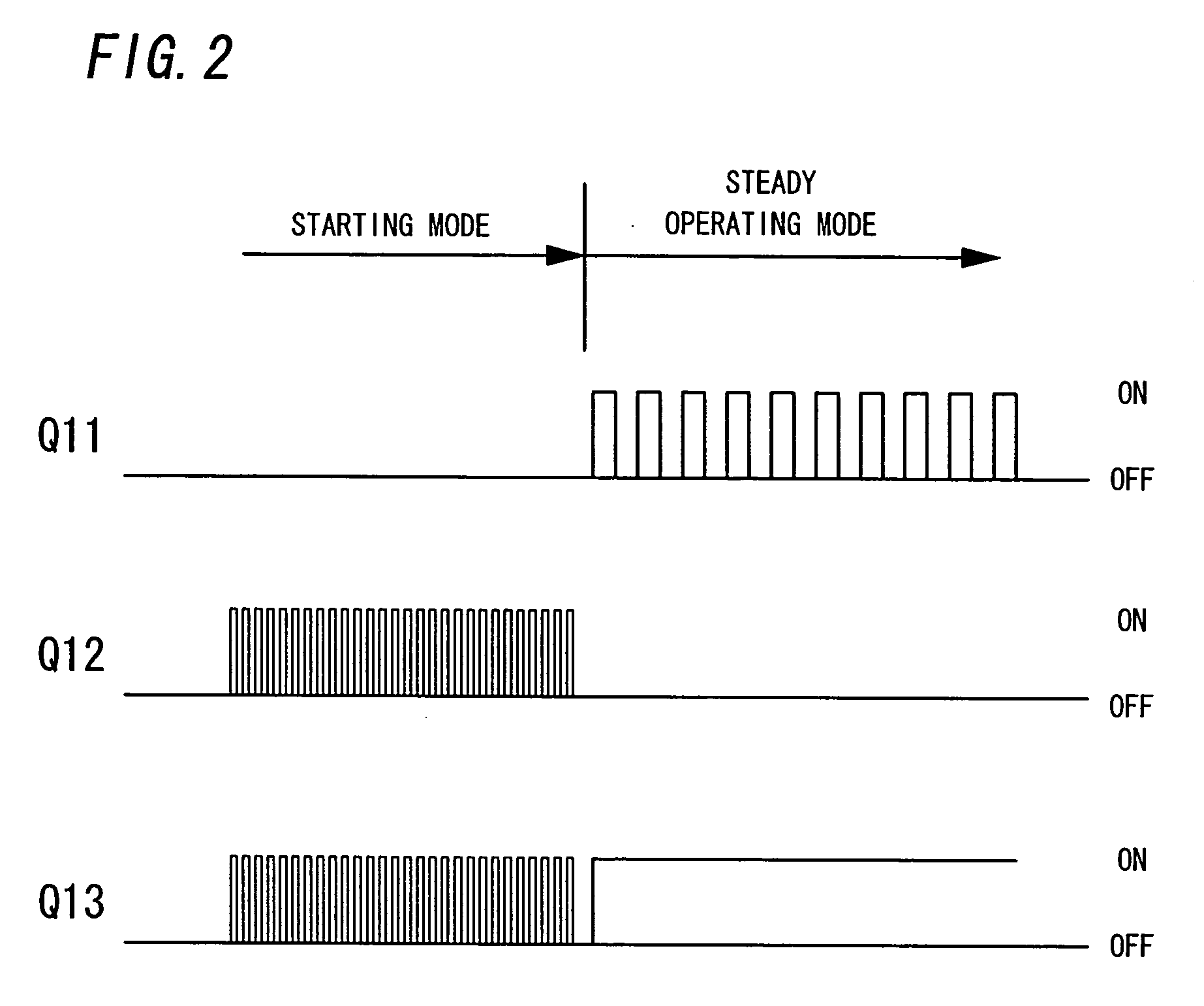

Discharge lamp ballast, lighting system and projector

InactiveUS7692391B2Reduce noiseIncrease the starting voltageAlternating current plasma display panelsElectric light circuit arrangementResonanceEngineering

A discharge lamp ballast having a starting circuit including a second inductor connected between a first end of a discharge lamp and the positive voltage side of a first capacitor; a second capacitor forming a resonance circuit together with the second inductor; a second switching element connected between the positive terminal of a DC power source and the second end of the lamp; a third switching element connected between the second end of the lamp and the negative voltage side of the first capacitor; and a starting controller that controls both switching elements. The starting controller alternately turns both switching elements on and off so as to contribute resonance voltage of the resonance circuit for starting of the lamp in case of the starting mode.

Owner:MATSUSHITA ELECTRIC WORKS LTD

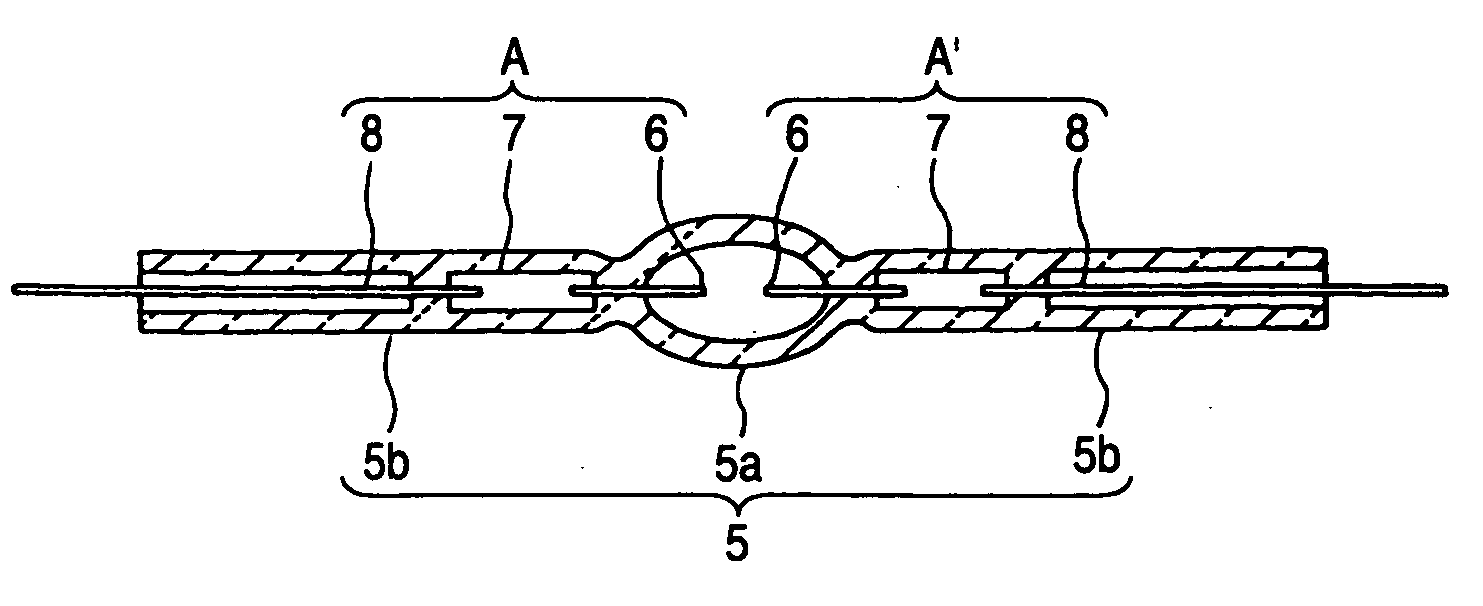

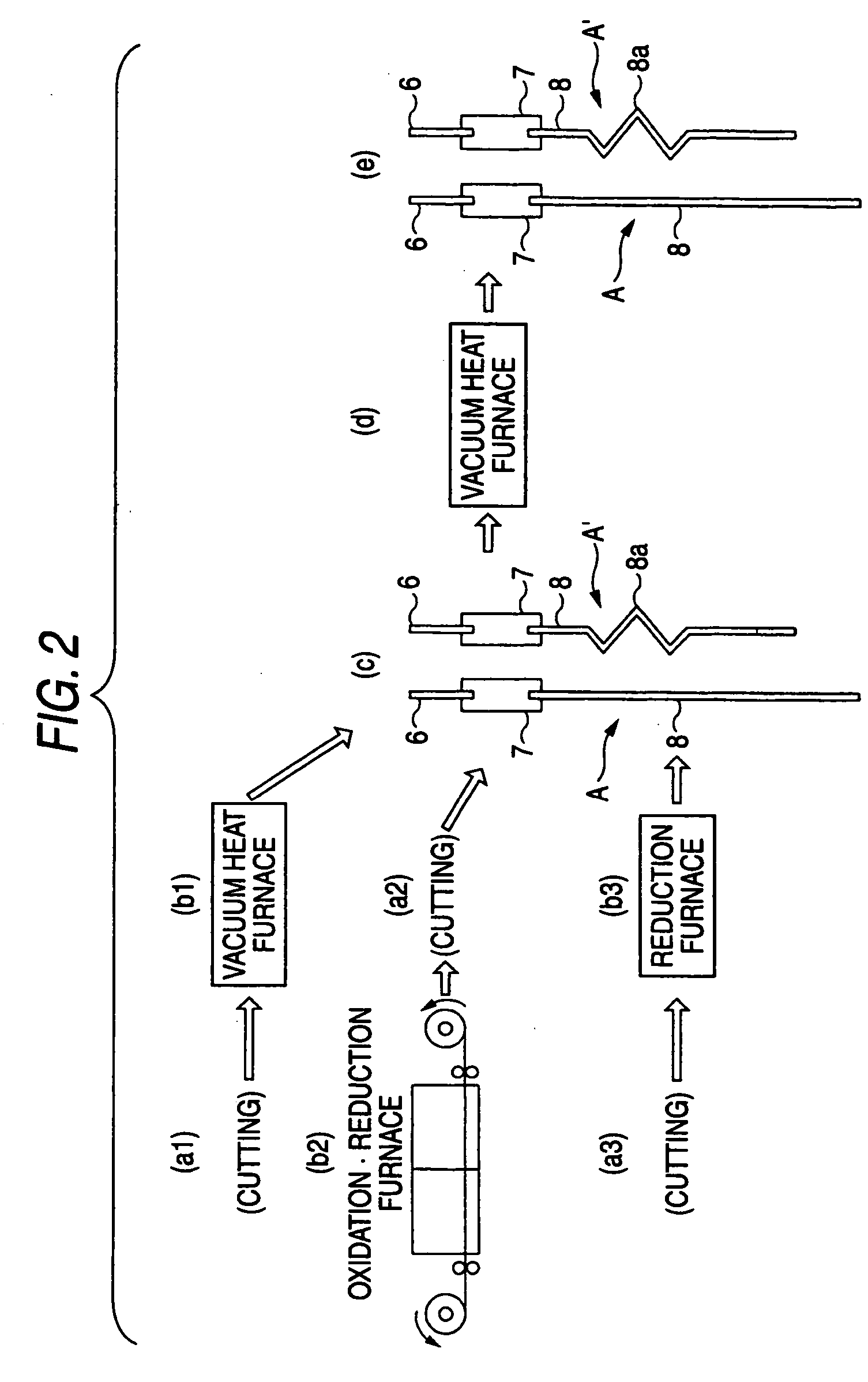

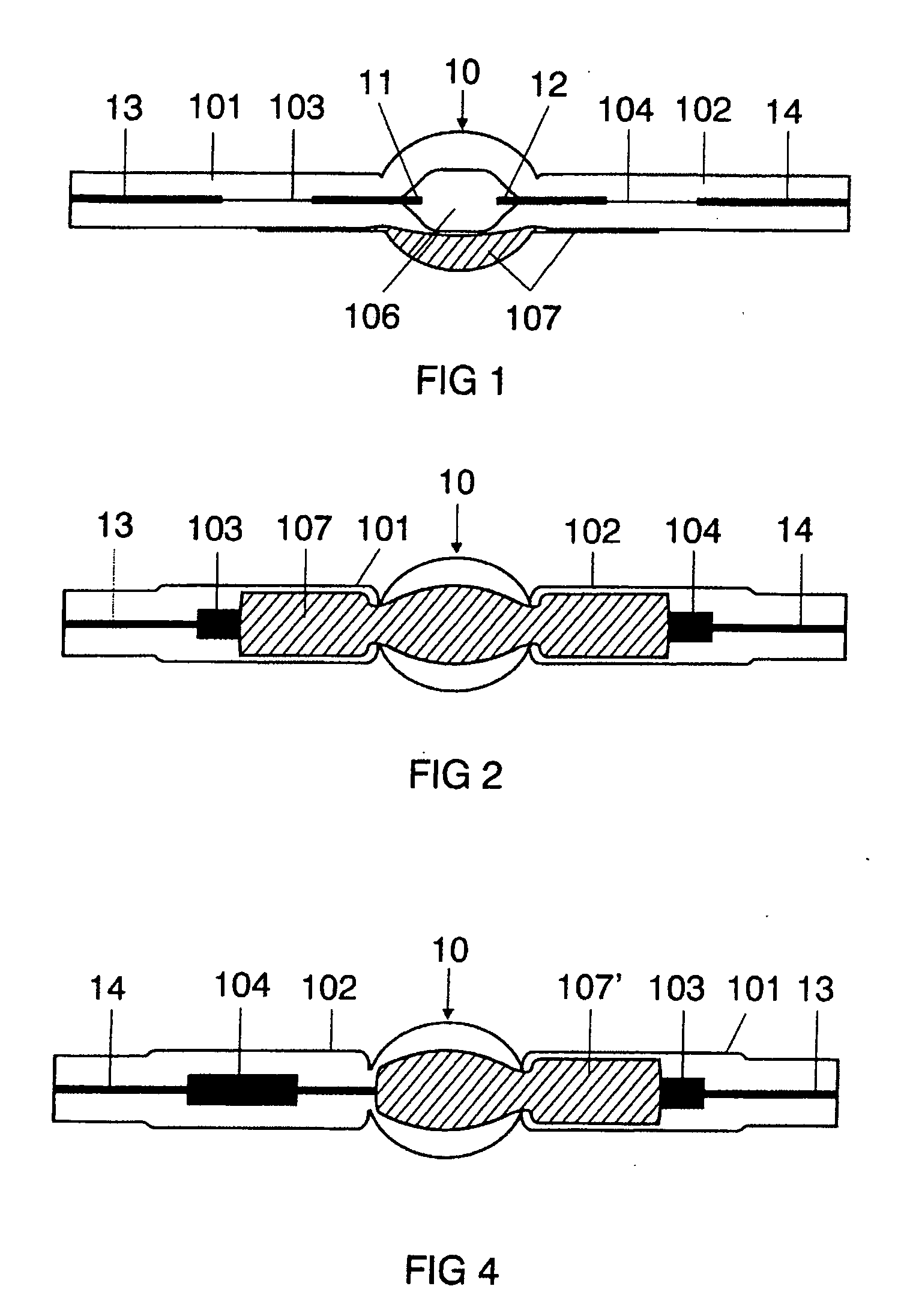

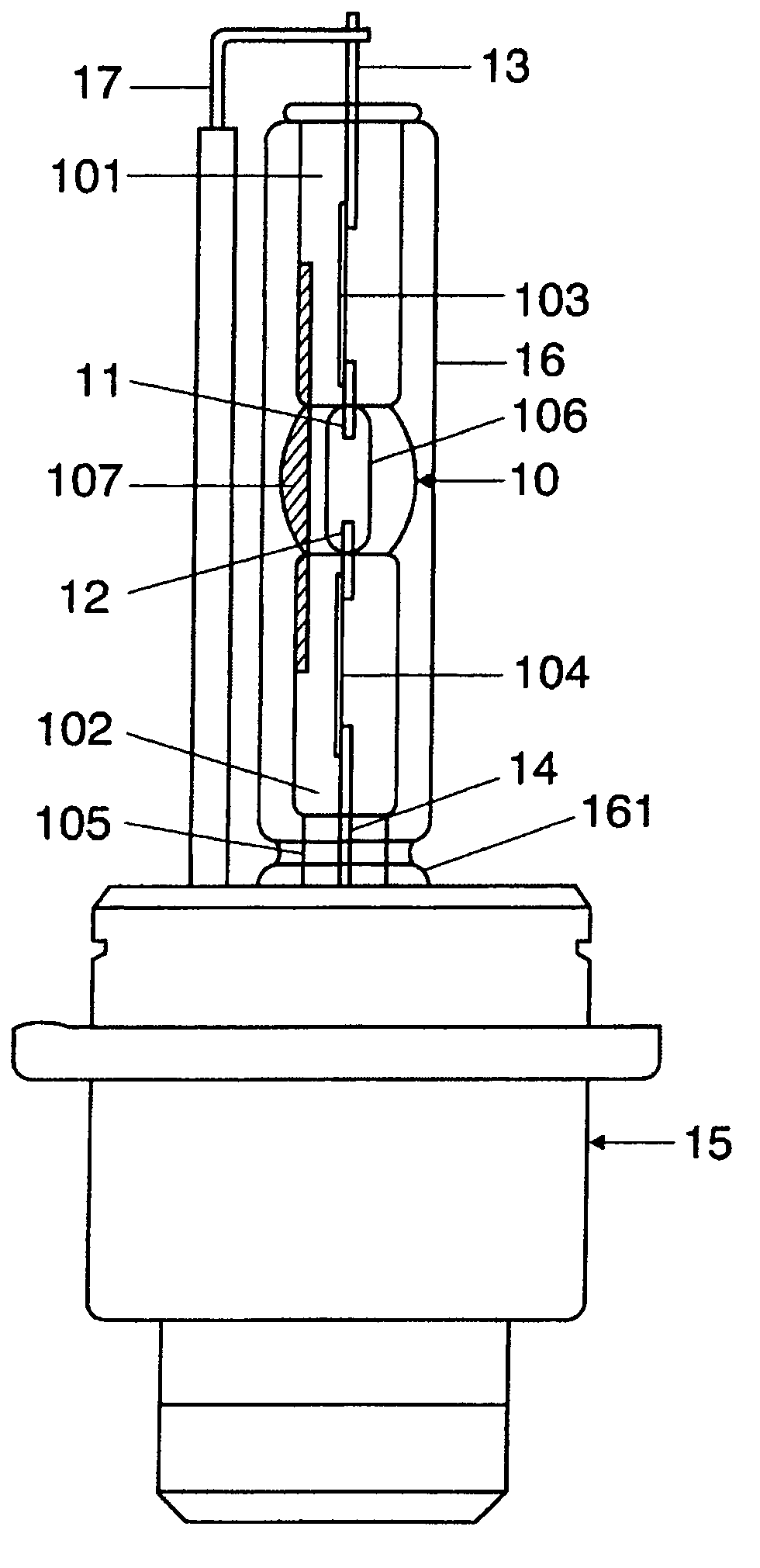

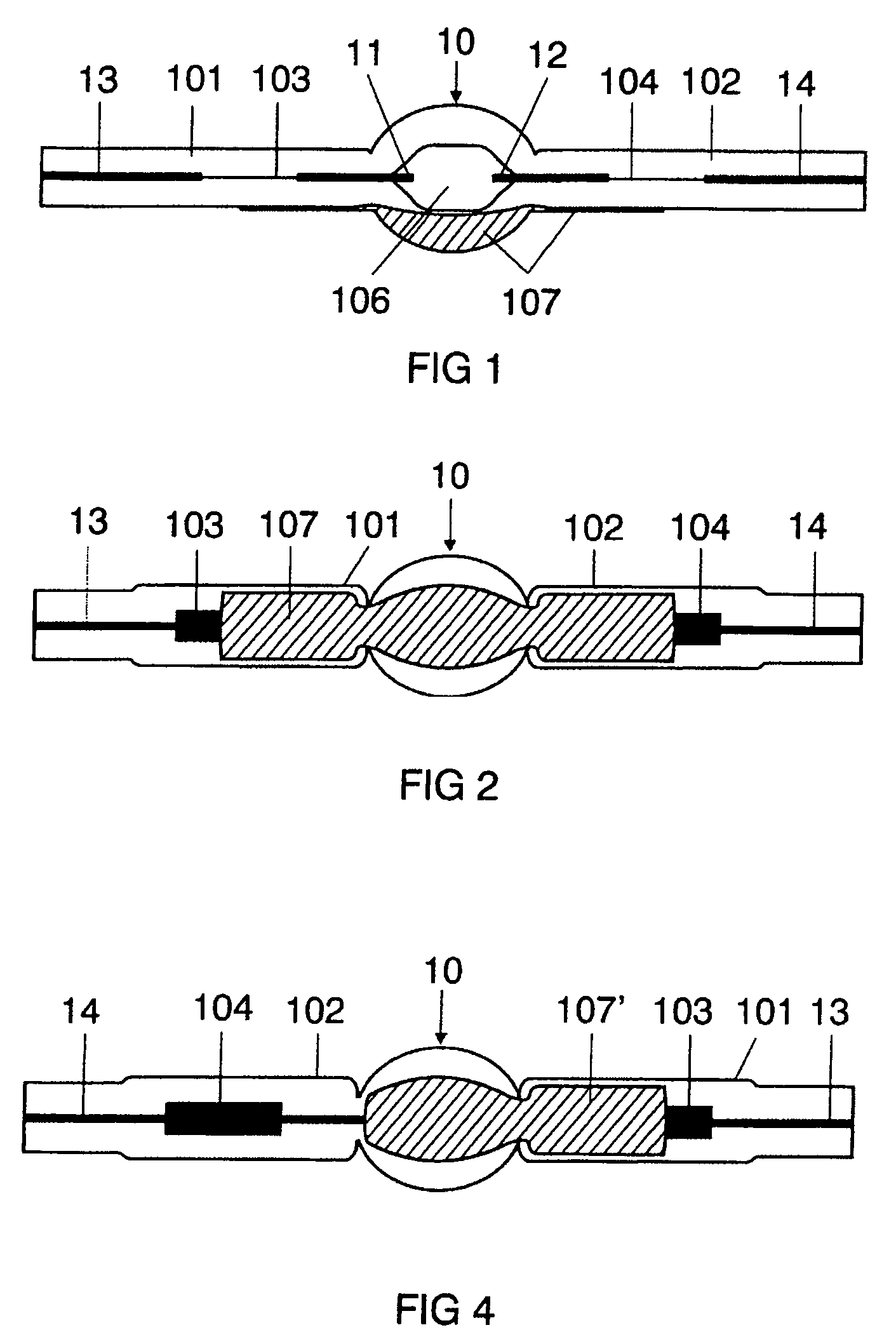

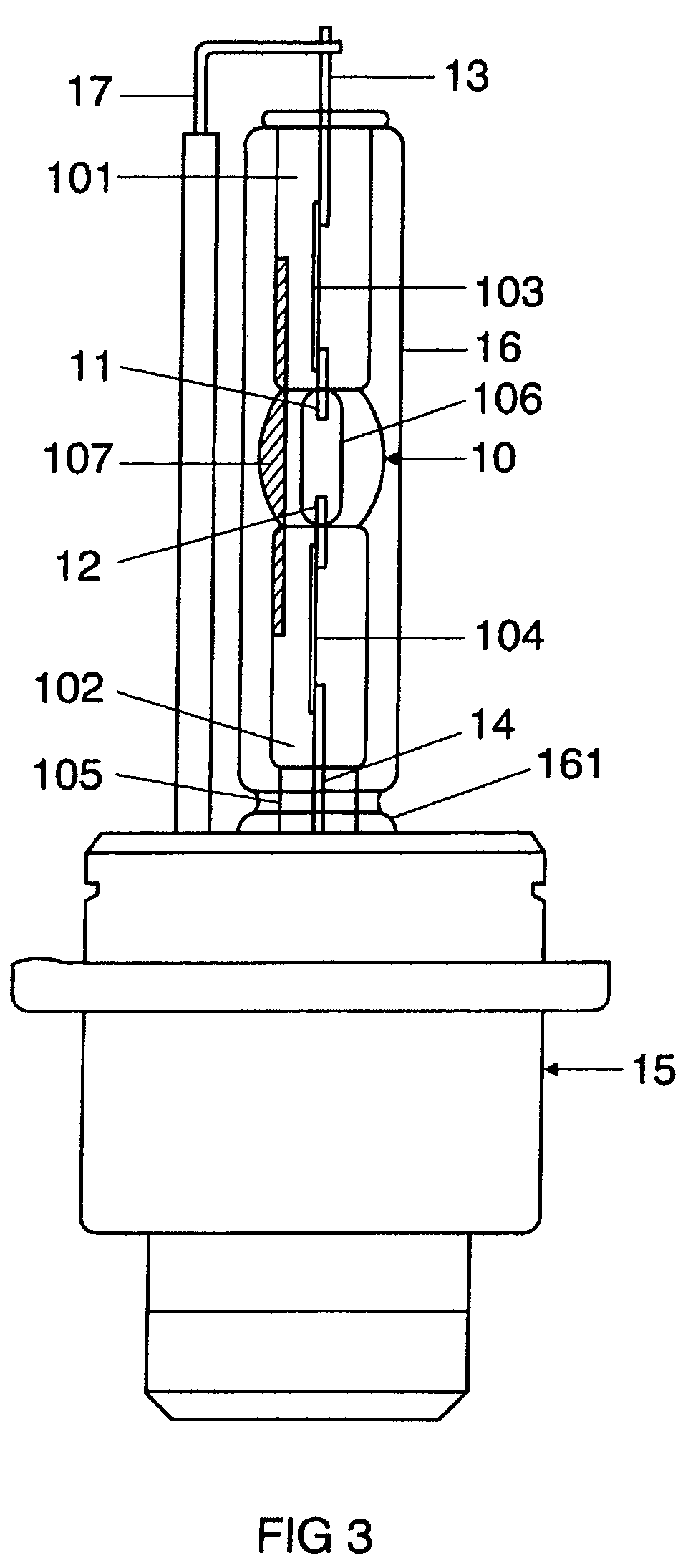

Arc tube of discharge lamp and method of manufacturing of arc tube

InactiveUS20060119264A1Restraining occurrence of flickerEffectively preventDischarge tube luminescnet screensElectroluminescent light sourcesWater contentVoltage

In an arc tube for discharge lamp, an electrode assembly is formed by integrally joining an electrode rod, a molybdenum foil, and a molybdenum lead wire. The electrode assembly is sealed into pinch seal portions located at both ends of a glass tube. The electrode assembly, before being pinch-sealed into the pinch seal portions, receives vacuum heat treatment at 200 to 800° C. Hereby, the water content of the assembly is adjusted to 10 ppm or less, and desirably to 3 ppm less and an oxide film attached to the surface of the electrode assembly is removed. Therefore, the quantity of impurity (water or gas) enclosed in the closed glass bulb is very small, so that it is possible to provide an arc tube in which the flicker is not produced, luminous flux of 3000 lm or more is obtained, and starting voltage can be lowered to about 15 kV.

Owner:KOITO MFG CO LTD

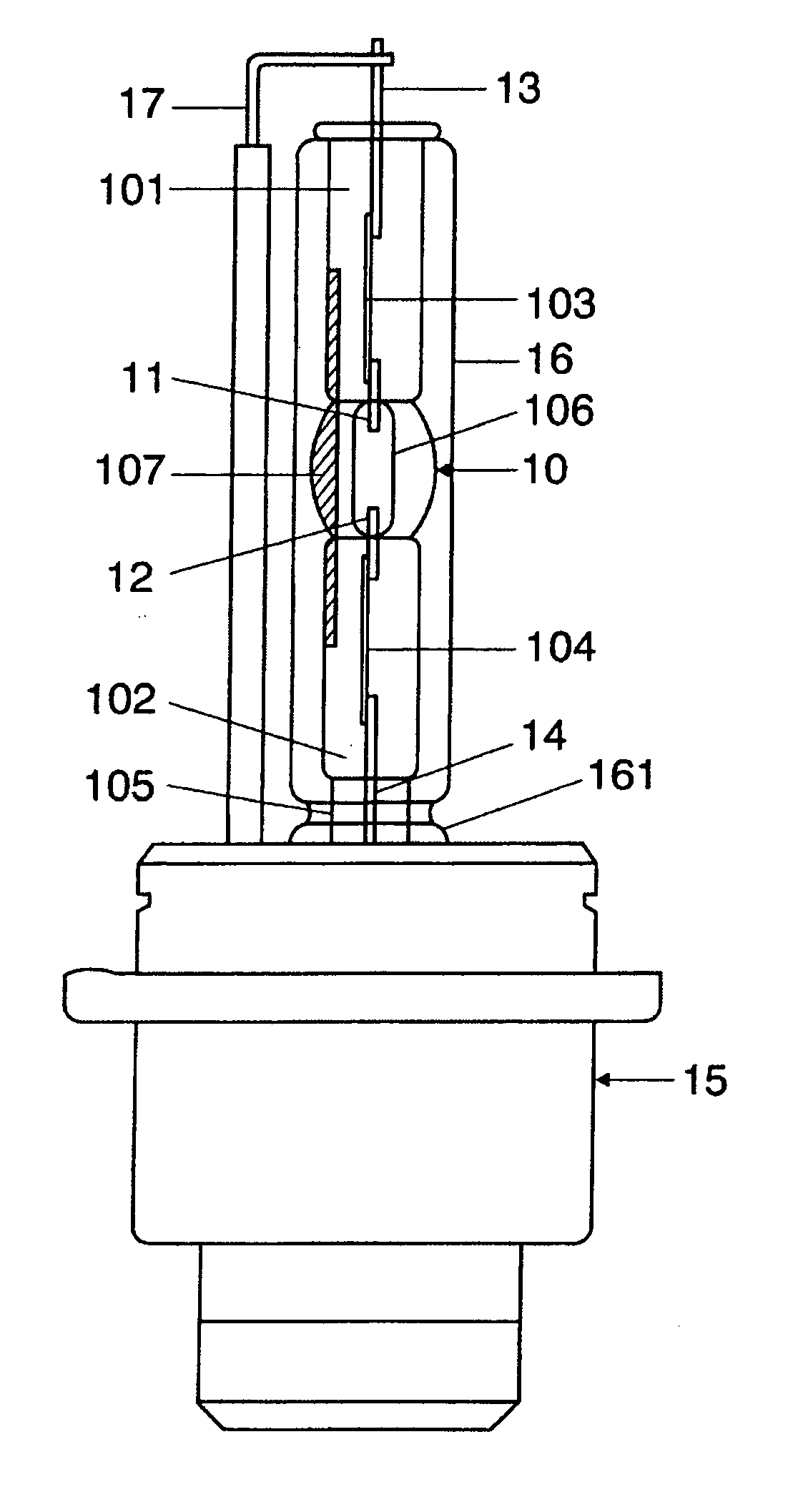

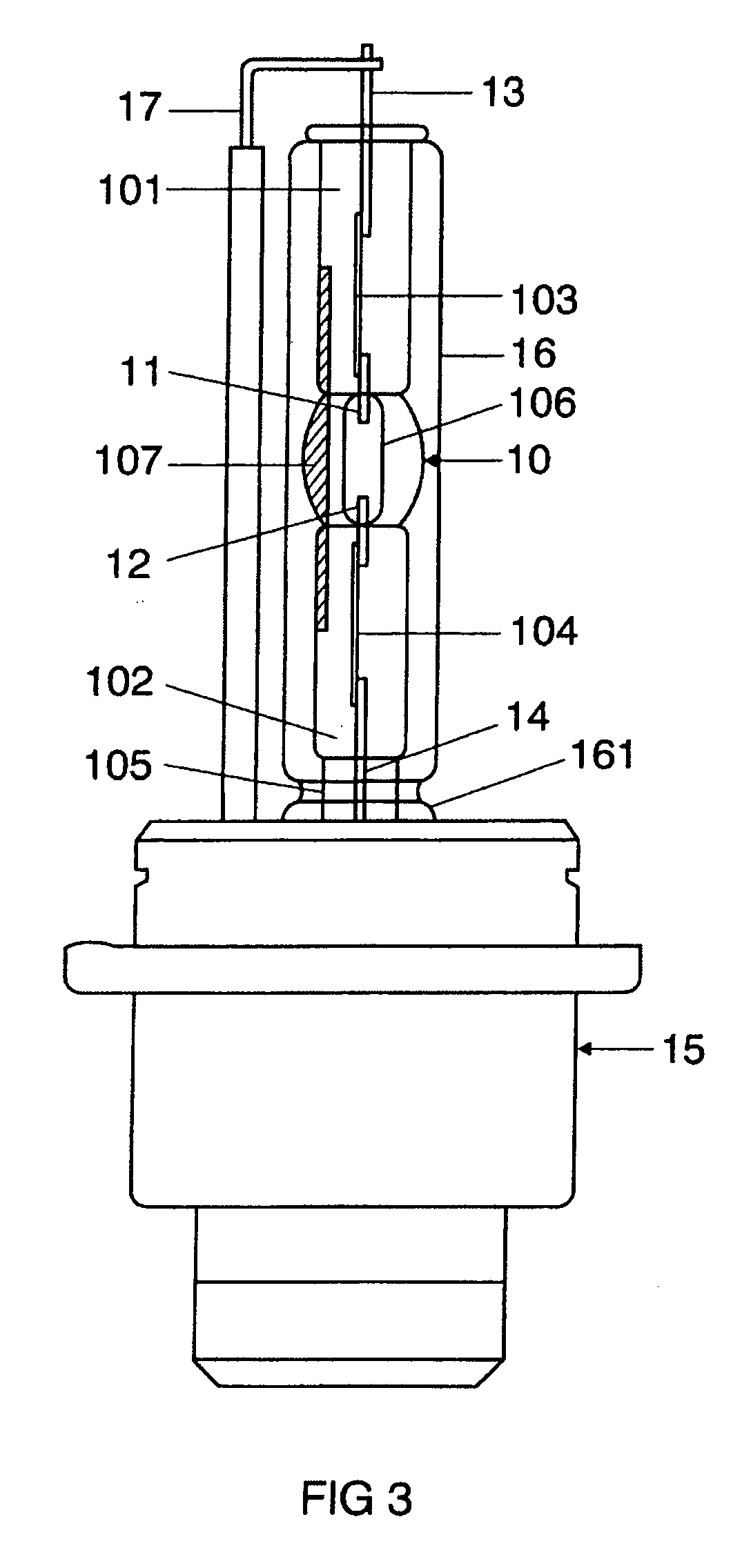

High-pressure discharge lamp

InactiveUS20060049764A1Increase capacityReduce the starting voltageSolid cathode detailsGas discharge lamp detailsCapacitanceConductive coating

The invention relates to a high-pressure discharge lamp having a transparent discharge vessel, an ionizable filling which is arranged in the discharge space of the discharge vessel and electrodes, which extend into the discharge space of the discharge vessel, for the purpose of producing a gas discharge, as well as power supply lines, which are passed out of the discharge vessel, for the purpose of supplying energy to the electrodes, the discharge vessel of the high-pressure discharge lamp being provided partially with an electrically conductive coating, with the result that a capacitive coupling is produced between the coating and at least one electrode and / or power supply line. As a result, the starting properties and the luminous efficiency of the lamp are improved.

Owner:OSRAM GMBH

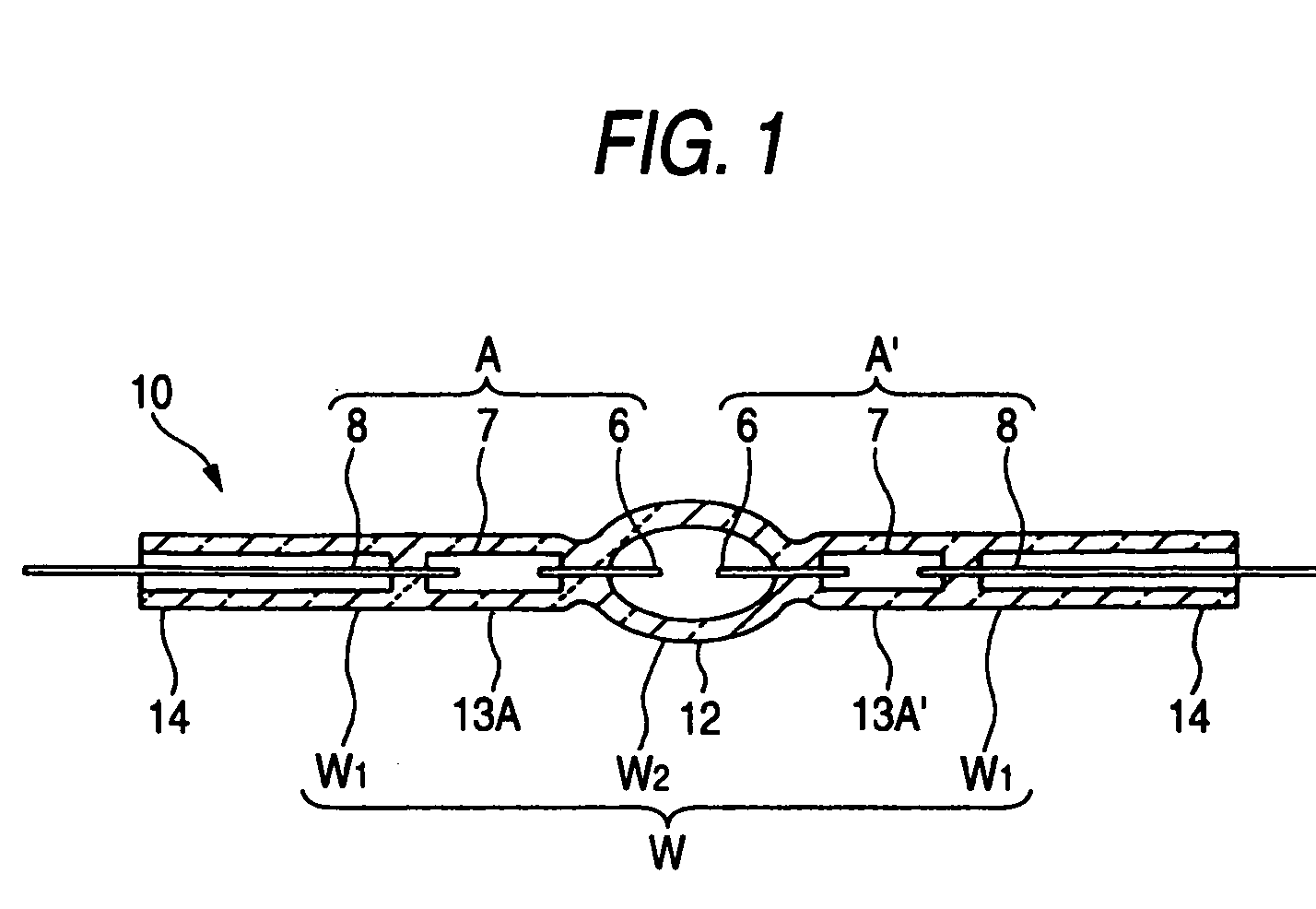

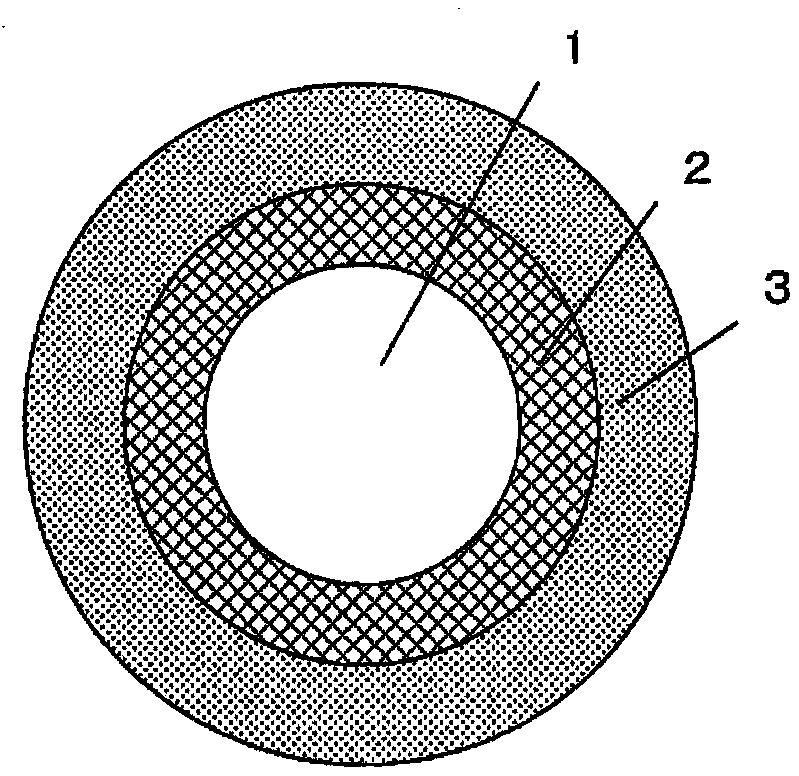

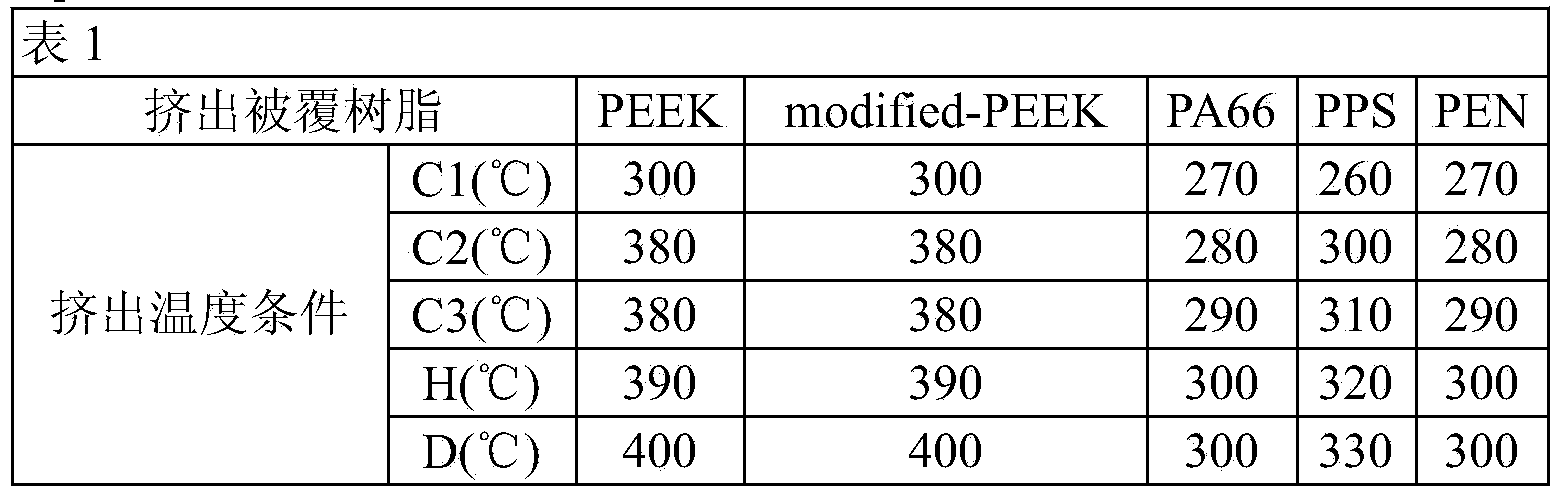

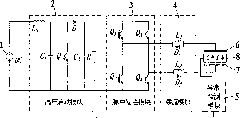

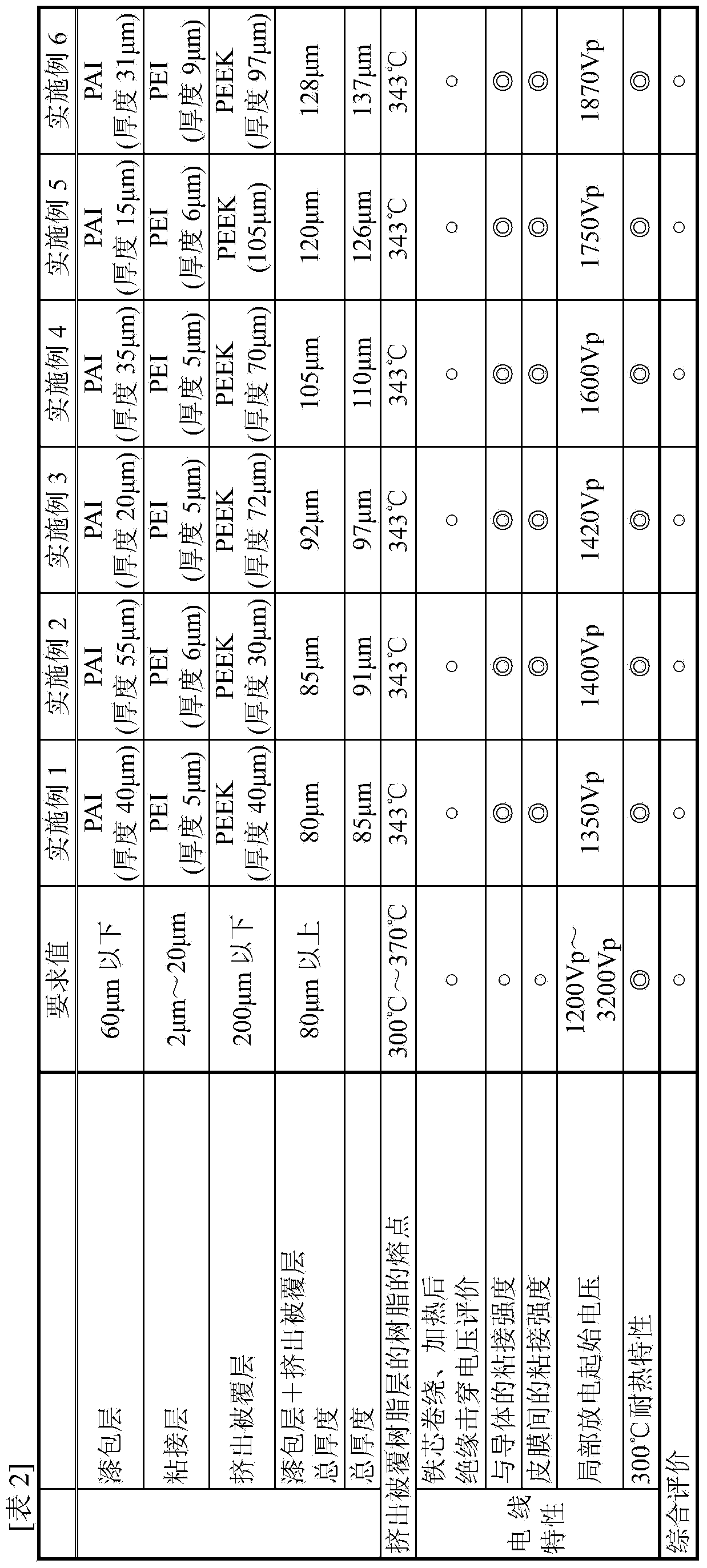

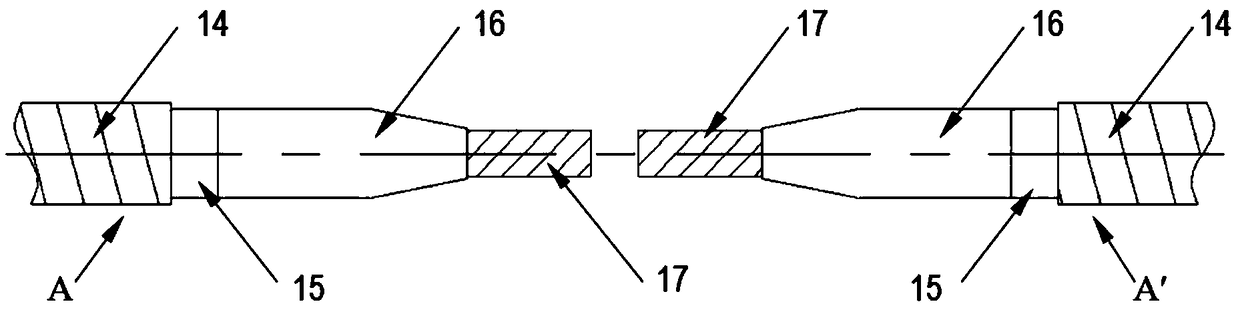

Invertor-surge resistant insulated wire

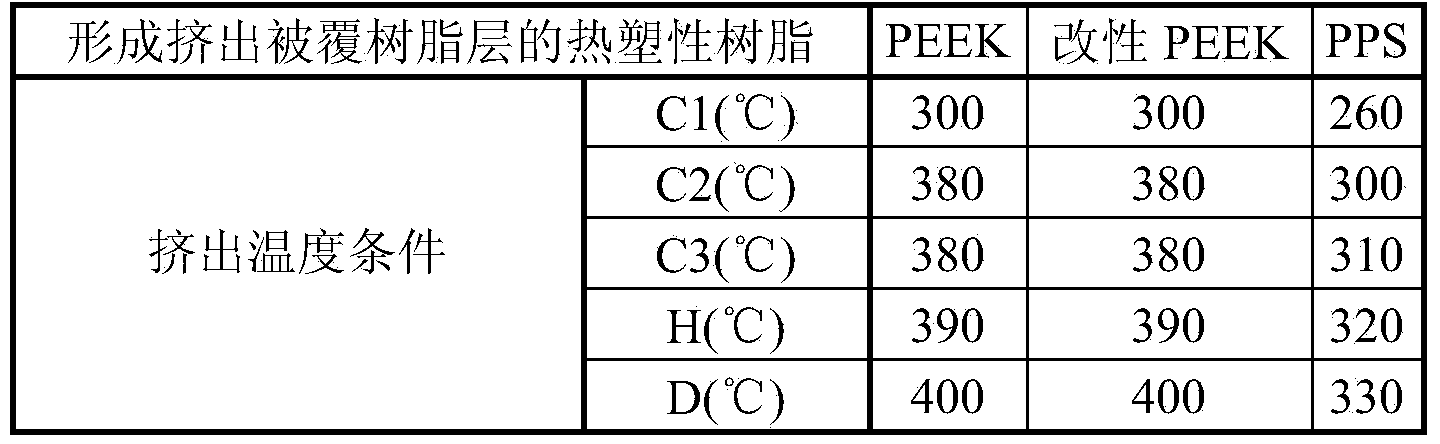

ActiveCN104170024AIncrease the starting voltageImprove insulation performanceWindings insulation materialPlastic/resin/waxes insulatorsDielectricElectrical conductor

An invertor-surge resistant insulated wire provided with at least one layer of an enamel fusion layer (2) on the outer circumference of a conductor (1), and at least one layer of an extrusion-coating resin layer (3) on the outer side of the enamel fusion layer (2). The combined thickness of the enamel fusion layer (2) and the extrusion-coating resin layer (3) is equal to or greater than 50μm, the thickness of the enamel fusion layer (2) is equal to or less than 60μm, and the thickness of the extrusion-coating resin layer (3) is equal to or less than 200μm. The minimum tensile elasticity of the extrusion-coating resin layer (3) at 25-250ºC is equal to or greater than 100MPa. The relative dielectric constant of an insulating layer, which is a combination of the enamel fusion layer (2) and the extrusion-coating resin layer (3), is equal to or less than 3.5 at 25 ºC, and equal to or less than 5.0 at 250 ºC. The relationship between the relative dielectric constant (ε1') of the enamel fusion layer (2) at 250 ºC and the relative dielectric constant (ε2') of the extrusion-coating resin layer (3) at 250 ºC satisfies (ε2' / ε1')>1.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Magnetron sputtering pulse power supply with high starting voltage

InactiveCN101824602AIncrease the starting voltageEliminate load voltage oscillationsVacuum evaporation coatingSputtering coatingSputteringAnomaly detection

The invention discloses a magnetron sputtering pulse power supply with high starting voltage, which comprises a DC input, a high-voltage starting module, a pulse generating module and a follow current module which are connected in turn, wherein the follow current module is connected with a substrate and a target in a magnetron sputtering device; the high-voltage starting module is connected with an abnormal detection module, and is used for providing a starting voltage of 1,500V for a magnetron sputtering process; the pulse generating module is used for generating pulse bias voltage; the follow current module is used for solving the problem that the output voltage produces large oscillation due to the special property of a plasma load during pulse magnetron sputtering; and the abnormal detection module is used for detecting the change of plasma load current and performing secondary high-voltage startup on the magnetron sputtering process according to the change of the load current when an abnormal condition happens. The power supply structure of the invention has the advantages of improving the ionization rate of plasma in the magnetron sputtering engineering, enhancing the combination strength of a film and a matrix and ensuring a deposition process.

Owner:XIAN UNIV OF TECH

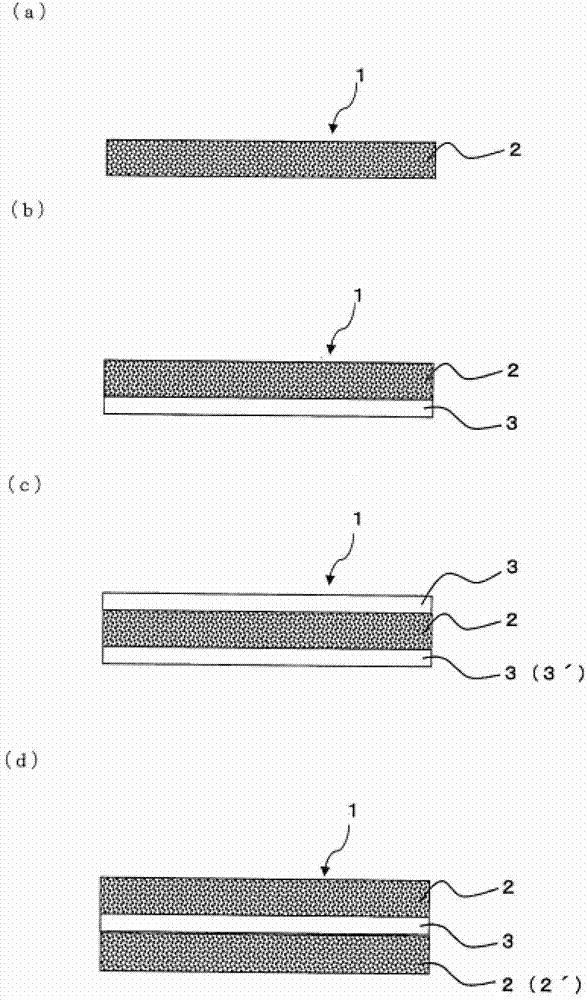

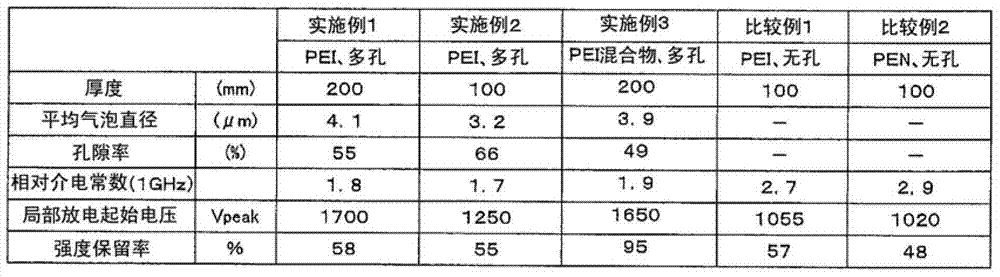

Electrically insulating resin sheet for motors and process for production thereof

InactiveCN103370857AImprove heat resistanceImprove insulation performanceWindings insulation materialWindings insulation shape/form/constructionPorosityEngineering

Provided are: an electrically insulating resin sheet for motors, which is used for achieving the insulation between coil wires or between a coil wire and an iron core in a motor, and which has high heat resistance, high electrical insulation performance and a high insulation breakdown voltage; and a process for producing the electrically insulating resin sheet. The electrically insulating resin sheet for motors, which is provided with a porous resin layer comprising a thermoplastic resin, is characterized in that the resin sheet has a relative permittivity of 2.0 or less at 1 GHz. It is preferred that the porous resin layer has an average cell diameter of 5.0 mum or less and contains cells in such an amount that the porosity is 30% or more.

Owner:NITTO DENKO CORP

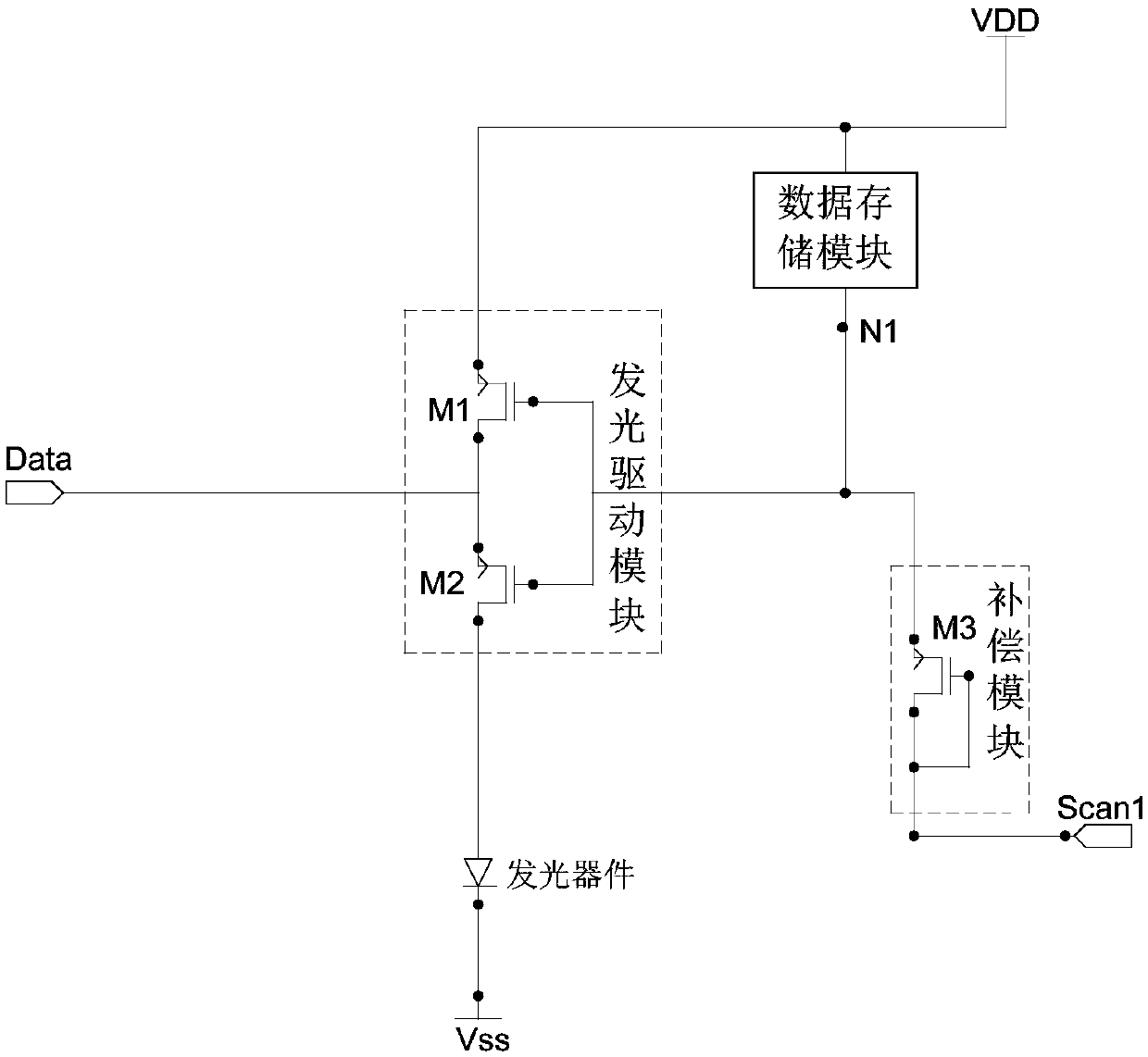

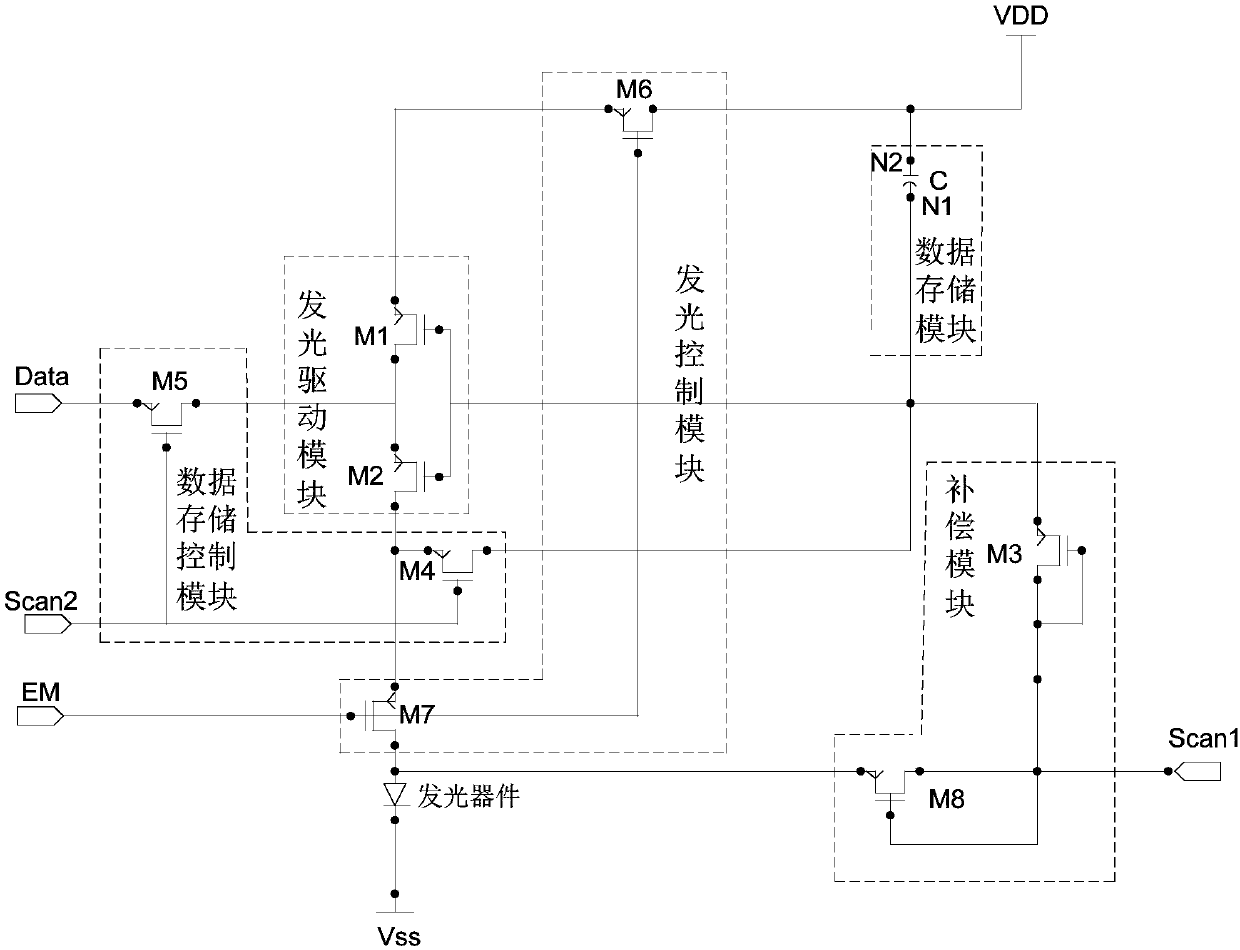

Pixel driving circuit, display device, and driving method of pixel driving circuit

ActiveCN109599064AReduce brightness inconsistenciesShorten write timeStatic indicating devicesDriving currentUltrasound attenuation

The embodiment of the invention provides a pixel driving circuit, a driving method of the pixel driving circuit and a display device, and solves the technical problem that a certain error exists in agate voltage of a driving transistor due to incomplete writing of a data signal in the prior art. According to the pixel driving circuit provided by the embodiment of the invention, when a data signalvoltage is transmitted to a data storage module, a starting point voltage of the discharge of the data storage module is increased by adopting the gate-drain short circuit of a compensation module and a second driving transistor. Therefore, the discharge time of the data storage module is shortened, the data signal writing time is shortened, the data signal writing speed is increased, the attenuation of the data signal during writing is reduced, the error voltage is reduced, the difference of a driving current is reduced, and the probability of inconsistent pixel brightness is reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

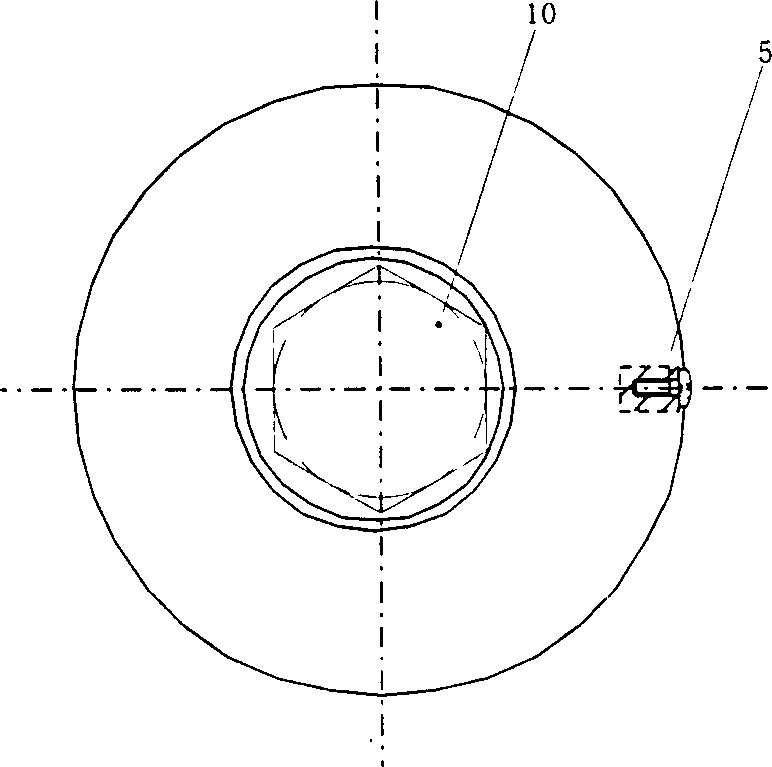

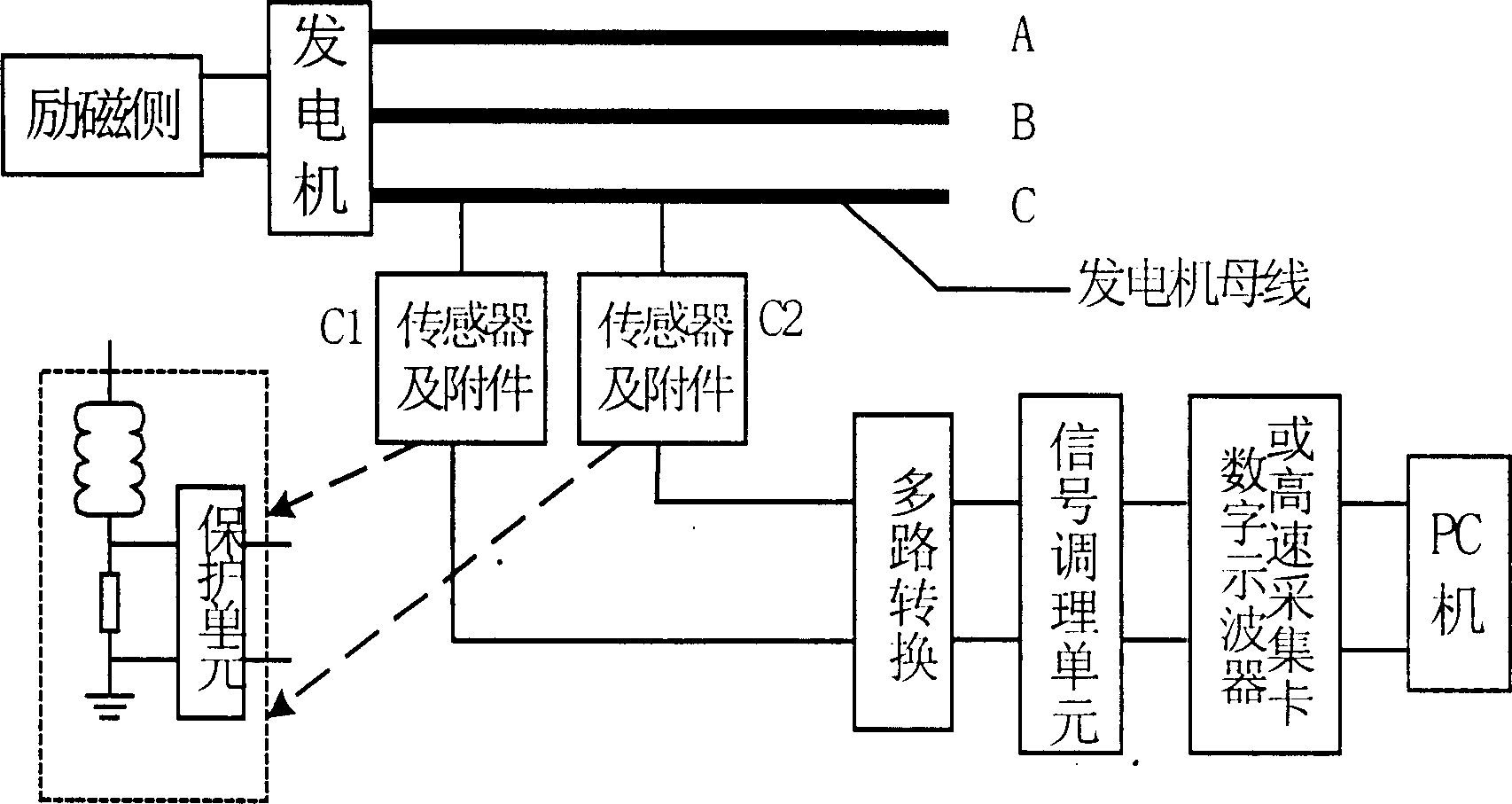

Ceramic capacitance sensor for ultra-high frequency on-line monitoring local high-voltage discharge

A UHF ceramic capacitor sensor for in-line monitor of local high-voltage discharge is composed of electrically insulating shell packaged by epoxy resin and the ceramic capacitor core with upper and lower copper electrodes and their conducting metal rod and metal strip. Its advantages are high sensitivity and minimal distortion. When a pair of such sensors are connected to the bus of one phase of electric generator, an anti-interference method for discriminating pulse delay can be implemented.

Owner:西安博源电气有限公司

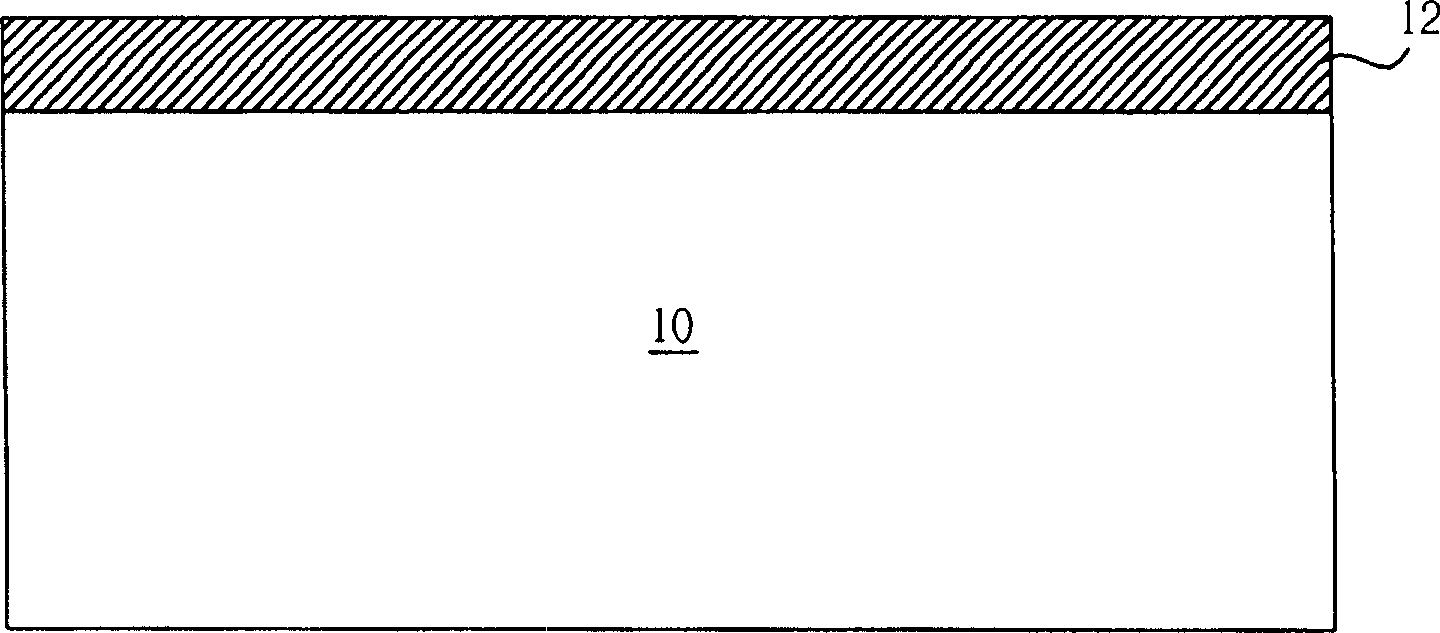

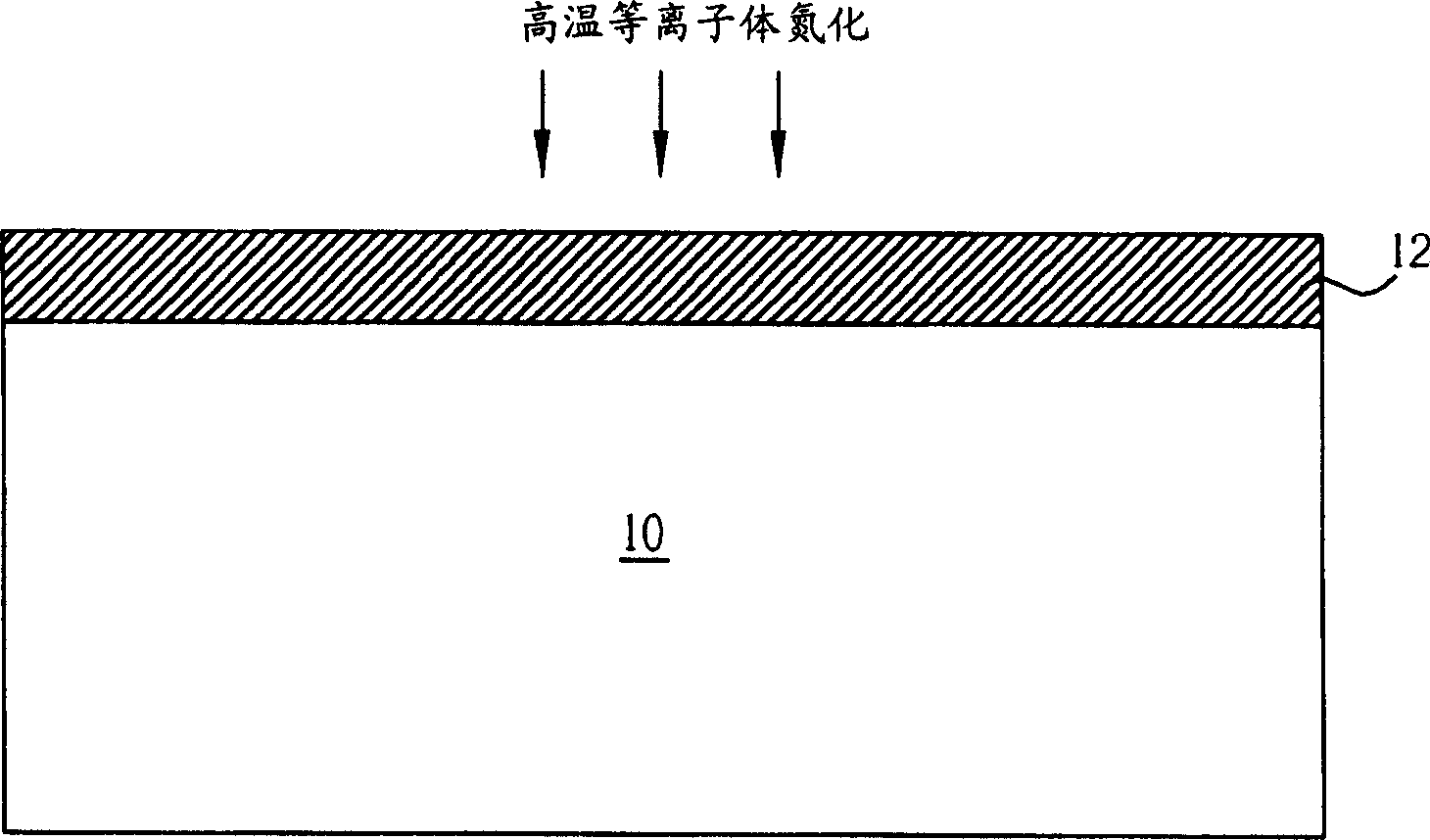

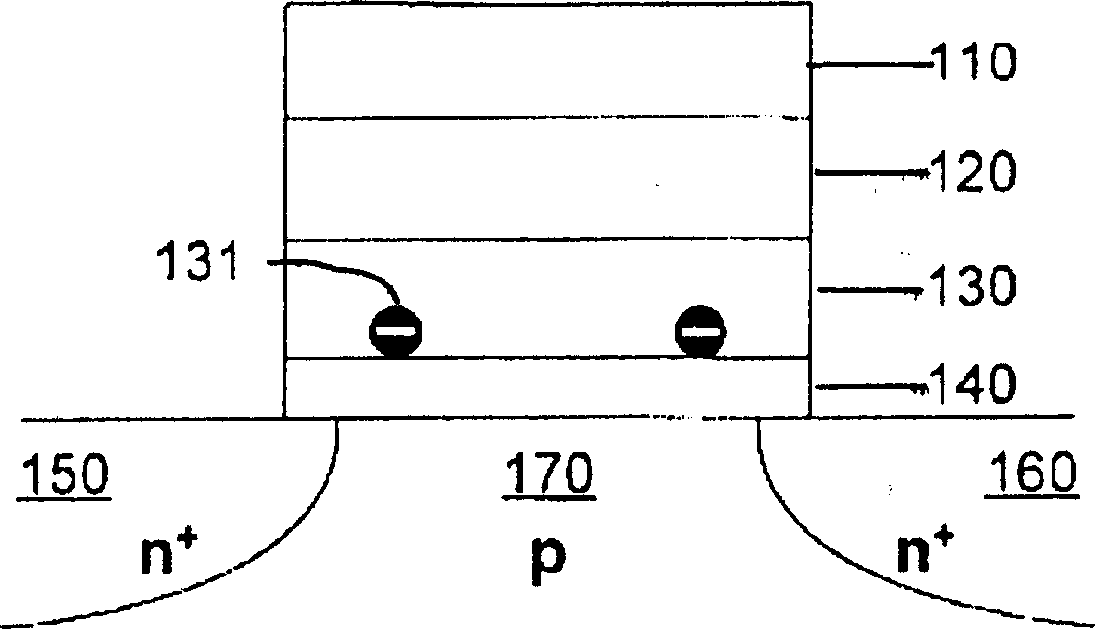

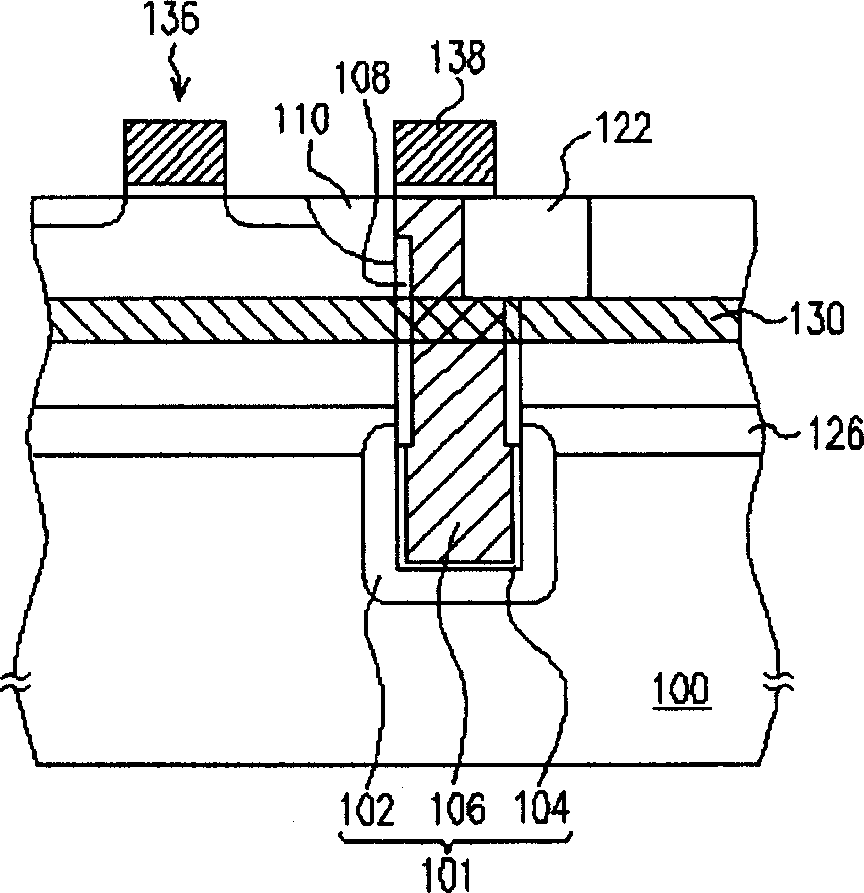

Method for making double layer grid dielectric layer

InactiveCN1825547AIncrease the starting voltageSimple interfaceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorNitrogen

The invention is a method for making a double-layer grid dielectric layer, firstly providing a semiconductor substrate and forming a silicon dioxide film on the semiconductor substrate, successively forming a noncrystalline silicon film on the silicon dioxide film and making a low-temperature plasma nitrogenization process to form the noncrystalline silicon film into a nitrogenous noncrystalline silicon film, and finally making an oxygen gas annealing process to make the oxygen gas react with the nitrogenous noncrystalline silicon film so as to form a nitrogen-enriched silicon oxynitride layer.

Owner:UNITED MICROELECTRONICS CORP

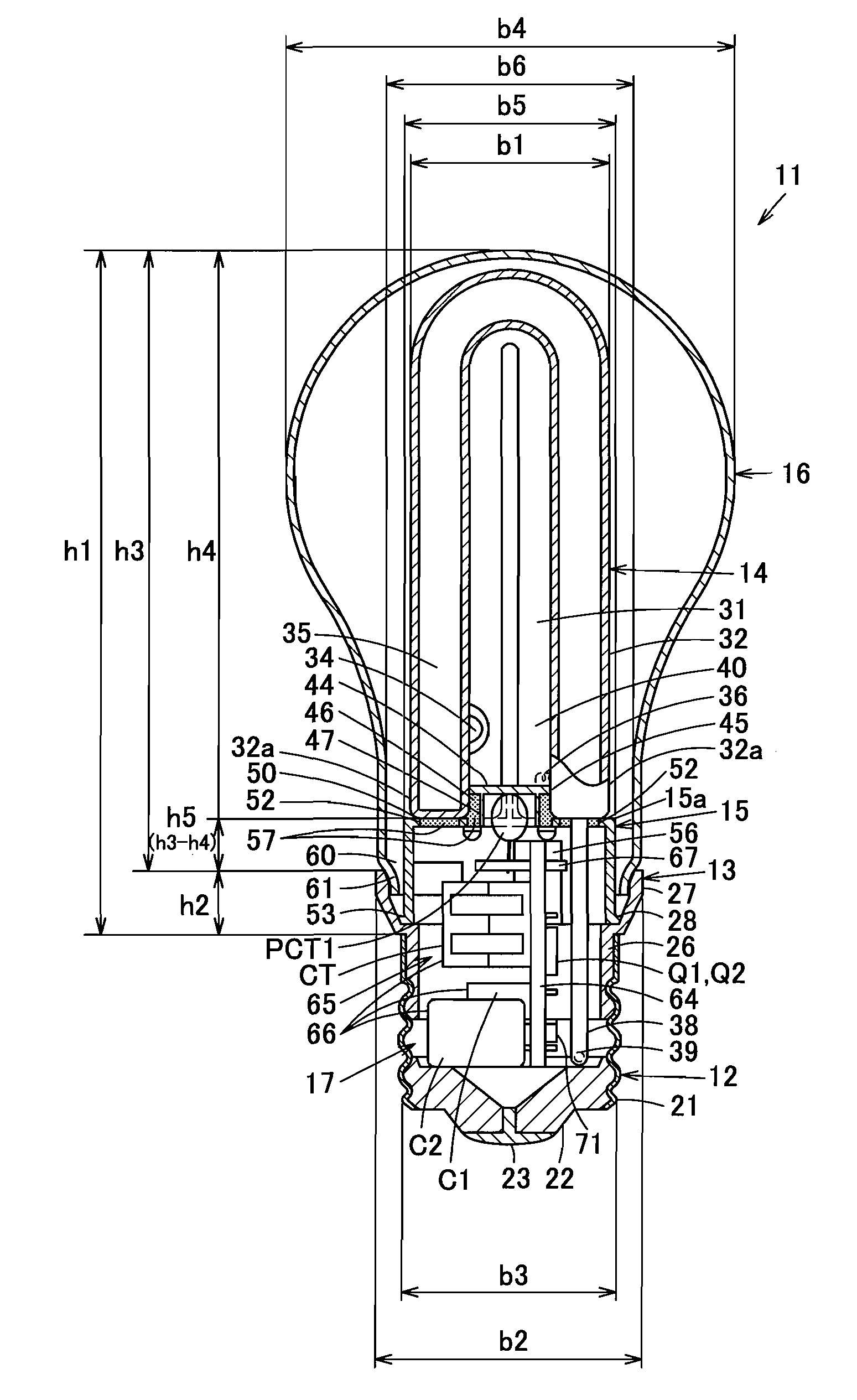

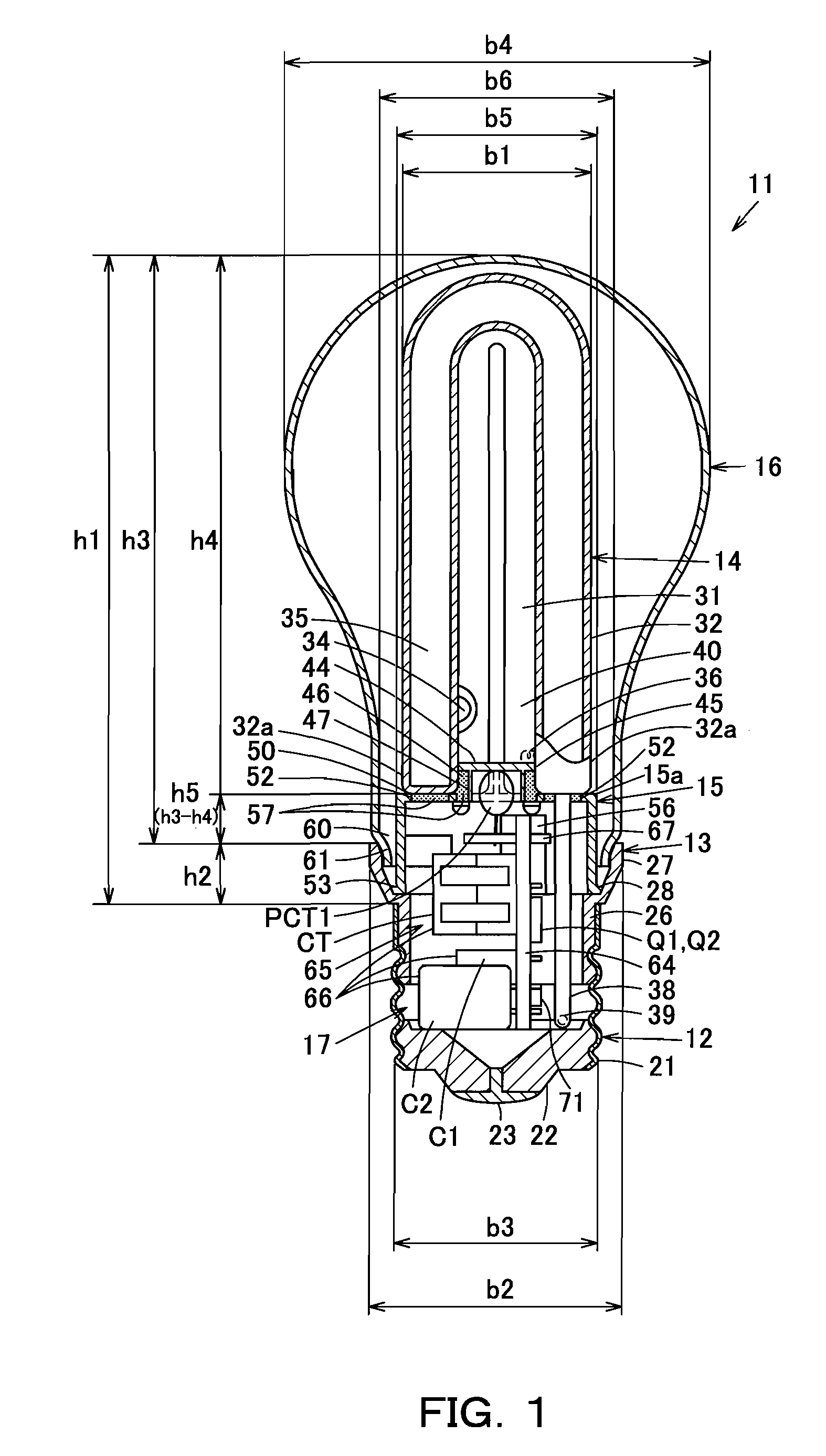

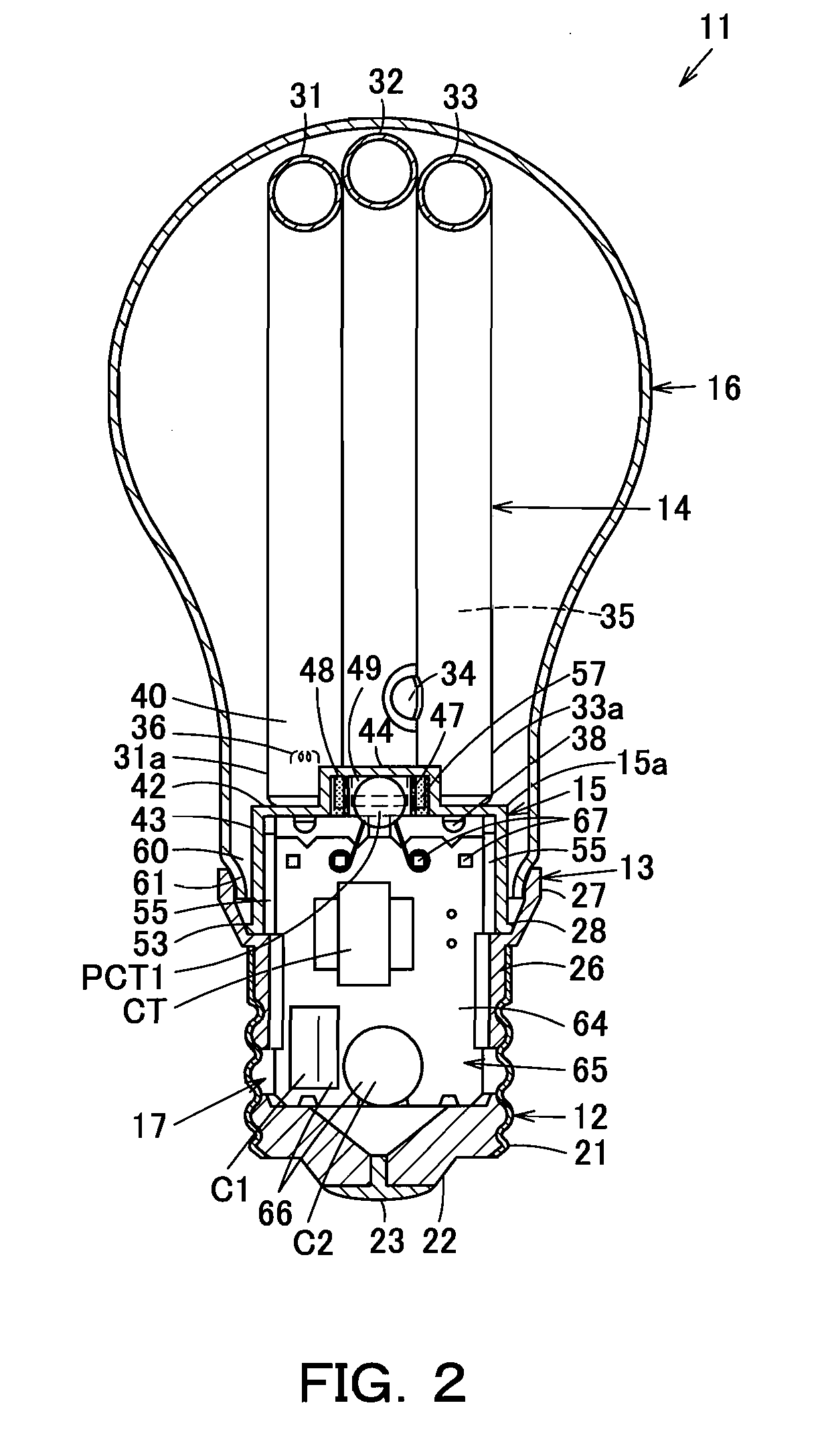

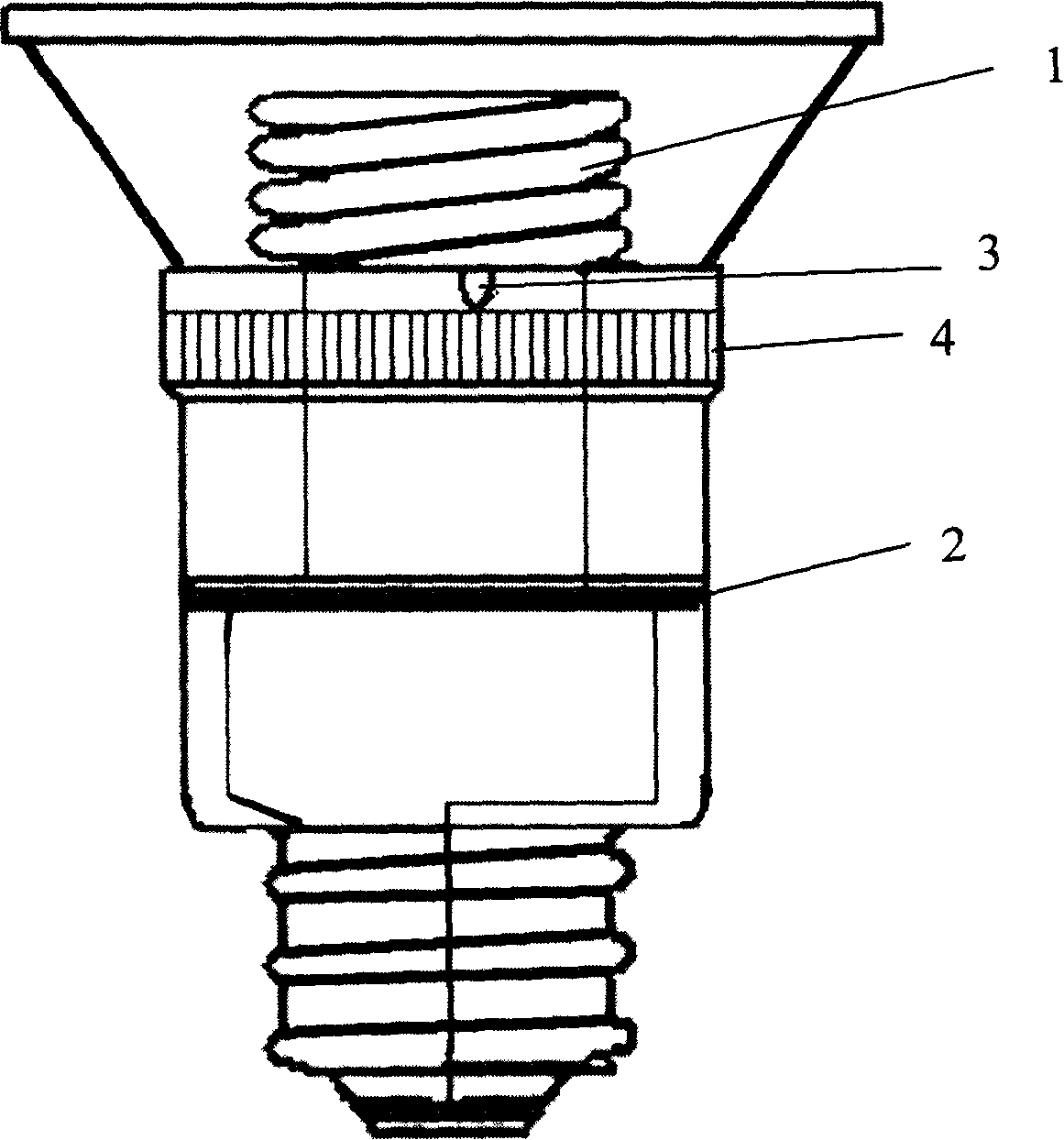

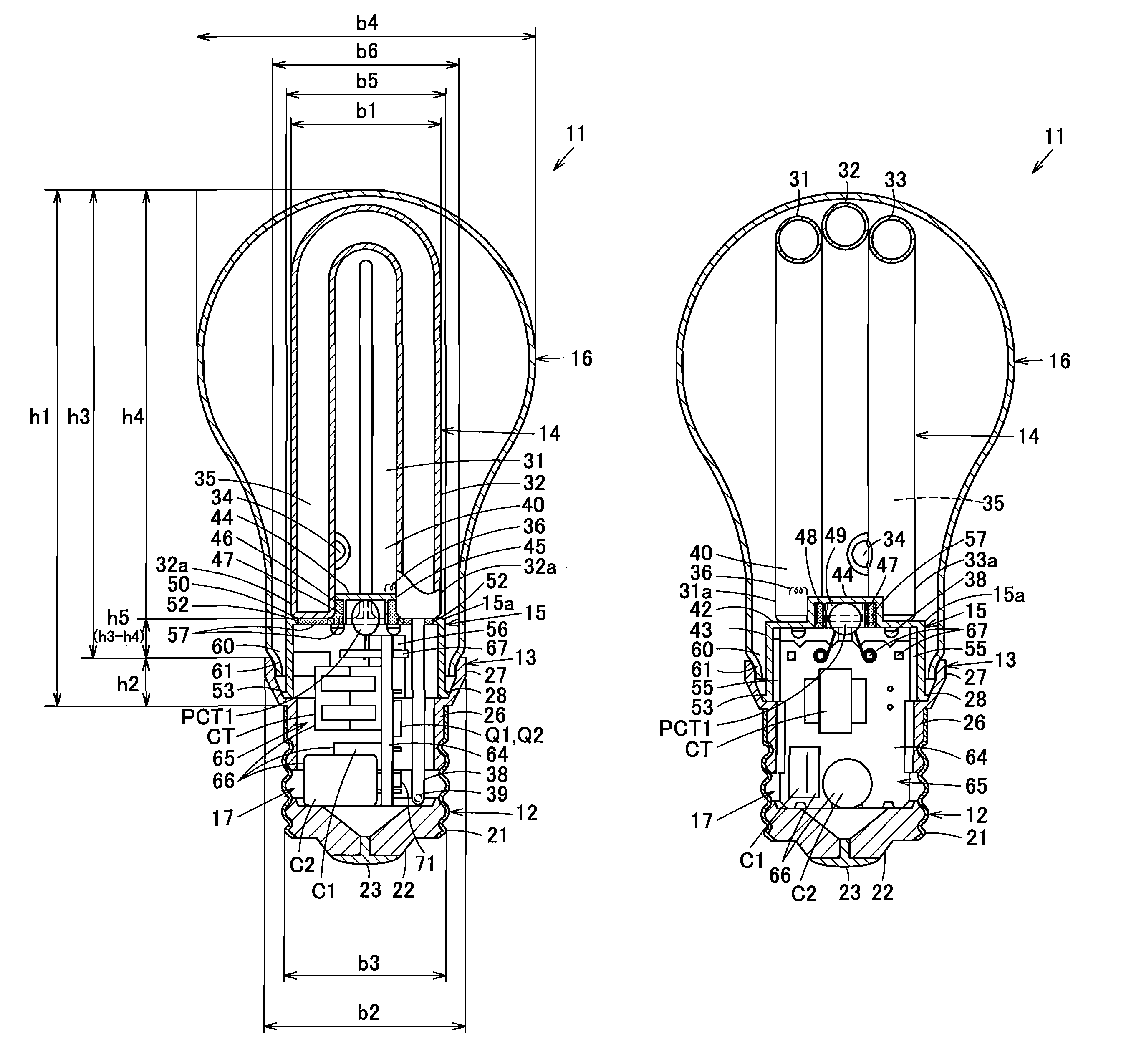

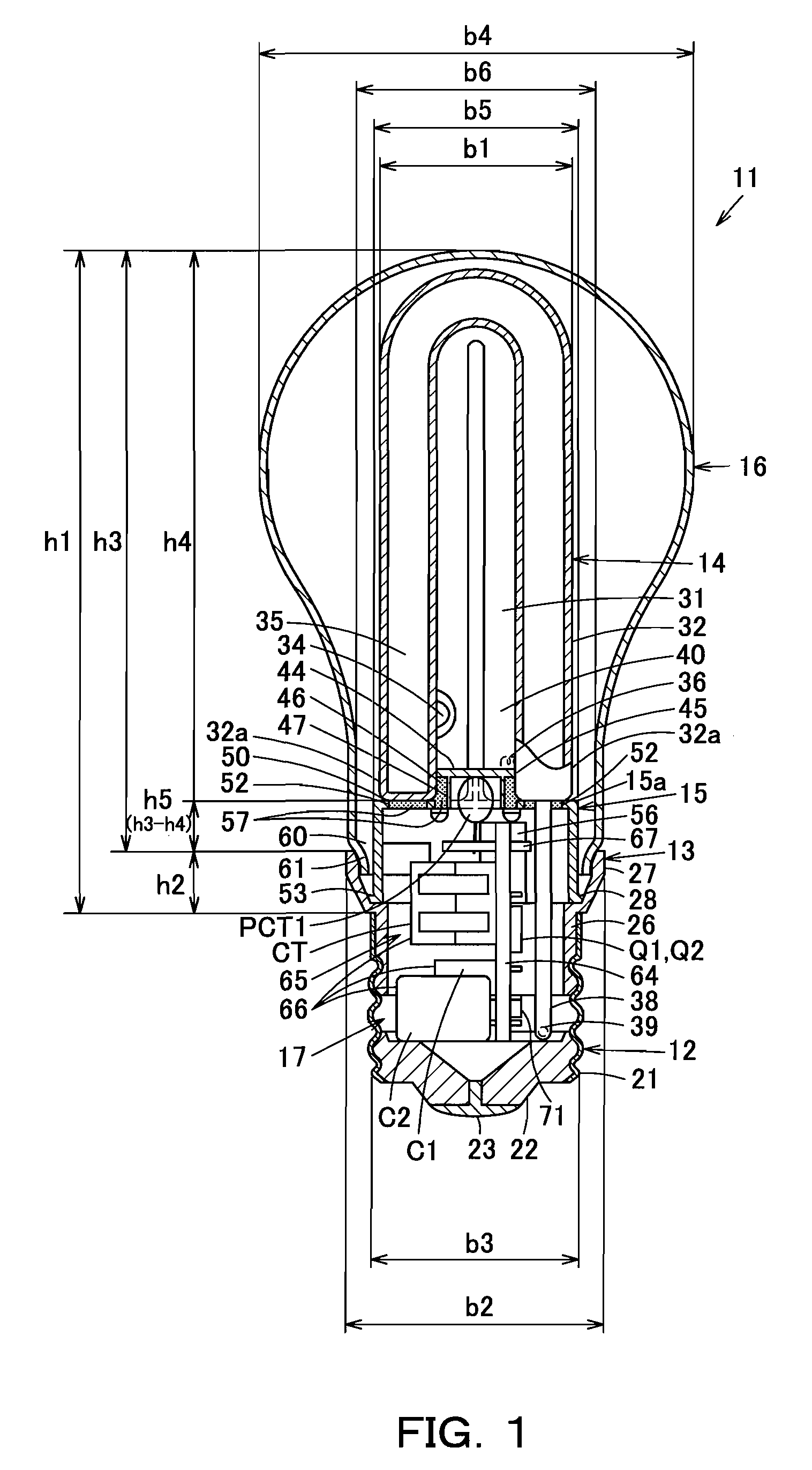

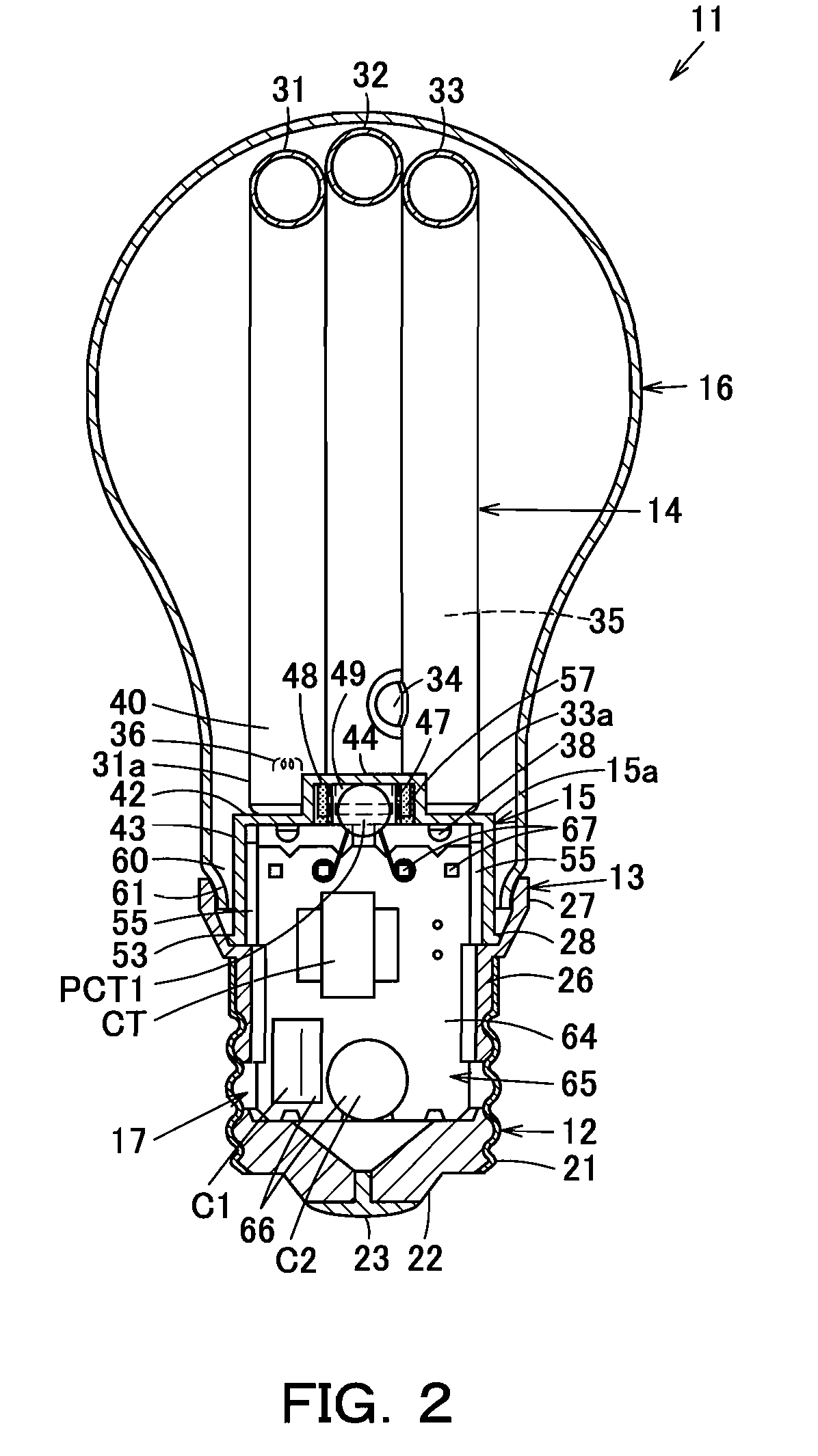

Self-ballasted fluorescent lamp and lighting apparatus

InactiveUS20090051265A1Improve light outputEasy to applyDischarge tube luminescnet screensElongate light sourcesLight equipmentEffect light

A self-ballasted fluorescent lamp includes a luminous tube that is formed in a bent shape with a pair of electrode-side end portions located at a the bottom end of the luminous tube. A cover houses a lighting device for lighting the luminous tube. A base is attached to the bottom end of the cover, and the luminous tube is supported at the top end, of the lamp. The outer diameter of a bulb of the luminous tube 14 ranges from 3 to 8 mm, and the maximum width of the luminous tube, is not greater than 30 mm. The cover is formed so that the proportion of the distance by which the cover extends from the base to the lamp length excluding the base ranges from 0 to 25%, and so that the maximum outer diameter of the cover ranges from 1.0 to 1.5 times the outer diameter of the base.

Owner:TOSHIBA LIGHTING & TECH CORP

High-pressure discharge lamp having electrically conductive transparent coating

InactiveUS7705540B2Increase capacityReduce the starting voltageSolid cathode detailsGas discharge lamp detailsCapacitanceConductive coating

The invention relates to a high-pressure discharge lamp having a transparent discharge vessel, an ionizable filling which is arranged in the discharge space of the discharge vessel and electrodes, which extend into the discharge space of the discharge vessel, for the purpose of producing a gas discharge, as well as power supply lines, which are passed out of the discharge vessel, for the purpose of supplying energy to the electrodes, the discharge vessel of the high-pressure discharge lamp being provided partially with an electrically conductive coating, with the result that a capacitive coupling is produced between the coating and at least one electrode and / or power supply line. As a result, the starting properties and the luminous efficiency of the lamp are improved.

Owner:OSRAM GMBH

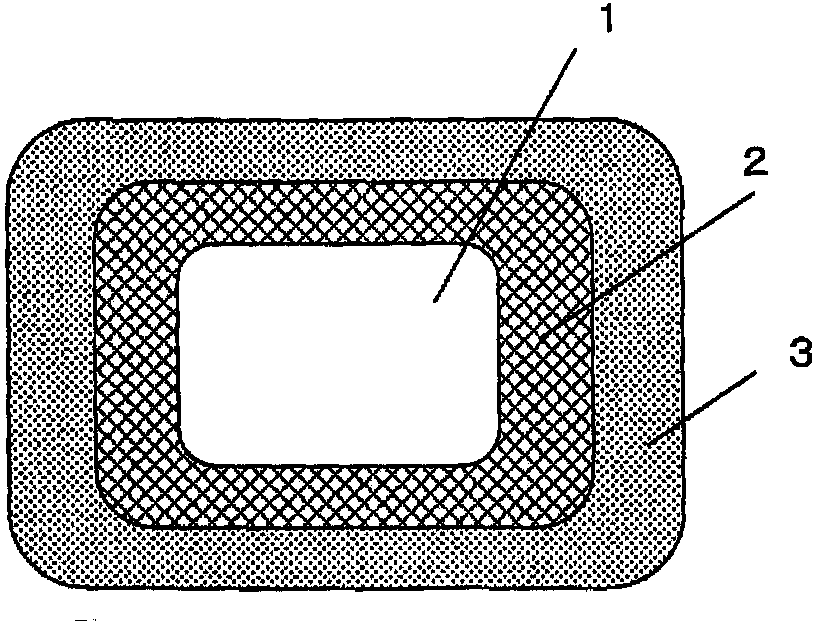

Inverter surge-resistant insulated wire and method for producing same

InactiveCN104170025AHigh bonding strengthExcellent abrasion resistanceInsulated cablesInsulatorsMolten stateVitrification

An inverter surge-resistant insulated wire wherein: at least one baked enamel layer and at least one extrusion coated resin layer, which is arranged on the outer side of the baked enamel layer, are provided around a conductor that has a rectangular cross-sectional shape; an adhesive layer having a thickness of 2-20 μm is provided between the baked enamel layer(s) and the extrusion coated resin layer(s); all of the extrusion coated resin layer(s) on the adhesive layer are formed of a same resin; the baked enamel layer(s) and the extrusion coated resin layer(s) in a cross-section of the inverter surge-resistant insulated wire have a rectangular cross-sectional shape; in the rectangular cross-sectional shape surrounding the conductor in the cross section and formed by the baked enamel layer(s) and the extrusion coated resin layer(s), both sides of at least one pair of sides among two pairs of sides that respectively face each other vertically or horizontally with respect to the conductor have a total thickness of the baked enamel layer(s) and the extrusion coated resin layer(s) of 80 μm or more, a thickness of the baked enamel layer(s) of 60 μm or less, and a thickness of the extrusion coated resin layer(s) of 200 μm or less; and the resin of the extrusion coated resin layer(s) has a melting point of from 300°C to 370°C (inclusive). A method for producing an inverter surge-resistant insulated wire, wherein an adhesive layer is formed around a baked enamel layer and a thermoplastic resin for forming an extrusion coated resin layer, said thermoplastic resin being in a molten state at a temperature that is higher than the glass transition temperature of the resin used for the adhesive layer, is extruded onto and brought into contact with the adhesive layer.

Owner:FURUKAWA ELECTRIC CO LTD +1

System and method for maximizing short-term energy storage in a supercapacitor array for engine start applications

ActiveUS20170328329A1Increase the starting voltageHigh voltageBatteries circuit arrangementsElectric motor startersElectrical batteryEngineering

A system for starting an internal combustion engine includes a battery system, a charger to receive DC battery power from the battery system and convert the power to a DC charging current, a supercapacitor array having a plurality of supercapacitor cells connected to the charger to receive the DC charging current therefrom, and a motor starter to start the internal combustion engine responsive to a DC input from the supercapacitor array. The charger modifies a voltage of the supercapacitor cells in an on-demand fashion, with the charger programmed to provide DC charging current to the supercapacitor array to hold the supercapacitor cells at a first voltage, receive a bump-up command indicative of an upcoming engine start and, responsive to receiving the bump-up command, provide DC charging current to the supercapacitor array to increase a voltage of the supercapacitor cells temporarily to a second voltage higher than the first voltage.

Owner:EATON INTELLIGENT POWER LTD

New type non-filament florescent lamp working in brightness arc transition zone

InactiveCN101202198AImprove reliabilityExtend your lifeElectric lighting sourcesVacuum evaporation coatingSurface brightnessInsulation layer

The invention relates to a novel wireless fluorescent lamp which works in a bright arc transition zone, comprising a lamp tube, an electrode, a drive, a lamp casing and a lamp cup or lampshade. The electrode consists of tungsten, or molybdenum or iron. More than one layers of anti cathode sputtering films are arranged on the surface of the electrode. Super-pure argon air is filled into the lamp tube with an air-filling pressure ranging from 800 Pa to 6665Pa. The work current of the lamp tube is between 7MA and 60MA. A cold end is arranged in the lamp tube and a titanium mercury zirconium aluminum 16 alloy amalgam or an indium mercury zirconium aluminum 16 alloy amalgam is arranged in the cold end. An insulation layer is arranged between the lamp cup or lampshade and the lamp casing. The cold end extends from the lamp cup or lampshade to the insulation layer. The invention enhances light effect and surface brightness, and has small volume, high flux, enhanced reliability and long service life. The manufacture of the drive is easy, the manufacturing cost is low and the cost performance is high, furthermore, the proposal of the EMC is easy, the cost for restraining electromagnetic interference wires is low and the effect for restraining electromagnetic interference is good.

Owner:陈宗烈

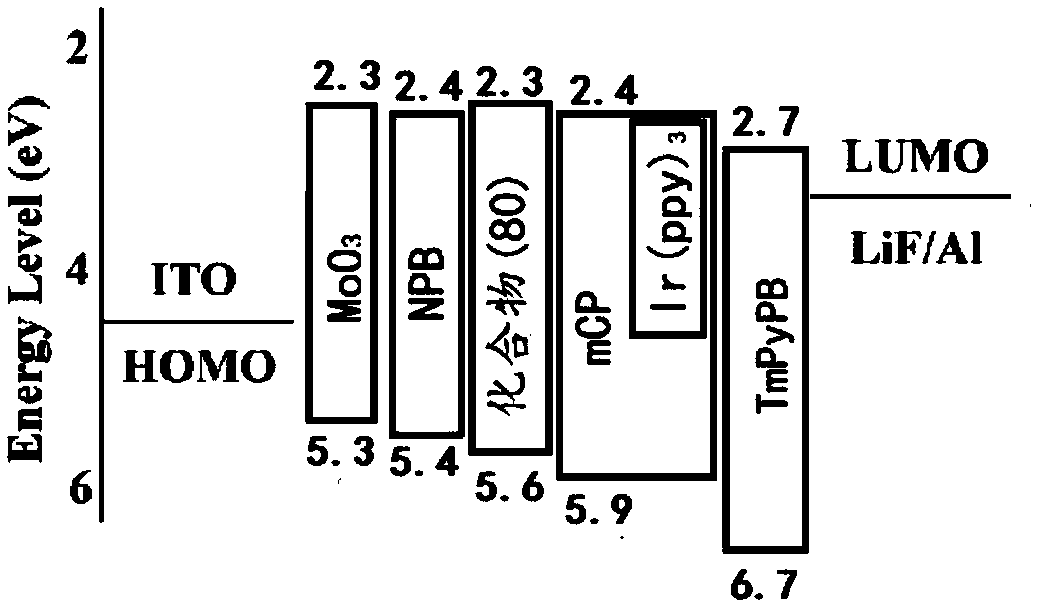

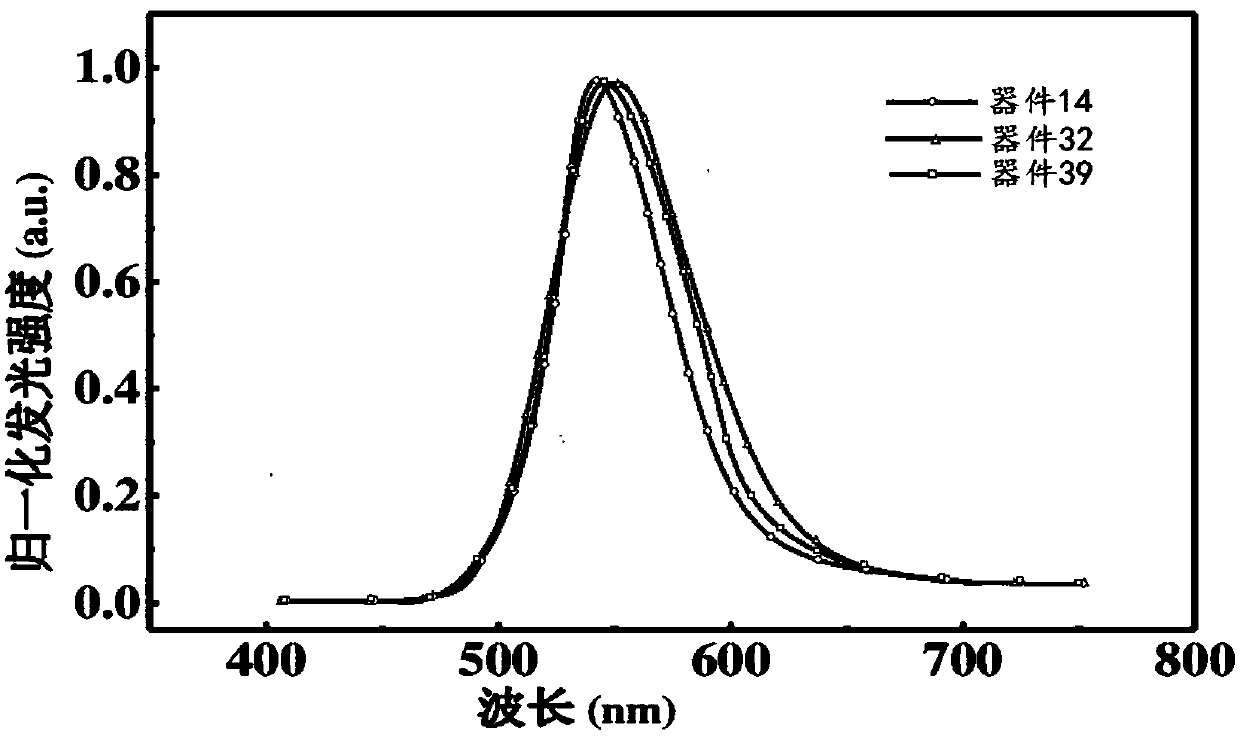

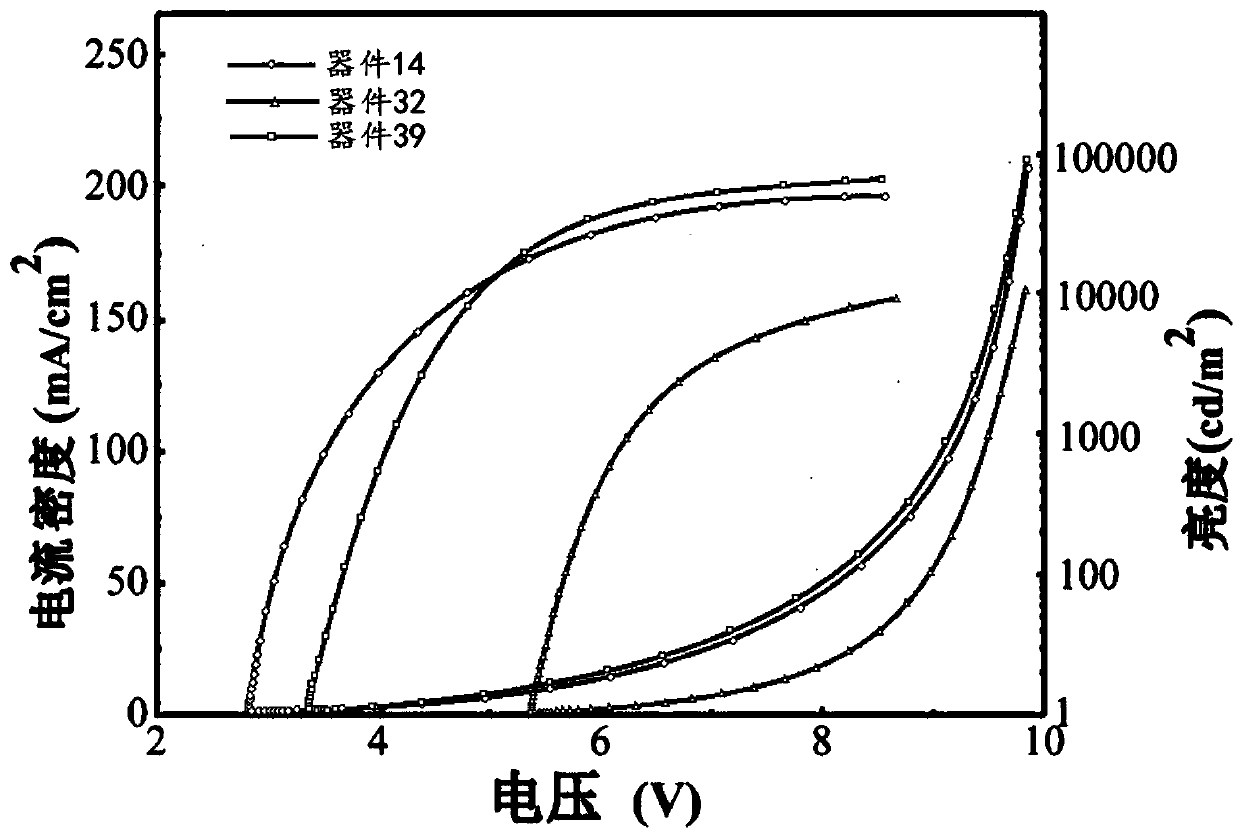

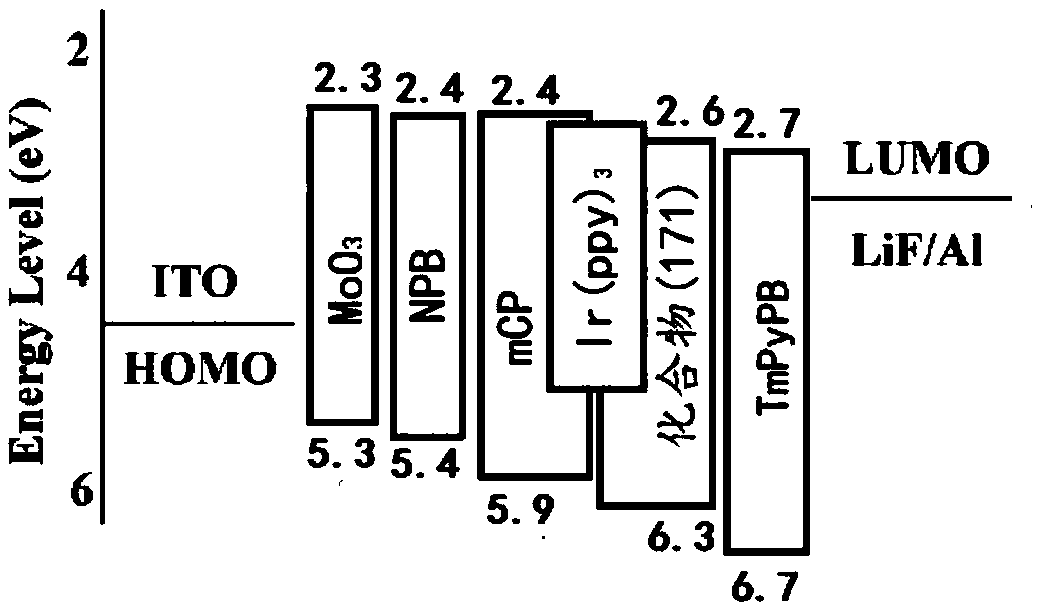

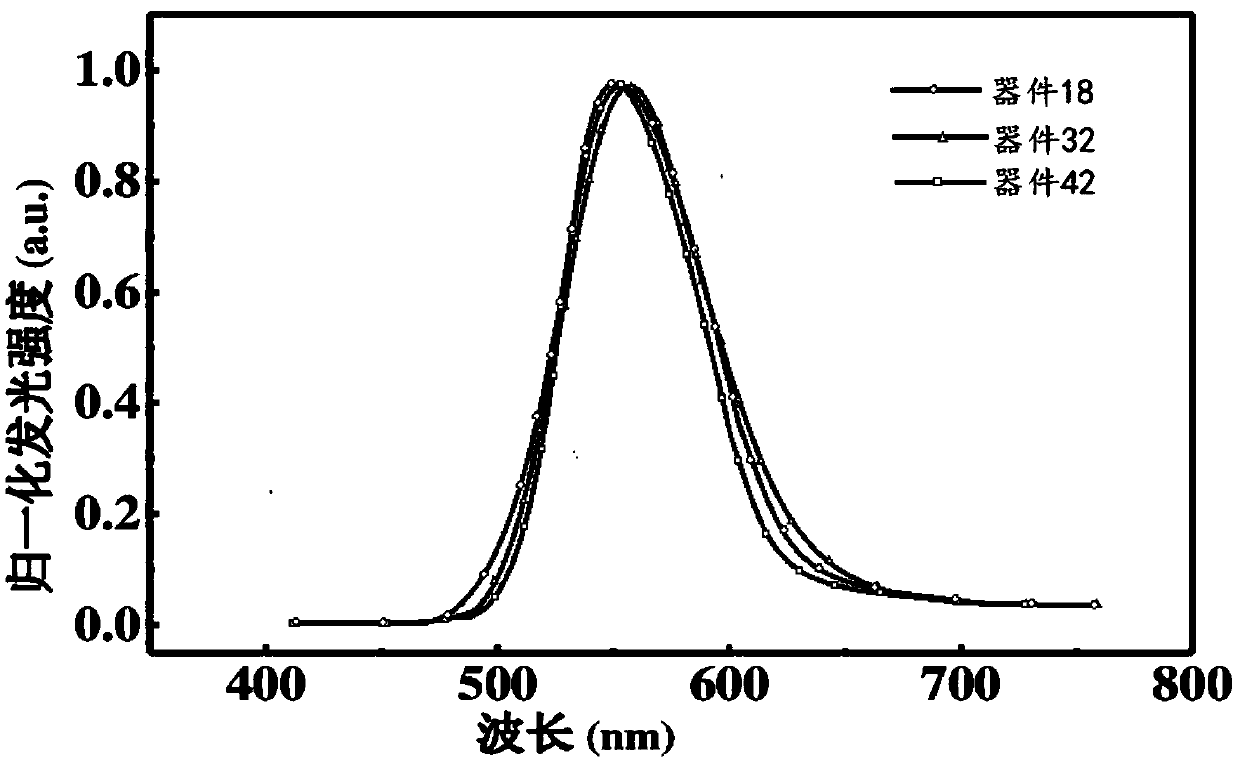

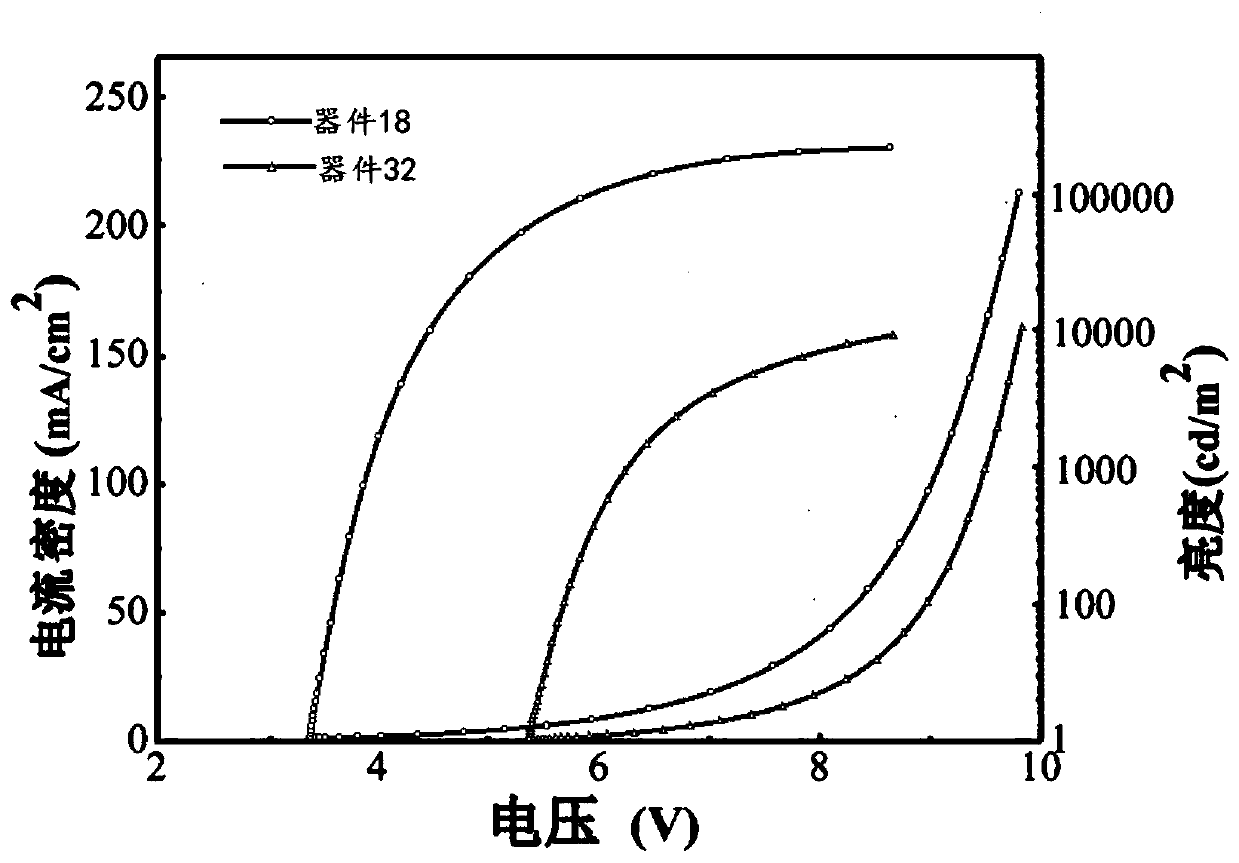

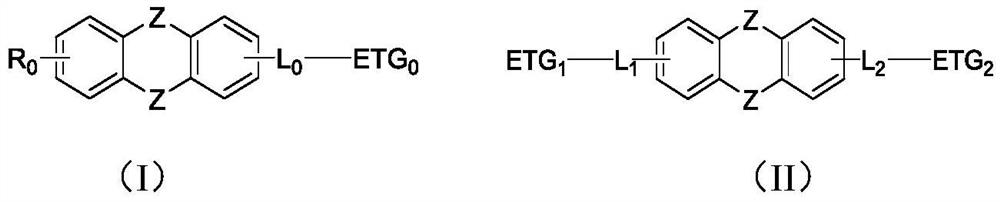

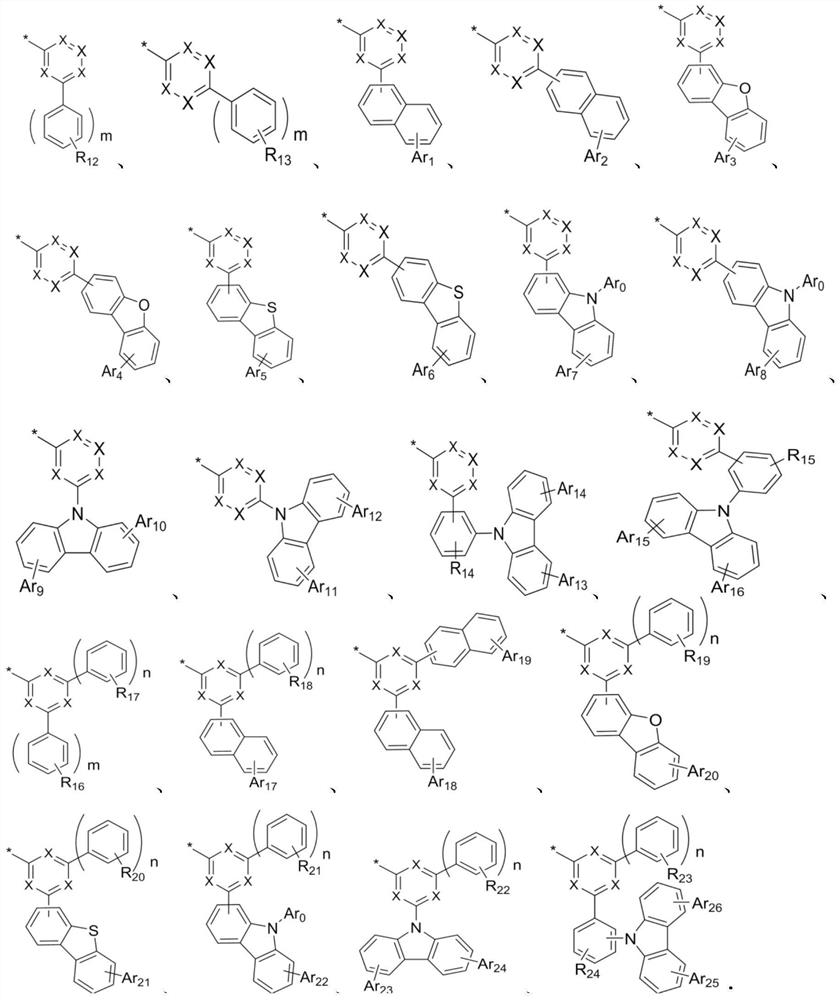

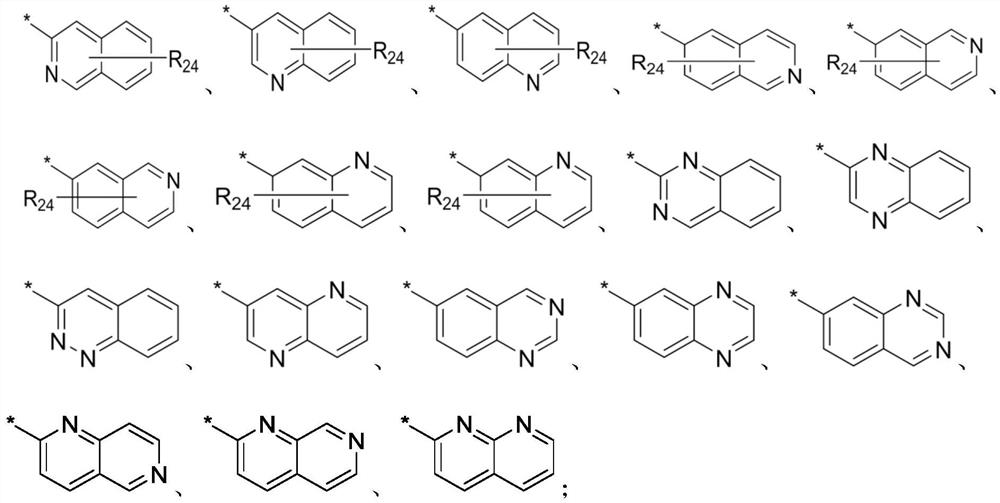

Fluorenone derivative, and preparation and application thereof

InactiveCN109574823AImprove luminous efficiencyImprove luminescence stabilityOrganic compound preparationSolid-state devicesQuantum efficiencyLuminous intensity

The invention discloses a fluorenone derivative, and preparation and application thereof. The fluorenone derivative takes a fluorenone structure containing electron deficiency carbonyl groups as a core, and an aromatic fused ring compound with the electron deficiency characteristic is further bridged to form a compound with high hole transfer. The fluorenone derivative serving as a hole transfer material and a luminous layer main body material of an OLED device has the advantages of remarkably improved performance of the device in starting voltage, luminous intensity, external quantum efficiency, current efficiency, power efficiency, chromaticity, half-life and the like, and enhanced working stability of the device.

Owner:WUHAN SUNSHINE OPTOELECTRONICS TECH CO LTD

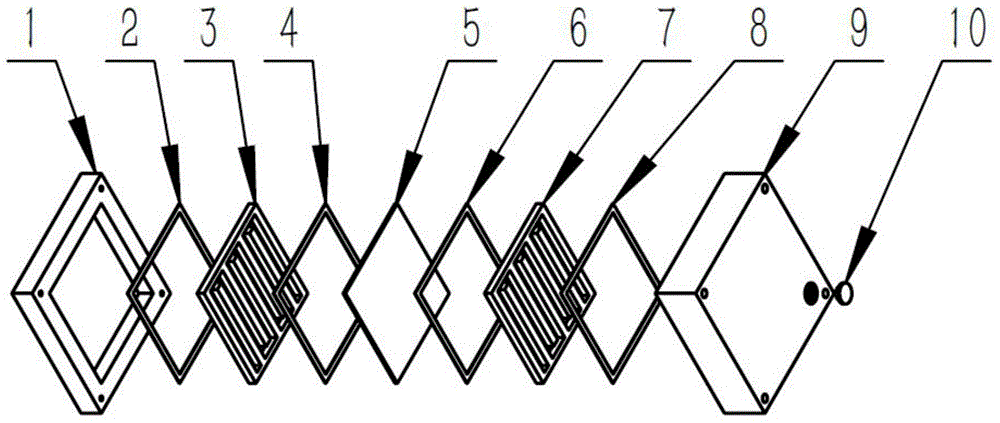

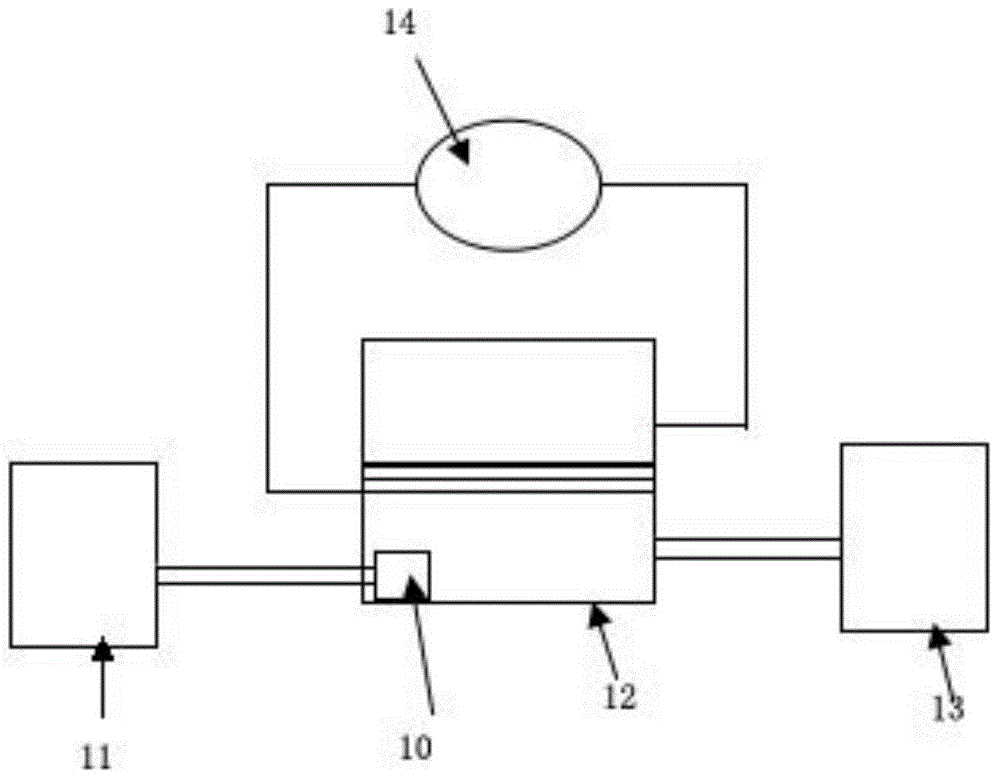

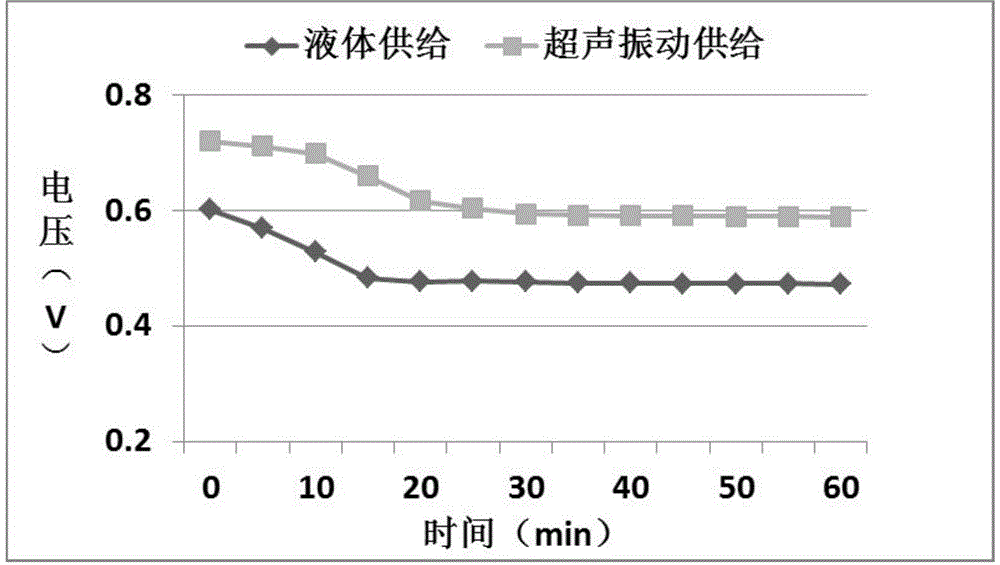

Direct methanol fuel cell fuel-feeding method and structure thereof

InactiveCN104362358AEvenly distributedImprove battery performanceReactant parameters controlFuel cellsDirect-ethanol fuel cell

The invention discloses a direct methanol fuel cell fuel-feeding method and a structure thereof. The structure comprises a fuel-feeding channel, an MEA membrane, an ultrasonic vibration transducer, a sealing device and an encapsulating housing, wherein the ultrasonic vibration transducer is arranged on the encapsulating housing by adopting manners of adhering, embedding or burying so as to become one part of the encapsulating housing of a fuel cell; when the cell is used, a vibration device is started to vibrate fuel to implement fuel atomizing supply. The direct methanol fuel cell fuel-feeding method has the advantage that the starting voltage, the transient performance and the stable performance of the fuel cell can be improved by only using mechanical vibration; meanwhile, the direct methanol fuel cell fuel-feeding method is a novel method capable of feeding the fuel to a current direct methanol fuel cell; the permeation of methanol can be effectively reduced, but the energy density of a system is not decreased.

Owner:WUHAN UNIV OF TECH

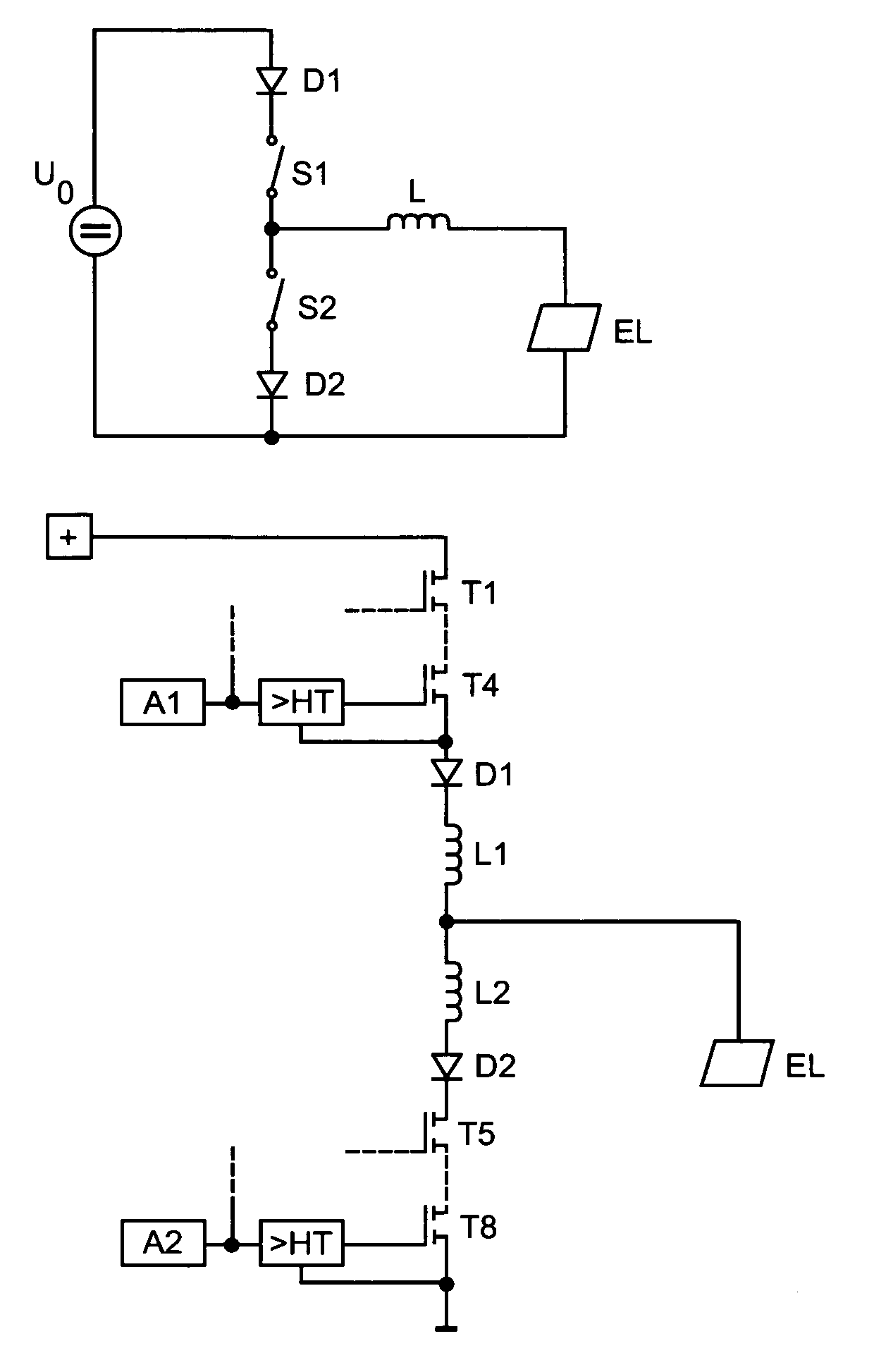

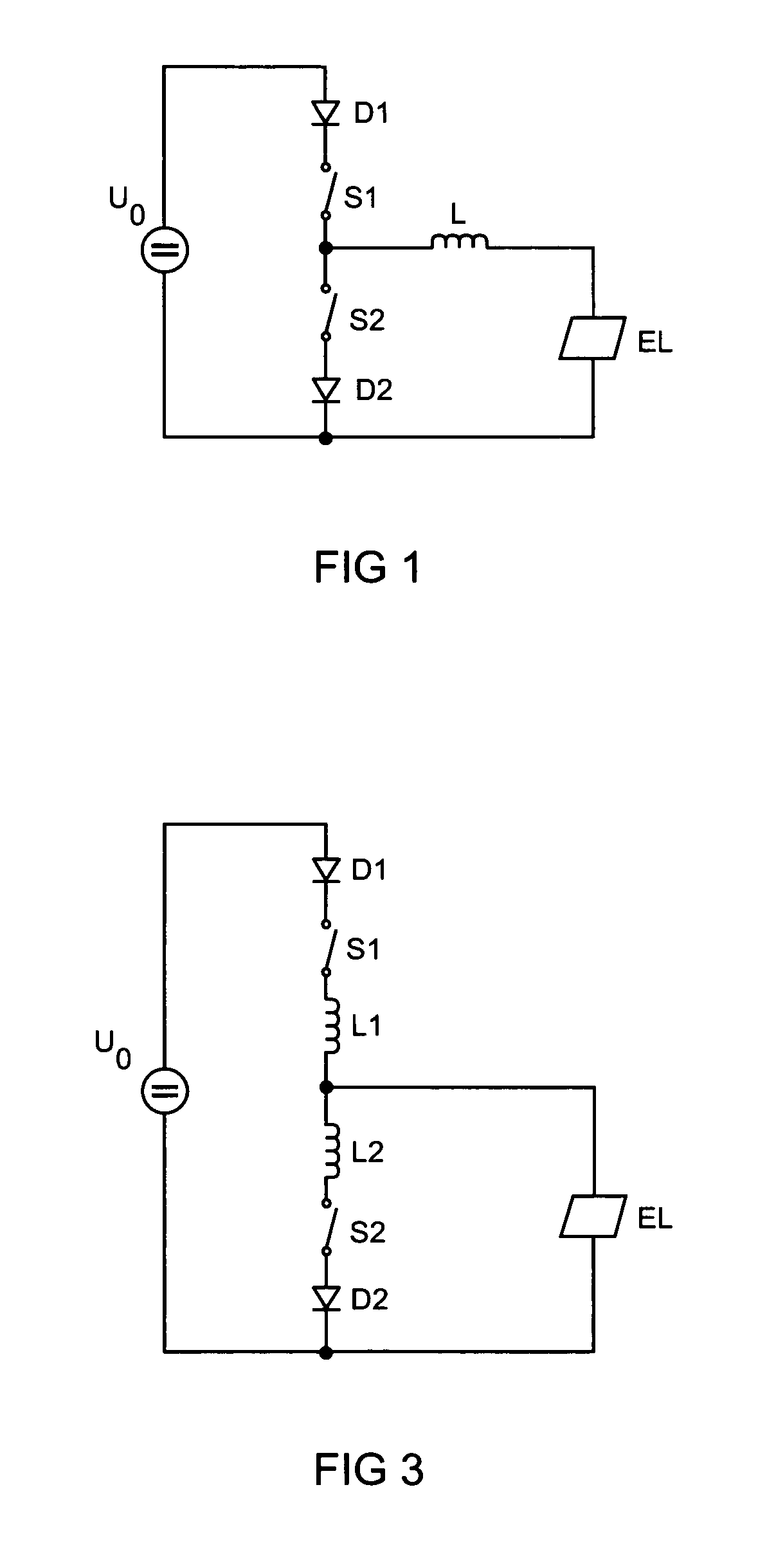

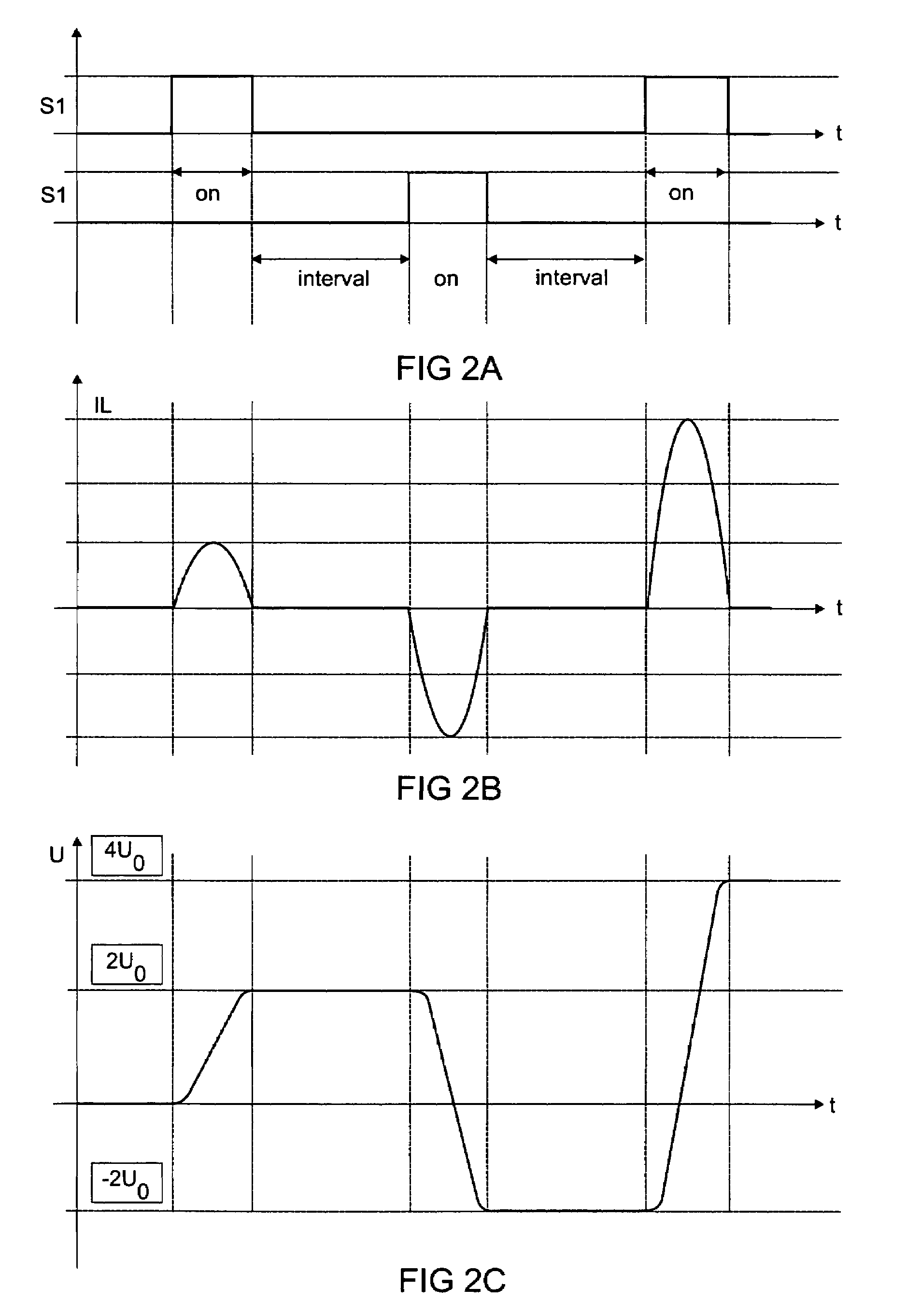

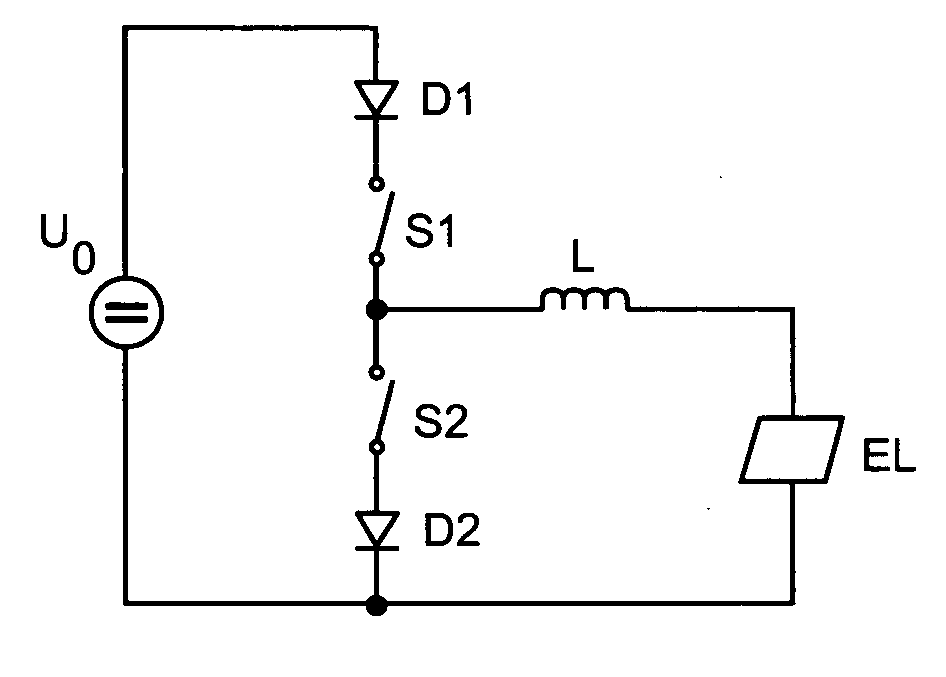

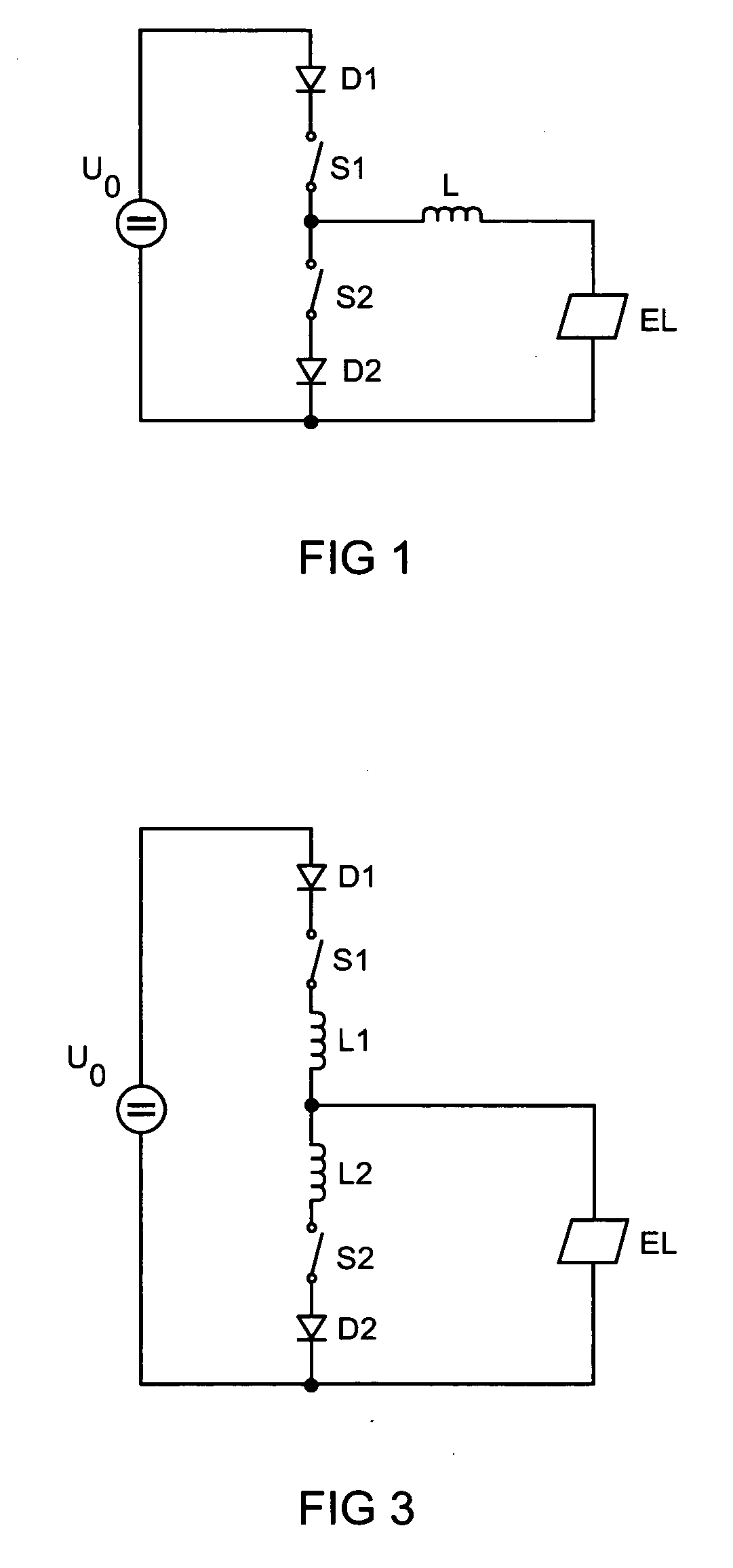

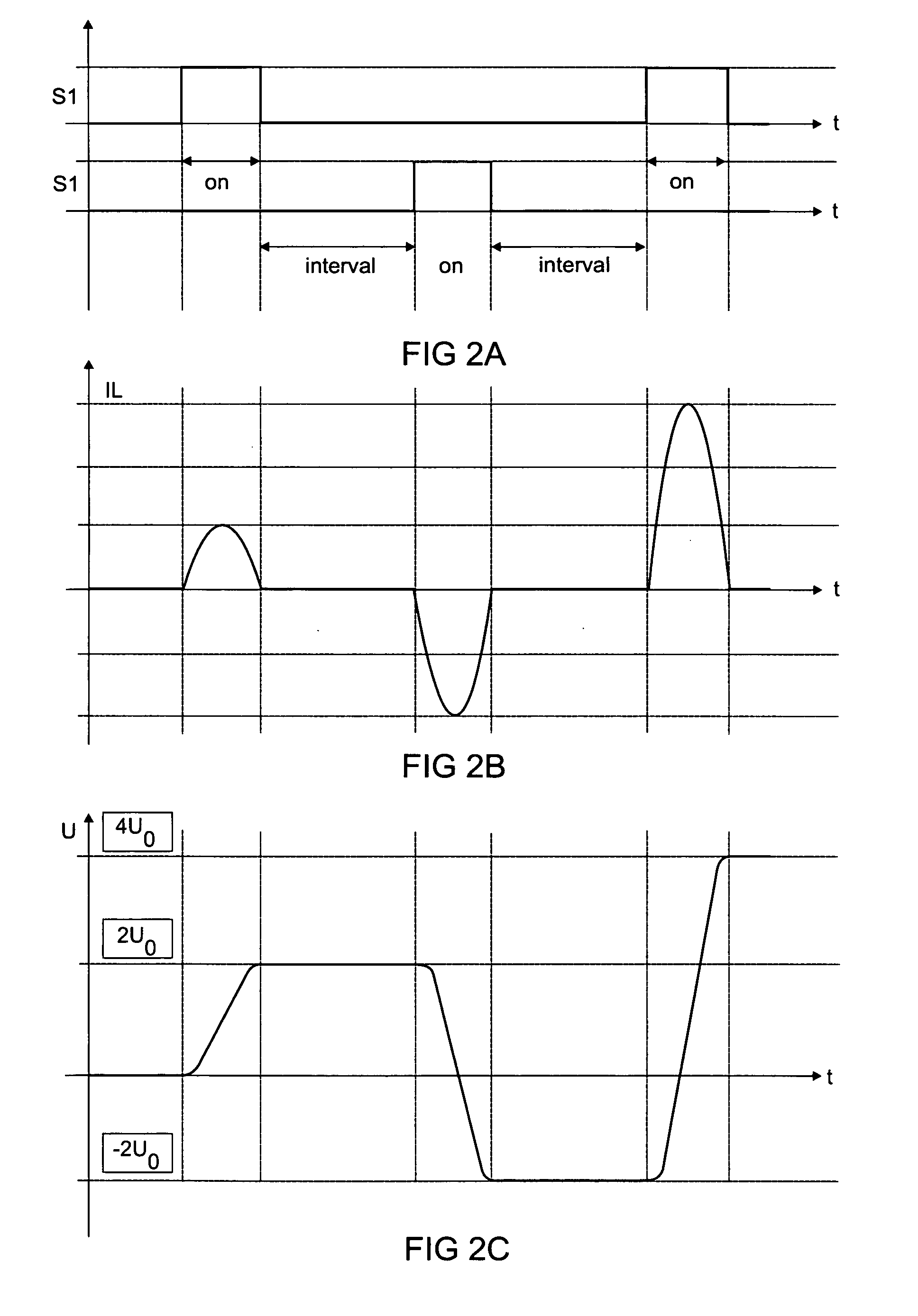

Circuit arrangement having a converter without a transformer but with an inductor for the pulsed operation of dielectric barrier discharge lamps

InactiveUS7355351B2Improve compactnessSmall dimensionElectrical apparatusElectric light circuit arrangementFull bridgeTransformer

Circuit arrangement having a converter without a transformer but with an inductor for the pulsed operation of dielectric barrier discharge lampsThe circuit arrangement according to the invention comprises an inductor-type converter for the pulsed operation of dielectric barrier discharge lamps (EL). The invention proposes both a half bridge variant and a full bridge variant. By selecting the inductance value of the inductor (L), it is possible to influence the edge steepness of the pulses, in the case of more than one inductor even independently for the rising and falling edges.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

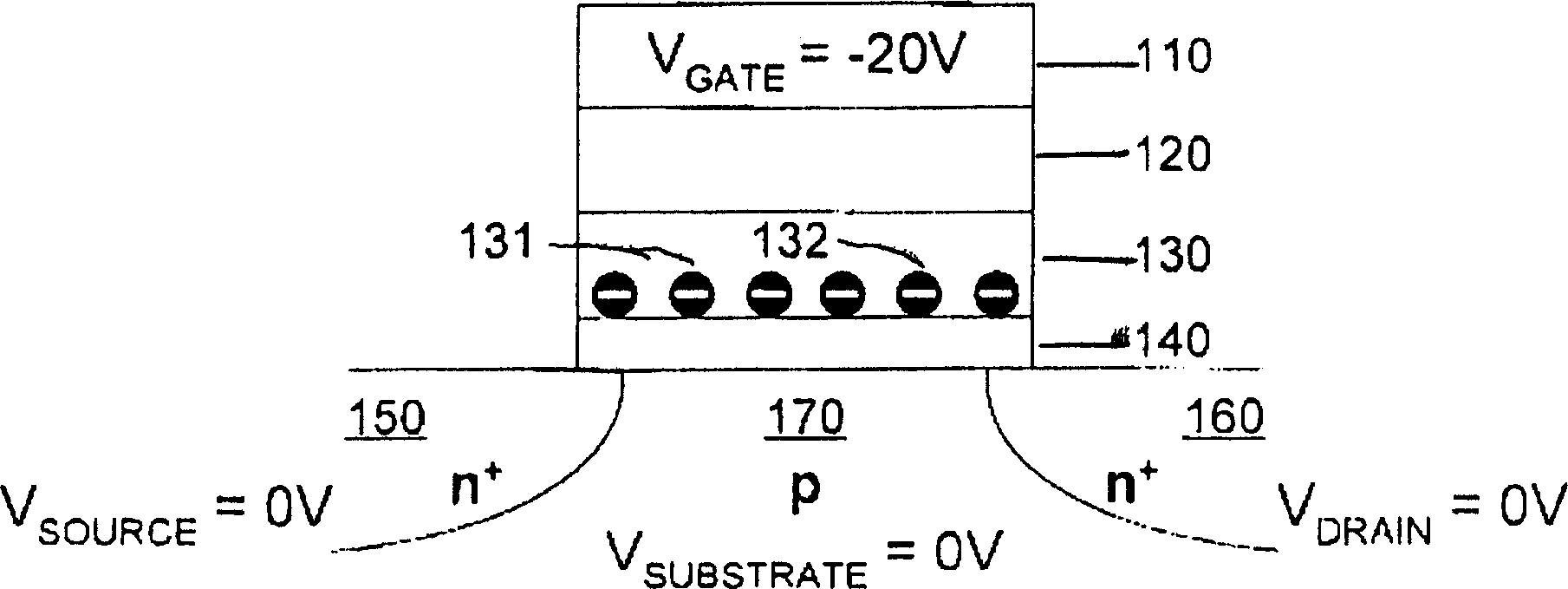

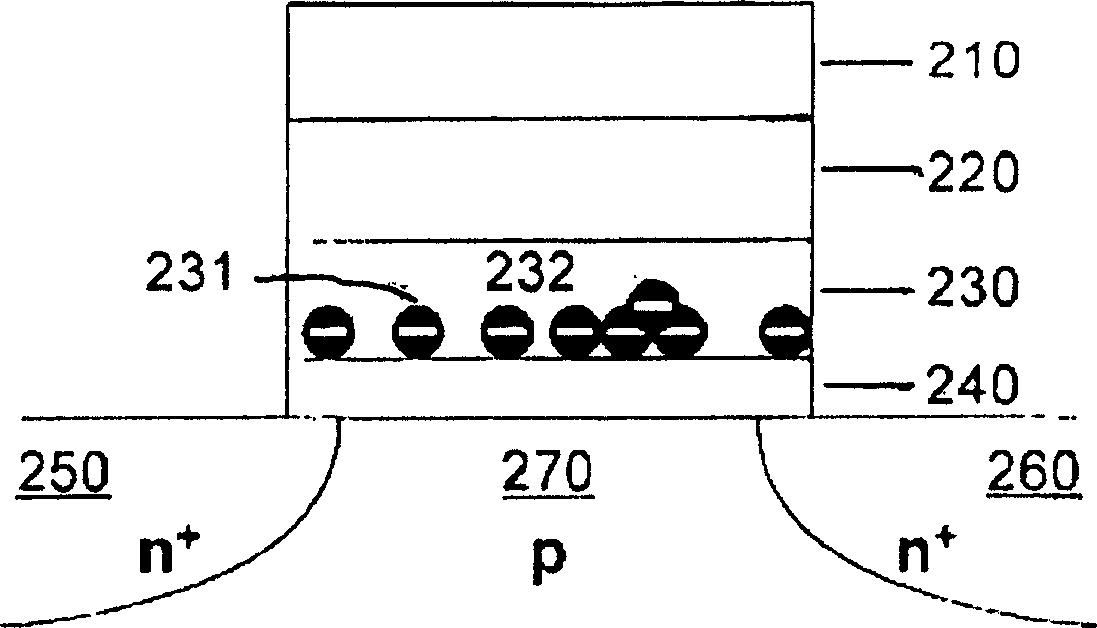

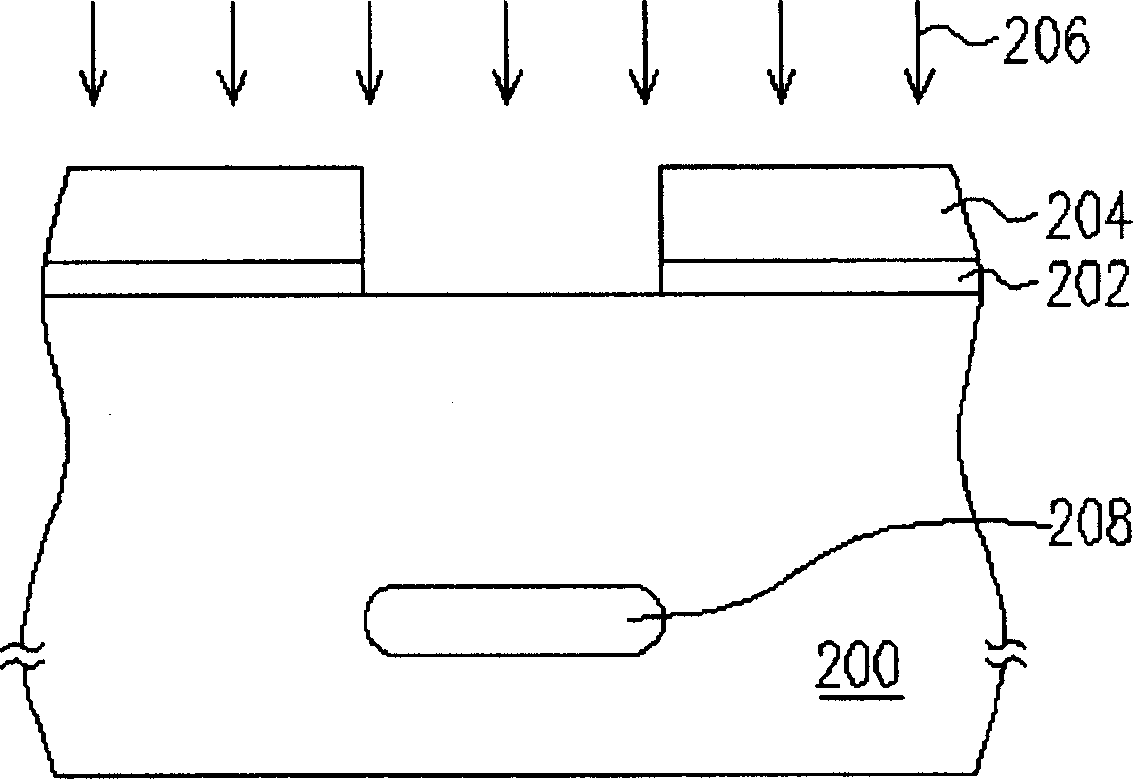

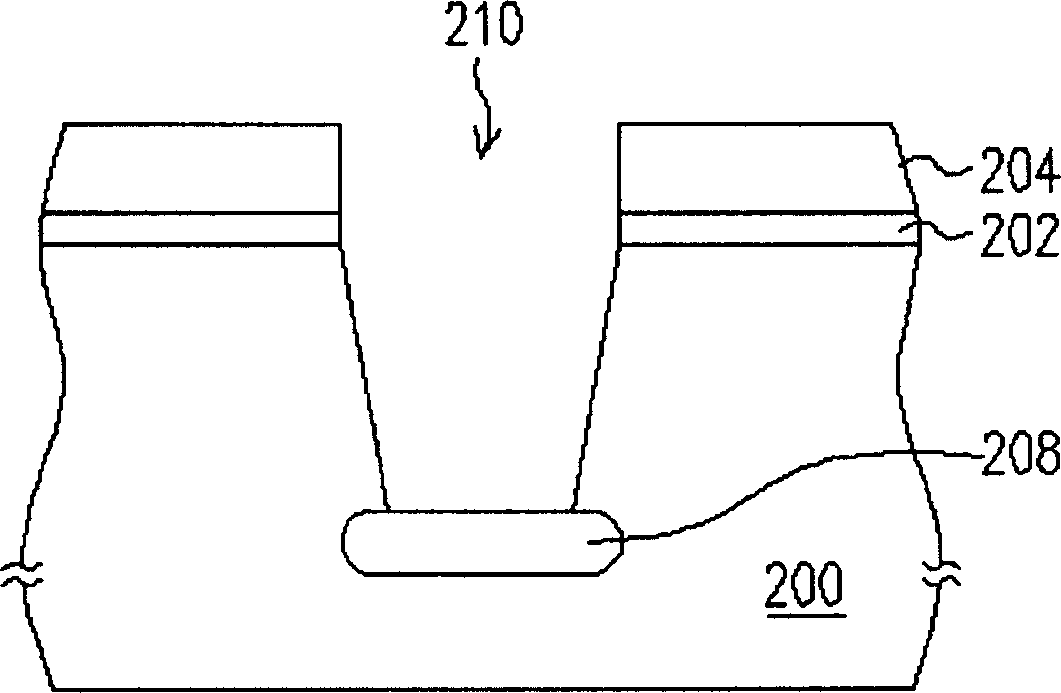

Operation scheme for spectrum shift in charge trapping non-volatile memory

ActiveCN1700448AReduce the starting voltageIncrease the starting voltageSolid-state devicesRead-only memoriesTrappingEngineering

A method of operating a memory cell comprises applying a first procedure (typically erase) to establish a low threshold state including a first bias arrangement causing reduction in negative charge in the charge trapping structure, and a second bias arrangement tending to the induce balanced charge tunneling between the gate and the charge trapping structure and between the charge trapping structure in the channel. A second procedure (typically program) is used to establish a high threshold state in the memory cell, including a third bias arrangement that causes an increase in negative charge in the charge trapping structure.

Owner:MACRONIX INT CO LTD

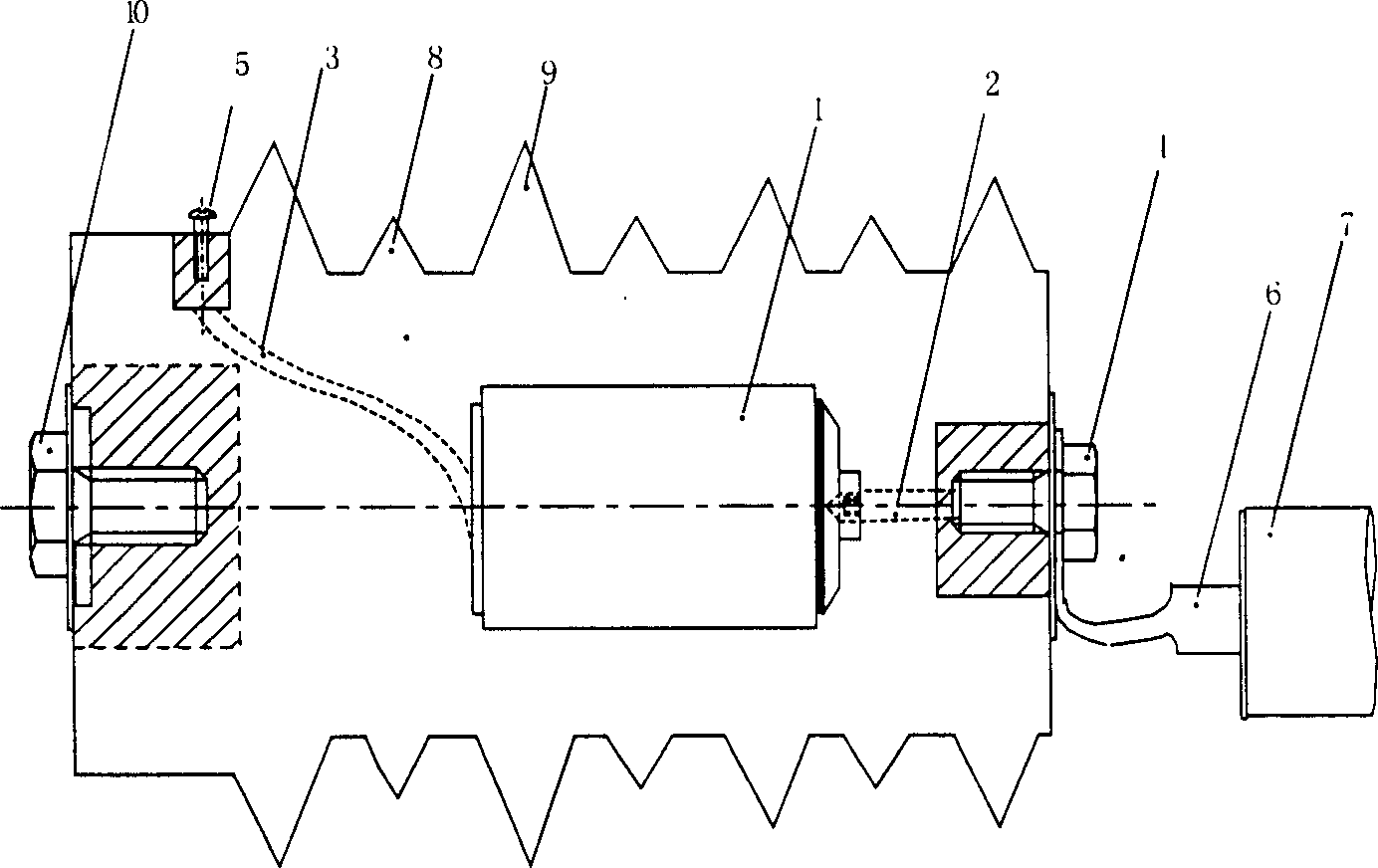

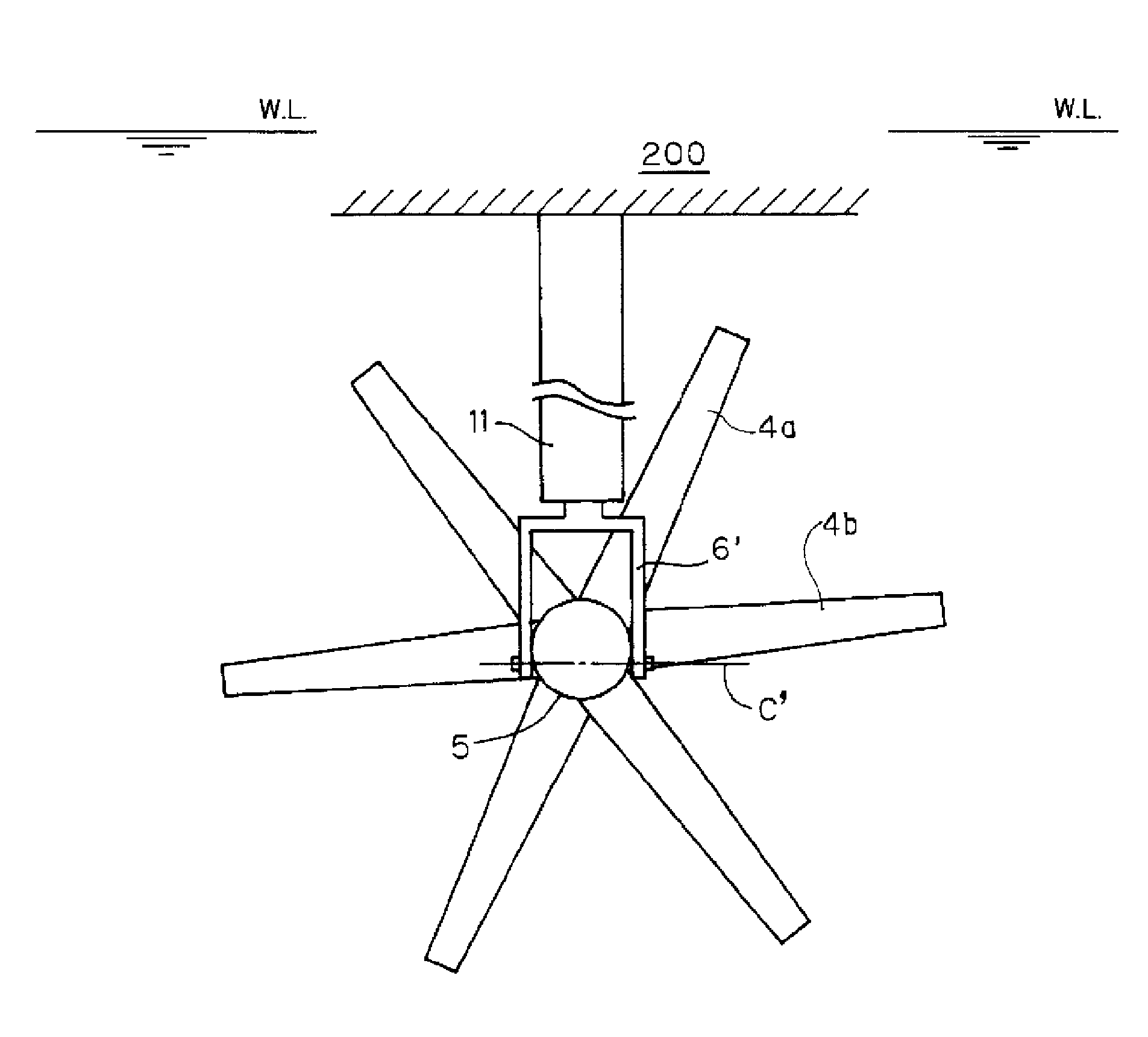

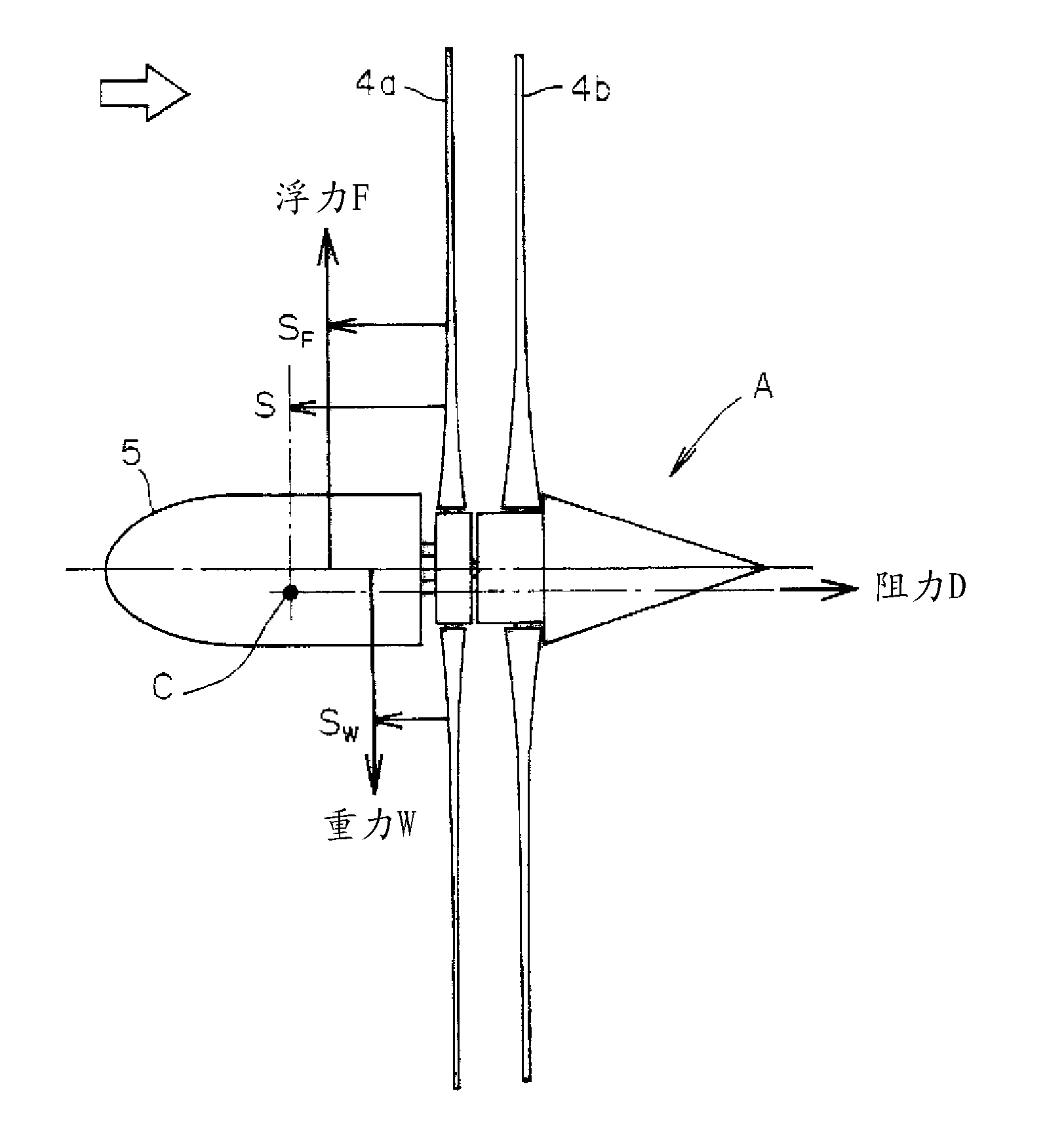

Submersible power generator

ActiveCN104246209AIncrease rotation speedRising Relative Rotational SpeedHydro energy generationReaction enginesPropellerWater flow

[Problem] To provide a submersible power generator which can be moored stably underwater and which can achieve a high startup voltage without being enlarged. [Solution] A submersible power generator is provided with: an inner / outer dual-rotary armature power-generating mechanism having an outer rotary armature and an inner rotary armature that faces the outer rotary armature and rotates in the opposite direction from the outer rotary armature; and a set of propellers arranged with coinciding axes, the torsional direction of the blades relative to the extending direction of the axes being opposite of each other. One propeller in the set of propellers is linked to one rotary armature among the inner and outer rotary armatures, the other propeller is linked to the other rotary armature, a casing is provided for sealing the inner / outer dual-rotary armature power-generating mechanism off from the external environment, the submersible power generator operates in water currents while submerged, and the buoyancy force (F) acting on the submersible power generator during operation is greater than the gravitational force (W) acting on the submersible power generator (when the generator is moored using mooring lines, F > W + the gravitational force acting on the mooring lines - the buoyancy force acting on the mooring lines).

Owner:KYOWA ENG CONSULTANTS

Fluorenone derivative, and preparation and application thereof

ActiveCN109574917AImprove luminous efficiencyImprove luminescence stabilityOrganic chemistrySolid-state devicesQuantum efficiencyLuminous intensity

The invention discloses a fluorenone derivative, and preparation and application thereof. The fluorenone derivative has the advantages that the fluorenone derivative takes fluorenone as a core, and acompound with new characteristics is formed through bridging between a heterocyclic ring and a receptor gene to serve as a luminous layer main body material and an electron transfer material of an OLED device, so that the performance of the device in starting voltage, luminous intensity, external quantum efficiency, chromaticity, half-life and the like can be remarkably improved, and the working stability of the device can be enhanced.

Owner:WUHAN SUNSHINE OPTOELECTRONICS TECH CO LTD

Discharge Lamp Ballast, Lighting System and Projector

InactiveUS20080218094A1Reduce noiseIncrease the starting voltageAlternating current plasma display panelsElectric light circuit arrangementResonanceInductor

A discharge lamp ballast. Its starting means comprises a second inductor connected between a first end of a discharge lamp and the positive voltage side of a first capacitor; a second capacitor forming a resonance circuit together with the second inductor; a second switching element connected between the positive terminal of a DC power source and the second end of the lamp; a third switching element connected between the second end of the lamp and the negative voltage side of the first capacitor; and a starting control means that controls both switching elements. The starting control means alternately turns both switching elements on and off so as to contribute resonance voltage of the resonance circuit for starting of the lamp in case of the starting mode. According to the invention, noise from the starting means can be reduced.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Circuit arrangement having a converter without a transformer but with an inductor for the pulsed operation of dielectric barrier discharge lamps

InactiveUS20070018590A1High voltageImprove compactnessElectrical apparatusElectric light circuit arrangementTransformerFull bridge

The circuit arrangement according to the invention comprises an inductor-type converter for the pulsed operation of dielectric barrier discharge lamps (EL). The invention proposes both a half bridge variant and a full bridge variant. By selecting the inductance value of the inductor (L), it is possible to influence the edge steepness of the pulses, in the case of more than one inductor even independently for the rising and falling edges.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

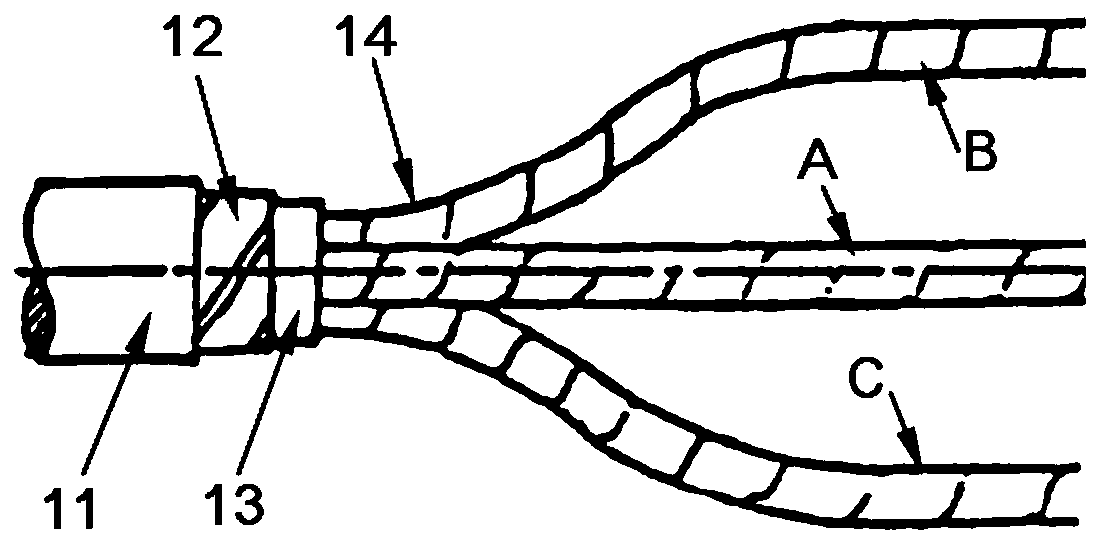

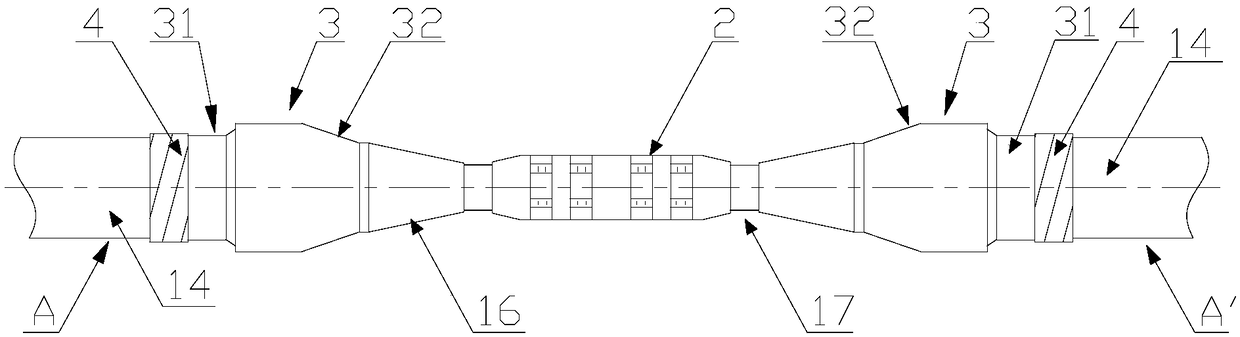

A cable wrapping intermediate joint and a manufacturing process thereof

PendingCN109245022AExcellent electrical performanceSafe and reliable operationCable junctionsApparatus for joining/termination cablesSingle phaseElectrical conductor

The invention provides a cable wrapping intermediate joint and a manufacturing process thereof, which are used for butt joint of two sections of three-core or single-core cables. The wrapping intermediate joint includes the connector wrapping connecting each single-phase cable, and the protective wrapping all the connectors; A tap wrap includes a pressure nozzle connected with a conductor core ofthat same-phase cable, a stress cone sleeved on the cable, a wound limiting step, a semi-conductive tape layer, an insulating tape layer, a tap shield layer, a copper mesh layer, a single-phase cablemetal shield tape, a PVC layer and a single-phase cable waterproof layer; The protective wrapping package comprises a binding layer, a cable metal shielding tape, a cable waterproof layer and a cablearmor layer from the inside to the outside. The winding intermediate joint of the invention can achieve the purposes of good connection, reliable insulation, good sealing performance, high mechanicalstrength, simple structure and convenient fabrication and installation of the conductor core of the cable, can ensure the safety and stability of the cable operation and obtain good economic benefits, and therefore has great popularization and application value.

Owner:SHANGHAI G&W ELECTRIC LTD +2

Electron transport type heteroanthracene derivative and organic electroluminescent device thereof

ActiveCN112239452AMaintain hole mobilityHigh quantum yieldOrganic chemistrySolid-state devicesOrganic electroluminescenceElectron transmission

The invention discloses an electron transport type heteroanthracene derivative, a preparation method and application thereof, and an organic electroluminescent device. The heteroanthracene derivativehas a parent nucleus structure of heteroanthracene, and is modified by a group to form a D-A type compound. The heteroanthracene derivative has remarkable and excellent fluorescence electroluminescentcharacteristics and electron transport characteristics, has relatively high quantum yield and electron mobility when being used as a luminescent object material, an electron transport material or a hole blocking material of an organic electroluminescent device, can effectively solve the problem of electron and hole imbalance in the device, emits purer light color, and compared with similar compounds and compounds in the prior art, has more remarkable advantages in starting voltage, current efficiency, service life and thermal stability.

Owner:WUHAN SUNSHINE OPTOELECTRONICS TECH CO LTD

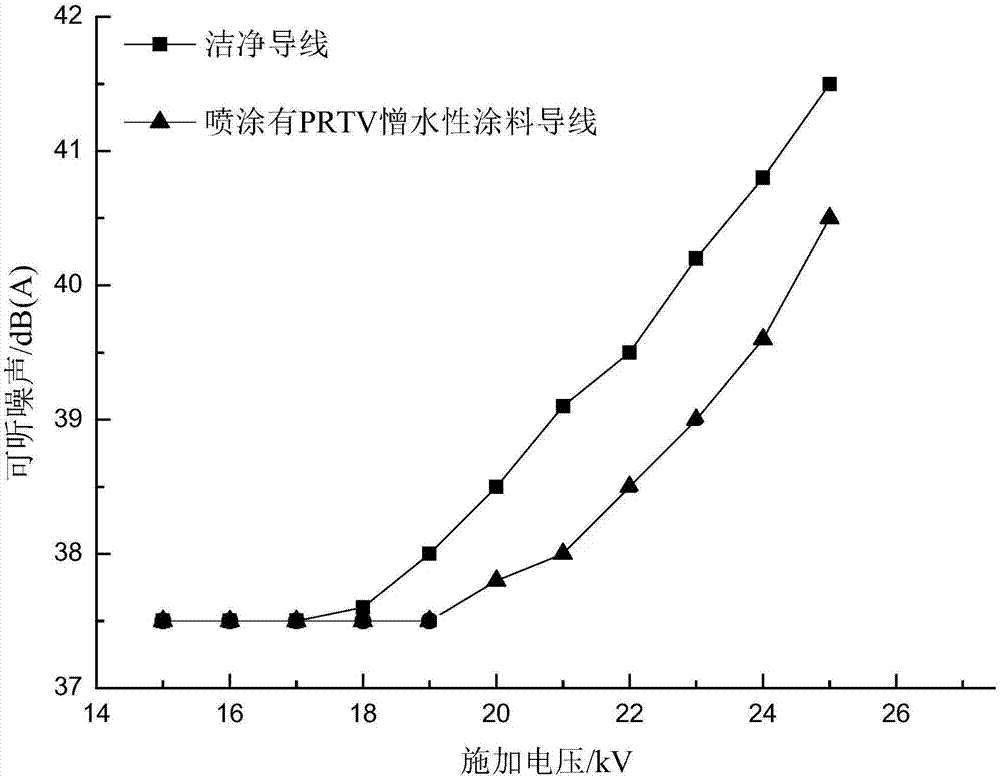

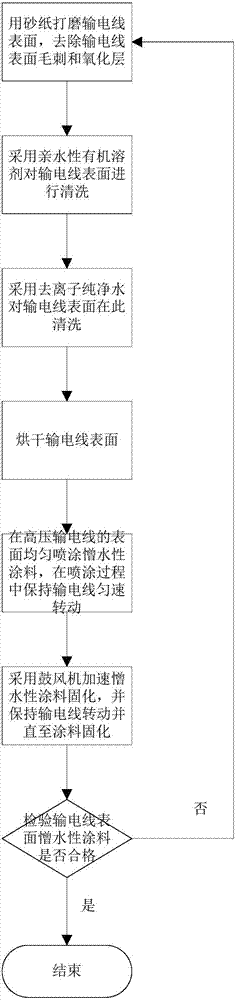

Noise lowering treatment method for corona audible noise of high-voltage power transmission line

InactiveCN107961964AReduces corona audible noiseReduce electric field distortionPretreated surfacesCleaning using toolsEngineeringElectric field distortion

The invention provides a noise lowering treatment method for a corona audible noise of a high-voltage power transmission line. The noise lowering treatment method for the corona audible noise of the high-voltage power transmission line comprises the following steps that S1, the surface of the high-voltage power transmission line is cleaned; S2, the surface of the high-voltage power transmission line is evenly coated with hydrophobic paint. By the adoption of the noise lowering treatment method for the corona audible noise of the high-voltage power transmission line, accumulation of water dropsand dirt on the surface of the power transmission line can be effectively reduced, so that the electric field distortion on the surface of a wire is reduced, so that the corona starting voltage of the high-voltage power transmission line is improved, and then the corona audible noise of the high-voltage power transmission line during severe weather can be lowered.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +2

Self-ballasted fluorescent lamp and lighting apparatus

InactiveUS7626322B2Improve light outputEasy to applyDischarge tube luminescnet screensElongate light sourcesLight equipmentEffect light

A self-ballasted fluorescent lamp includes a luminous tube that is formed in a bent shape with a pair of electrode-side end portions located at a the bottom end of the luminous tube. A cover houses a lighting device for lighting the luminous tube. A base is attached to the bottom end of the cover, and the luminous tube is supported at the top end, of the lamp. The outer diameter of a bulb of the luminous tube 14 ranges from 3 to 8 mm, and the maximum width of the luminous tube, is not greater than 30 mm. The cover is formed so that the proportion of the distance by which the cover extends from the base to the lamp length excluding the base ranges from 0 to 25%, and so that the maximum outer diameter of the cover ranges from 1.0 to 1.5 times the outer diameter of the base.

Owner:TOSHIBA LIGHTING & TECH CORP

Structure of shallow ridge isolation area and dynamic DASD and its mfg method

ActiveCN1601719AImprove uniformityAvoid the situation of electric leakageTransistorSemiconductor/solid-state device manufacturingEngineeringIon implantation

First, patterned mask layer is formed on a substrate. Next, an ion-implantation step is carried out in order to form a doping range on substrate uncovered by mask layer. Then, an etching step is carried out in order to patternize substrate. Thus, a groove is formed on the substrate, and doping area is exposed at bottom of groove. A insulating layer is filled into the groove to form a shallow groove isolation region. In the invention, doping area is formed at bottom of shallow groove isolation region, and not formed at side wall.

Owner:PROMOS TECH INC

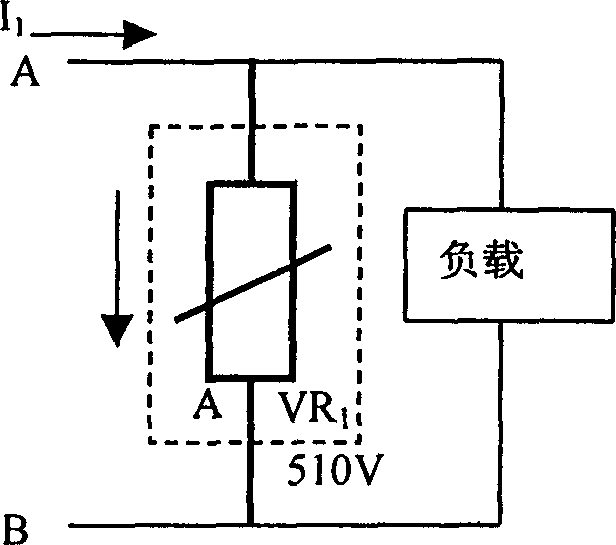

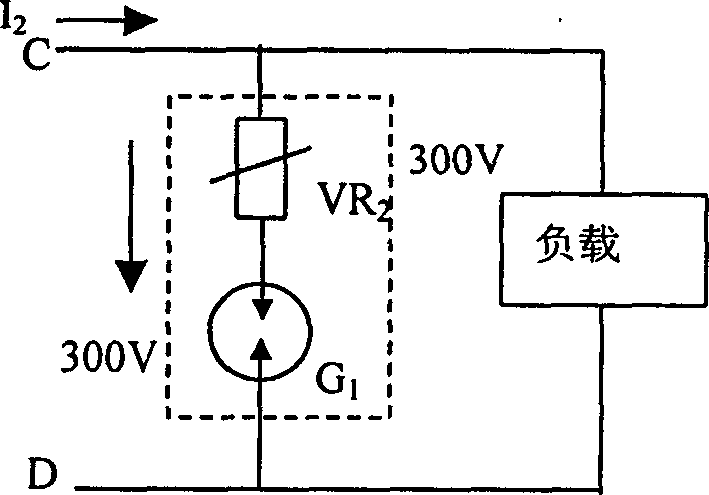

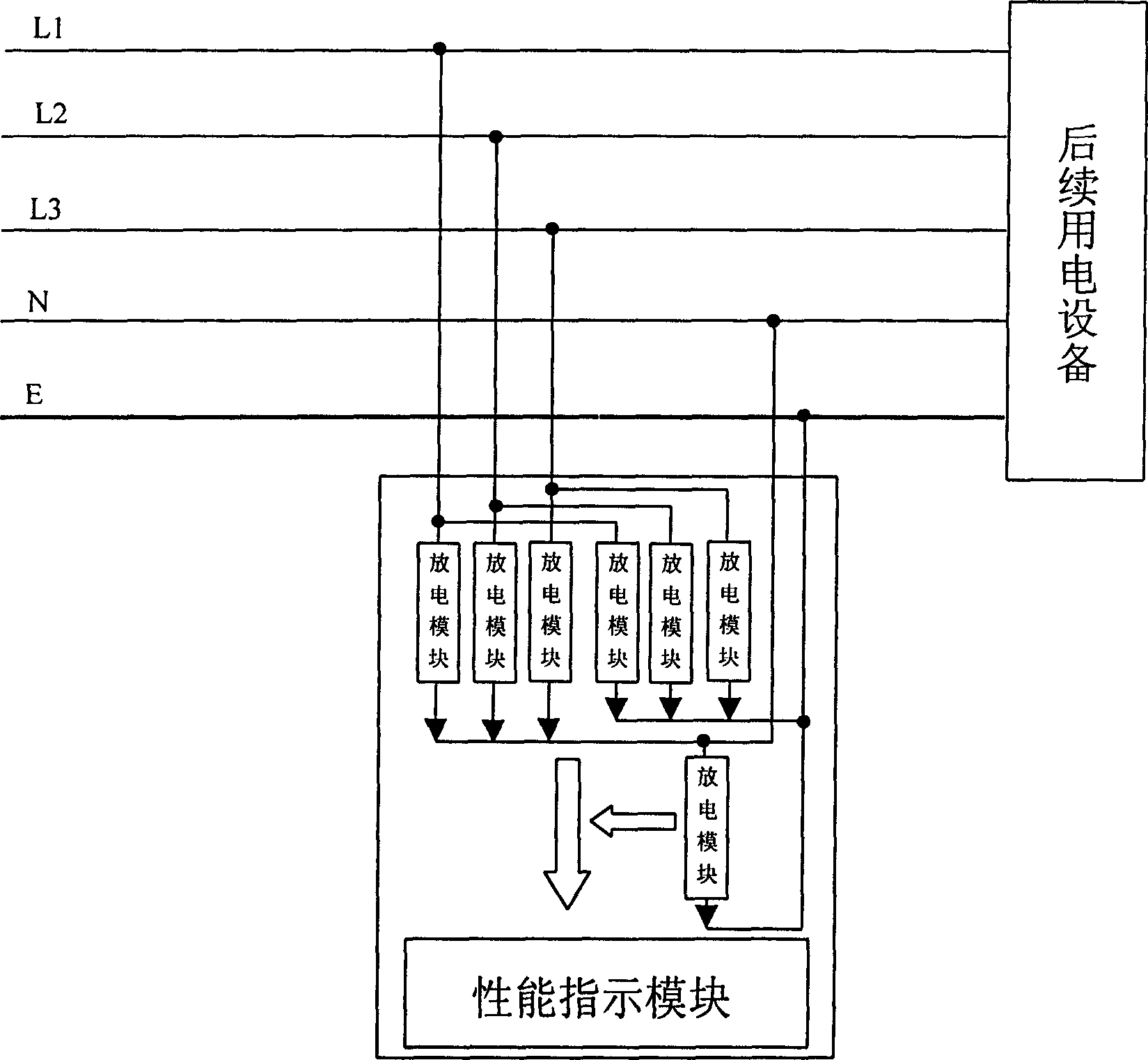

Lightning protection for power supply

InactiveCN1146096CQuick responseSo as not to damageEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceEngineering

The lightning arrester for power source is composed of at least more than one discharging modules and performance figure circuits that are connects to two lines among phase line, zero line or ground line. The discharging module consists of main discharging circuit and starting circuit connected in parallel. The main discharging circuit includes voltage dependent resistor VR2 and gas discharge tube in serial. The starting circuit includes voltage dependent resistor VR1. The invented device solves the issue of high residual pressure before starting the gas discharge tube completely by using the structure of combining the main discharging circuit and the gas discharge tube. After the gas discharge tube starts, then the main discharging circuit does main discharging task. Morecover the element with lower starting voltage can be selected for the gas discharge tube and the voltage dependent resistor, so as to realize lower residual pressure, higher starting voltage and higher response speed.

Owner:沈艺明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com