Structure of shallow ridge isolation area and dynamic DASD and its mfg method

A technology of dynamic random access and shallow trench isolation, which is applied in semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve problems such as junction leakage and improvement, and achieve the effect of improving uniformity and avoiding gradient improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

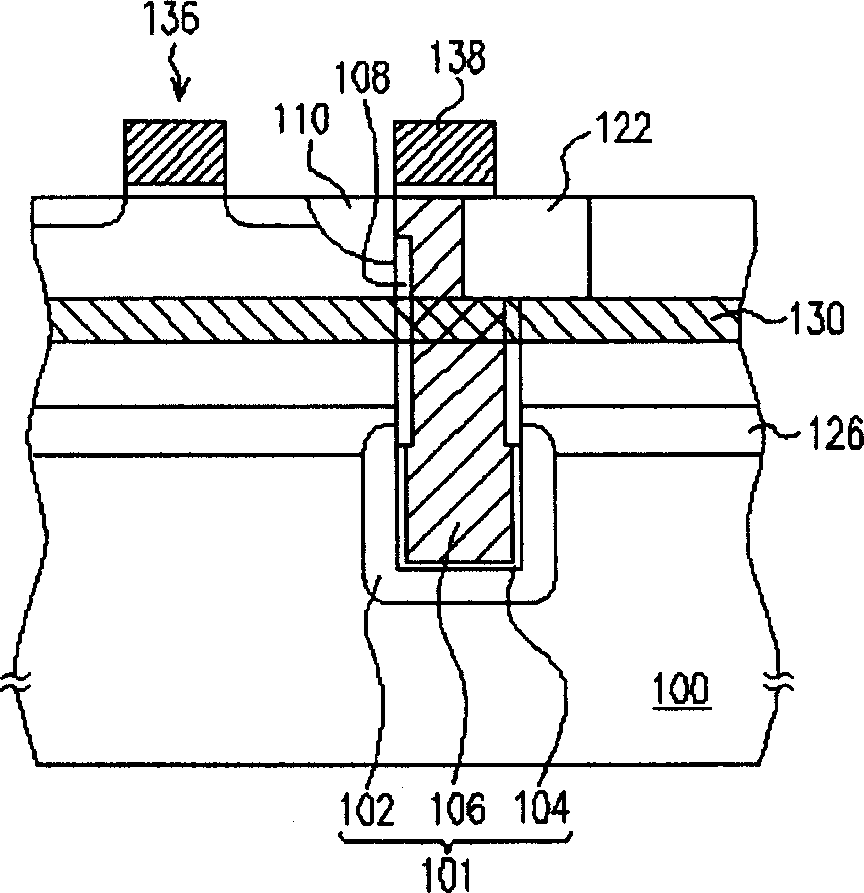

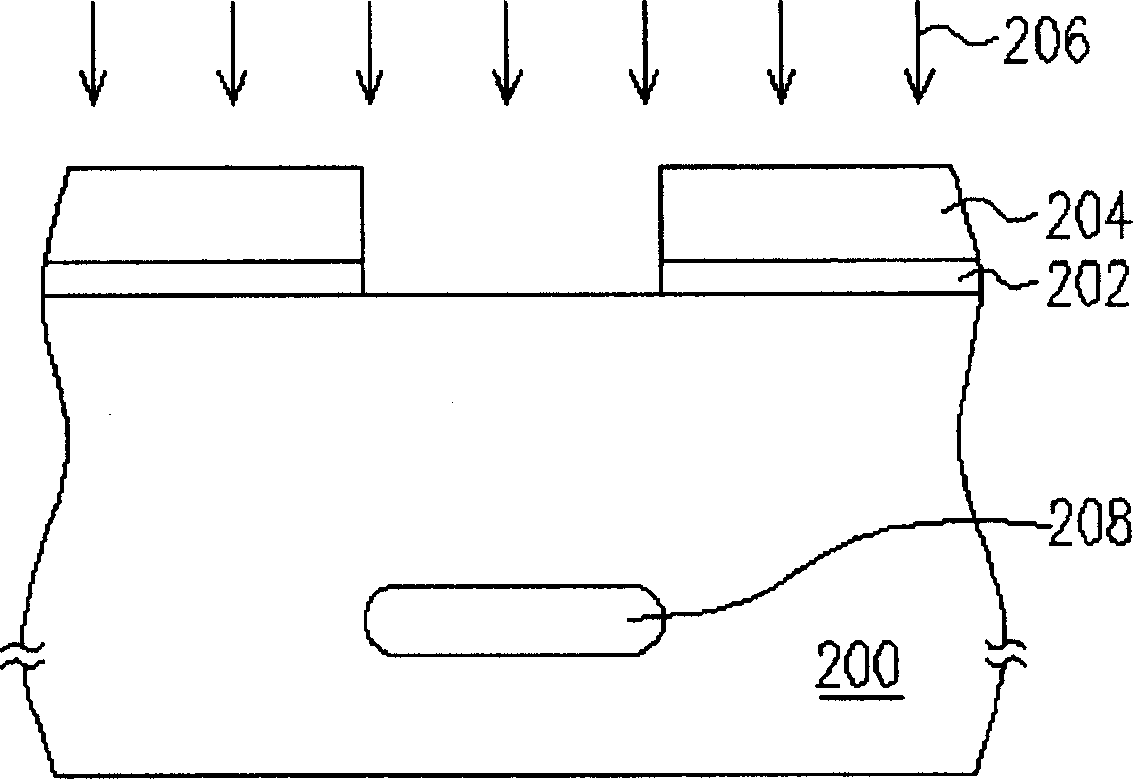

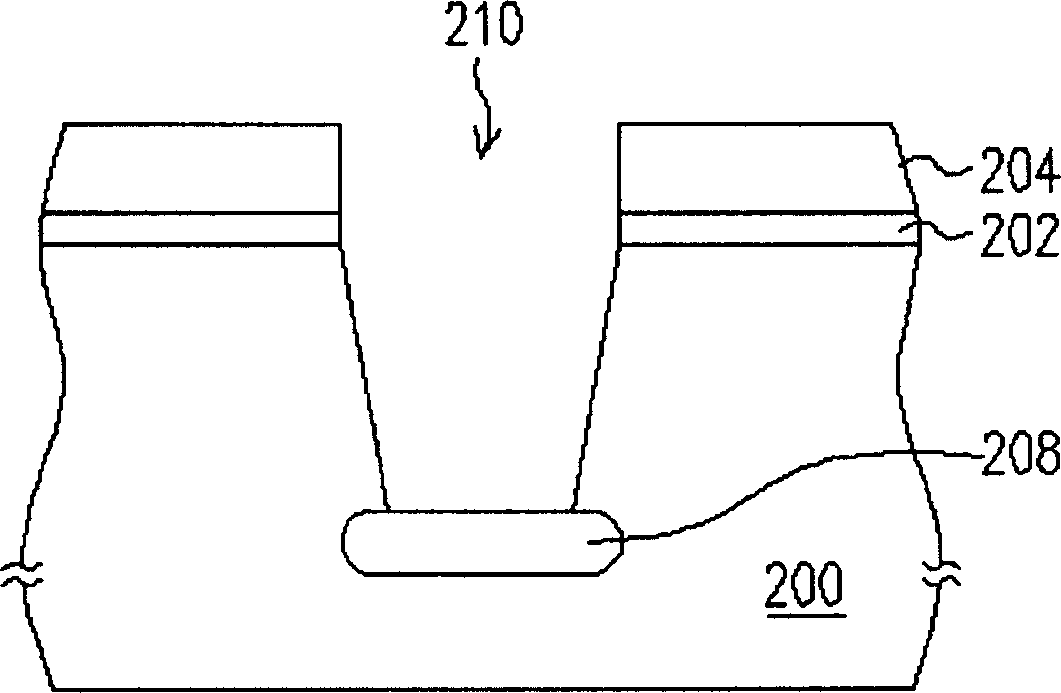

[0035] Figure 2A to Figure 2C As shown, it is a schematic cross-sectional view of a manufacturing process of a shallow trench isolation region according to a preferred embodiment of the present invention. Please refer to Figure 2A First, a pad oxide layer 202 and a mask layer 204 are formed on a substrate 200 . Wherein, the pad oxide layer 202 is used to protect the surface of the substrate 200, and the thickness of the mask layer 204 is, for example, greater than 600 angstroms, which may be a silicon nitride layer, a stacked layer of a silicon nitride layer / photoresist layer , or a stacked layer of silicon nitride layer / silicon oxide layer / photoresist layer, depending on the process requirements. The method for forming the mask layer 204 and the pad oxide layer 202 is, for example, to first form an oxide thin layer (not shown) on the surface of the substrate 200, and then form a mask material layer (not shown) on the oxide thin layer, After forming a patterned photoresis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com