Direct methanol fuel cell fuel-feeding method and structure thereof

A methanol fuel cell and fuel supply technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as battery startup performance decline, and achieve the effects of alleviating catalyst poisoning, high battery performance, and improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are further descriptions of the technical solutions of the present invention, not as limitations on the scope of protection.

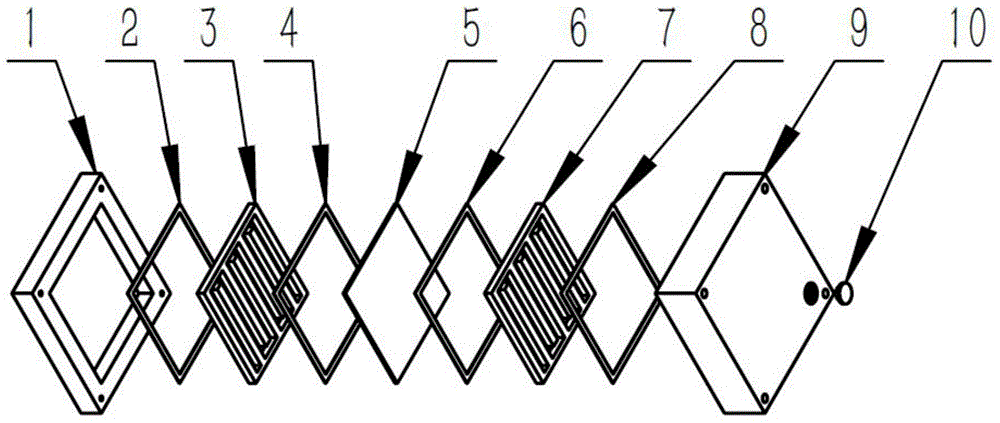

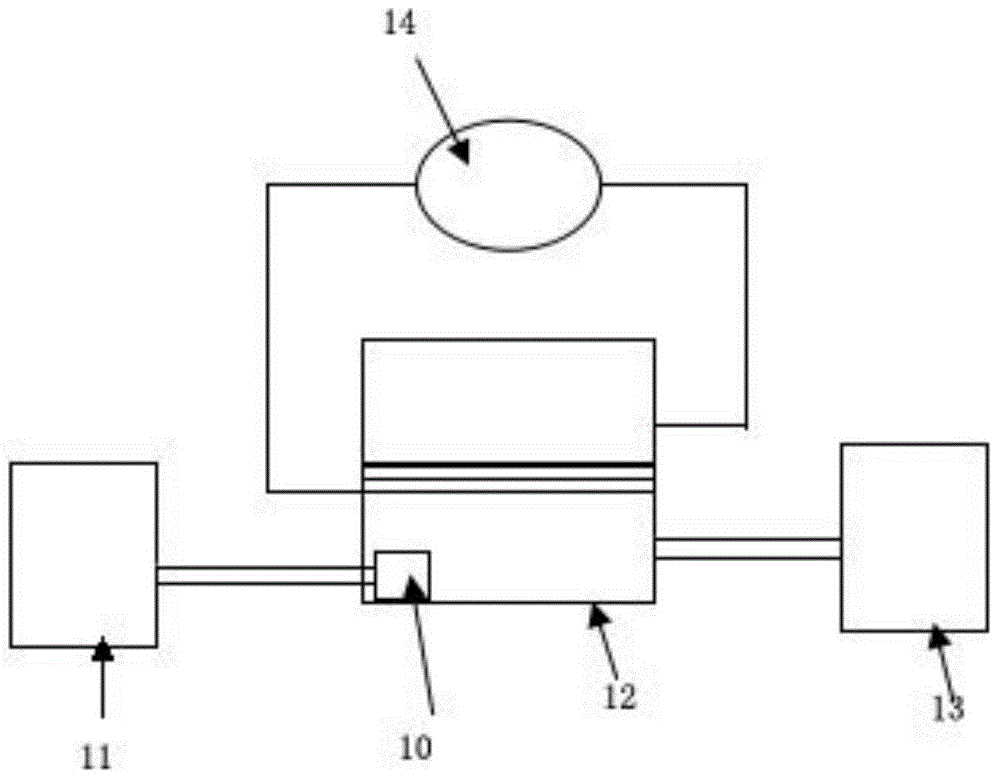

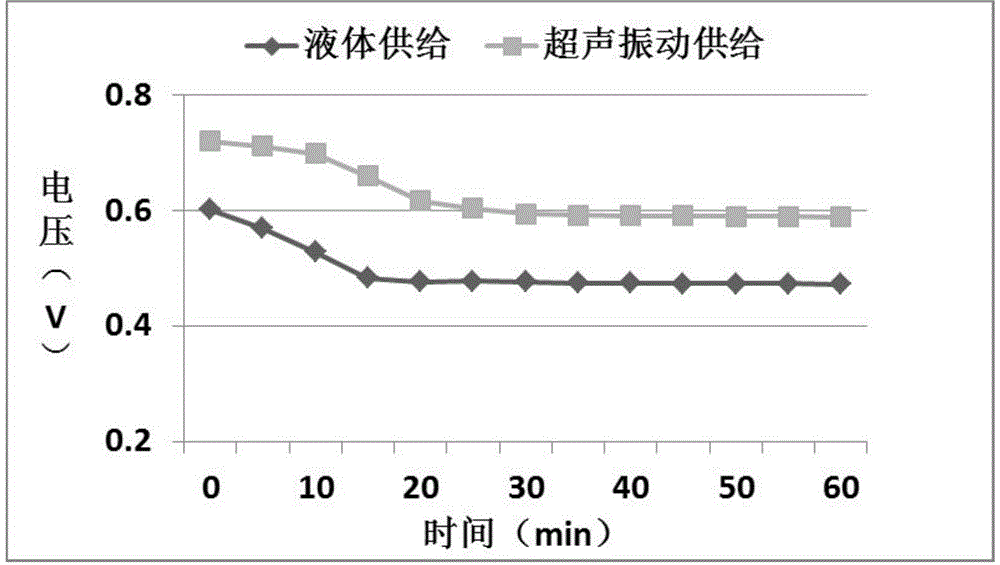

[0024] Refer to attached figure 1 , the fuel channel 7 and the flow field channel 3 of the direct methanol fuel cell sandwich the MEA membrane 5, seal it through the sealing rings 4 and 6, package it through the packaging shell 1 and 9, seal it through the sealing rings 2 and 8, and seal the shell 1 and 9 are connected by bolts or other means. The ultrasonic vibration transducer is installed on the packaging shell by means of adhesion, inlay or embedding, so that it becomes a part of the fuel cell packaging shell. When working, it radiates ultrasonic waves to the fuel that is about to enter the anode fuel supply channel, so that it can be absorbed by a tiny liquid. The drops enter the supply channel. The fuel supplied by the vibration method enters the internal reaction of the battery in the form of tiny droplets, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com