Patents

Literature

44results about How to "Reduced spherulite size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

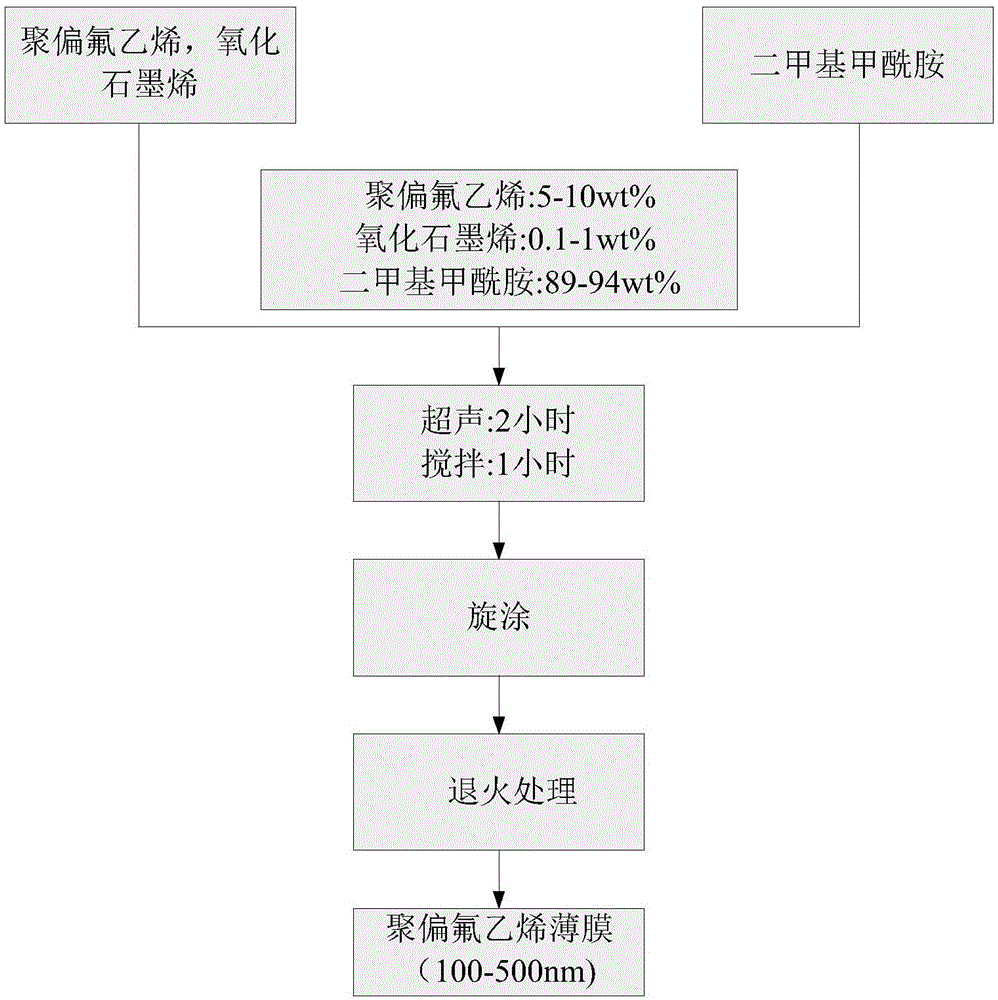

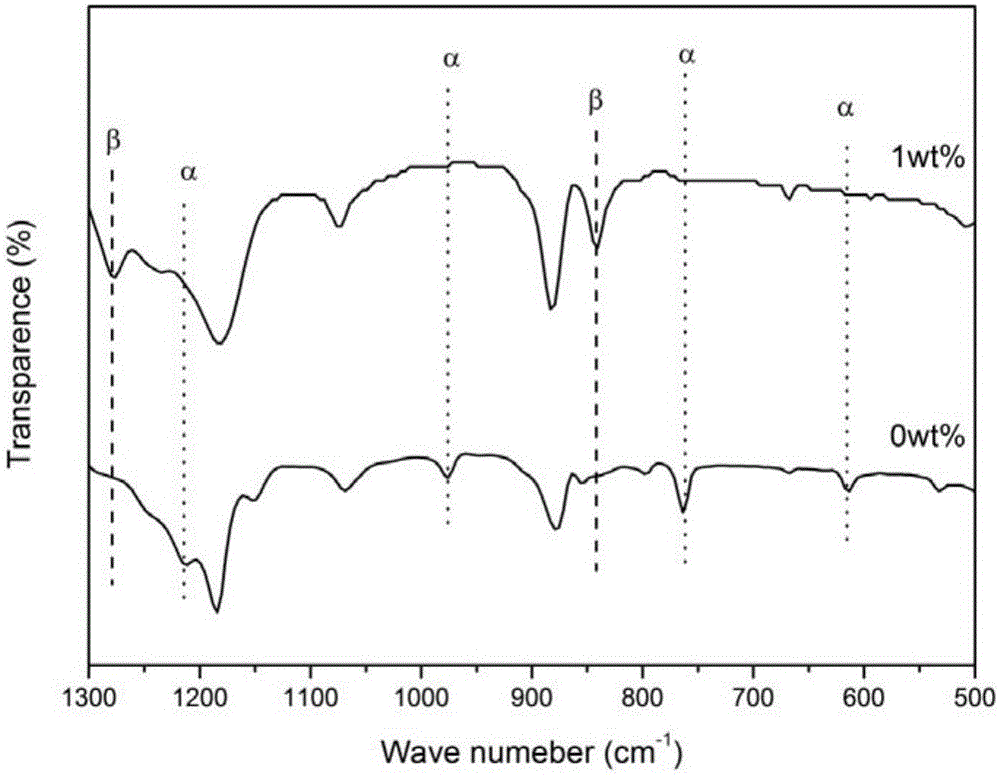

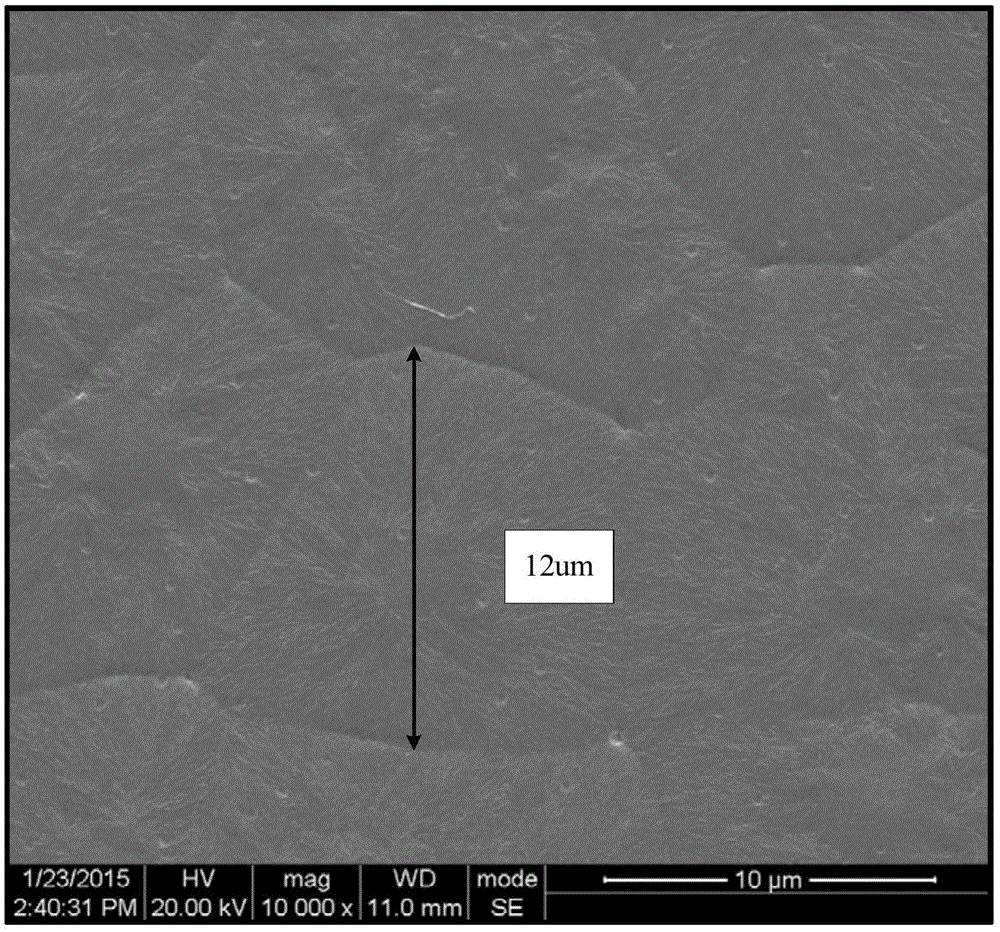

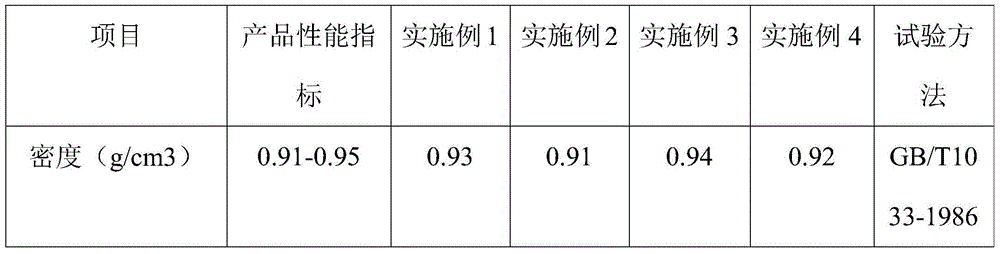

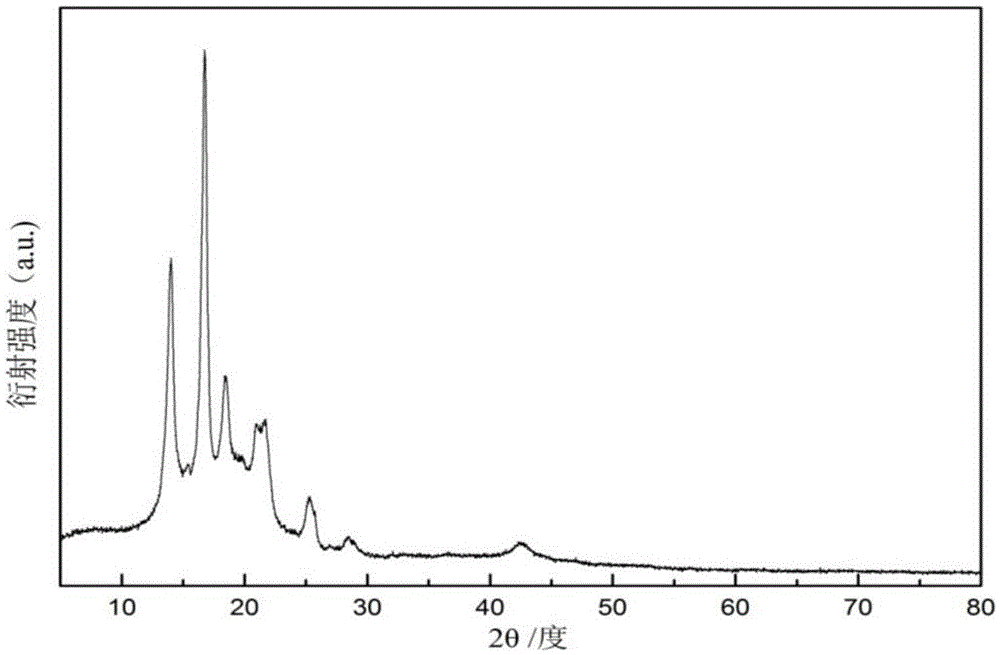

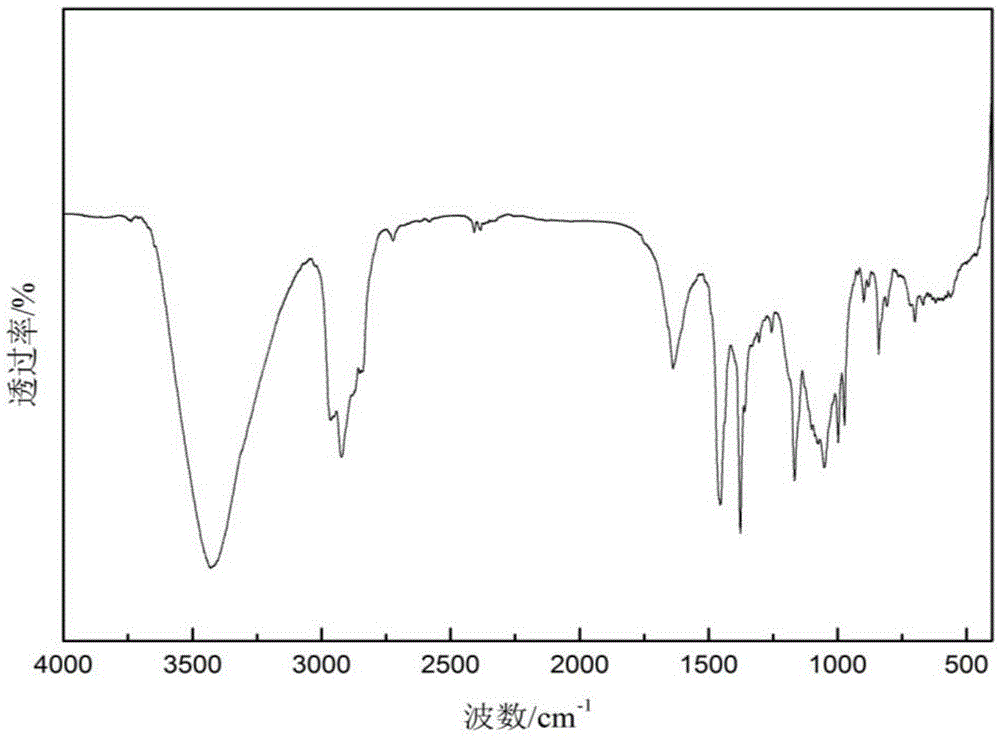

Preparation method for polyvinylidene fluoride nanometer film with beta crystal phase

The invention provides a preparation method for a polyvinylidene fluoride (PVDF) nanometer film with a beta crystal phase, which belongs to the fields of pyroelectric thin film materials and terahertz detection. The preparation method comprises the following steps: dissolving graphene oxide and polyvinylidene fluoride in an organic solvent and carrying out ultrasonic treatment and magnetic stirring so as to obtain a uniformly dispersed film-making solution; standing the film-making solution for defoaming; preparing a wet film by using a spin coating method; and subjecting the film to heat treatment in an atmospheric environment to realize drying and crystallization of the film so as to obtain the polyvinylidene fluoride nanometer film with the beta crystal phase. According to the invention, the content of the beta crystal phase in PVDF is increased by doping of GO and the PVDF nanometer film is prepared by using the spin coating method; the preparation method is simple, is easy to control, has low requirements on equipment and low cost and can realize preparation under common atmospheric conditions; and the prepared PVDF film is uniform and smooth, has good compactness and stable pyroelectric performance and provides powerful support for development of a thin-film pyroelectric terahertz detector.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

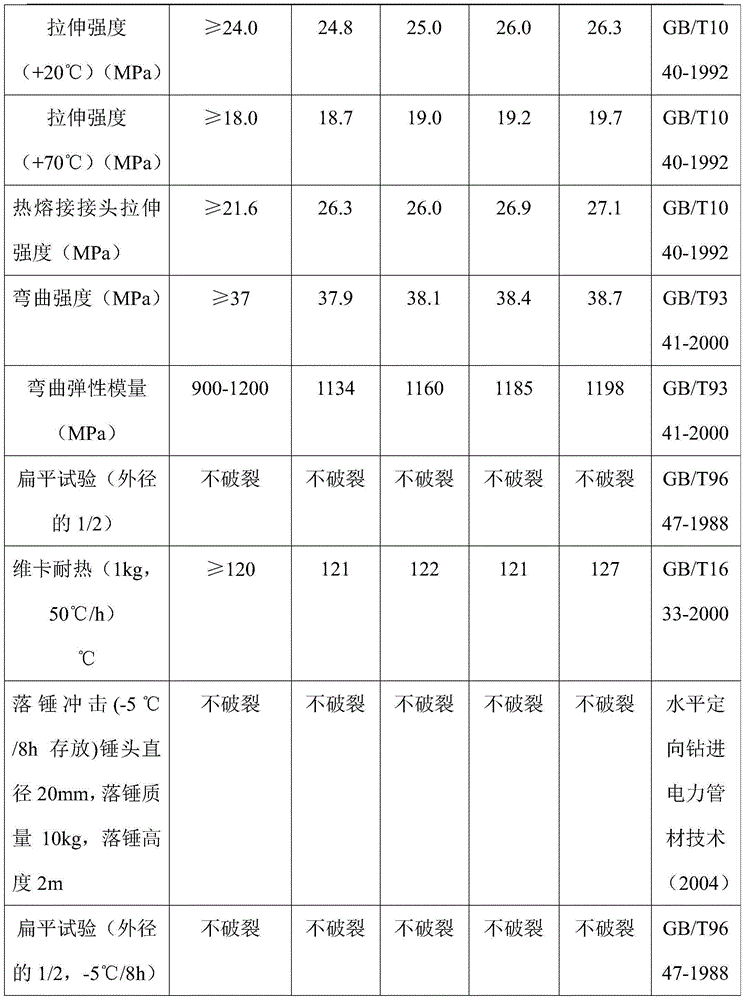

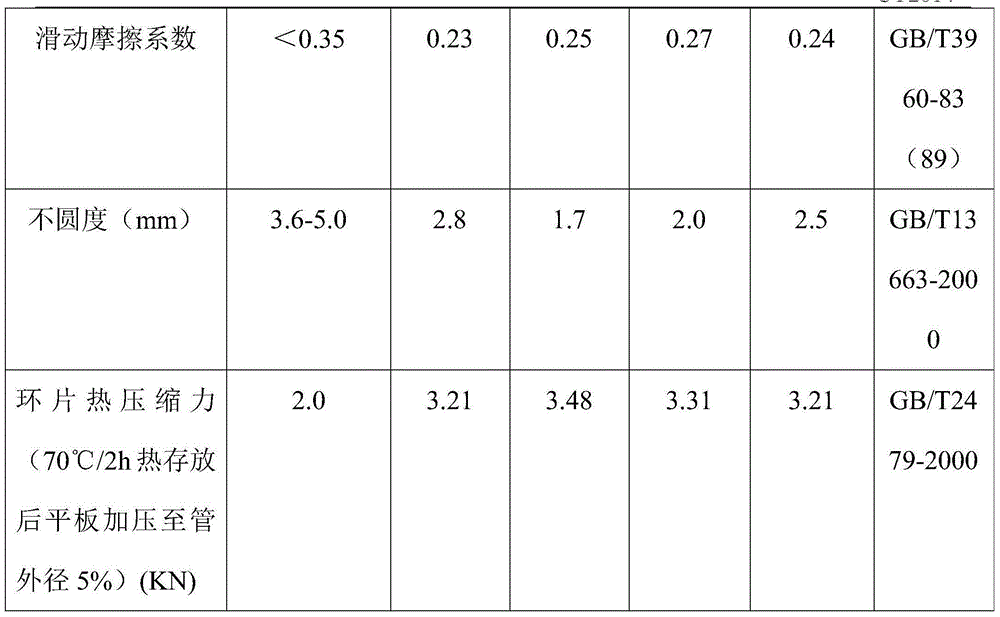

Anti-impact MPP (molypermalloy powder core) electric protection tube

The invention discloses an anti-impact MPP (molypermalloy powder core) electric protection tube. The anti-impact MPP electric protection tube is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 5-15 parts of ethylene-propylene-diene monomer, 10-25 parts of talcum powder, 3-10 parts of brucite powder, 5-12 parts of modified micro silicon powder, 0.8-2 parts of colouring agent, 5-15 parts of nano mica, 0.5-2 parts of antioxidant, 0.5-2 parts of polytetrafluoroethylene, 10-25 parts of modified shell powder, 5-15 parts of modified hectorite, 5-25 parts of novel organic montmorillonite, 5-18 parts of melamine cyanurate, 10-25 parts of modified crystal whisker, 15-30 parts of long glass fiber, 3-8 parts of expandable graphite and 5-20 parts of intumescent flame retardants. The anti-impact MPP electric protection tube has excellent impact resistance, flame retardance, ageing resistance, cold resistance and heat resistance.

Owner:安徽宁国市高新管业有限公司

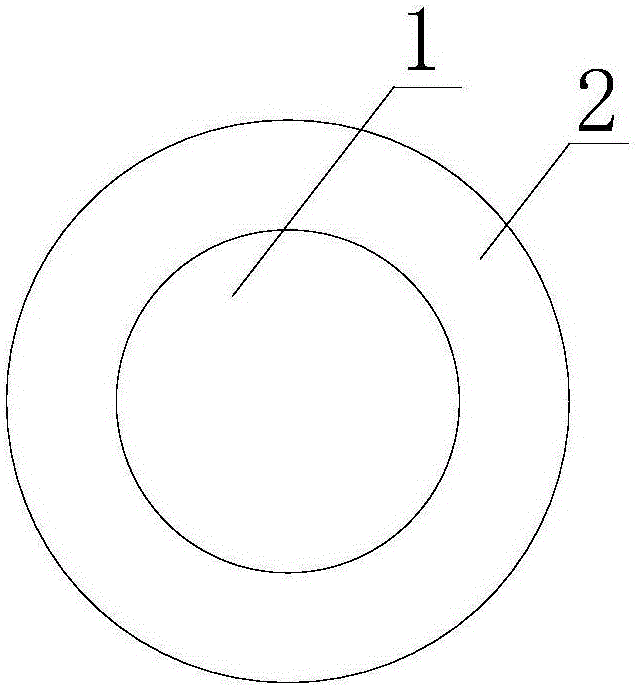

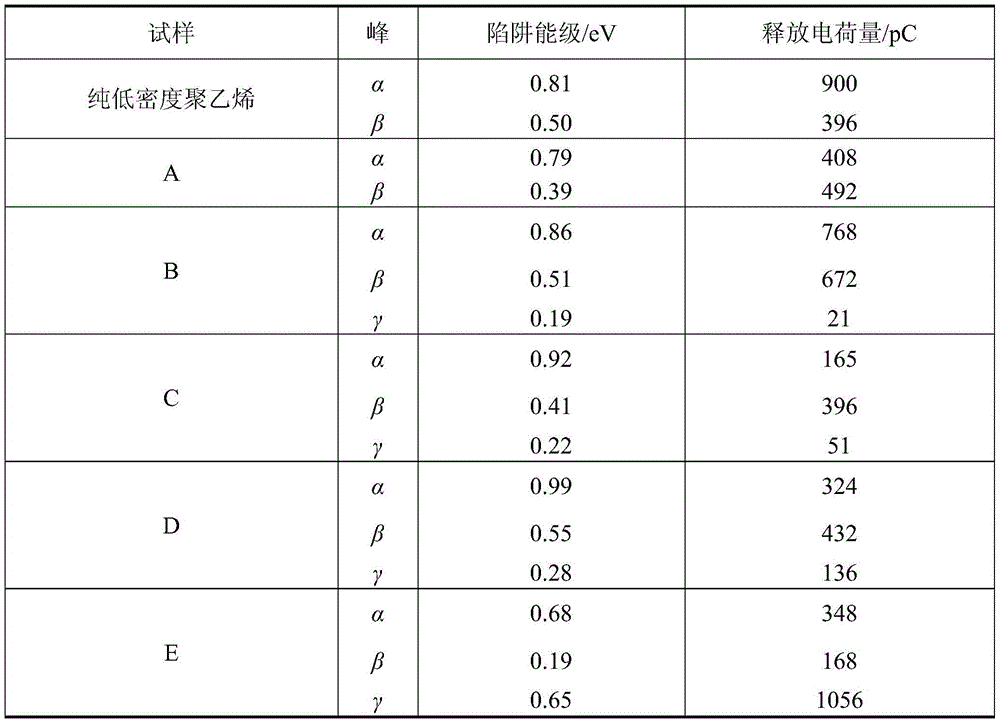

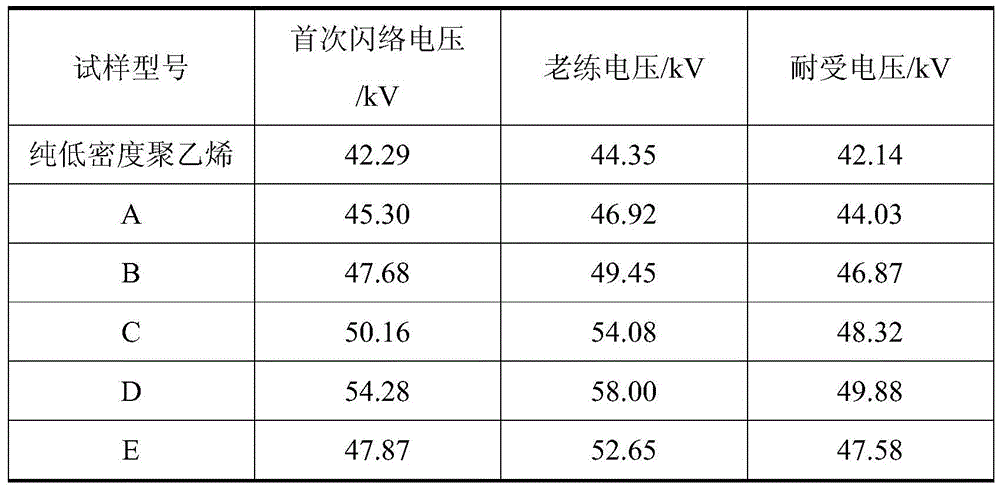

High voltage direct current cable insulation material

InactiveCN103665525AGood physical propertiesExcellent overall performancePlastic/resin/waxes insulatorsPartial dischargePower flow

The invention provides a high voltage direct current cable insulation material, which comprises the following components in parts by weight: 100 parts of LDPE (Low-density Polyethylene), 1-2 parts of CPE (Chlorinated Polyethylene), 0.5-1.5 parts of BaTiO3, 0.6-1.5 parts of conductive potassium titanate whisker, 1-2.5 parts of a cross-linking agent, and 0.1-0.5 part of an antioxygen. A semiconductive polyolefin shielding material prepared from the high voltage direct current cable insulation material has the advantages of ultra-smooth surface feature, good physical property and excellent overall performance; electric current is effectively output to form a favorable uniform electric field, and partial discharge or insulation breakdown caused by severe electric field concentration due to surface defects of a semiconductive shielding layer is prevented; ionized charge and injected charge are absorbed in a deep trap, so that charge accumulating in a local area is avoided, space charge accumulation in a cable insulation material is restrained, and electrical conductivity of the cable insulation material is reduced.

Owner:WUXI JIANGNAN CABLE

Method for preapring poly3-hydroxy alkyl acid ester/carbondioride-propylene epoxide copolymer/starch terpolymer blend

The present invention belongs to the preparation method of poly-3-hydroxyalkanate / carbon dioxide-epoxypropane copolymer / starch ternary mixture. The ternary mixture is formed from carbon dioxide epoxypropane copolymer, poly-3-hydroxyalkanate, starch, talcum powder, boron nitride and tetra[beta-(3,5-di-tert-butyl-4- hydroxyphenyl) propanoicacid] pentaerythritol (antioxidant Ky-7910). The said materials are mechanically mixed in high-speed stirring machine, extruded in twin screw extruder machine and granulated. The temp. of melt material is 175-185 deg.C, and the obtained resin of poly-3-hydroxyalkanate / carbon dioxide-epoxypropane copolymer / starch ternary mixture can be used for preparing film, plate material, sheet material and injection-moulded into plastic components.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

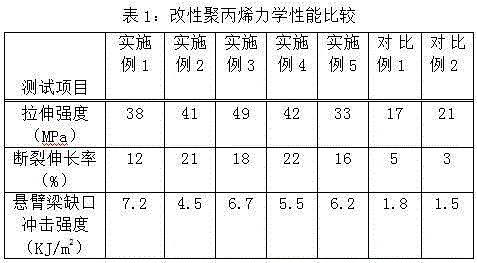

Graphene-oxide-modified polypropylene composite material

The invention discloses a graphene-oxide-modified polypropylene composite material which is prepared from graphene-oxide-modified polypropylene, ethylene propylene diene monomer rubber, a butadiene-acrylonitrile copolymer, a silane coupling agent, zinc borate, magnesium hydroxide, pentaerythritol, epoxy soybean oil, tritolyl phosphate, pentaerythritol stearate, yttrium oxide, nano mica powder, talcum powder, silicon micropowder, 1,3,2,4-di(3,4-dimethylbenzylidene)sorbitol, an ethylene-octylene copolymer and 2-hydroxy-4-n-octyloxy diphenyl ketone. The graphene-oxide-modified polypropylene composite material has the advantages of high strength, excellent heat resistance, excellent flame retardancy and favorable heat stability.

Owner:ANHUI LANTONG TECH CO LTD

Polyester/carbon nano tube-nucleating agent composite material and preparation method thereof

InactiveCN102532817AImprove performanceReduced spherulite sizeMaterials preparationDimethyl terephthalate

The invention belongs to the technical field of high polymer material preparation, and in particular relates to a polyester / carbon nano tube-nucleating agent composite material and a preparation method thereof. The composite material provided by the invention comprises the following components in parts by weight: 78 parts of dimethyl terephthalate, 61-100 parts of 1,3-propylene glycol, 0.0078-0.78 part of ester exchange catalyst, 0.0078-0.78 part of polymerization catalyst, 0.05-5 parts of carbon nano tube and 0.02-2 parts of nucleating agent. The invention also provides the preparation method of the polyester / carbon nano tube-nucleating agent composite material. The preparation method comprises two steps, namely ester exchange and polymerization. For the composite material provided by the invention, the addition of the nucleating agent enhances the heterogeneous nucleation crystallization capability, improves the crystallization speed, reduces the sphaerocrystal size of dimethyl terephthalate and improves mechanical property; at the moment, the strength-increasing and toughening capabilities are mainly exerted by the addition of the carbon nano tube so that the great improvement of the property of the composite material can be realized only by less filling, thus the application field of the composite material is greatly expanded.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method of low-strength low-elongation terylene filament

InactiveCN102618961AFluffy goodImprove breathabilityMelt spinning methodsMonocomponent polyesters artificial filamentHeat resistanceAntimony trioxide

The invention relates to a modified polyester raw material of a low-strength low-elongation terylene filament, which comprises the raw material components as follows: terephthalic acid, ethylene glycol, inorganic sub-micron particles, a catalyst and a flatting agent, wherein the molar ratio of ethylene glycol to terephthalic acid is (1.3-1.8) : 1; the inorganic sub-micron particles are CaCO3 or CaSO4, and the mass ratio of the inorganic sub-micron particles to terephthalic acid is 0.5-2%; the catalyst is ethylene glycol antimony or antimony trioxide, and the mass ratio of the catalyst to terephthalic acid is 0.03-0.06%; and the flatting agent is TiO2, and the mass ratio of the flatting agent to terephthalic acid is 0.1-1.0%. The preparation method comprises the steps as follows: performing melt spinning on the modified polyester, drawing, cooling, and winding to obtain the low-strength low-elongation terylene filament. The low-strength low-elongation terylene filament has the advantages that the hygroscopicity, bulkiness and air permeability of the product are improved; the situation that fibers in the tearable non-woven medical gauze are arranged according to a certain direction is improved, and the service life is prolonged; the heat resistance and the heat stability are improved as compared with the those of the non-woven fabric and other tearable gauze and hygienic cloth; and the light fastness is good, the gloss retention, the color retention and the yellowing resistance and the like can be improved, and the use field is enlarged.

Owner:ZHEJIANG JIABAO NEW FIBER GROUP

High strength impact-resistant cable

InactiveCN105733094ALow priceLight in massPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceElectrical conductor

The invention discloses a high strength impact-resistant cable. The high strength impact-resistant cable comprises a conductor, wherein a sheath wraps the conductor; the sheath is made from a polypropylene composite material, and raw materials in parts by weight of the polypropylene composite material comprise: 100 parts of polypropylene, 15-30 parts of polyurethane, 5-20 parts of nylon 66, 2-5 parts of polypropylene grafted polystyrene, 2-6 parts of 1,2-polybutadiene, 10-25 parts of modified filler, 3-8 parts of nano rubber powder, 1-5 parts of sodium 2,2'-methylene-di(4,6-di-n-butyl phenol) phosphate, 0.5-2 parts of stearic acid, 0.5-2 parts of dibenzoyl peroxide, 3-15 parts of a flame retardant and 1-3 parts of an antioxidant. The high strength impact-resistant cable provided by the invention has high strength, good impact resistance, excellent anti-aging and flame retardant properties and long service life.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

Preparation method for recyclable high-voltage direct-current cable material with function of inhibiting space charge

InactiveCN104927190AImprove thermomechanical propertiesEnhanced inhibitory effectPlastic/resin/waxes insulatorsElastomerProcedure Agents

The invention relates to a preparation method for a recyclable high-voltage direct current cable material with the function of inhibiting space charge, and belongs to the technical field of transmission equipment. The preparation method comprises the following steps: mixing isotatic polypropylene, an elastomer, an antioxidant, a fire retardant and a processing aid for 6-10 minutes under the conditions that the temperature is 190-200 DEG C, and the revolving speed is 40-60 r / min to prepare the high-voltage direct current cable material, wherein the ratio of isotatic polypropylene to the elastomer is 1:(0-0.7), and isotatic polypropylene and the elastomer are 100 parts by weight, the antioxidant is 0.5-1 part by weight, the fire retardant is 2-5 parts by weight, and the processing aid is 0.5-1 part by weight. The recyclable high-voltage direct-current cable material takes a mixture of a thermoplastic polymer material and the elastomer as the raw material, the melting point of the polymer material is higher than or equal to 150 DEG C, and the content of octylene in the elastomer is smaller than 14%. The recyclable high-voltage direct-current cable material has the advantages that under the condition that the thermomechanical properties of thermoplastic resin are improved, the space charge of the recyclable high-voltage direct-current cable material can be inhibited well, the recyclable high-voltage direct-current cable material can be recycled after the design lifetime is reached, and environment is not damaged.

Owner:TSINGHUA UNIV

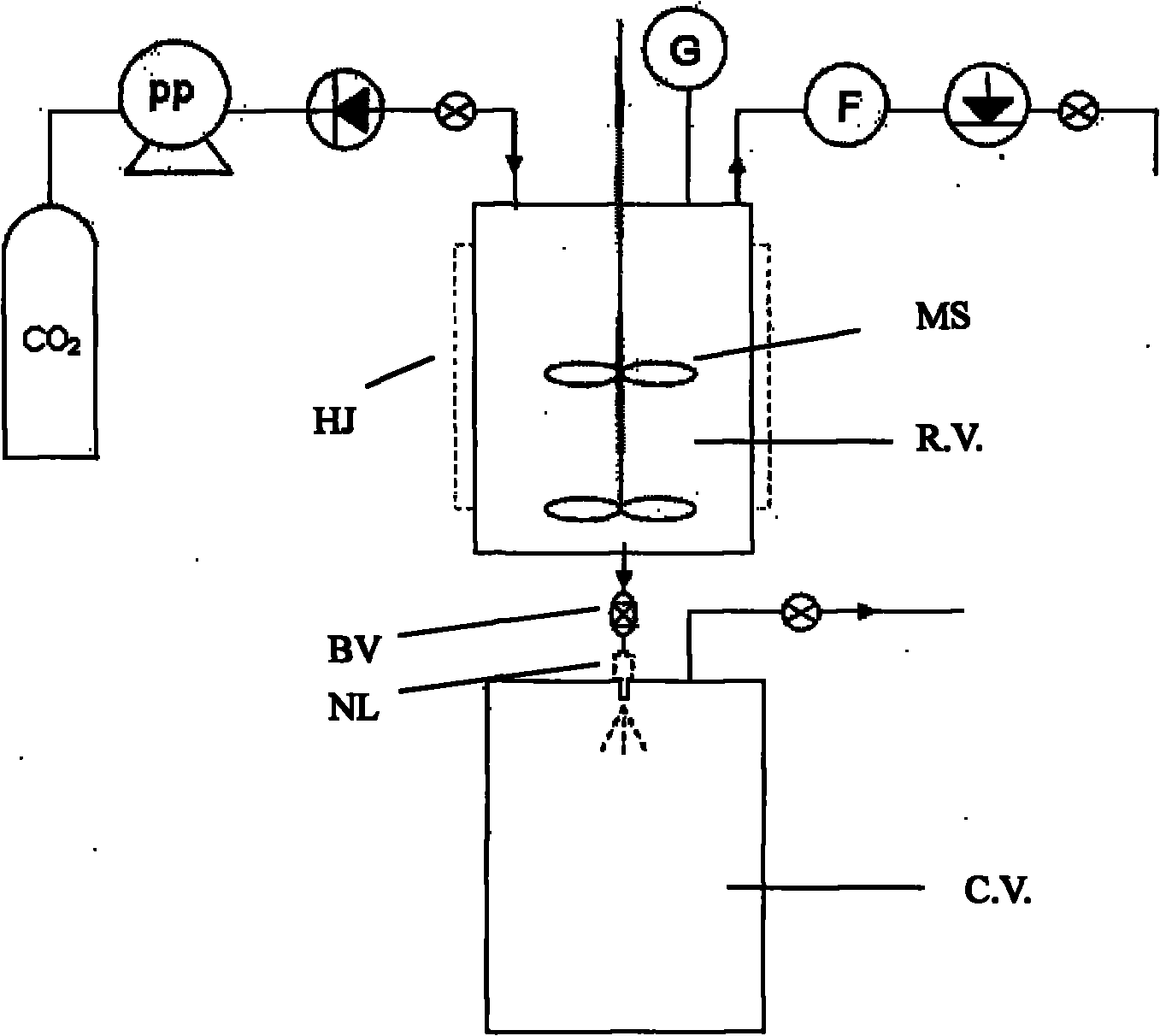

Nano calcium carbonate strengthened microcrystal polypropylene composite material synthesized by supercritical fluid rapid diffusion method

InactiveCN101824185ALower melting temperatureEvenly distributedBulk chemical productionPolypropylene compositesDiffusion methods

The invention realizes the even distribution of nano calcium carbonate in PP (Polypropylene) by carrying out filling modification on the PP through applying a supercritical CO2 rapid diffusion technology, thereby greatly improving the stability and the mechanical performance of the modified material. The supercritical CO2 plays a role of plasticization on the PP by unique gas-liquid two-phase performance in the production process, the melting temperature of the PP is reduced, and meanwhile, CaCO3 is uniformly distributed in the PP by the high diffusion and permeability of supercritical CO2. The invention researches a high-performance nano CaCO3 filled microcrystal PP powder. The effect of a microcrystal attributes to the sharp diffusion process from a supercritical state to normal temperature and normal pressure of the whole system; a crystal nucleus of the PP is too late to grow due to the sharp performance of conversion; the optical performance and the transparency are greatly improved by great reduction of the sphaerocrystal size, and the microcrystal structure is beneficial to reducing the contraction of a final injection molding product; and the invention improves the size stability of products and is an ideal high-grade automobile special material.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

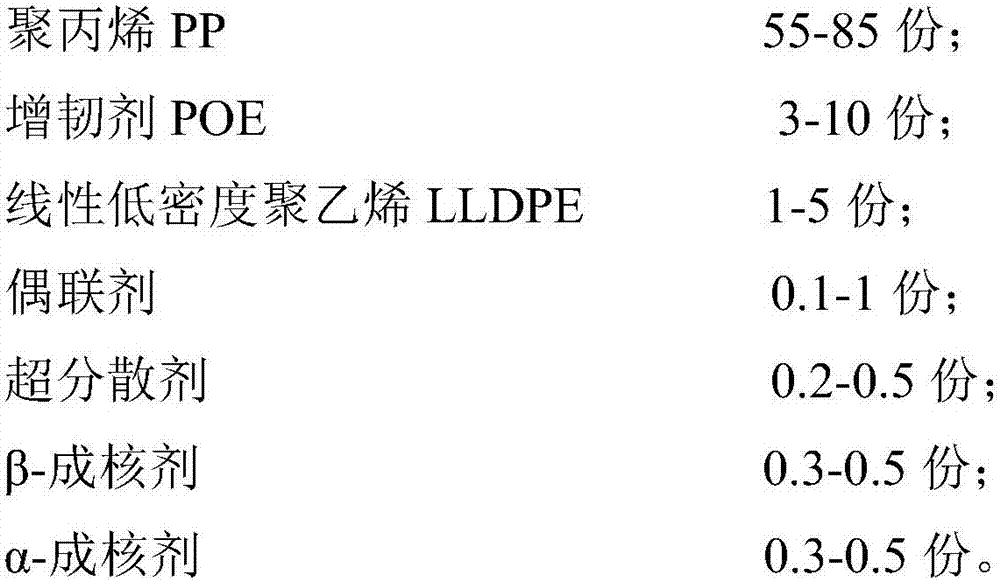

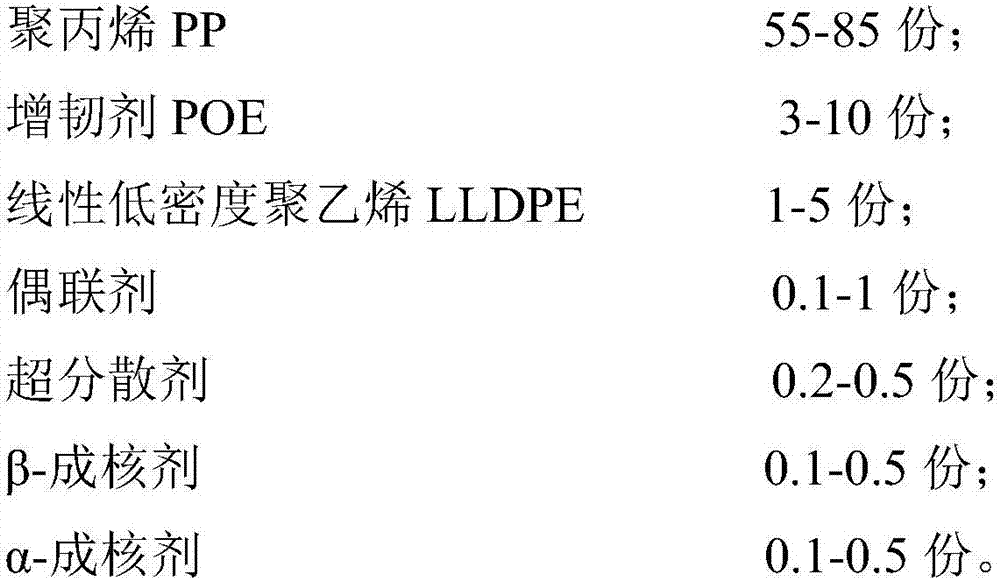

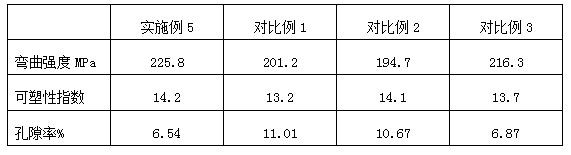

Modified polypropylene for handles of ceilings of automobiles

InactiveCN107254101ARaise the crystallization temperatureHigh crystallinityElastomerLinear low-density polyethylene

The invention discloses modified polypropylene for handles of ceilings of automobiles. The modified polypropylene which is a composite material comprises, by weight, 55-85 parts of polypropylene (PP), 3-10 parts of toughening agents POE (polyolefin elastomers), 1-5 parts of linear low-density polyethylene (LLDPE), 0.1-1 part of coupling agents, 0.2-0.5 part of hyper-dispersants, 0.1-0.5 part of beta-nucleating agents and 0.1-0.5 part of alpha-nucleating agents. The modified polypropylene has the advantages of high rigidity and toughness and wide application range.

Owner:SUZHOU SUNWAY POLYMER

High-strength siliceous brown glaze electric porcelain and preparation method thereof

ActiveCN112898003ALow softening temperatureImprove liquidityCeramic materials productionClaywaresSesquioxideManganese

The invention discloses high-strength siliceous brown glaze electric porcelain and a preparation method thereof, and relates to the technical field of siliceous electric porcelain. The invention discloses a high-strength siliceous brown glaze electric porcelain, the raw materials comprise a blank material and a brown glaze material; the blank material comprises the following raw materials: kaolin, wollastonite, Jiepai mud, siliceous porcelain waste powder, low-melting-point glass powder, spodumene, yttrium oxide, ceramic-grade talcum powder and a nucleating agent; the brown glaze material is composed of the following raw materials: potassium feldspar powder, quartz powder, blank mud, calcite powder, cooked talcum powder, iron oxide, chrome green, manganese sesquioxide and Jiepai mud. The invention also discloses the preparation method of the brown glaze electric porcelain. The siliceous brown glaze electric porcelain has the advantages of simple and easily available raw materials, low cost, high bending strength, good plasticity and good stability; and the brown glaze is low in cost, short in glaze dipping time, good in glazing effect, ruddy and full in glaze surface, bright in luster, stable in color generation and free of color difference, and the strength of the brown glaze electric porcelain is improved by 10% or above compared with the strength of the brown glaze electric porcelain before glazing.

Owner:湖南省醴陵市华电电瓷制造有限公司

Preparing method of polyadipic acid butanediol ester-terminal hydroxyl multiwalled carbon nanotube composite film

ActiveCN105601963AVariety of performance interventionsGeneration promotion/inhibitionComposite filmBottle

A preparing method of a polyadipic acid butanediol ester-terminal hydroxyl multiwalled carbon nanotube composite film comprises the steps: (1) weighing 0.5g of PBA, placing in a volumetric flask, dividing into two parts, and adding good solvent chloroform of PBA respectively to fully dissolve the PBA; (2) weighing MWCNTs-OH subjected to vacuum drying treatment, placing in two bottles and determining the volume with chloroform to obtain MWCNTs-OH trichloromethane turbid liquid; (3) blending the PBA solution with the MWCNTs-OH solution to prepare the PBA / MWCNTs-OH blended film casting liquid; (4) preparing the PBA / MWCNTs-OH blended film casting liquid into a composite film at normal temperature, standing and melting the PBA / MWCNTs-OH composite film to remove a thermal history, annealing and crystallizing for culture to obtain the PBA / MWCNTs-OH composite film material. The process method is simple, can be applied to industrial production and has broad application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Insulating medium capable of improving vacuum surface flashover voltage and preparation method of insulating medium

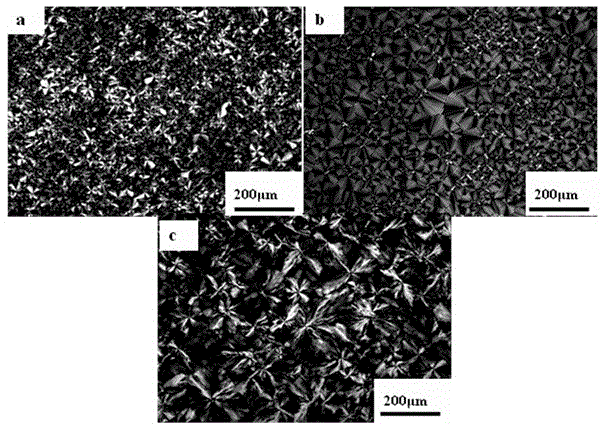

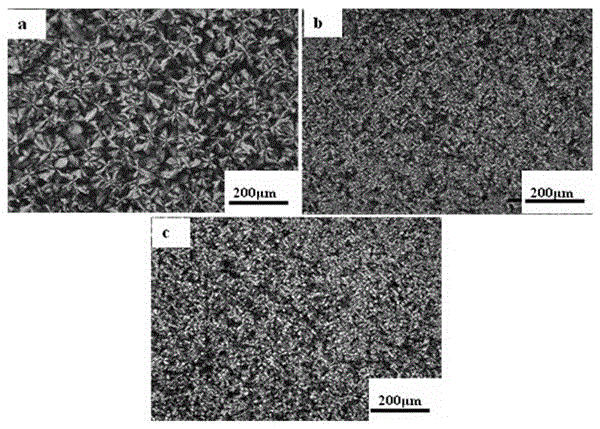

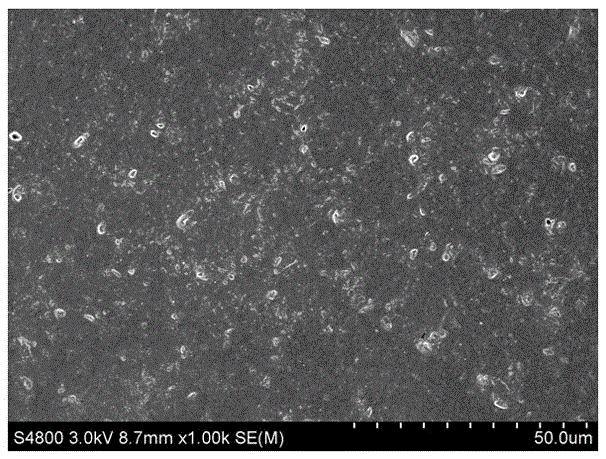

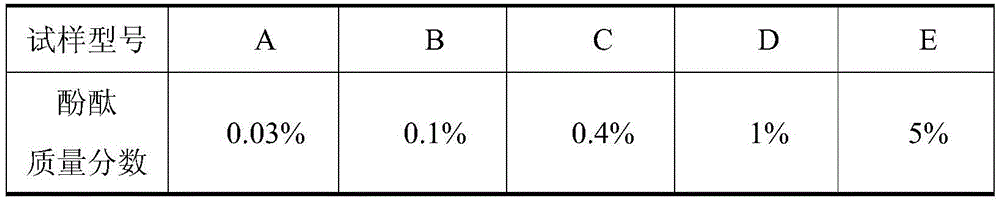

InactiveCN105489322AImproving vacuum surface flashover performanceHigh crystallinityOrganic insulatorsMolten statePhenolphthalein

The invention provides an insulating medium capable of improving a vacuum surface flashover voltage and a preparation method of the insulating medium. The insulating medium comprises phenolphthalein and a semi-crystalline polymer material, wherein the amount of the phenolphthalein is assumed to be a; the amount of the semi-crystalline polymer material is assumed to be b; on the basis of mass fraction, a is smaller than or equal to 5% and greater than 0; b is smaller than 100% and greater than or equal to 95%; and the preparation method of the insulating medium comprises the following steps: (1) drying the phenolphthalein and the semi-crystalline polymer material at 50-80 DEG C; (2) heating the dried semi-crystalline polymer material in a molten state; (3) adding the phenolphthalein to the molten semi-crystalline polymer material, and carrying out melt blending on the phenolphthalein and the molten semi-crystalline polymer material for 30-50 minutes to obtain a composite material; (4) extruding the composite material, and naturally cooling the composite material to a room temperature; and (5) carrying out hot press molding on the cooled composite material to obtain an insulating medium sample. The vacuum surface flashover voltage of the insulating medium can be significantly improved; and the preparation method is low in process difficulty, high in operability and high in reliability, and can be widely applied to the field of high-voltage insulating materials.

Owner:XI AN JIAOTONG UNIV +1

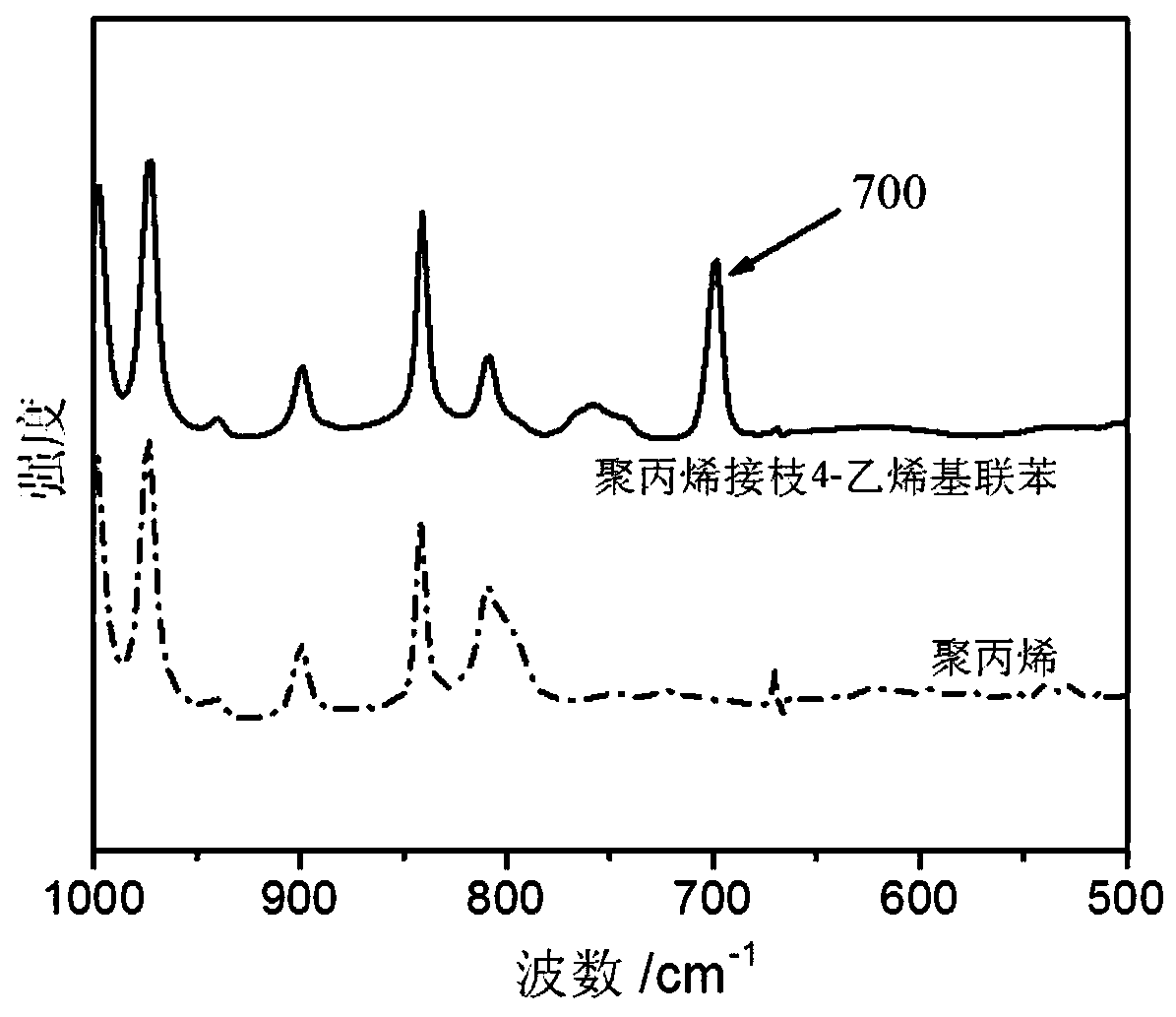

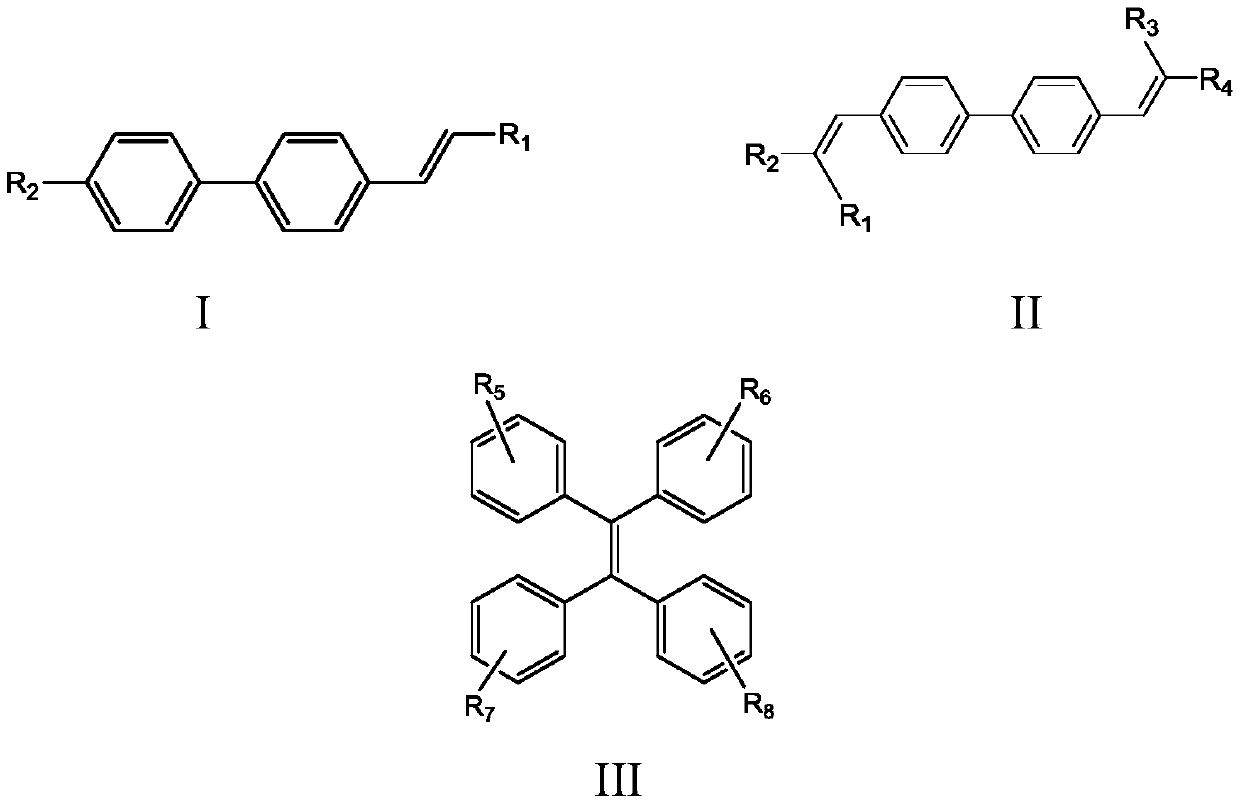

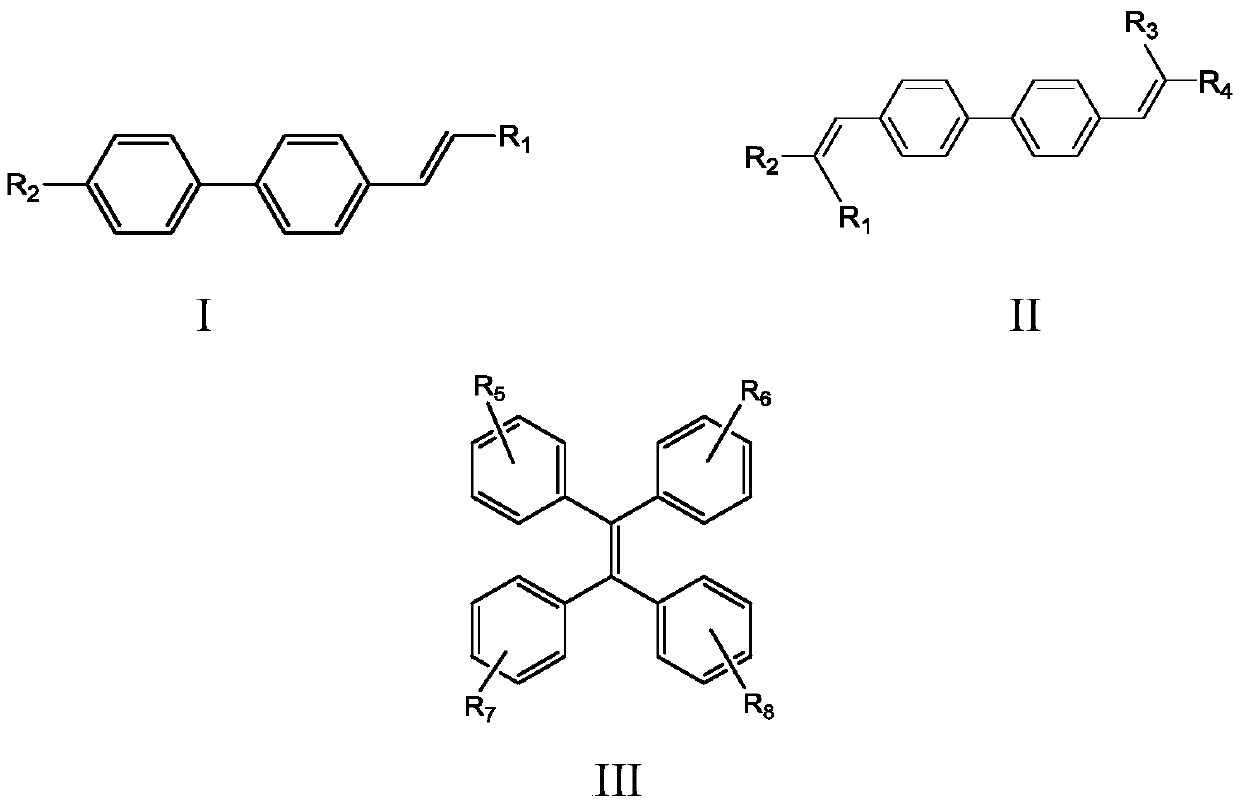

Polypropylene macromolecular stiffening nucleating agent as well as preparation method and application thereof

The invention relates to the field of high polymer materials, and discloses a polypropylene macromolecular stiffening nucleating agent which comprises phosphate and a polypropylene grafted vinyl biphenyl derivative. A preparation method of the polypropylene macromolecular stiffening nucleating agent comprises the following steps: mixing 100 parts by mass of polypropylene, 0.5-30 parts by mass of the biphenyl derivative, 0.01-0.2 part by mass of the phosphate and 0.05-0.5 part by mass of an initiator; subjecting the mixture to melt mixing in blending equipment at the temperature of 160-220 DEGC to prepare the stiffening nucleating agent. The stiffening nucleating agent has more outstanding advantages in compatibility and dispersity when compared with polypropylene; the blended phosphate and the side branch chain of the vinylbiphenyl derivative in the structure are used as nucleation sites of polypropylene crystallization; the crystallization nucleation density is increased, the crystallization rate is increased, the spherocrystal size is reduced, and the crystallization temperature of polypropylene is increased. Compared with single-benzene-ring acrylate macromolecular nucleating agents, the stiffening nucleating agent has the advantage that the mechanical property of polypropylene can be more remarkably improved.

Owner:杭州聚丰新材料有限公司

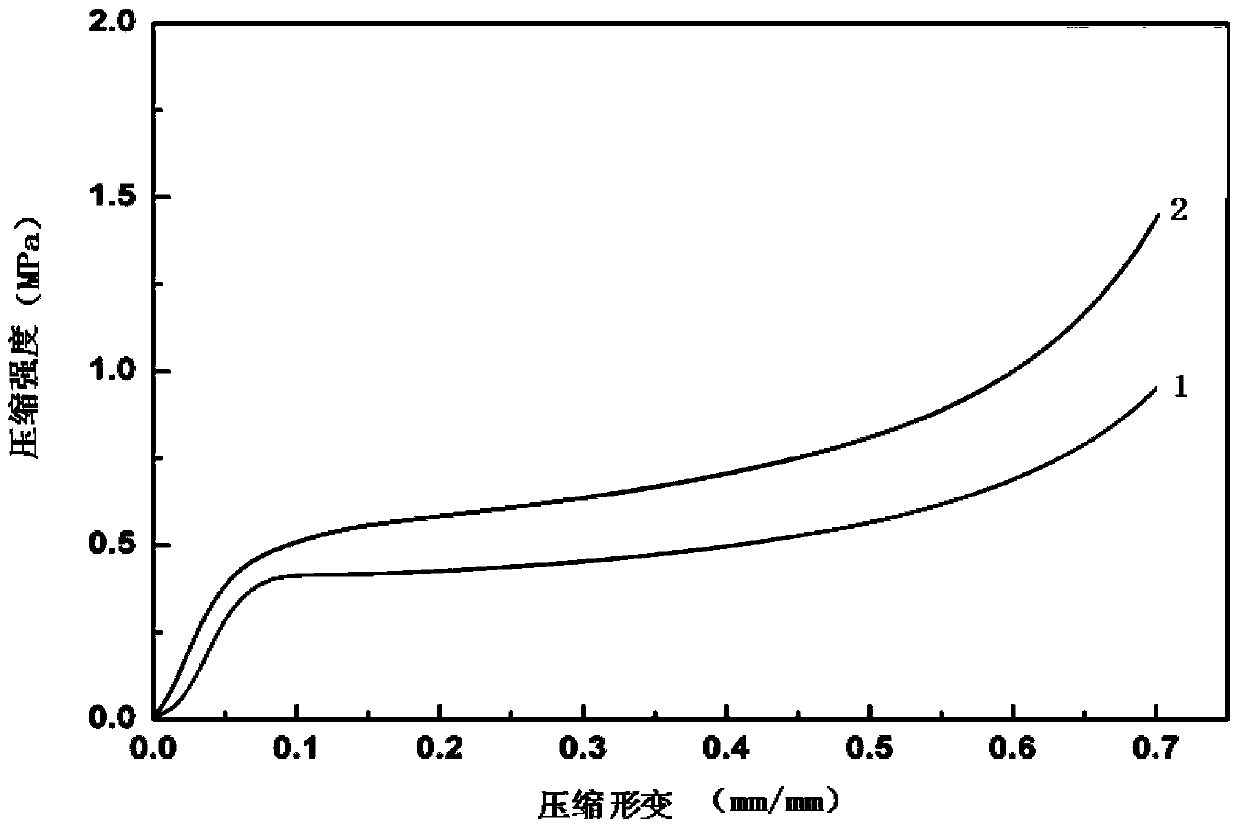

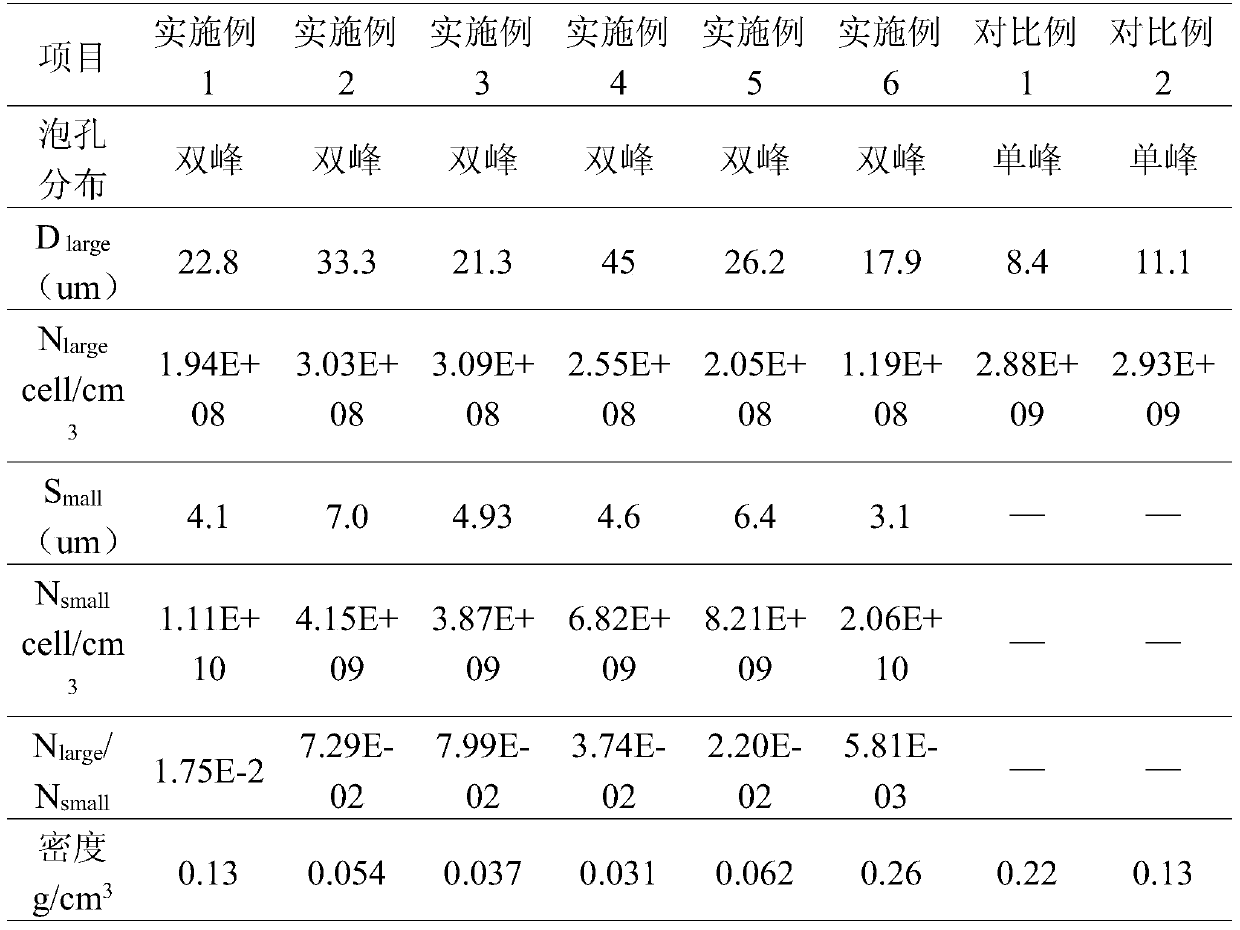

Polypropylene foam material with bimodal distribution and preparation method thereof

ActiveCN105385024BRelative density is smallImprove mechanical propertiesPolymer scienceInorganic particle

The invention discloses a bimodal distribution type polypropylene foaming material and a preparing method thereof and belongs to the technical field of polymer porous materials. The technical problems of the prior art that a method for preparing a bimodal distribution type foaming material is complicated, limitation degree is high, and controllability is low are solved. The bimodal distribution type foaming material is mainly composed of porous inorganic particles and polypropylene resin, wherein the mass percent of the porous inorganic particles is 0.05-10%, particle size is 50 nanometers to 50 microns, specific surface area is 150<2> / g or above, and pore diameter is 0.3-20 nanometers. The relative density of the bimodal distribution type foaming material is 0.03-0.9 g / cm<3>, large pores with the average diameter of 15-50 microns and small pores with the average diameter of 1-10 microns are provided, and the ratio of the pore density of the large pores to the pore density of the small pores is 0.001-5:1. The bimodal distribution type foaming material has the advantages of being small in relative density and high in mechanical performance and has broad application prospects.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

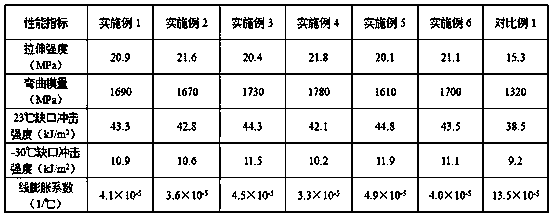

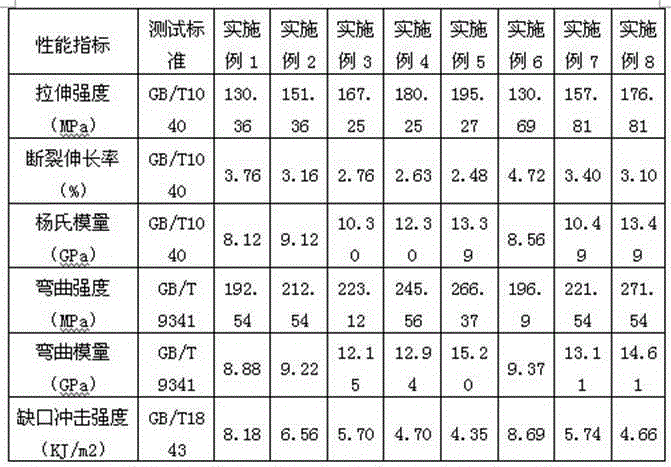

Special low-linear expansion coefficient polypropylene material for bumpers, and preparation method thereof

The invention relates to the technical field of modified polypropylene materials for automobiles, and provides a special low-linear expansion coefficient polypropylene material for bumpers, and a preparation method thereof. Polypropylene is toughened and modified with thermoplastic polyurethane, a compatibilizer prepared from maleic anhydride grafted polypropylene and dodecanediamine is used to improve the interfacial bonding between the polypropylene and the thermoplastic polyurethane, glass fibers are adopted to modify the polypropylene to increase the strength and reduce the linear expansion coefficient, and a titanate coupling agent is used to improve the dispersibility of the glass fibers in the polypropylene. Compared with special polypropylene materials prepared by conventional methods, the special polypropylene material prepared in the invention has the advantages of high tensile strength, high flexural modulus, high notch impact strength, significantly reduced linear expansioncoefficient, and realization of good dimensional stability of the bumpers.

Owner:成都市水泷头化工科技有限公司

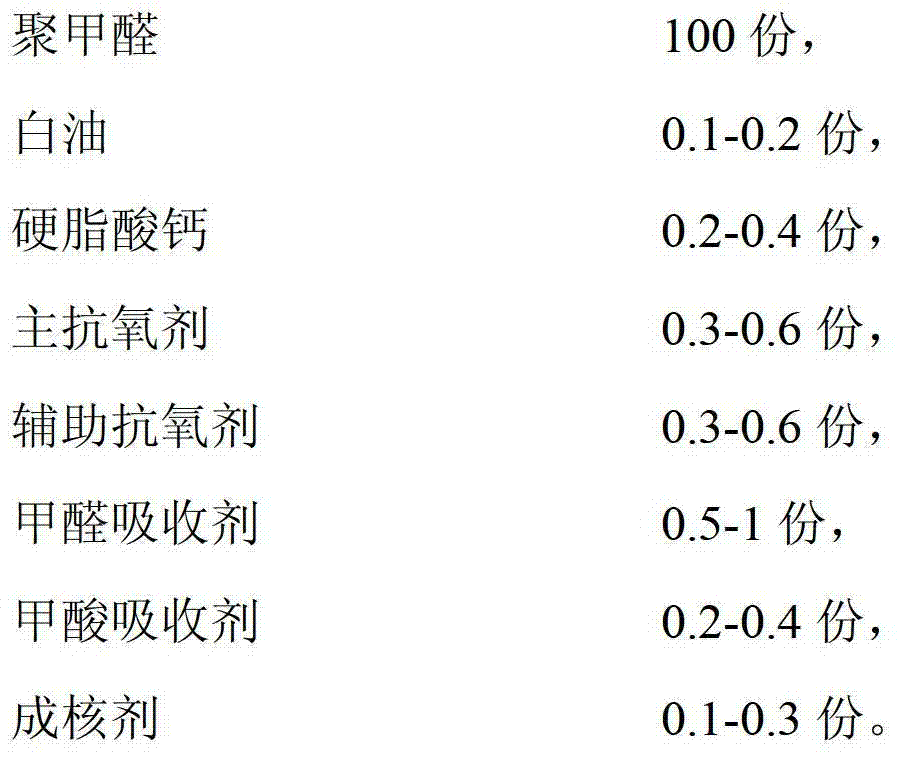

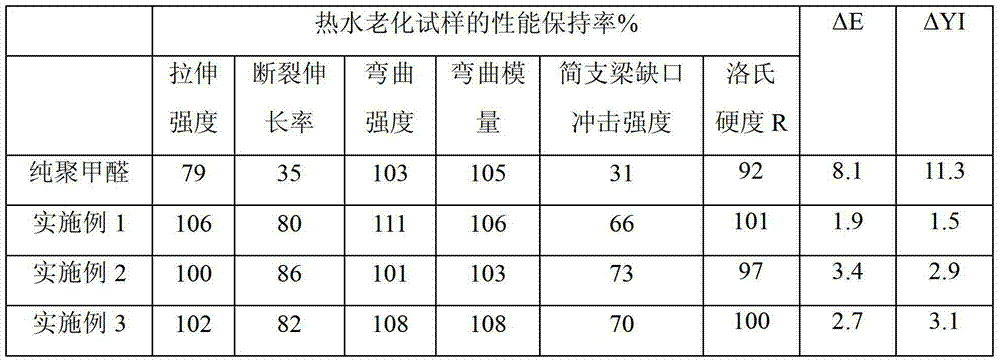

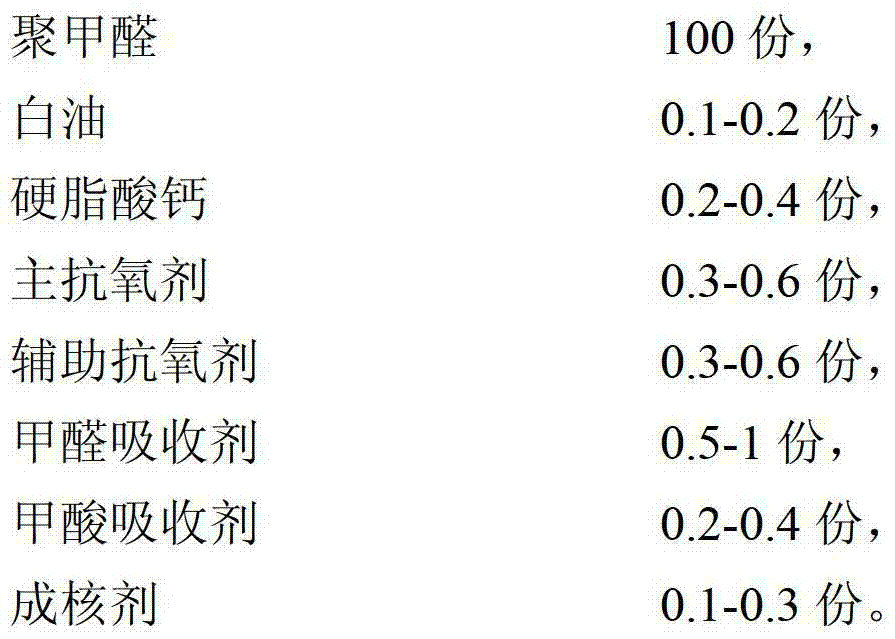

Hot-water resistance polyformaldehyde composition and preparation method thereof

The invention belongs to the technical field of material, and relates to a hot-water resistance polyformaldehyde composition and a preparation method thereof. The hot-water resistance polyformaldehyde composition comprises the following ingredients by weight part: 100 parts of polyformaldehyde, 0.1-0.2 parts of white oil, 0.2-0.4 parts of calcium stearate, 0.3-0.6 parts of main anti-oxidant, 0.3-0.6 parts of auxiliary anti-oxidant, 0.5-1 part of formaldehyde absorbent, 0.2-0.4 parts of formic acid absorbent and 0.1-0.3 parts of nucleating agent. Compared with the prior art, through the boiling by water and aging experiment of the prepared composition, the mechanical property conservation rate is high, aberration and yellowing index change are little, and the hot-water resistance is obviously increased.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

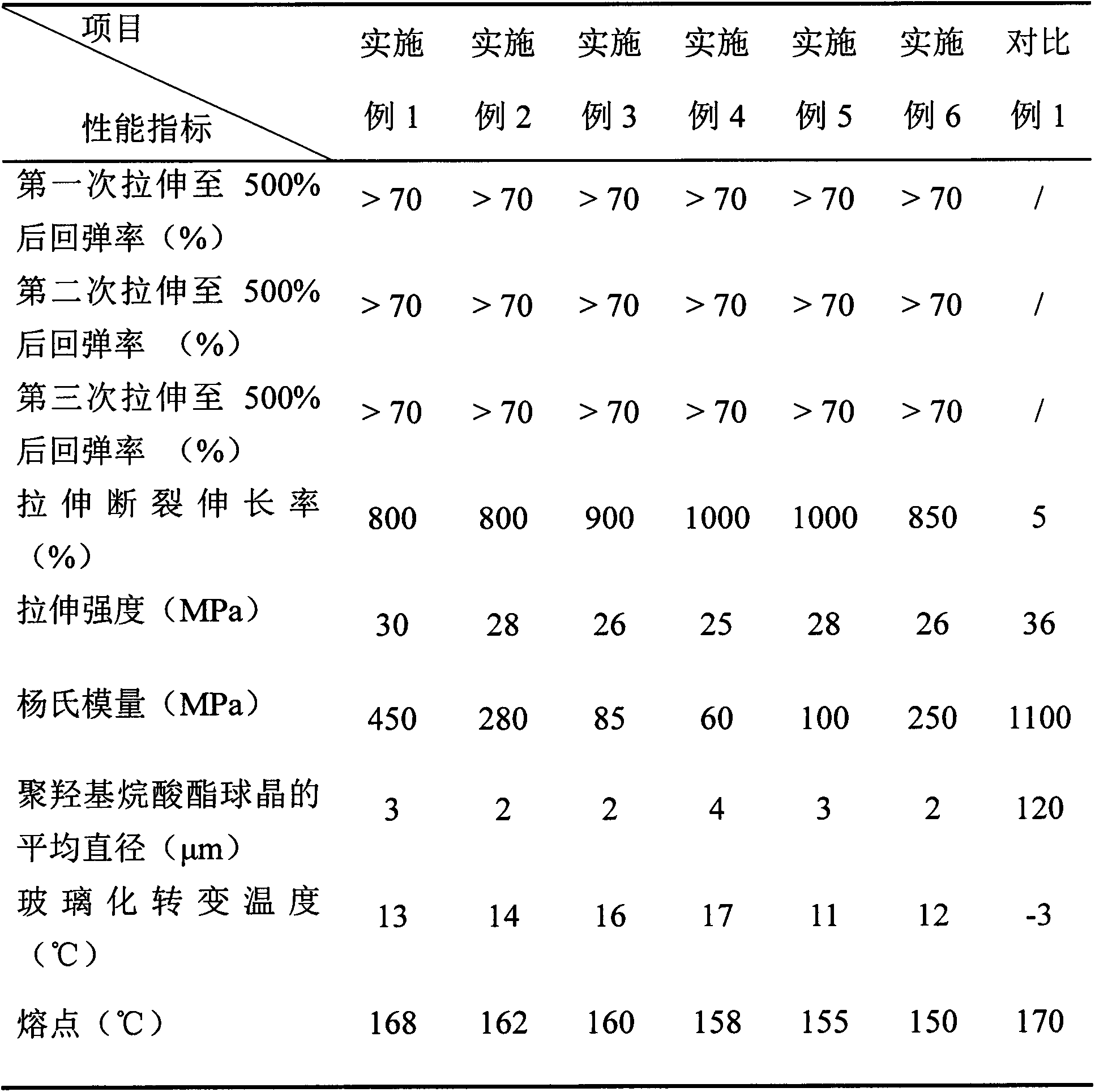

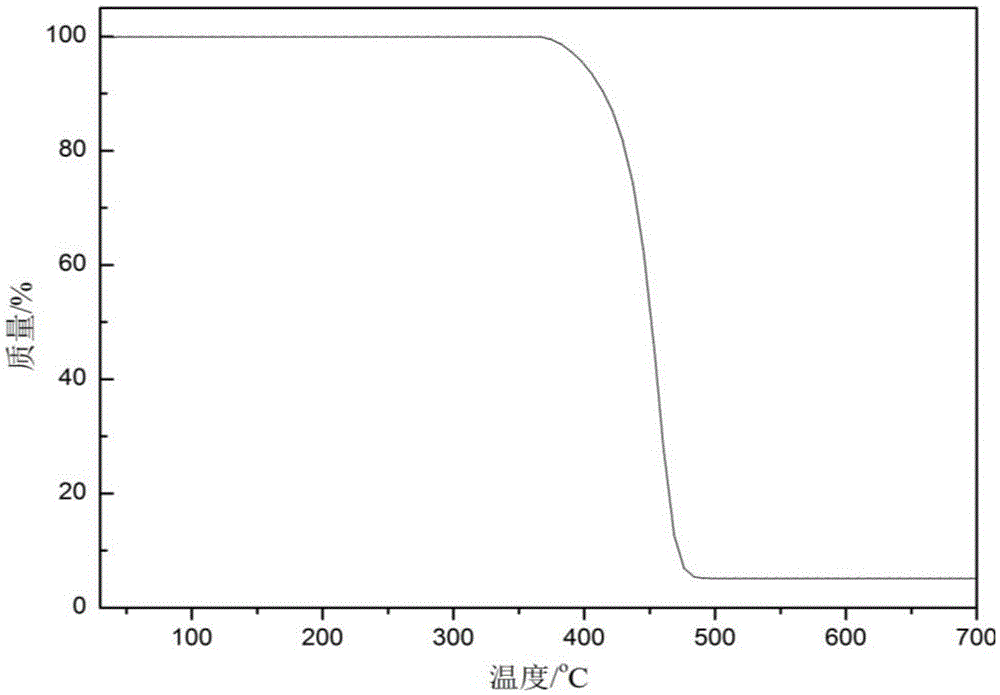

A bio-based thermoplastic elastomer material and a preparation method thereof

InactiveCN103642183AHigh biomass contentReduced spherulite sizeThermoplastic elastomerEthylene Homopolymers

The invention discloses a bio-based thermoplastic elastomer material and a preparation method thereof. The bio-based thermoplastic elastomer material comprises following raw materials by weight: 10-60 parts of a 3-hydroxybutyrate homopolymer, 10-60 parts of a hydroxyalkanoate copolymer, 10-120 parts of an ethylene-vinyl acetate random copolymer and 0.01-3 parts of a functional auxiliary agent. The bio-based thermoplastic elastomer material prepared by the preparation method has characteristics of small spherocrystal dimension, high springback rate, good resilience after being repeatedly stretched, high strength, large elongation percentage, excellent thermoplastic properties, and the like. The preparation method is simple and prone to industrialization.

Owner:JIANGNAN UNIV

Nano-Al2O3 modified biopolymer material and preparation method thereof

ActiveCN106700455AIncrease the rate of crystallizationHigh strengthBiopolymerBiocompatibility Testing

The invention discloses a nano-Al2O3 modified biopolymer material and a preparation method thereof. The nano-Al2O3 modified biopolymer material is formed through mixing and extruding 3-20 parts of a modifying nano-Al2O3 material, 97-80 parts of P(3HB-co-4HB), 0.1-0.3 parts of a heat stabilizer and 0.1-0.3 parts of a lubricant. A biopolymer material poly(3-hydroxy butyrate-3-co-4-hydroxy butyrate) [P(3HB-co-4HB)] material is modified with nano-Al2O3 through a melt blending technology to improve the disadvantages of low crystallization rate, severe post-crystallization, low strength and poor toughness of the [P(3HB-co-4HB)] material, and the [P(3HB-co-4HB)] material has good biodegradability and biocompatibility, so the nano-Al2O3 modified biopolymer material has wide application prospect in the fields of biological and degradable materials.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation method of polypropylene composite material used for shell cover of storage battery

ActiveCN105542308AImprove liquidityImprove low temperature impact strengthAntimony oxideMechanical properties of carbon nanotubes

The invention discloses a preparation method of a polypropylene composite material used for a shell cover of a storage battery. The preparation method is characterized by comprising the following steps: taking the following raw materials in parts by weight: 10 to 20 parts of dried raw material PP (Polypropylene) powder, 70 to 85 parts of high-transparency homopolymerized PP, 5 to 15 parts of ethylene propylene diene monomer, 0.1 to 0.3 part of a nucleating agent of the raw materials, 0.5 to 1 part of a silicon flame retardant and 1 to 2 parts of an antimony oxide flame retardant; mixing all the raw materials to obtain a mixture; pouring the mixture into a mixing machine, and stirring and mixing for 5 to 10 minutes; then adding the mixture into a double-screw extruder, and fusing, extruding, cooling, dicing and drying; injecting and molding to prepare the polypropylene composite material used for the shell cover of the storage battery. The composite material prepared by the invention has good mechanical properties and high-temperature-resisting and low-temperature-resisting stability properties, is particularly suitable for the shell cover of the storage battery, and also can be used for fields including packages with high transparency requirements, medical equipment, household articles, common industries and the like.

Owner:MIANYANG HONGQI NEW MATERIAL SCI & TECH

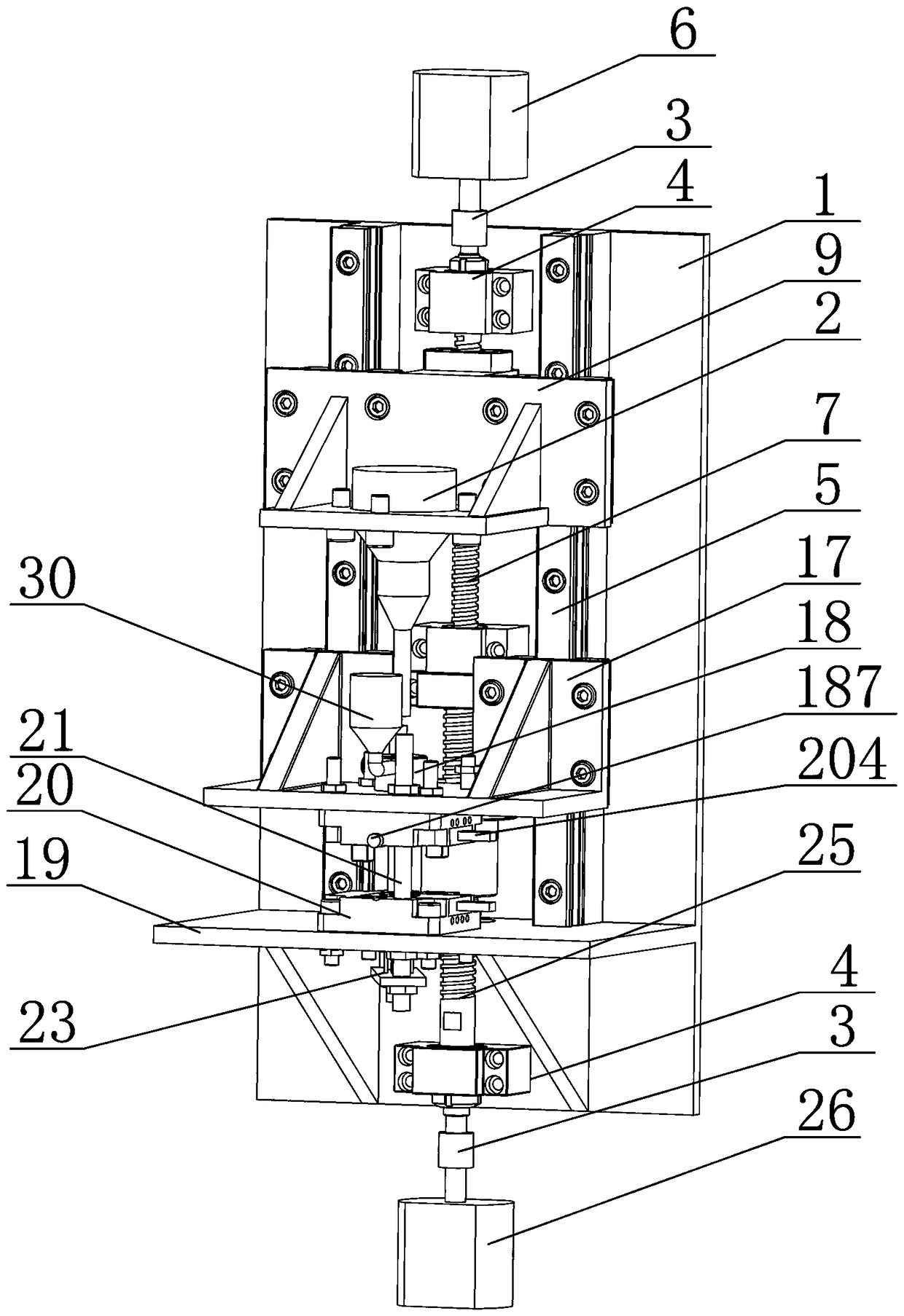

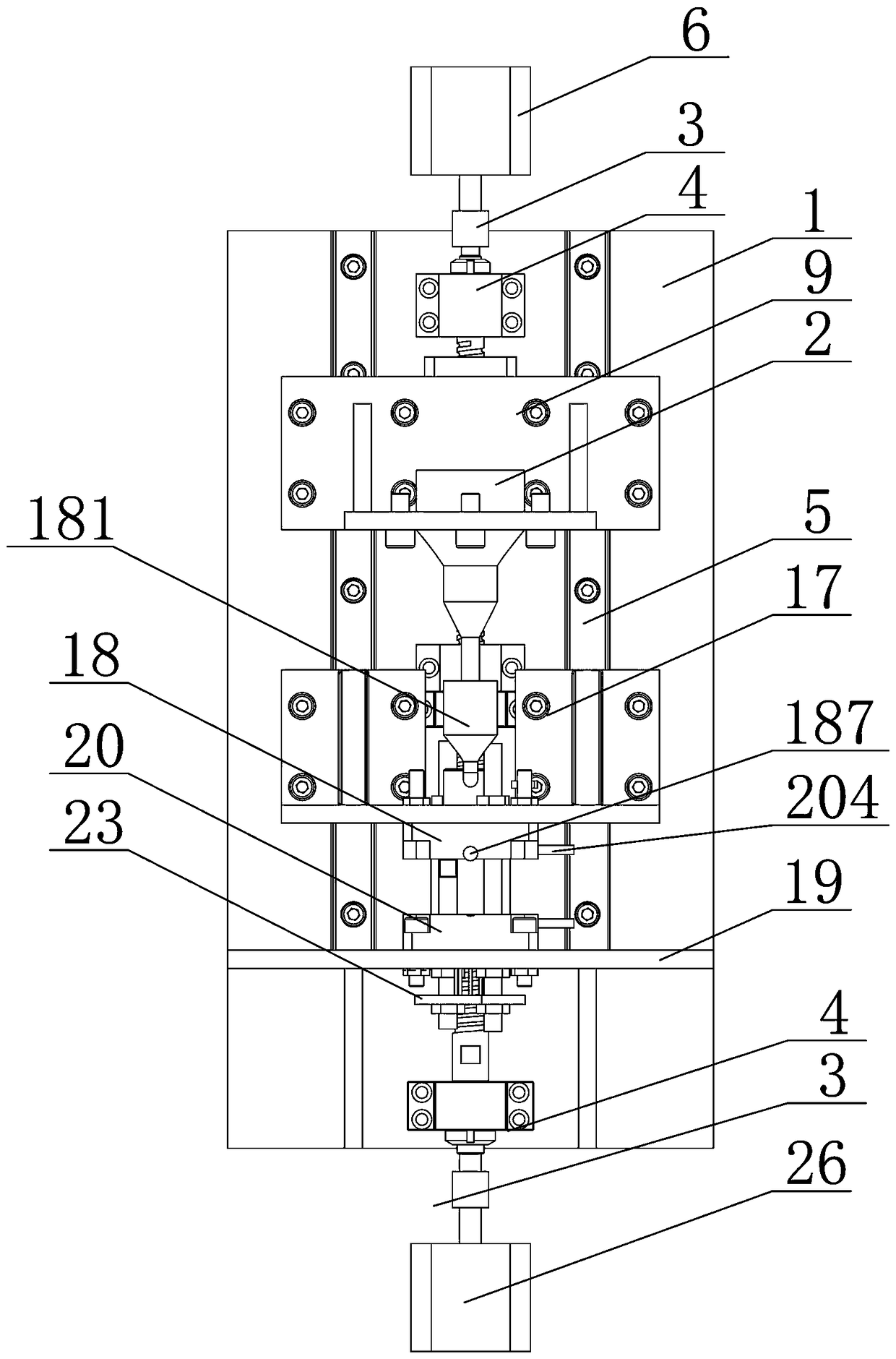

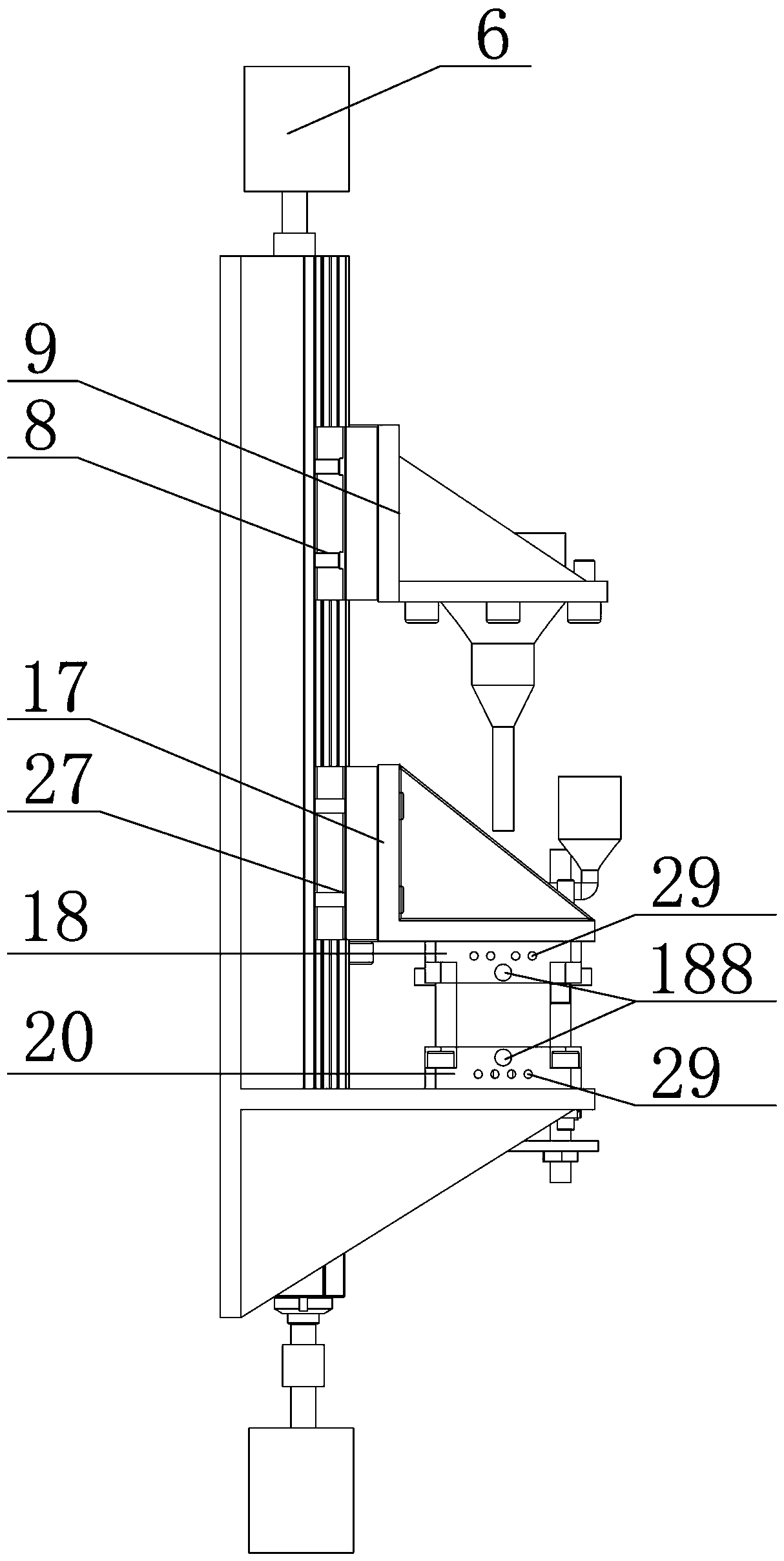

Ultrasonic plasticizing and injection molding equipment for micro-nano device

PendingCN109228195AFast melt plasticizationUniform melting and plasticizingMicro nanoUltrasonic sensor

The invention provides ultrasonic plasticizing and injection molding equipment for a micro-nano device. The ultrasonic plasticizing and injection molding equipment comprises a base and an injection structure and a molding structure which are arranged on the base, wherein the injection structure comprises an ultrasonic transducer and an injection driving unit for driving the ultrasonic transducer to achieve vertical feeding, the ultrasonic transducer is used for melting and plasticizing polymer particles in the molding structure, and assisting in injection molding of a molten polymer; the molding structure comprises a mold unit and a mold clamping unit, wherein the mold clamping unit is used for mold closing, mold clamping and mold opening of the mold unit; and the mold unit comprises an upper mold with a built-in upper mold core and a lower mold with a built-in lower mold core, wherein the upper mold core is matched with the lower mold core to form a molding cavity to mold the molten polymer under maintained pressure.

Owner:ZHENGZHOU UNIV

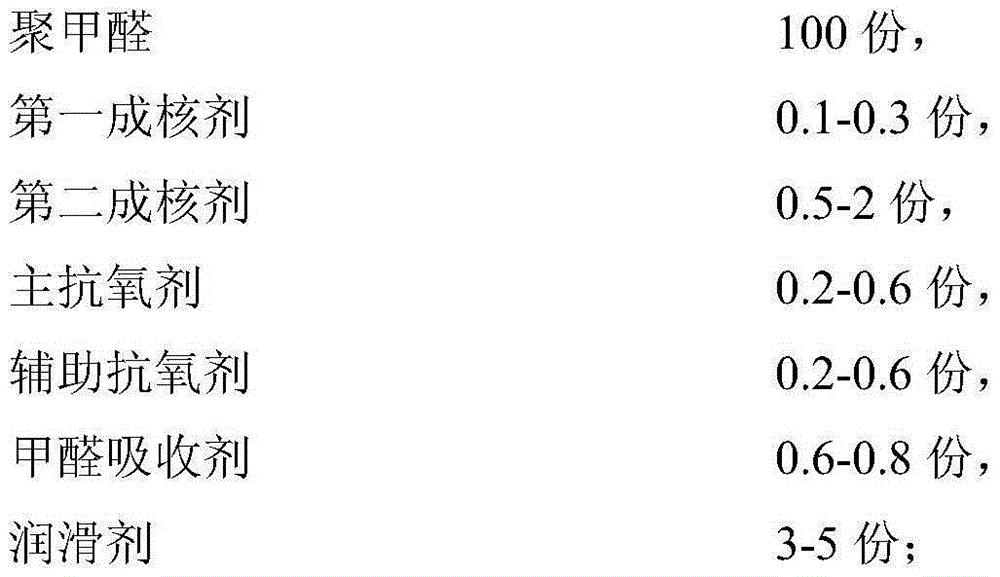

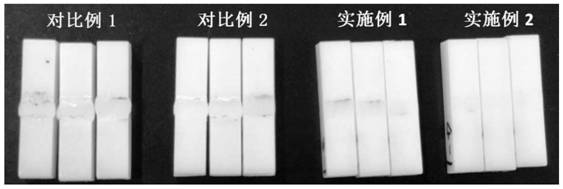

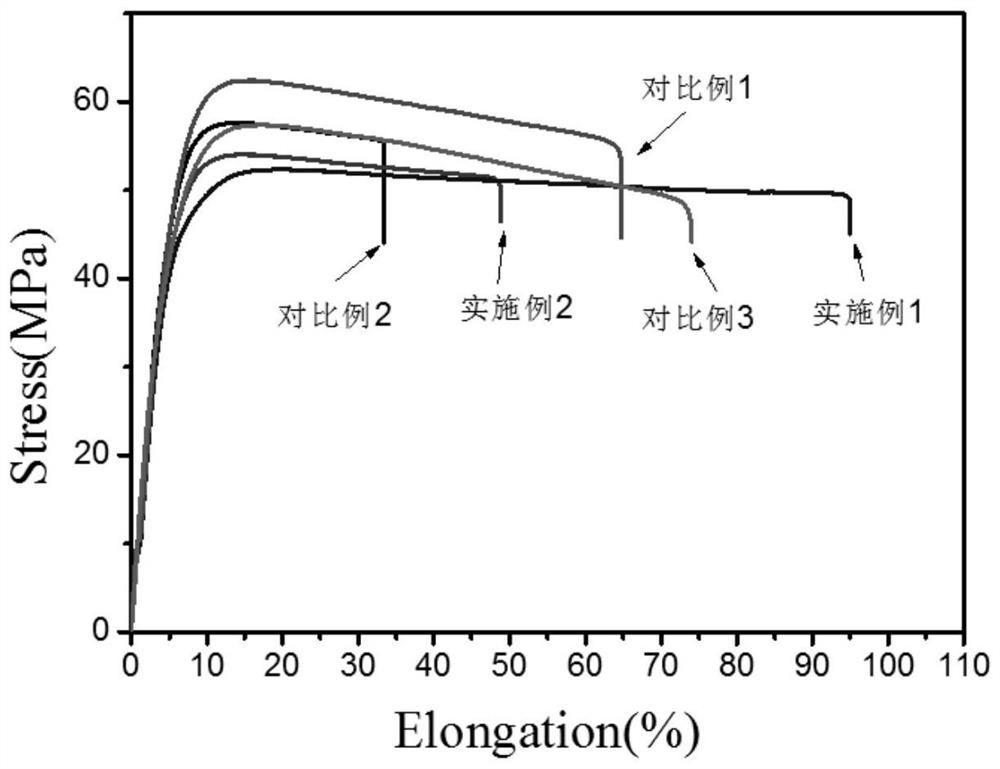

A kind of toughened polyoxymethylene composition and preparation method thereof

ActiveCN103087460BReduced spherulite sizeImprove notched impact strengthPolyoxymethylenePolymer science

The invention belongs to the technical field of polymer materials, and discloses a toughened polyformaldehyde composition and a preparation method thereof. The toughened polyformaldehyde composition is prepared from the following components, by weight, 100 parts of polyformaldehyde, 0.1-0.3 part of a first nucleating agent, 0.5-2 parts of a second nucleating agent, 0.2-0.6 part of a main antioxidant, 0.2-0.6 part of an auxiliary antioxidant, 0.5-0.8 part of a formaldehyde absorber, and 3-5 parts of a lubricant. The toughened polyformaldehyde composition preparation method comprises the following steps: adding 100 parts by weight of polyformaldehyde, 0.1-0.3 part by weight of a first nucleating agent, 0.5-2 parts by weight of a second nucleating agent, 0.2-0.6 part by weight of a main antioxidant, 0.2-0.6 part by weight of an auxiliary antioxidant, 0.5-0.8 part by weight of a formaldehyde absorber, and 3-5 parts by weight of a lubricant to a high speed mixer to uniformly mix for 5-10 min, carrying out melt blending on the uniformly-mixed mixture through a vented co-rotating twin screw extruder, and carrying out extrusion granulation, wherein a screw rotation speed is controlled to 210-280 rotation / min. The toughened polyformaldehyde composition has characteristics of improved toughness, good tension strength, good rigidity and low cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

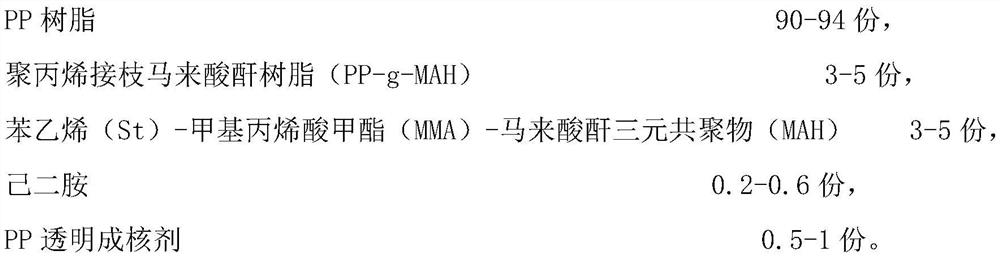

A kind of high-gloss piano black pp/pmma alloy resin composition and preparation method thereof

The invention relates to a high-gloss piano black PP / PMMA alloy resin composition and a preparation method thereof. The PP / PMMA alloy resin composition comprises the following components in parts by weight: 17-40 parts of polypropylene PP resin masterbatch, polypropylene 60-75 parts of methyl methacrylate PMMA resin, 0-8 parts of toughening agent, 0.3-2.0 parts of black toner, 0.1-1.5 parts of antioxidant, 0.2-1.5 parts of weather resistance agent. The PP / PMMA alloy resin obtained by the invention has the appearance of high-gloss piano black, and meanwhile, it also takes into account the excellent scratch resistance, weather resistance and dimensional stability of PMMA, and the excellent fatigue resistance and chemical resistance of PP. The obtained PP / PMMA has a high-gloss piano black appearance, and has excellent weather resistance, scratch resistance, chemical resistance and impact resistance. It is very suitable for the selection of paint-free piano black for automotive exteriors.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

A kind of antistatic, friction-resistant and wear-resistant polyoxymethylene material and preparation method thereof

ActiveCN109796723BImprove antistatic performanceImprove friction and wear propertiesPolyoxymethylenePolymer science

The invention discloses an antistatic, friction-resistant and wear-resistant polyoxymethylene material and a preparation method thereof. The polyoxymethylene material is a mixture of polyoxymethylene, ionic liquid and polytetrafluoroethylene. Its preparation method is to vacuum-dry polyoxymethylene, ionic liquid and polytetrafluoroethylene at 80-120°C for 24-48 hours respectively; dry the polyoxymethylene, ionic liquid and polytetrafluoroethylene according to the mass ratio of 100:0.1-2 : 1-20, put into melt extrusion equipment and carry out melt extrusion at 170-200 DEG C to obtain a mixture; discharge the mixture from the melt extrusion equipment and lower to normal temperature to obtain a polyoxymethylene material. The polyoxymethylene material in the present invention has excellent antistatic performance and friction and wear resistance, and its preparation method only needs to use common melting extrusion equipment, and the industrial preparation is simple.

Owner:安徽贺赢新材料科技有限公司

Flame-retardant and anti-impact cable

ActiveCN105741912ALow priceLight in massPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAntioxidant

The invention discloses a flame-retardant and anti-impact cable. The flame-retardant and anti-impact cable comprises a conductor, wherein the conductor is covered with a sheath; the sheath is prepared from a polypropylene composite material; and the polypropylene composite material comprises the following raw materials: polypropylene, ethylene-propylene-diene monomer rubber, epoxy resin, ethylene-propylene-diene monomer rubber grafted maleic anhydride, 1,2-polybutadiene, nanomicelle powder, magnesium hydroxide, red phosphorus, zinc borate, calcium sulfate whisker, cellulose whisker, gypsum, calcium carbonate, 2,2-methylene-di(4,6-di-n-butyl-phenol) sodium phosphate, stearic acid, dicumyl peroxide, a silane coupling agent, triethylhexyl phosphoric acid and an antioxidant. The flame-retardant and anti-impact cable is high in strength, good in impact resistance and excellent in flame retardant property.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

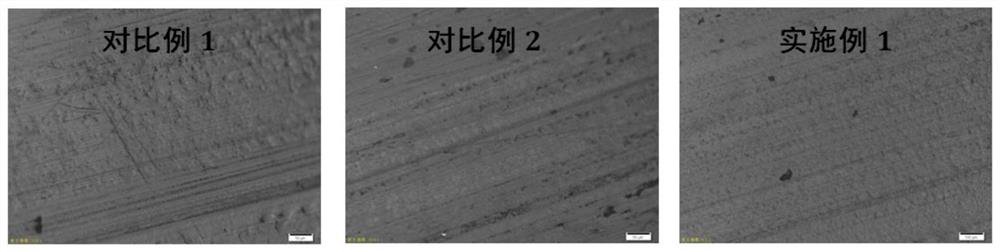

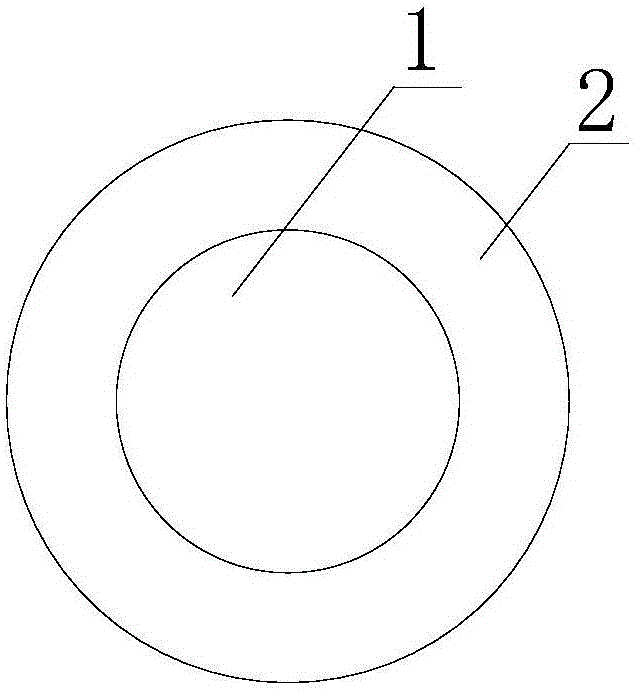

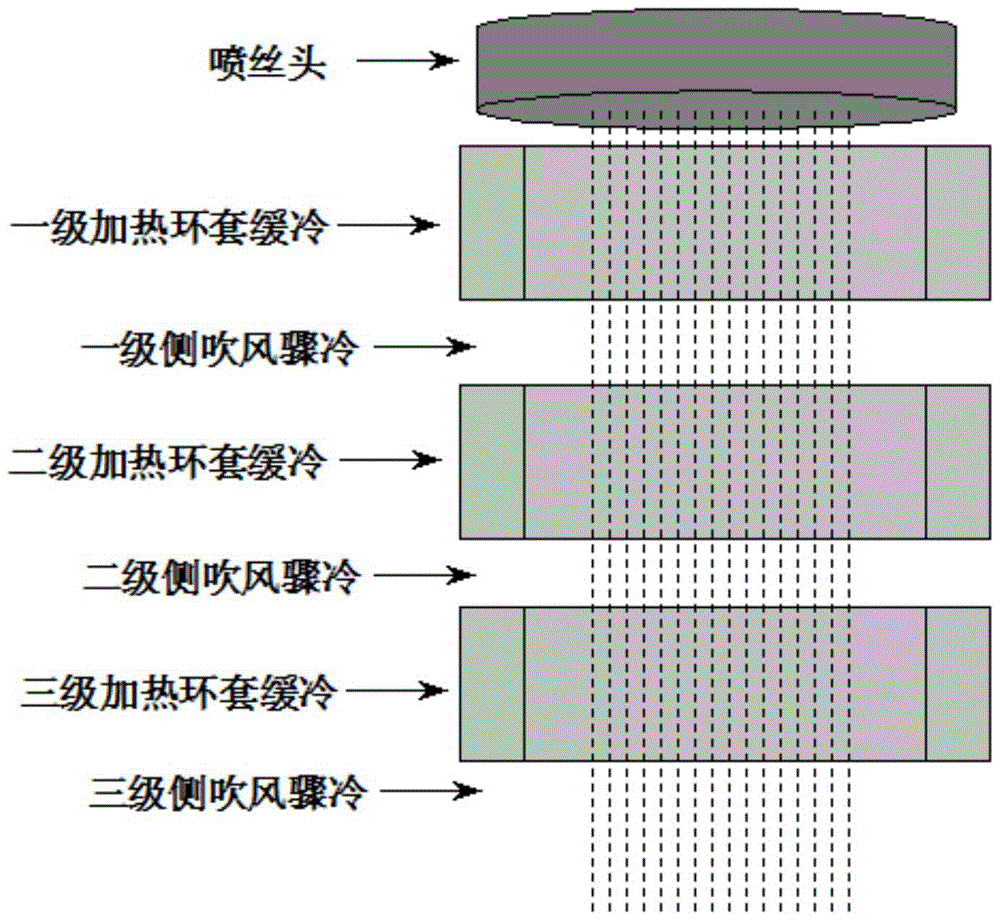

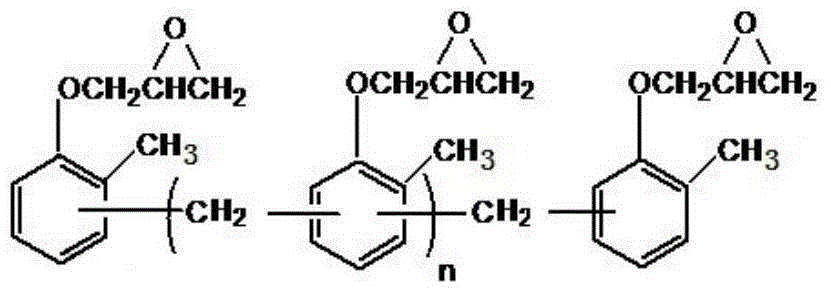

A kind of preparation method of polyoxymethylene primary fiber

ActiveCN105177756BFast crystallizationReduce surface defectsArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentPolyoxymethyleneFiber

The invention discloses a method for preparing polyformaldehyde nascent fibers. The method includes the specific steps that polyformaldehyde resin and a small amount of o-cresol formaldehyde epoxy resin are evenly mixed and then placed into a vacuum drying box to be dried; the dried mixed materials are heated and fused in a screw extruder; spinning is carried out through a spinning assembly, spun filaments pass through a stage-by-stage slow-cooling and shock-cooling device (please see a figure in the specification) and are naturally cooled, then oil applying clustering and winding are carried out, and the nascent fibers are obtained. By means of the preparing method, the crystallinity of polyformaldehyde is effectively inhibited, the crystallization speed of the polyformaldehyde is decreased, good spinnability is given to the polyformaldehyde resin, the defects of broken filaments, surface micropores and the like generated in the multi-rate stretching process of the fibers are reduced, finished fibers obtained after the nascent fibers are stored for a period of time and then subjected to hot-air slow pulling processing are excellent in performance, the implementing method is simple, and production cost is low.

Owner:TANGSHAN KAILUAN CHEM TECH CO LTD

High-content fiber-reinforced polyoxymethylene composite material and its preparation method

ActiveCN102942764BImprove mechanical propertiesImprove corrosion resistanceDispersityPolyoxymethylene

The invention discloses a high-content fiber-reinforced polyoxymethylene composite material and a preparation method thereof. The composite material comprises, by mass, 43.5-76.7wt% of acetal resin, 20.0-50.0wt% of reinforcement fibers after surface treatment, 3-5wt% of novolac, 0.2-0.5wt% of an antioxidant and 0.1-1.0wt% of a formaldehyde absorbent. The novolac is added into the composite material, the motion of polyoxymethylene molecular chains is interfered after mixing of the novolac with polyoxymethylene, the dimension of polyoxymethylene spherocrystals is obviously reduced, the degree of crystallinity is reduced, mobility and dispersity of fibers in resin are promoted, the mechanical property of the prepared high-content fiber-reinforced polyoxymethylene composite material is greatly improved; the used reinforcement fibers are subjected to surface treatment through a coupling agent and the surface modification effect is improved; and the mechanical property of the polyoxymethylene can be improved by using a novel reinforcing material of basalt fibers for reinforcing the polyoxymethylene.

Owner:KAILUAN ENERGY CHEM +1

Preparation method of fusible polytetrafluoroethylene

The invention provides a preparation method of meltable polytetrafluoroethylene. The preparation method comprises steps as follows: (1), perfluoroalkyl vinyl ether with a general formula of Rf-O-CF=CF2 and tetrafluoroethylene have a polymerization reaction so as to provide an additive copolymer, wherein Rf represents a perfluoroalkyl group with 1-5 carbon atoms, the melt index of the additive copolymer is 0.1-0.3g / 10 min; (2), in the presence of the additive copolymer prepared in the step (1), perfluoroalkyl vinyl ether and tetrafluoroethylene which are the same as those used in the step (1) have the polymerization reaction to provide a target copolymer, and the melt index of the target copolymer is 10-50 g / 10 min.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

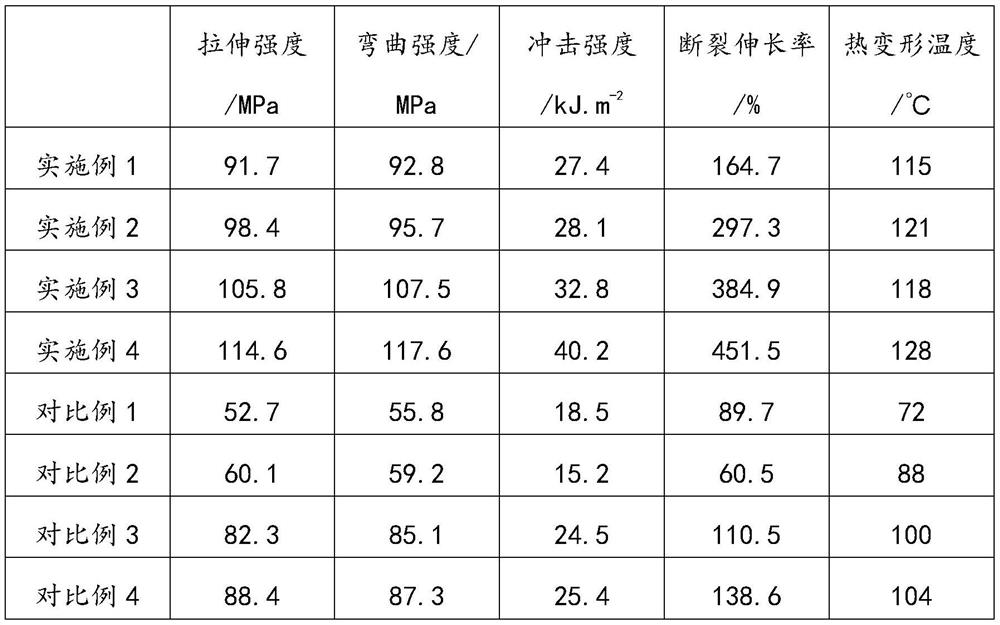

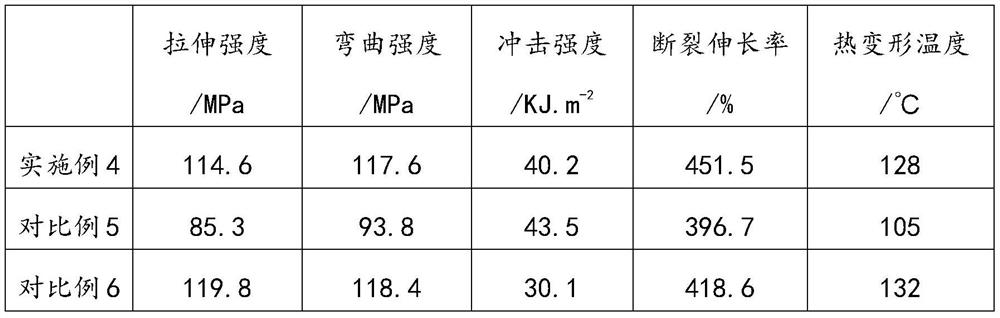

A kind of high toughness polylactic acid composite material for environment-friendly tableware and preparation method thereof

ActiveCN112080115BImprove the interface binding forceGood compatibilityBio-packagingPolyethylene glycolAluminum silicate

The invention discloses a high-toughness polylactic acid composite material for environment-friendly tableware and a preparation method thereof, and relates to the technical field of polylactic acid composite materials. The high-toughness polylactic acid composite material for environment-friendly tableware disclosed in the present invention is composed of the following raw materials by mass fraction: 40-65 parts of modified polylactic acid, 35-60 parts of adipic acid-modified vegetable fibers, and 0.5-60 parts of sodium rosin 1 part, 8-15 parts of polyethylene glycol, 0.5-0.8 parts of magnesium aluminum silicate, and 2-5 parts of lubricant, the invention also discloses a preparation method of the high-toughness polylactic acid composite material for environmental protection tableware. The high-toughness polylactic acid composite material provided by the present invention has excellent impact resistance, can withstand high temperature, its thermal deformation temperature exceeds 115°C, and has excellent mechanical properties, high toughness, not easy to be brittle, and prolongs the use of The composite material is non-toxic and completely biodegradable, and can be widely used in environmental protection tableware, food packaging and other fields.

Owner:湖南钜亿新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com