Preparation method for polyvinylidene fluoride nanometer film with beta crystal phase

A polyvinylidene fluoride and nano-film technology, applied in the field of pyroelectric film materials, can solve the problems of incapable film preparation, poor dispersion, and high equipment requirements, and achieve uniform PVDF film, stable pyroelectric performance, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

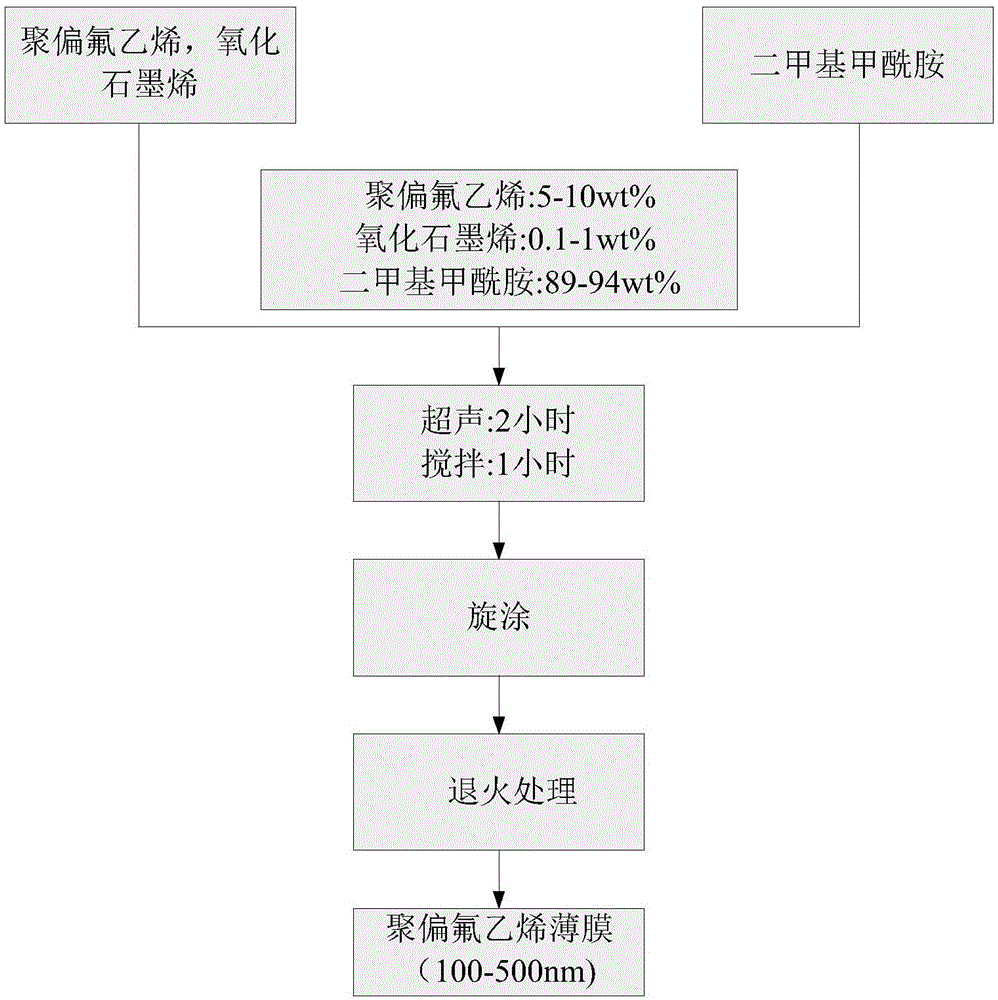

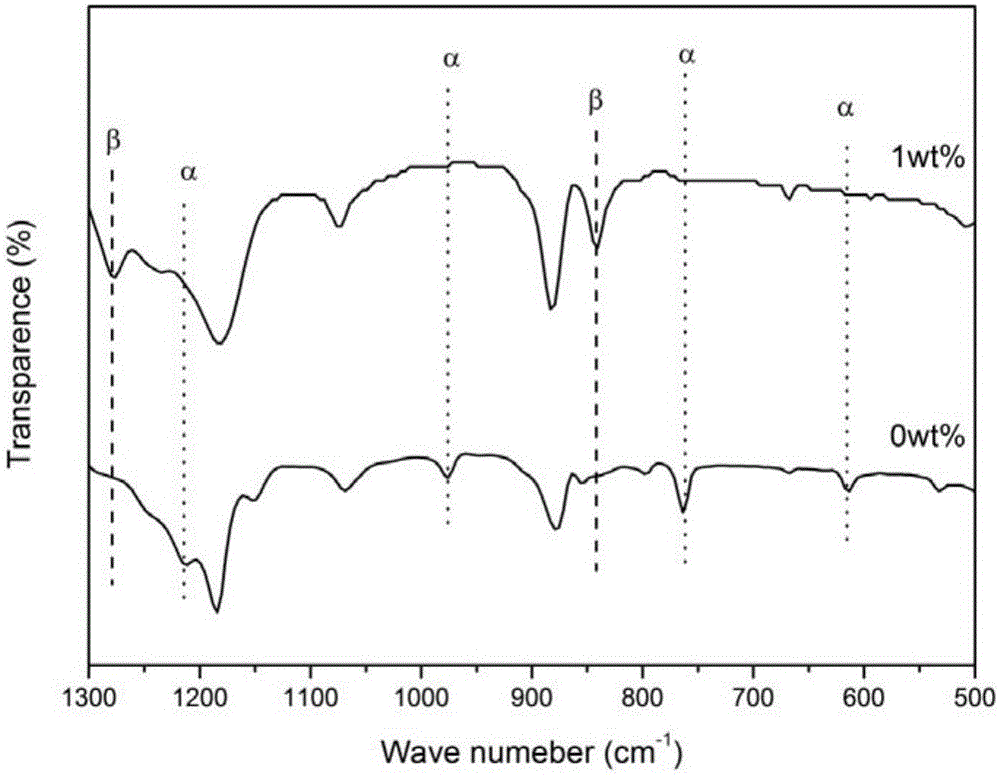

[0026] In this example, PVDF films with GO doping concentrations of 0wt% and 1wt% were prepared respectively, that is, pure PVDF films and polyvinylidene fluoride nanofilms with β crystal phase provided by the present invention, and the invention of the present invention is further illustrated by comparison Effect; the specific preparation process includes the following steps:

[0027] Step 1. Use N,N-Dimethylformamide (N,N-Dimethylformamide, DMF for short) as the organic solvent, take 10mL of DMF and put it into beaker 1, weigh 1g of PVDF and put it into beaker 1; then measure 10ml of DMF and put it into In beaker 2, weigh 1gPVDF and 100mgGO into beaker 2;

[0028] Put beaker 1 and beaker 2 into an ultrasonic cleaner, the ultrasonic frequency is 80W, the ultrasonic time is 2h, and the ultrasonic temperature does not exceed 60°C; finally, put beaker 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com