A kind of high-gloss piano black pp/pmma alloy resin composition and preparation method thereof

A technology of alloy resin and piano black, which is applied in the field of high-gloss piano black PP/PMMA alloy resin composition and its preparation, which can solve the problems of poor compatibility between PP and PMMA, lower transmittance of PP/PMMA, and inability to obtain piano black materials, etc. problem, achieve the effect of reducing spherulite size, accelerating PP crystallization and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Described PP resin master batch preparation method comprises the following steps:

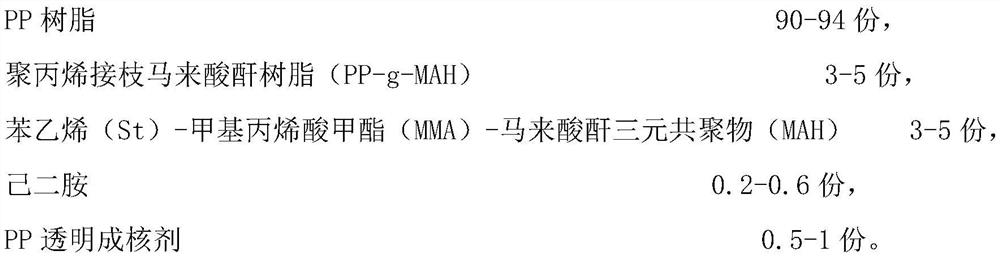

[0052](1) take by weighing 90-94 parts of PP resin, 3-5 parts of polypropylene grafted maleic anhydride resin, 3-5 parts of styrene-methyl methacrylate-maleic anhydride terpolymer by the aforementioned parts by weight parts, 0.2-0.6 parts of hexamethylene diamine and 0.5-1 part of PP transparent nucleating agent, mix well to obtain a premix;

[0053] (2) adding the premix into a twin-screw extruder, melt extrusion, cooling and pelletizing to obtain PP resin masterbatch.

[0054] In step (2), the extrusion temperature of the melt extrusion is 200-220° C., and the rotational speed of the screw is 200-500 rpm.

[0055] The refractive index of the PMMA is 1.49, and the transmittance is ≥85%;

[0056] The toughening agent is a core-shell toughening agent ACR resin with polybutyl acrylate as the core and methyl methacrylate as the shell, and the refractive index of the toughening agent is 1....

Embodiment 1

[0078] The present embodiment provides a high-gloss piano black PP / PMMA alloy resin composition, and its raw material composition is as follows:

[0079]

Embodiment 2

[0081] The present embodiment provides a high-gloss piano black PP / PMMA alloy resin composition, and its raw material composition is as follows:

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com