High-content fiber-reinforced polyoxymethylene composite material and its preparation method

A fiber-reinforced, composite material technology, applied in the field of high-content fiber-reinforced polyoxymethylene composite material and its preparation, can solve the problems of reduced impact strength, uneven distribution of carbon fibers, large spherulite size, etc., and achieves improved tensile strength and bending. Strength, promotion of flow and dispersibility, effect of spherulite size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

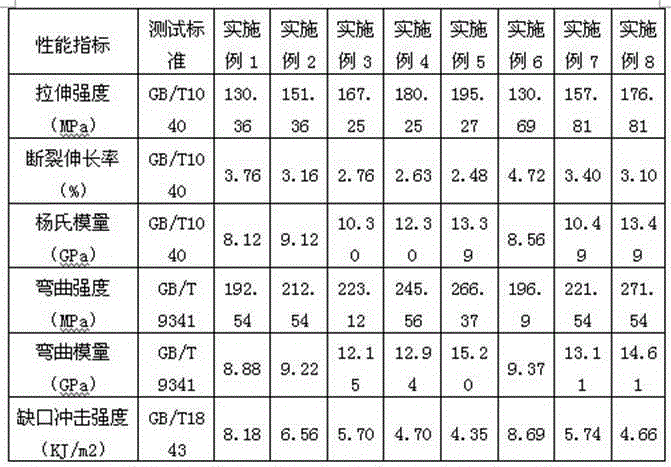

Examples

Embodiment 1

[0028] Example 1: This high-content fiber-reinforced polyoxymethylene composite material adopts the following raw material ratio and preparation method.

[0029] Raw material ratio: 58.5wt% polyoxymethylene copolymer, 35.0wt% alkali-free glass fiber treated with silane coupling agent A-173, 5.0wt% novolak resin, 168 0.25wt% antioxidant, 1010 antioxidant 0.25wt%, melamine 0.5wt%, copolyamide 0.5wt%. Among them, the novolac resin has 9 structural units and a number average molecular weight of 972.

[0030] The surface treatment method of glass fiber: firstly, the glass fiber is washed successively with concentrated sulfuric acid, 10wt% sodium hydroxide solution and acetone, then rinsed with double distilled water, and dried; then put the fiber into 5wt% vinyl tris(β-methoxy In the solution of silane coupling agent, solvent is water:methanol:acetic acid=10:50:1 (volume) mixed solvent, wherein the consumption of silane coupling agent is 0.4wt% of glass fiber, then ultrasonic Sha...

Embodiment 2

[0032] Example 2: This high-content fiber-reinforced polyoxymethylene composite material adopts the following raw material ratio and preparation method.

[0033] Raw material ratio: polyoxymethylene copolymer 53.5wt%, glass fiber treated with silane coupling agent A-173 40.0wt%, novolac resin 5.0wt%, antioxidant 168 0.25wt%, antioxidant 1010 0.25wt %, melamine 0.5wt%, copolyamide 0.5wt%. Among them, the novolac resin has 8 structural units and a number average molecular weight of 864.

[0034] The surface treatment method of glass fiber is the same as embodiment 1.

[0035] Preparation method: put polyoxymethylene, novolac resin, antioxidant, and formaldehyde absorbent in a high-speed mixer and mix evenly, then add the mixed pellets from the barrel of the twin-screw extruder; at the same time, the surface-treated The dried glass fiber is added through the side feed port in the middle section of the twin-screw extruder, and the vacuum pump at the end of the twin-screw extrude...

Embodiment 3

[0036] Example 3: This high-content fiber-reinforced polyoxymethylene composite material adopts the following raw material ratio and preparation method.

[0037] Raw material ratio: 43.5wt% polyoxymethylene, 25wt% each of glass fiber and carbon fiber treated with vinyltriethoxysilane (total 50.0wt%), 5.0wt% novolac resin, antioxidant 168 0.25 wt%, antioxidant 1010 0.25wt%, melamine 0.5wt%, dicyandiamide 0.5wt%. Among them, the novolac resin has 10 structural units and a number average molecular weight of 1080.

[0038] The surface treatment method of glass fiber and carbon fiber: first, the glass fiber and carbon fiber are washed with concentrated sulfuric acid, 10wt% sodium hydroxide solution and acetone in sequence, then rinsed with double distilled water and dried; then put the fiber into 5wt% vinyl tri( In the solution of β-methoxyethoxy) silane coupling agent, solvent is the mixed solvent of water:methanol:acetic acid=10:50:1 (volume), wherein the consumption of silane c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com