Patents

Literature

123results about How to "Improve the effect of surface modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of hydrophilic polyvinylidene fluoride microporous membrane

InactiveCN1704152AImprove hydrophilicitySimple processSemi-permeable membranesPhysical chemistryFiber type

The invention relates to a method for preparing hydrophilic PVDF microporous barrier. The principal raw material is polyvinylidene fluoride with the range of molecular weight: 5000 to 50000. It prepares hydrophilic PVDF microporous barrier by the method of separating solution and compounding dip-coating modification. It especially suits the occasion of effluent treatment, medicine separation and biochemy. The technology can prepare microporous barriers with plate type and hollow fiber type.

Owner:杨虎

Method for preparing ultrafine platy copper-zinc alloy powder

The invention relates to a method for preparing ultrafine platy copper-zinc alloy powder by using a horizontal stirring and grinding method, belonging to the technical field of preparation of metal powder material. The method comprises the steps of: mixing the copper-zinc alloy powder, grinding media and various grinding aids, putting the mixture into a sealed grinding bin of a horizontal high-energy stirring machine, introducing a protective atmosphere which mainly contains inert gas such as nitrogen and argon and the like, introducing water or oil with the temperature of 15-100 DEG C into a water cooling sleeve of a ball milling machine, controlling the rotating speeds at different stages, grinding, dispersing, modifying and grading the alloy powder to finally obtain copper alloy powder with the meshes of minus 300. In the method, the annealing process of the traditional method is abolished, and proper grinding process parameters are adopted, and the method has the advantages of short production process, high production efficiency, stable process and the like, and the prepared powder material has good platy effect and surface performance. The method also can be used for zinc-aluminum mixing ball milling and the production of powder such as zinc-aluminum alloy powder and the like, in which the degree of oxidation needs to be controlled.

Owner:KUNMING UNIV OF SCI & TECH

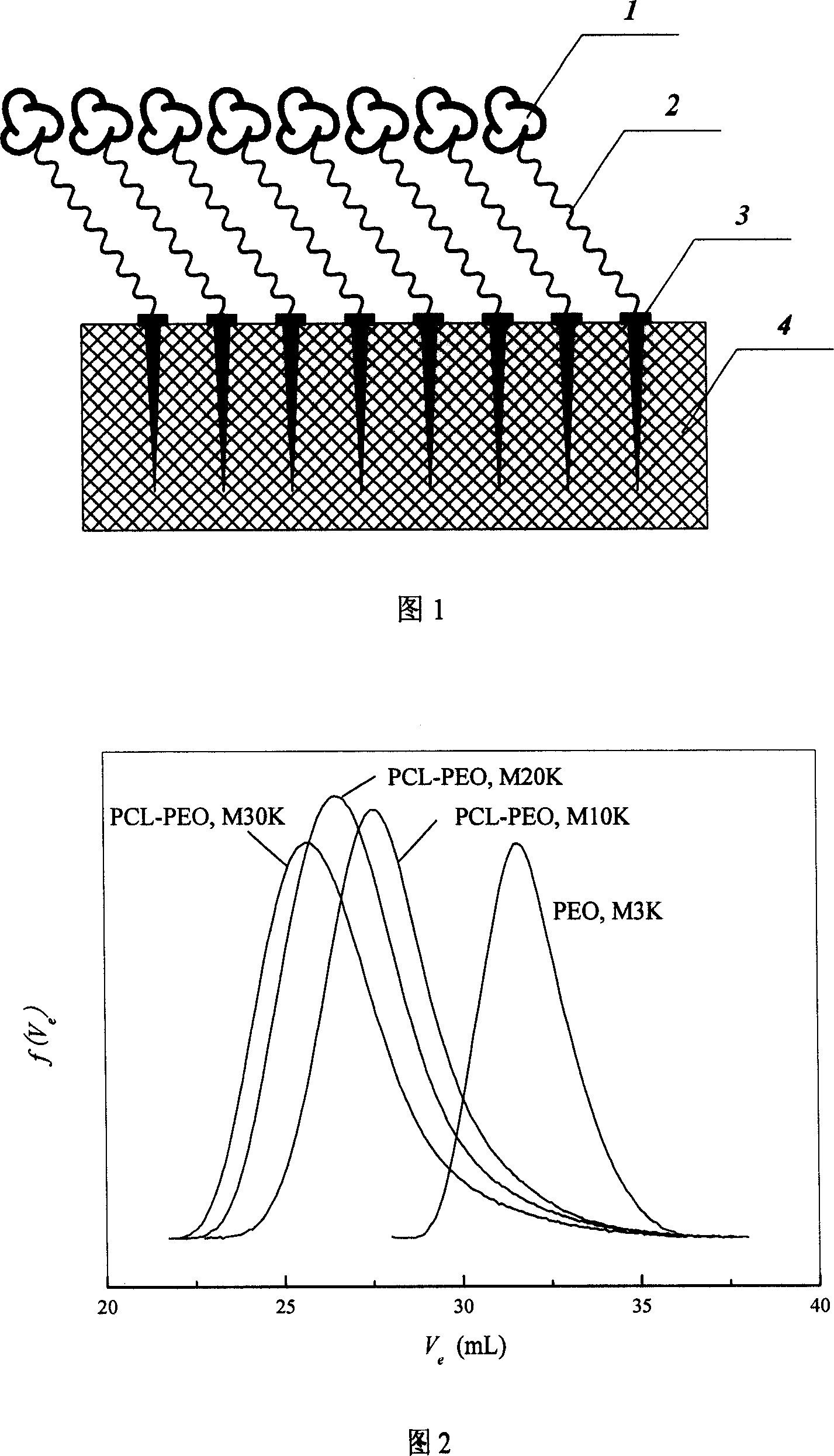

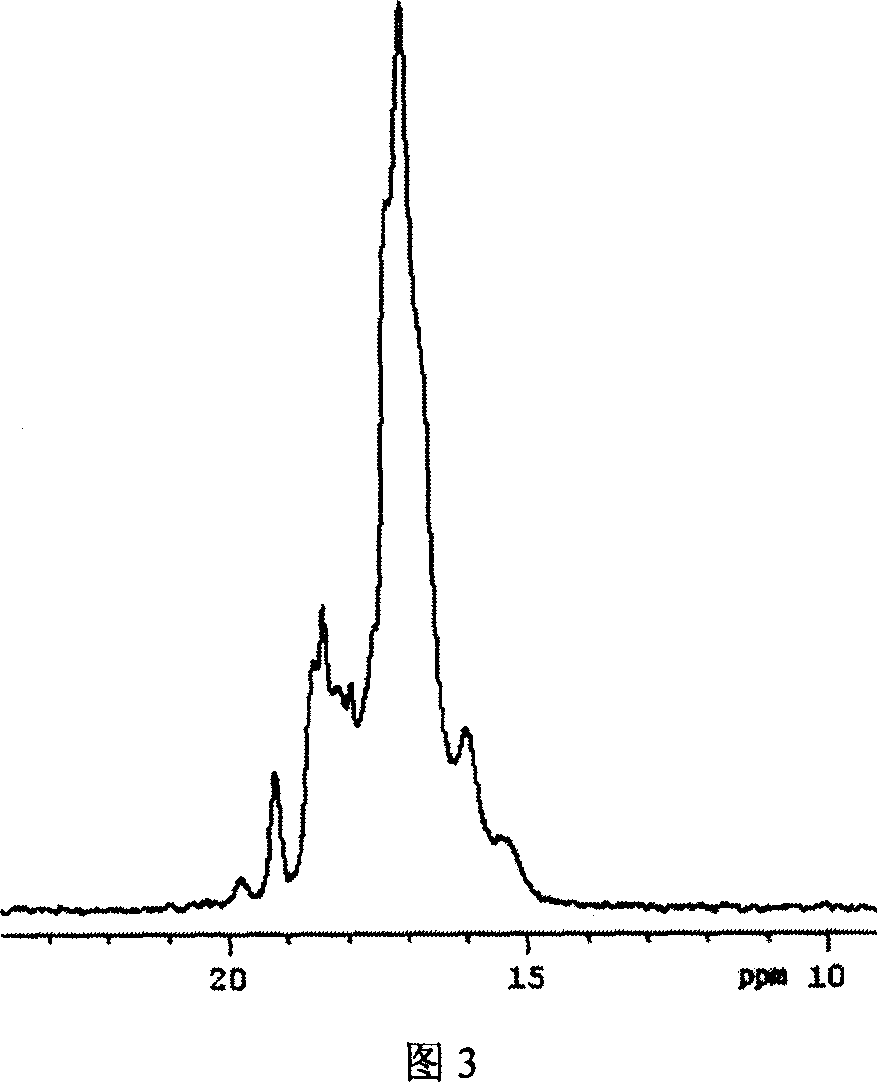

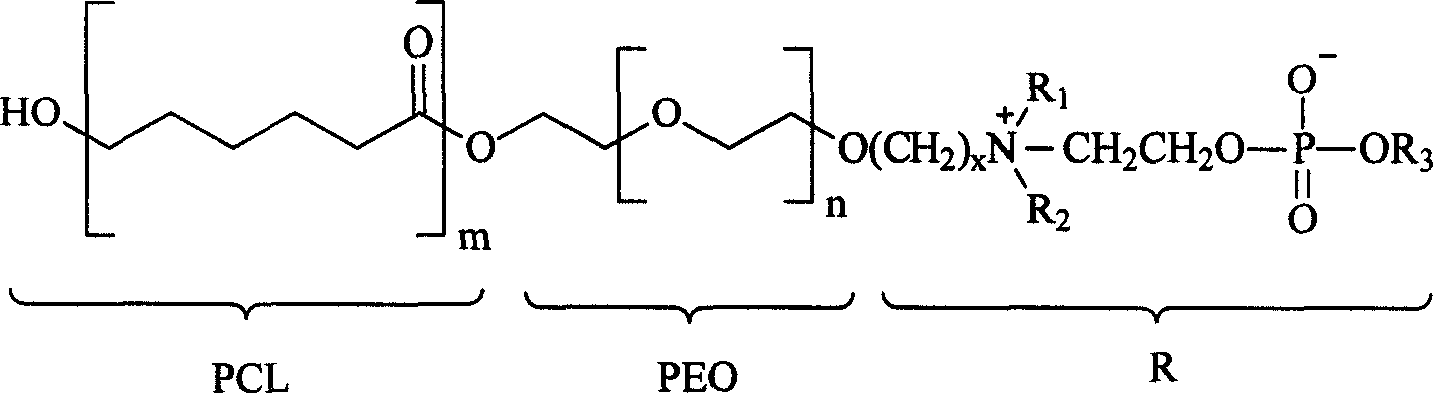

Polycaprolactone-polyethylene glycol block copolymer, and its preparing method and use

InactiveCN1978492AImprove the effect of surface modificationSurface modification achievedPharmaceutical non-active ingredientsPhosphorylcholinePolyethylene glycol

This invention provides the periodic copolymer PCL-PEO-R which was polymerized with poly-epsilon-caprolactone and polyethylene glycol. The polymerization degree of PCL segment is between 10 and 1000, and the corresponding molecular weight is between 1000 and 100000; the polymerization degree of PEO segment is between 10 and 100, and the corresponding molecular weight is between 400 and 5000; the interval group between tertiary amine N and PEO is the alkyl made up of 2-10 carbon atoms, and the selective preference number of carbon atom is 2-4. The other two alkyls on the atom of tertiary amine N may be the same either the different methyl or ethyl. The alkyls which were used to composite phosphorylcholine were made up of the liner chain or the branched chain, and the saturated or the unsaturated alkyls with 1-20 carbon atoms. This invention also provides the preparation of the interpolymer, as well as its application in the preparation of biology medical material.

Owner:NANJING UNIV

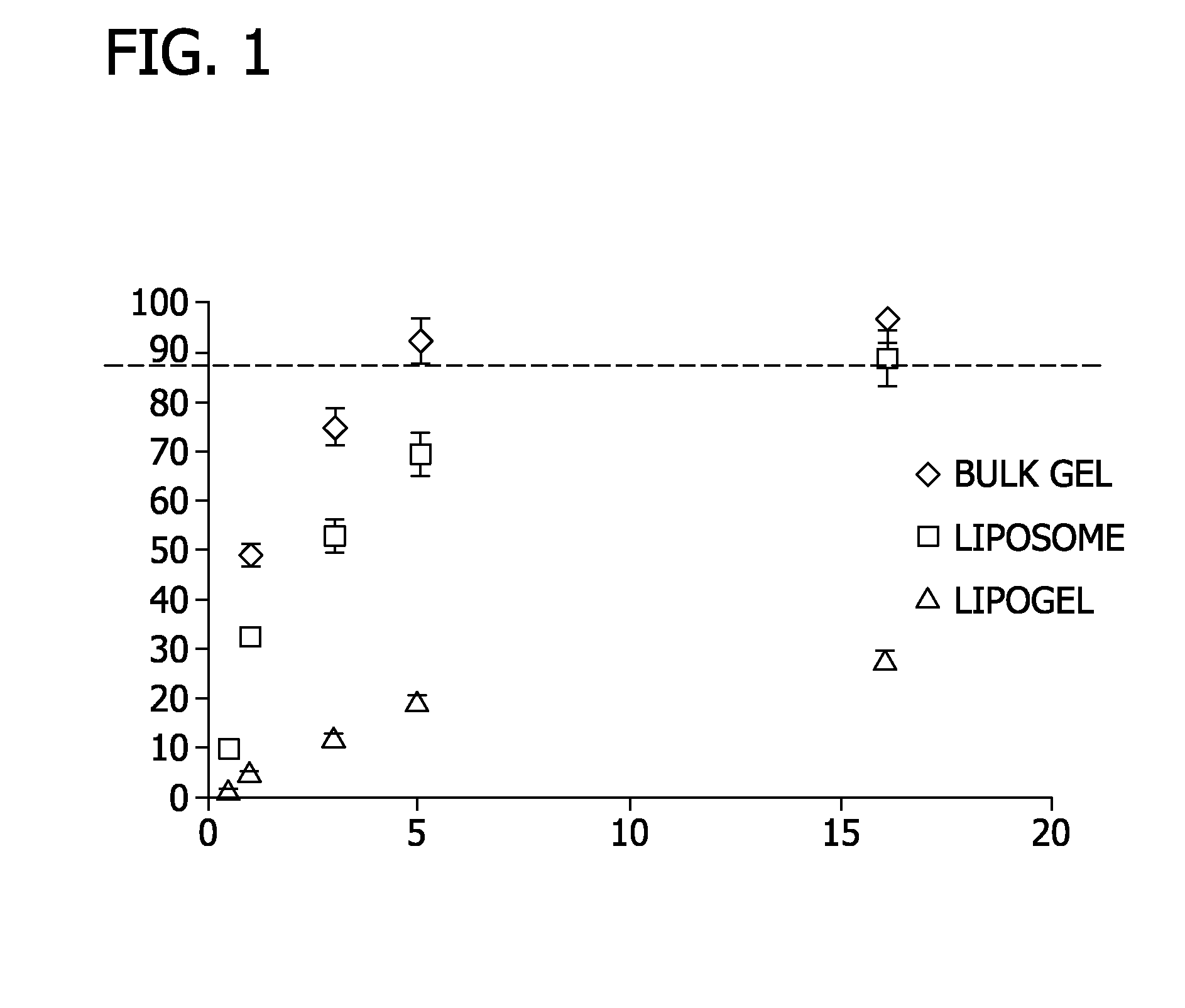

Liposome-encapsulated hydrogels for use in a drug delivery system

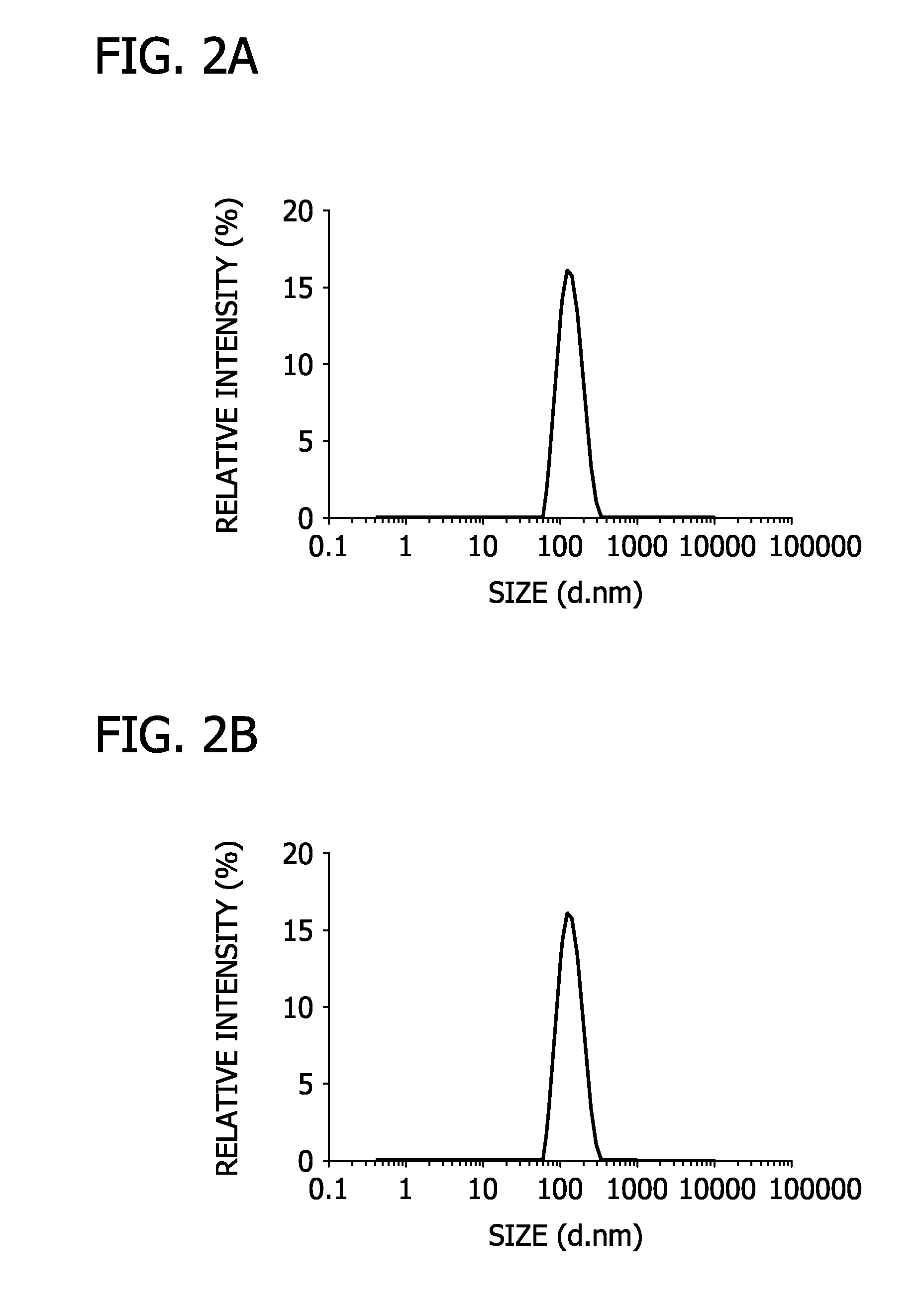

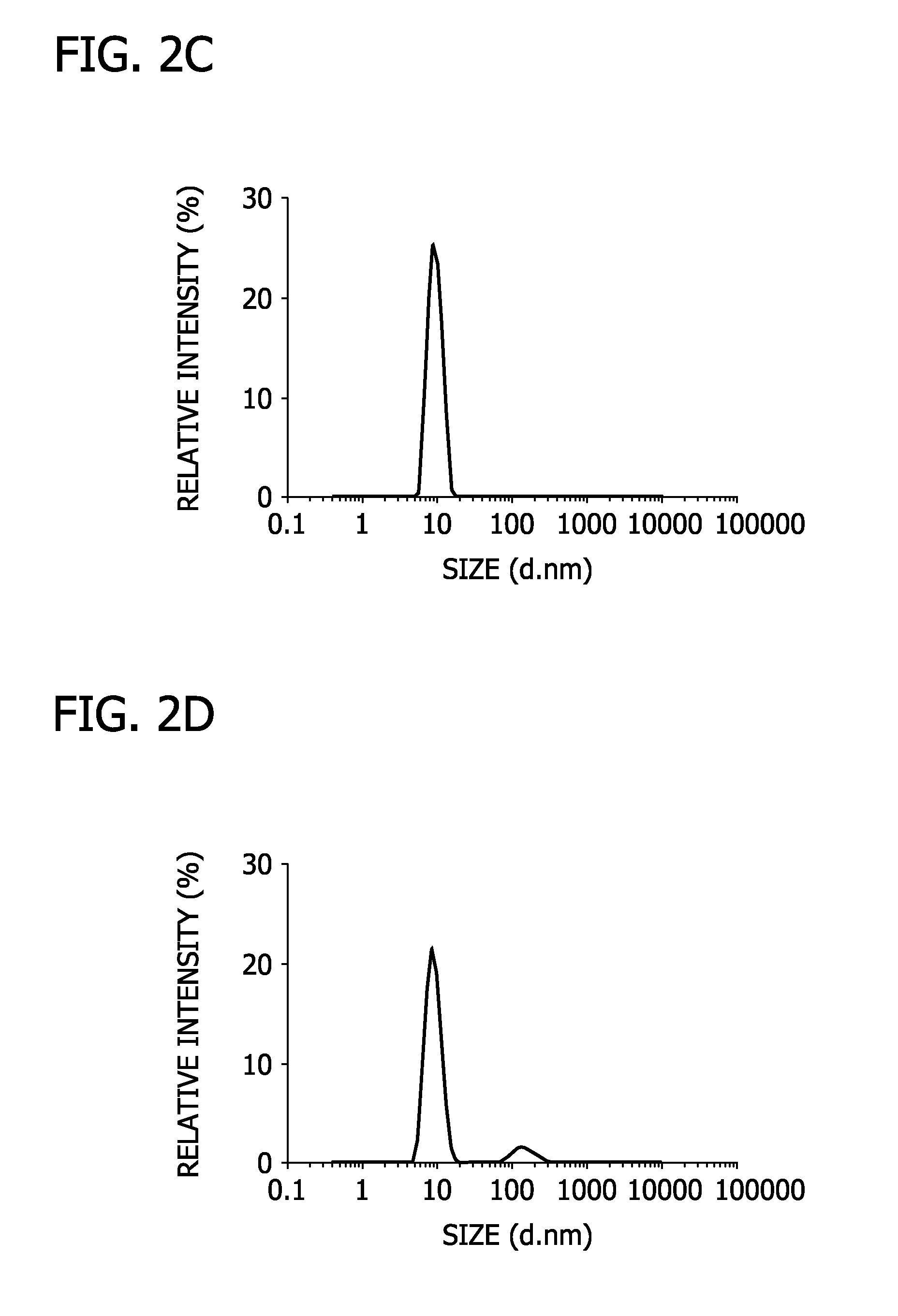

InactiveUS20140127287A1High drug loadingSustained releaseBiocideAnimal repellantsLiposomeDrug molecule

Owner:WISCONSIN ALUMNI RES FOUND

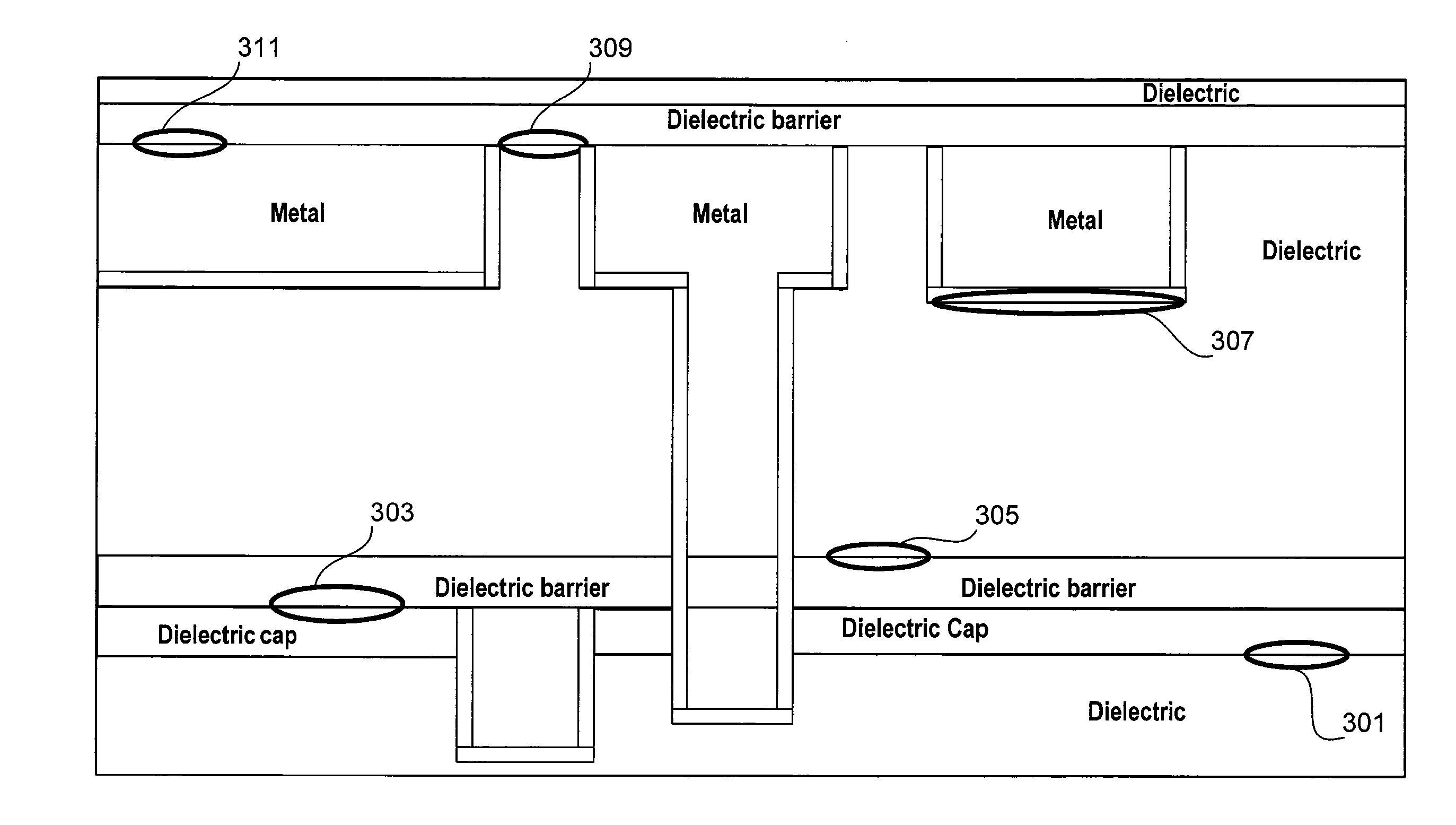

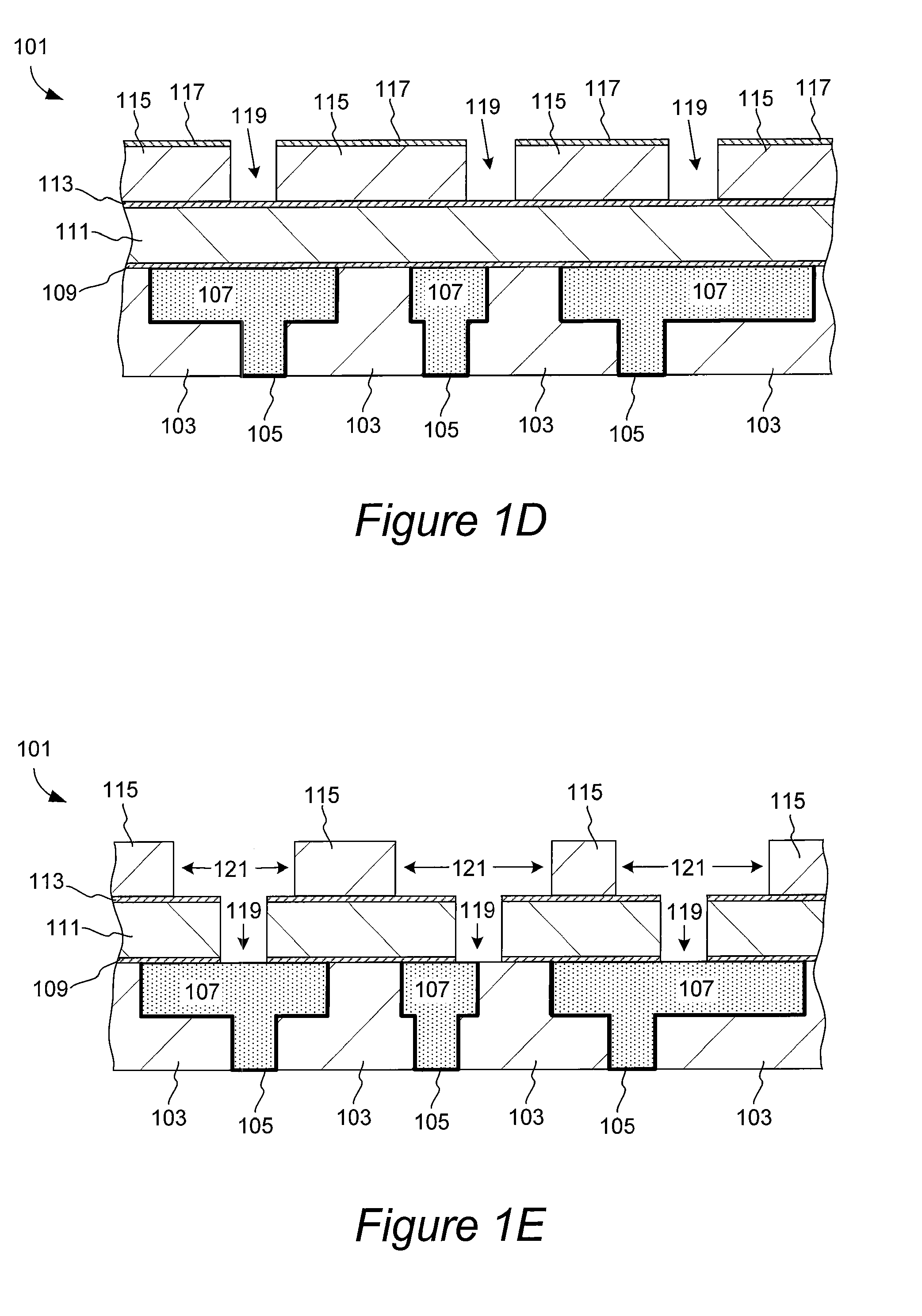

Enhancing adhesion of cap layer films

InactiveUS20140094038A1Improve adhesionEnhance surface modificationSemiconductor/solid-state device manufacturingPhysicsSurface modification

The present invention provides methods and apparatuses for improving adhesion of dielectric and conductive layers on a substrate to the underlying layer. The methods involve passing a process gas through a plasma generator downstream of the substrate to create reactive species. The underlying layer is then exposed to reactive species that interact with the film surface without undesirable sputtering. The gas is selected such that the interaction of the reactive species with the underlying layer modifies the surface of the layer in a manner that improves adhesion to the subsequently formed overlying layer. During exposure to the reactive species, the substrate and / or process gas may be exposed to ultraviolet radiation to enhance surface modification. In certain embodiments, a single UV cure tool is used to cure the underlying film and improve adhesion.

Owner:NOVELLUS SYSTEMS

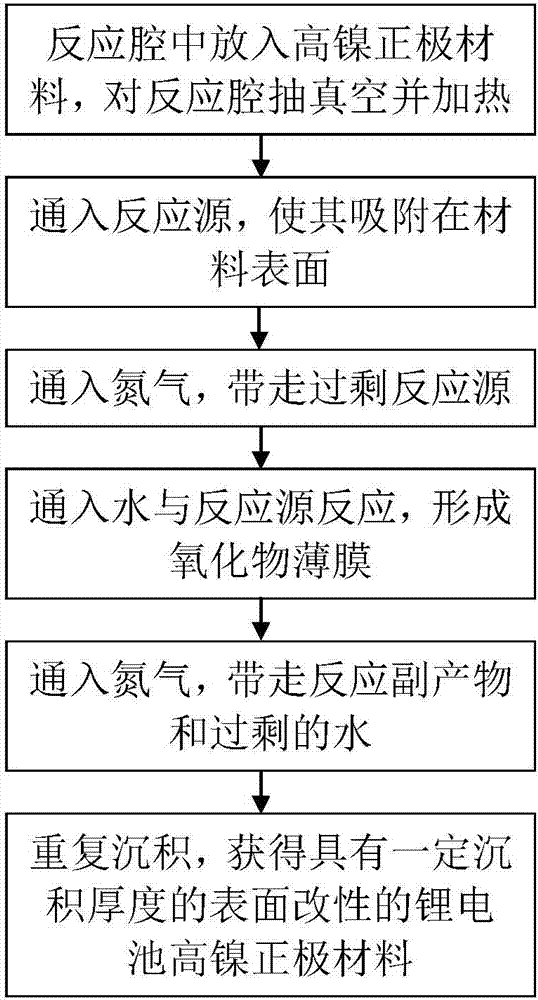

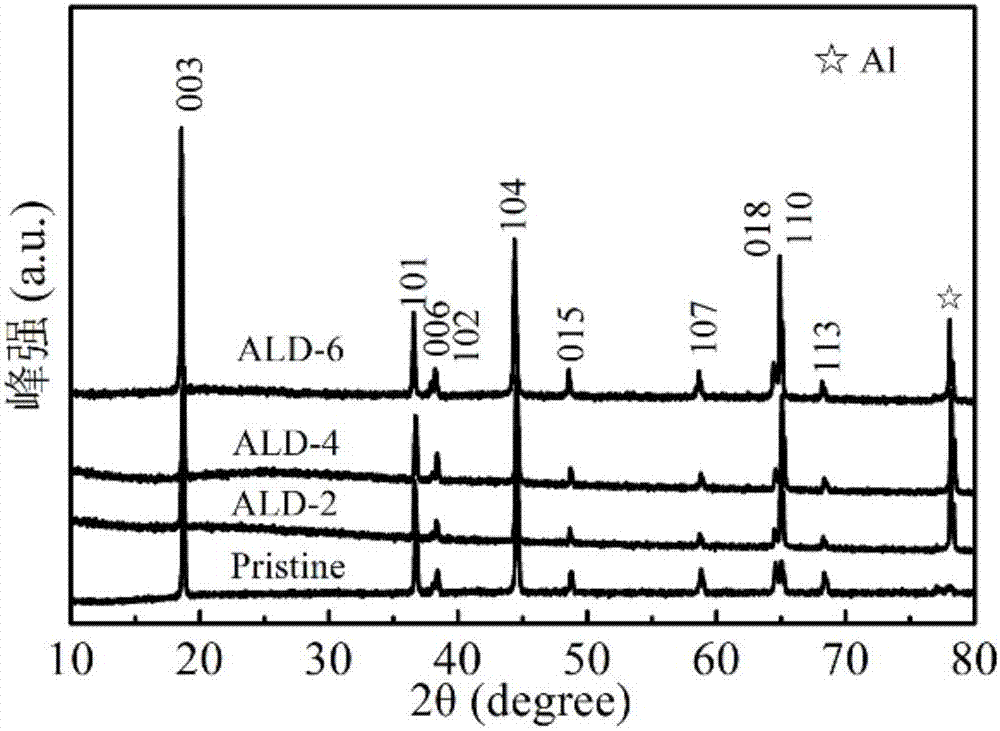

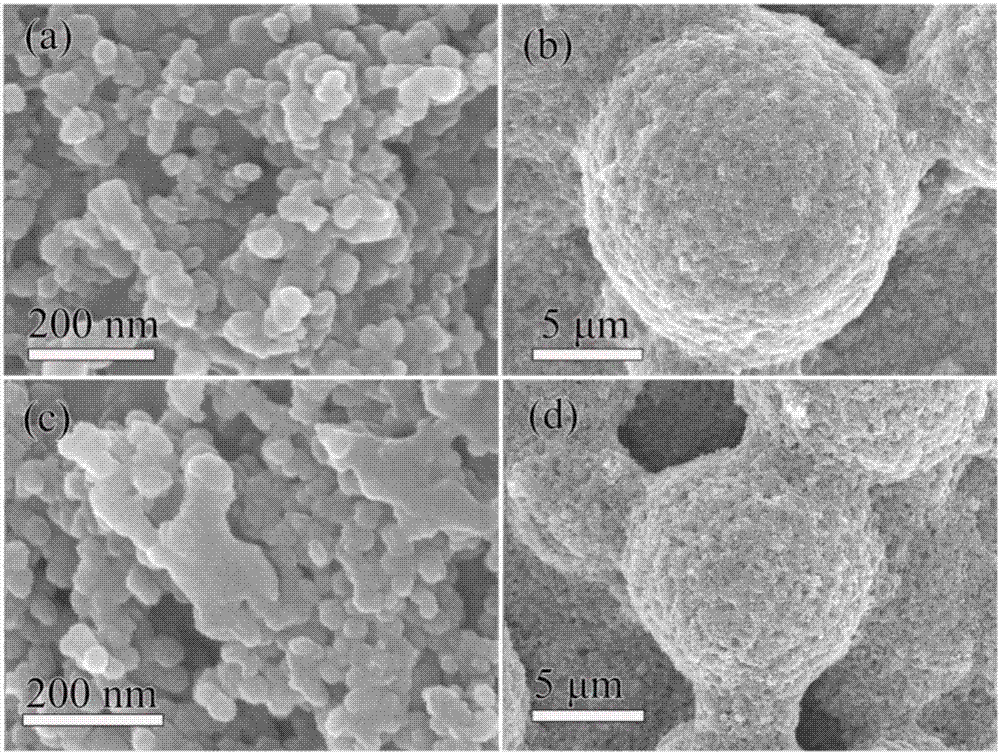

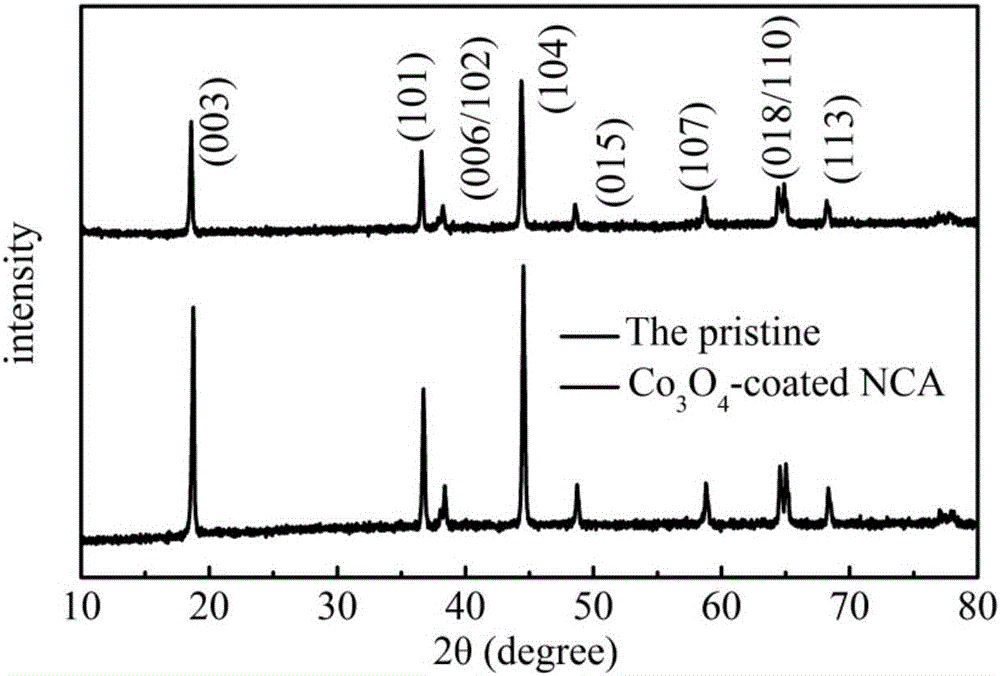

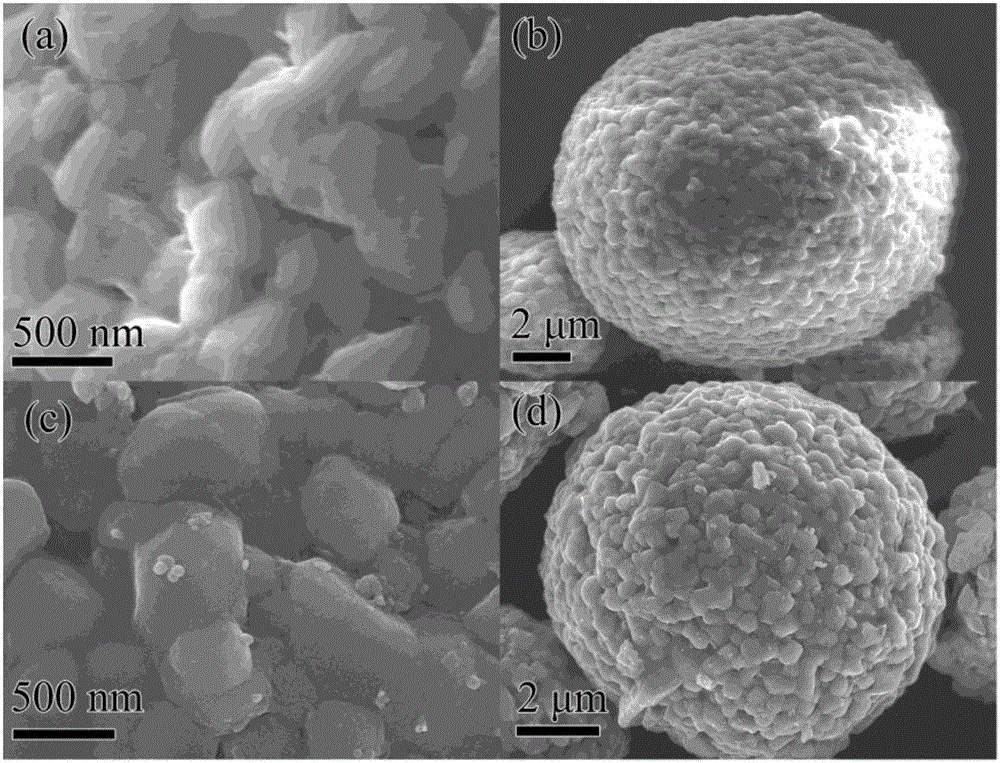

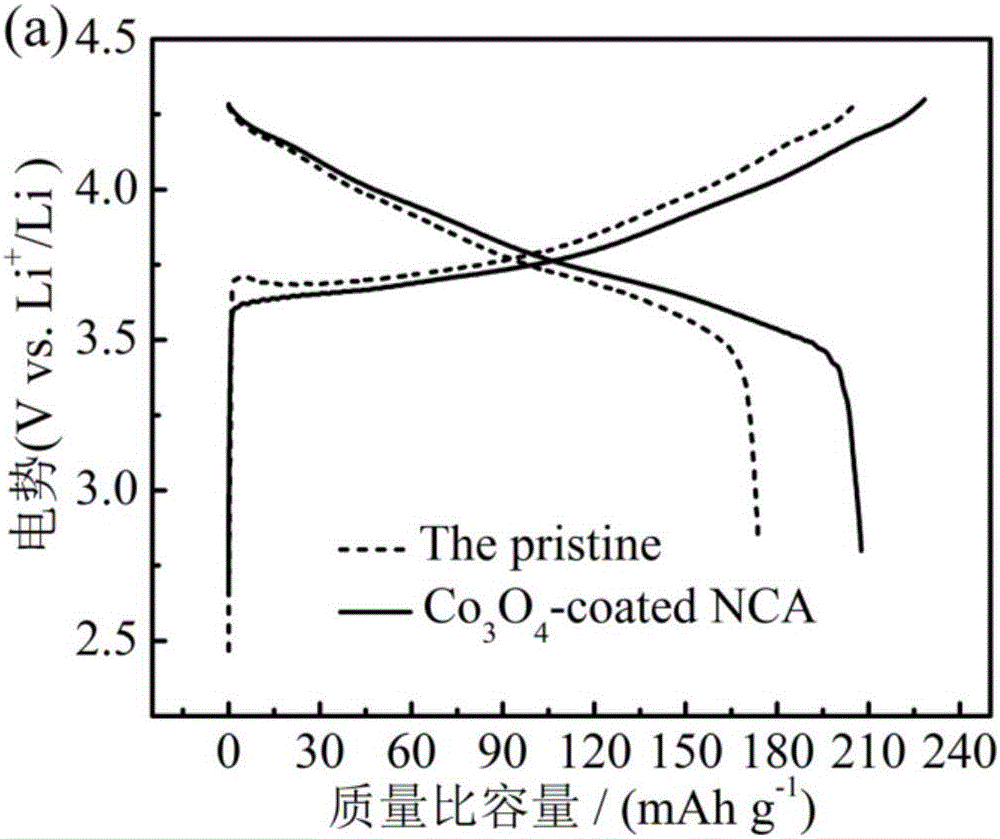

Preparation method and product of surface modified lithium battery high-nickel positive electrode material

InactiveCN107240684AImprove uniformityControl thicknessCell electrodesSecondary cellsLithium-ion batteryAtomic layer deposition

The invention belongs to the field of secondary lithium ion batteries, and discloses a preparation method of a surface modified lithium battery high-nickel positive electrode material. The preparation method comprises the following steps: putting high-nickel positive electrode material into a reaction cavity of an atomic layer deposition system, and vacuumizing the reaction cavity for 5 to 10 s, so that the temperature of the reaction cavity is 140 to 160 DEG C; introducing a reaction source so that the pressure of the reaction cavity reaches 5 to 8 mbar; introducing N2 to take away redundant reaction source in the reaction cavity; introducing water to react with the reaction source, and carrying out surface deposition on the high-nickel positive electrode material to obtain an oxide film; introducing N2 to take away redundant water in the reaction cavity; and repeating the above steps to obtain the surface modified lithium battery high-nickel positive electrode material. The invention also provides the surface modified lithium battery high-nickel positive electrode material prepared by the method, and a positive electrode piece and a lithium ion secondary battery prepared from the material. The positive electrode material has the advantages of simple and practicable preparation method, easily controlled thickness for a cladding layer and the like, and is applicable for large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

Porous Cured Epoxy Resin

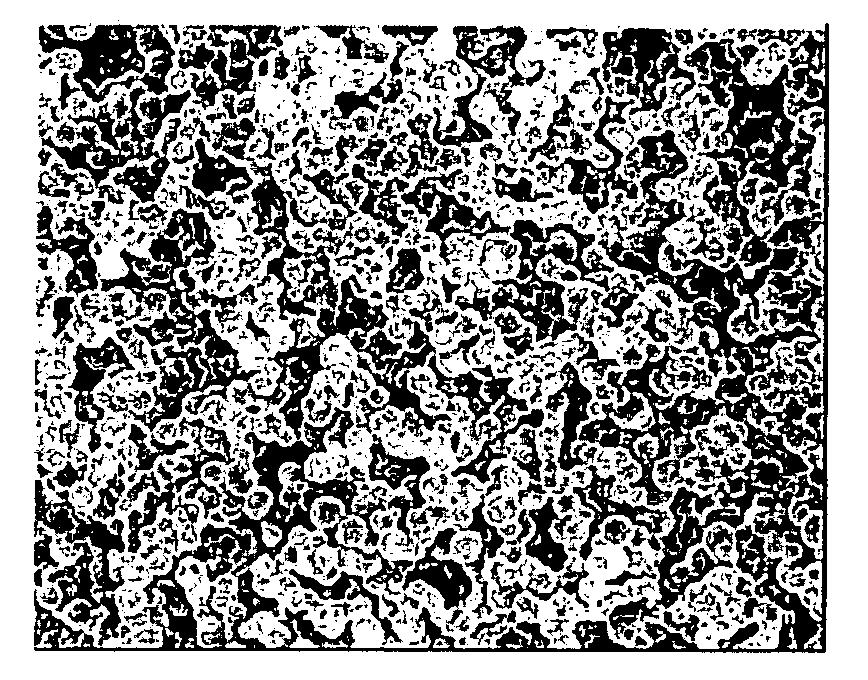

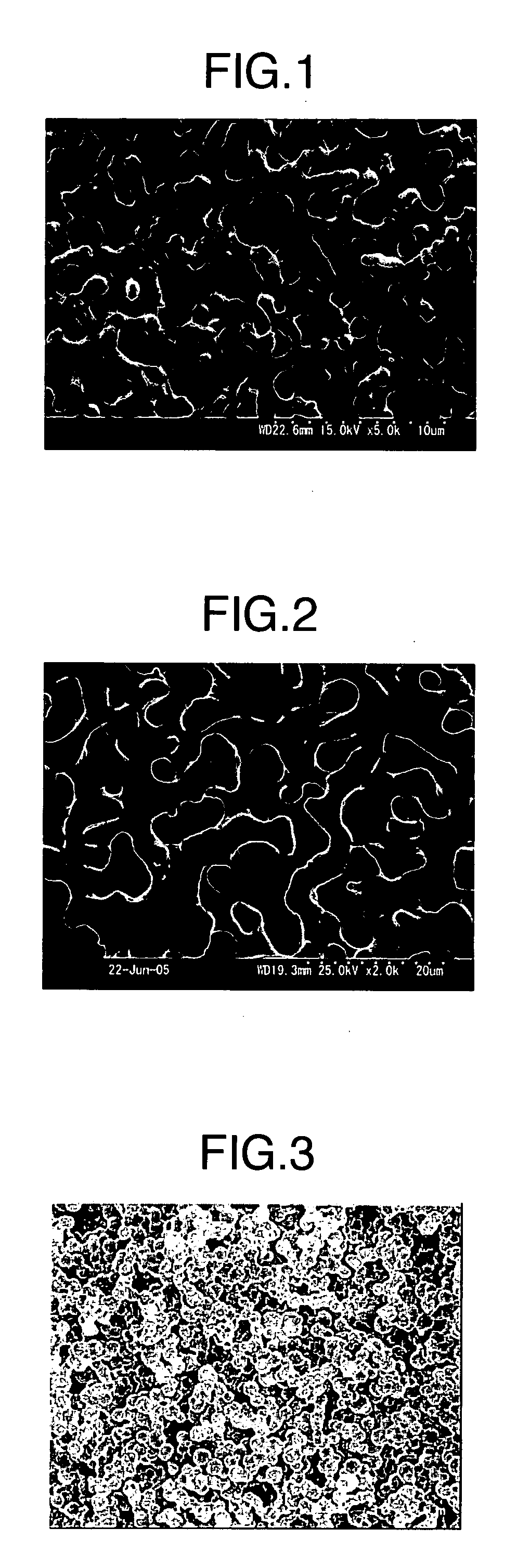

InactiveUS20080210626A1Excellent recognizabilityFacilitate surface modificationIon-exchange process apparatusMembranesParticle aggregationPore diameter

A porous object comprising a three-dimensional network skeleton of a cured epoxy resin and having interconnecting pores, characterized in that the three-dimensional network skeleton forms a non-particle-aggregation type porous object constituted of a three-dimensional branched columnar structure, the proportion of aromatic-ring-derived carbon atoms to all the carbon atoms as a component of the cured epoxy resin is 0.10-0.65, and the porous object has a porosity of 20-80% and an average pore diameter of 0.5-50 μm.

Owner:EMAUS KYOTO

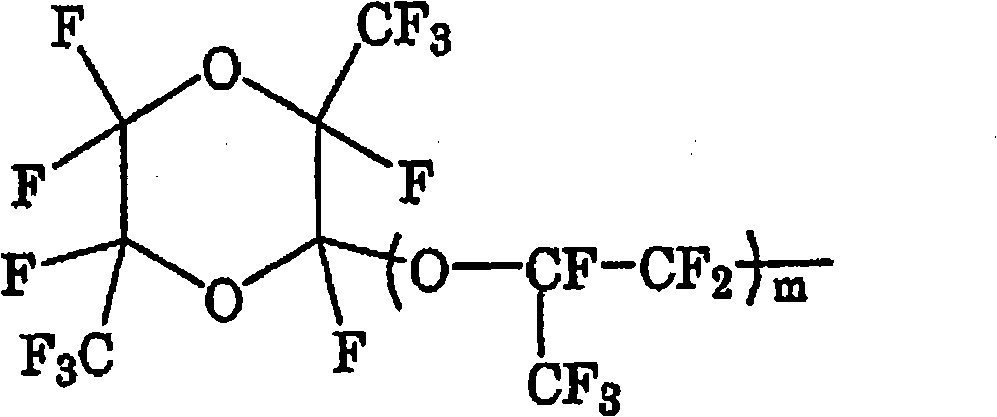

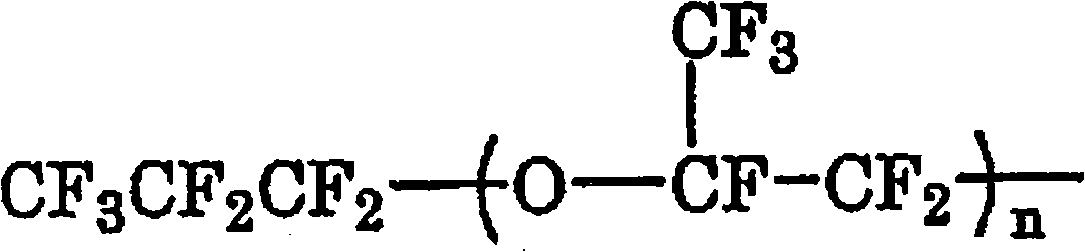

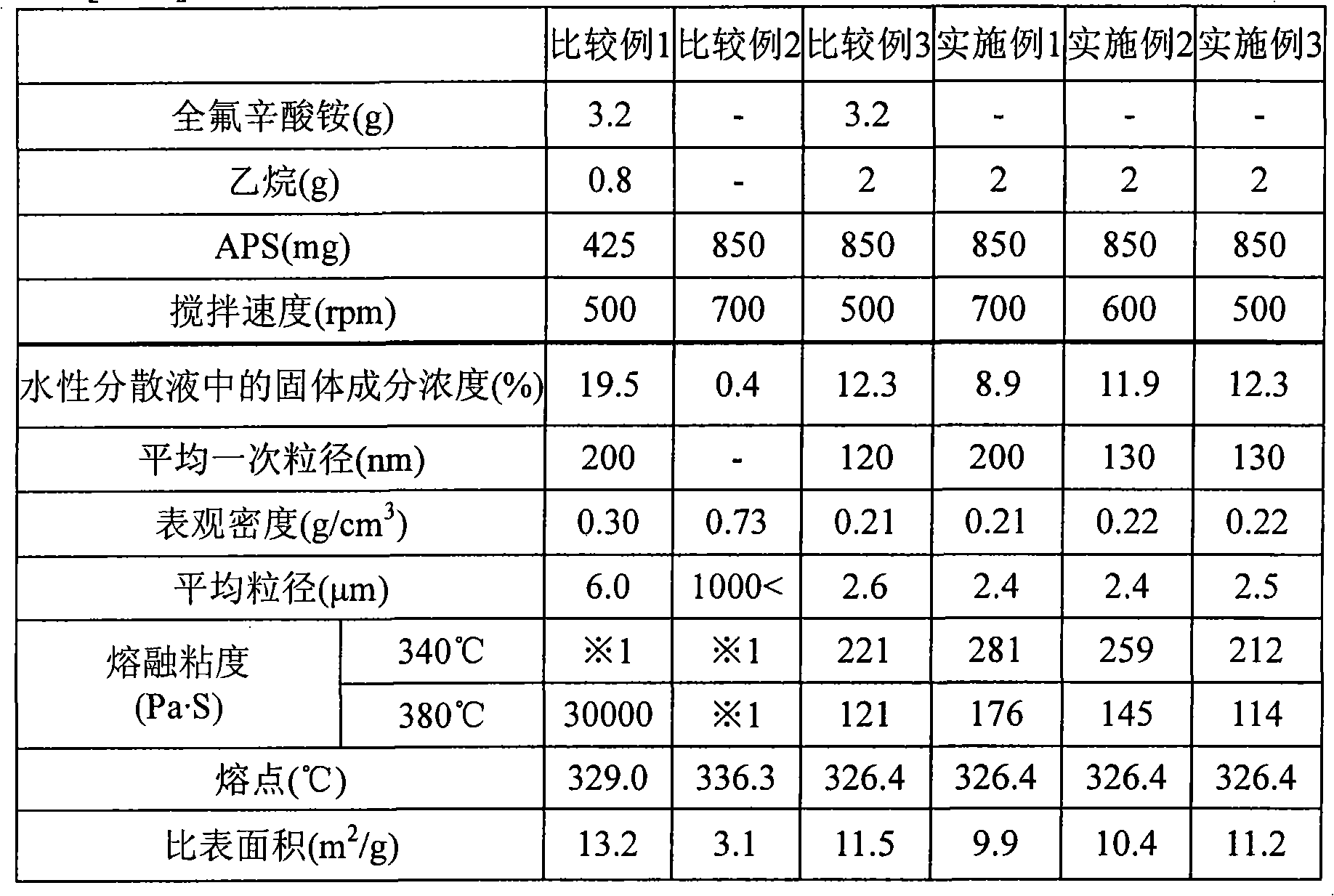

Aqueous dispersion of low molecular weight polytetrafluorethylene and preparation method thereof

ActiveCN101333269AEasy to slideGood oil resistanceCosmetic preparationsToilet preparationsHalohydrocarbonPeroxide

The invention relates to a lowmolecular weight polytetrafluoroethylene dispersion liquid and a preparing method thereof, relates to a method for preparing lowmolecular weight polytetrafluoroethylene (PTEE) dispersion liquid with low cost and without adding fluorine-containing surfactant. In the method, without adding fluorine-containing surfactant, on the basis of a chain transfer agent, emulsion polymerization of tetrafluorethylene (TFE) is carried out in aqueous medium containing a polymerization initiator or emulsion polymerization of monomers capable of copolymerizing with TFE and TFE. The method is characterized in that the chain transfer agent is a compound which is selected from at one of hydrocarbon having 1-3 H and C and halohydrocarbon having 1-3 C, the polymerization initiator is a water-soluble peroxide.

Owner:DAIKIN IND LTD

Functional calcium carbonate and method for producing the same

ActiveCN101456969AIncrease dosageDosage remains the samePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsInterface layerPerformance index

The invention discloses a functionality calcium carbonate and a preparation method thereof. The functionality calcium carbonate is prepared by compound treatment technology of 'wet method + dry method' of superfine coarse whiting, fine calcium carbonate particle, nanometer calcium carbonate and a modification agent. The functionality calcium carbonate of the invention can promote resin plasticization, reduce melt viscosity, improve melt fluidity and melt intensity, make product surface smooth and fine and have the function of processing an addition agent ACR, and meanwhile is provided with the function of strengthening coupling and excellent surface modification effects. Appropriate increasing of padding of the system does not affect each performance index of the product. The functionality calcium carbonate and the preparation method thereof has the advantages of improving dispersivity and compatibility of each component of prescription system, improving plasticity of bonding strength of interface layer, having excellent interface layer performance, realizing the function of annealing strengthening and strengthening.

Owner:NANJING XIEHE CHEM

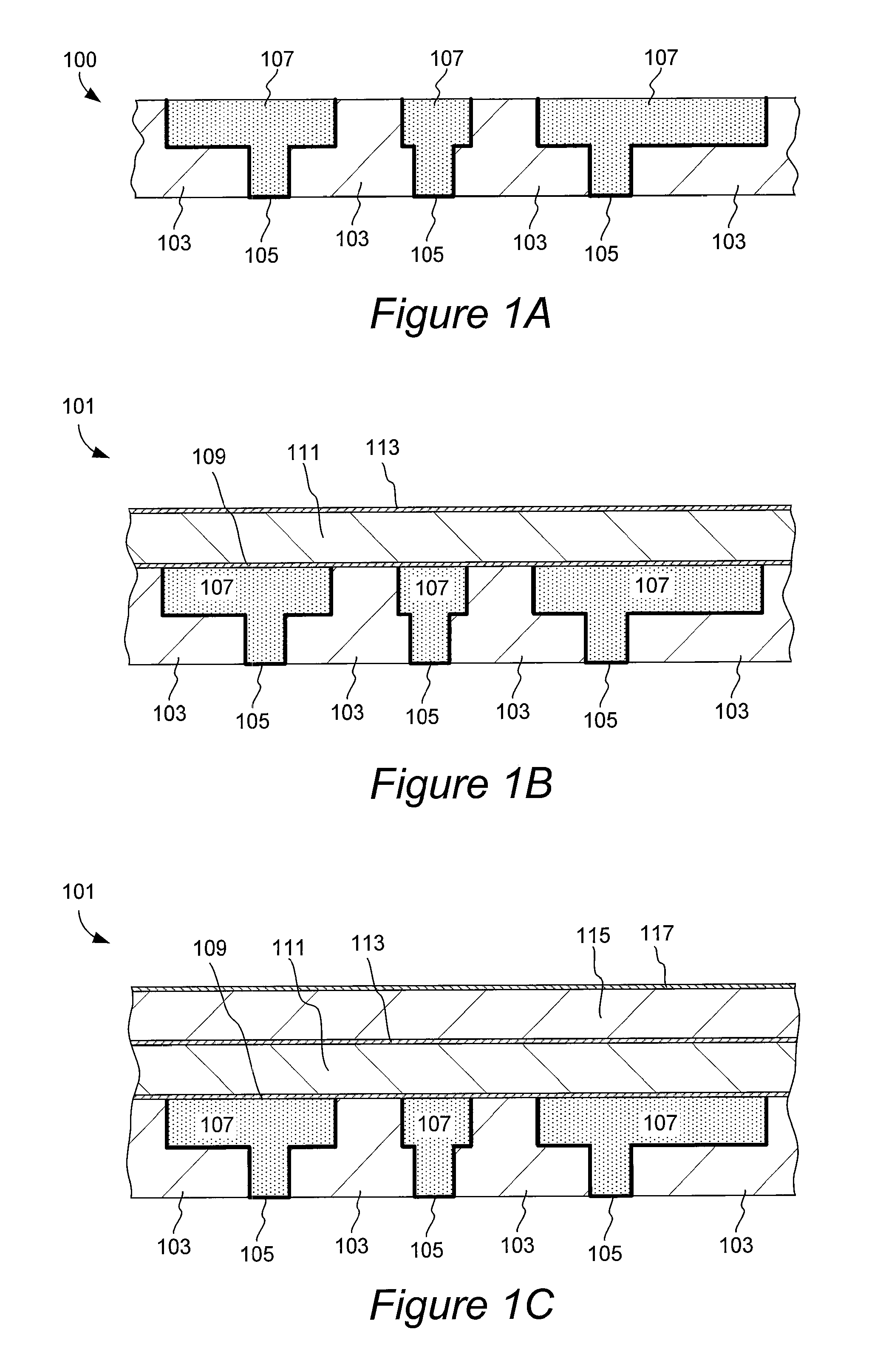

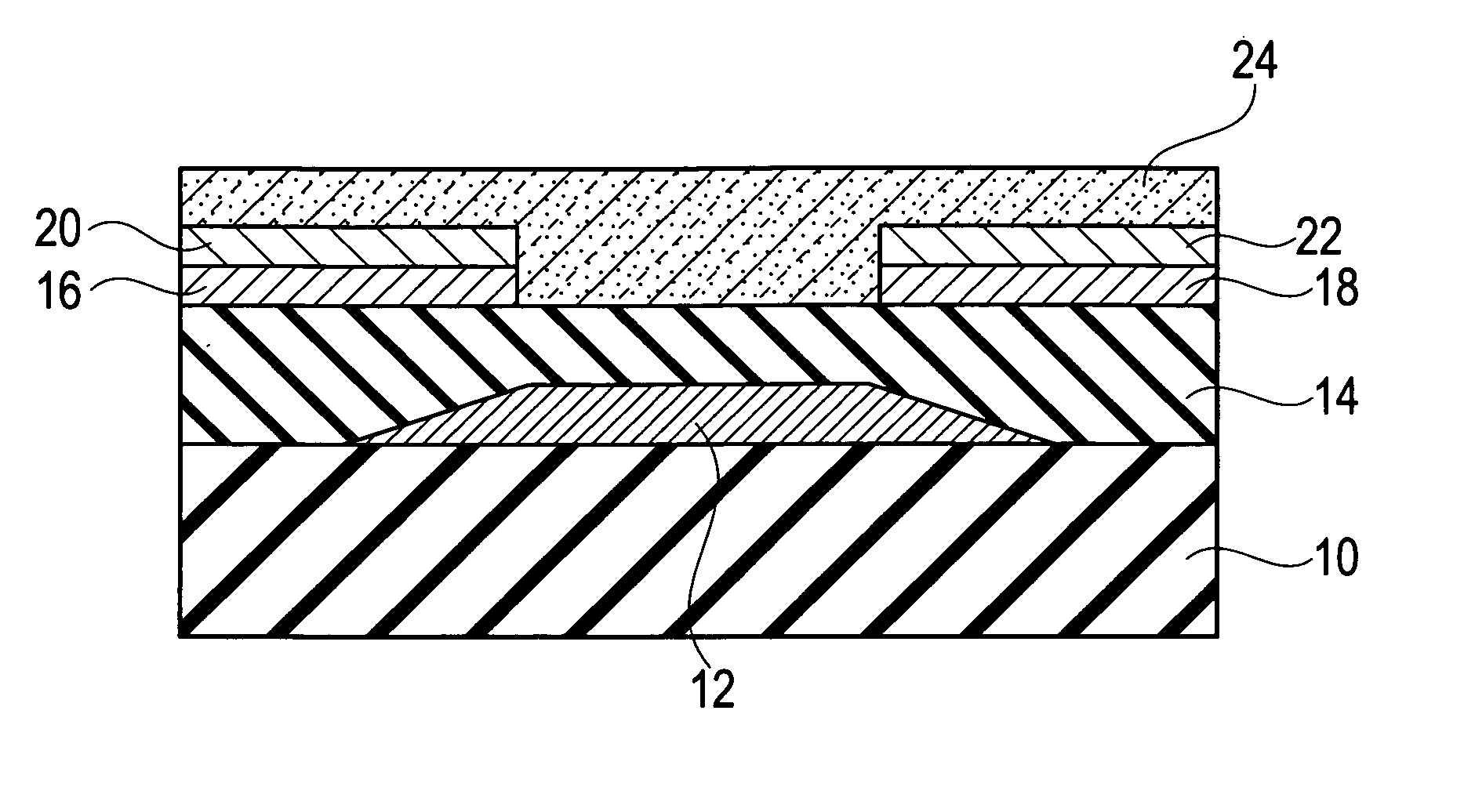

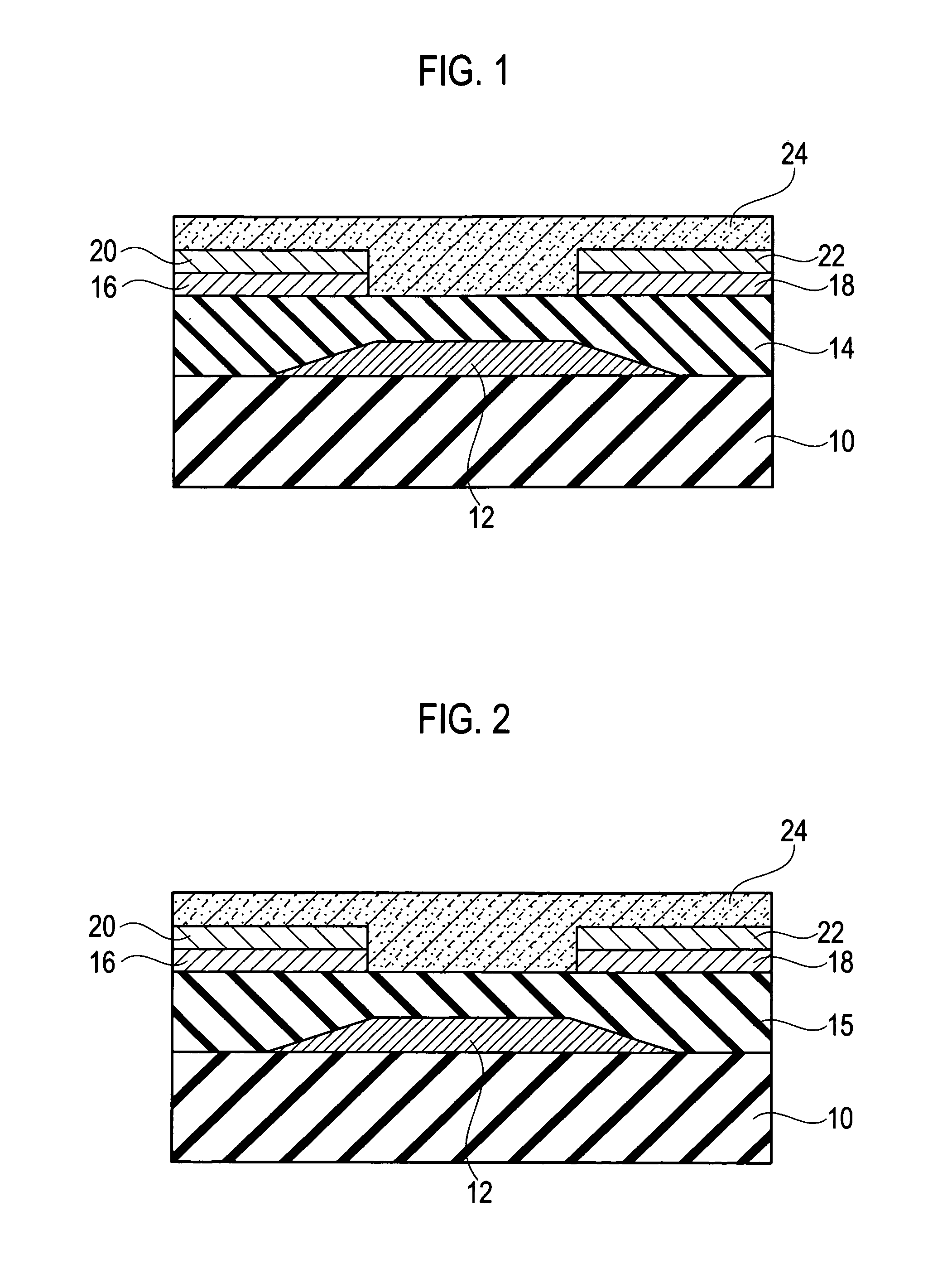

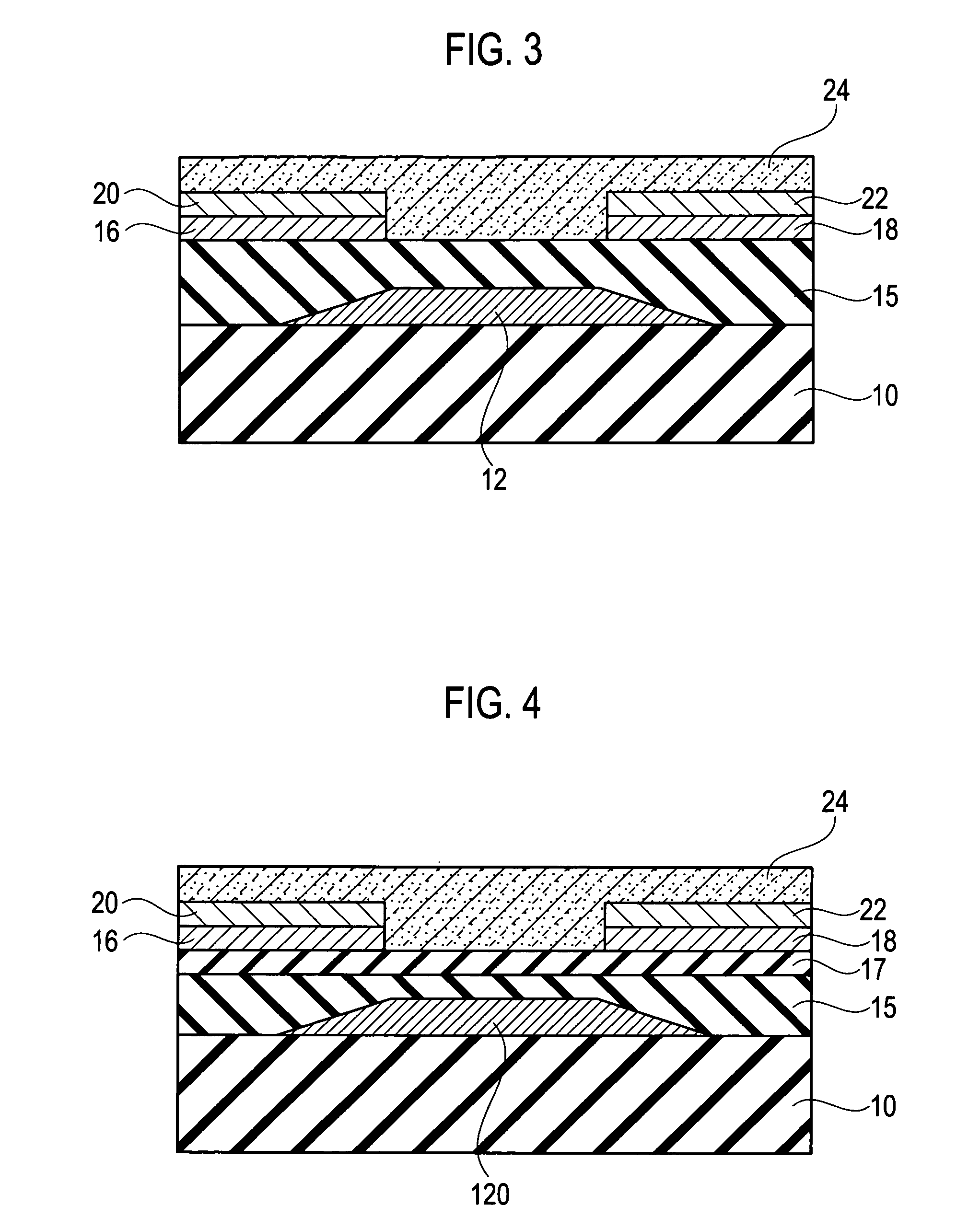

Organic Semiconductor Device

InactiveUS20100301311A1Improve featuresImprove the effect of surface modificationSolid-state devicesSemiconductor/solid-state device manufacturingLow voltageSilicon dioxide

Provided is an organic semiconductor device, suitable for the integration, including an organic thin film transistor of low voltage drive and high driving current.The organic semiconductor device including an organic thin film transistor comprising: a substrate (10); a gate electrode (12) disposed on the substrate (10); a first gate insulating film (15) disposed on the gate electrode (12); a second gate insulating film (17) disposed on the first gate insulating film (15); a source electrode (16, 20) and a drain electrode (18, 22) disposed on the second gate insulating film (17) and composed of a layered structure of a first metal layer (16, 18) and a second metal layer (20, 22); and an organic semiconductor layer (24) disposed on the gate insulating film (17) and between the source electrode (16, 20) and the drain electrode (18, 22). The first gate insulating film (15) is composed of an insulating film having a dielectric constant higher than that of the second gate insulating film (17), and the second gate insulating film (17) is composed of a silicon dioxide film thinner than the first gate insulating film (15), thereby providing a laminated type gate insulating film structure as a whole.

Owner:ROHM CO LTD

Surface modified lithium battery high-nickel anode material and preparation method thereof

InactiveCN106207130AImprove conductivityImprove stabilityCell electrodesSecondary cellsSalt solutionMetal

Owner:HUAZHONG UNIV OF SCI & TECH

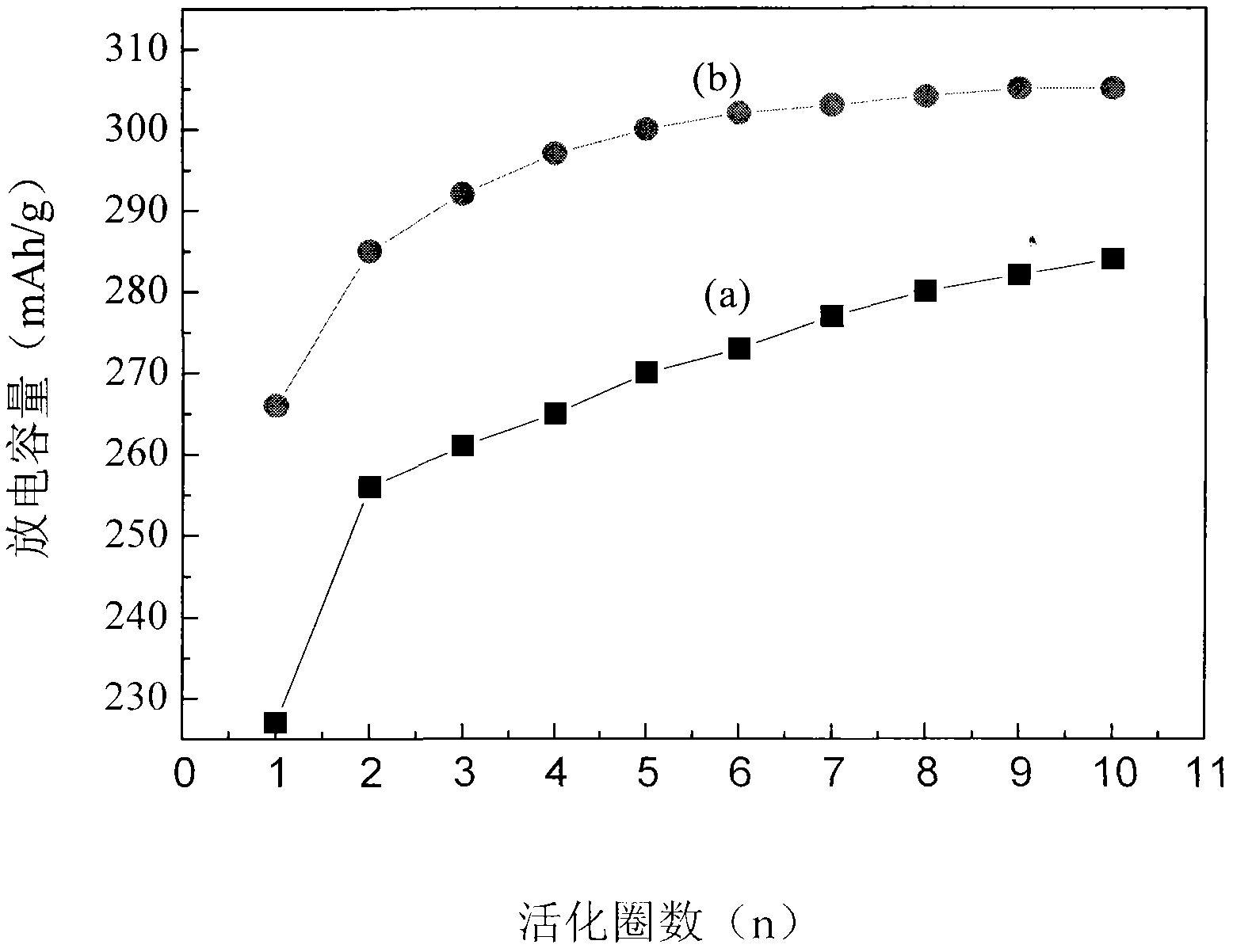

Method for Improving the Electrochemical Performance of Hydrogen Storage Alloy Powder Using Electropolymerized Polyaniline

ActiveCN102274965AEasy to operateReduce manufacturing costCell electrodesElectrophoretic coatingsElectrochemistryCorrosion

The invention relates to a method for improving the electrochemical performance of hydrogen storage alloy powder by utilizing electropolymerization polyaniline, and belongs to the technical field of the surface treatment of hydrogen storage alloy. The method comprises the following steps of: putting hydrogen storage alloy powder of which the granularity is between 100 and 400 meshes into mixed solution containing phenylamine and protonic acid in a certain ratio, and stirring uniformly at a speed of between 50 and 100 revolutions / minute, wherein the mass ratio of the hydrogen storage alloy powder to the mixed solution is 10 / 100-100 / 100; and applying direct-current voltage of between 1 and 2 V for 0.5 to 5 minutes by taking the hydrogen storage alloy powder as an anode and graphite as a cathode, so that the phenylamine performs electro-deposition polymerization reaction on the surface of the hydrogen storage alloy powder to form a polyaniline membrane layer. In the method, a polyanilinewrapped membrane with electrical conductivity and corrosion resistance is formed on surfaces of hydrogen storage alloy powder particles to improve the hydrogen storage capacity, high-multiplying power discharging performance and cyclic stability of the hydrogen storage alloy. The method has the characteristics of simplicity of operation, low production cost, obvious improvement effect and the like.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD +1

Surface modified nanometer material serving as lubricating oil additive as well as preparation method and application thereof

ActiveCN103804960AReduce the temperatureFast preparationAdditivesPigment treatment with macromolecular organic compoundsMechanical millingOil additive

The invention belongs to the technical fields of a nanometer material and lubricating oil, and discloses a surface modified nanometer material serving as a lubricating oil additive as well as a preparation method and an application thereof. The preparation method mainly comprises the following steps: putting a mixture of powder to be treated and a surface modification agent as well as grinding balls in a ball-milling tank of an improved dielectric barrier discharge plasma assisted mechanical milling device, feeding a discharge atmosphere medium, controlling the temperature of the ball-milling tank, adjusting discharge parameters, and starting the mechanical milling device so as to carry out dielectric barrier discharge plasma assisted mechanical milling, thus obtaining the surface modified nanometer material. The obtained powdery surface modified nanometer material can be added to the lubricating oil so as to improve the performance of the lubricating oil. The preparation method is simple to operate and good in controllability; the obtained surface modified nanometer material is small in particle size, high in activity, good in surface modification and extremely easy to deposit, flatly spread and diffuse on a mechanical friction surface and has excellent dispersion property in the lubricating oil, so that the friction of mechanical movement parts is reduced, and the worn surface is repaired.

Owner:麦卡伦(厦门)润滑油有限公司

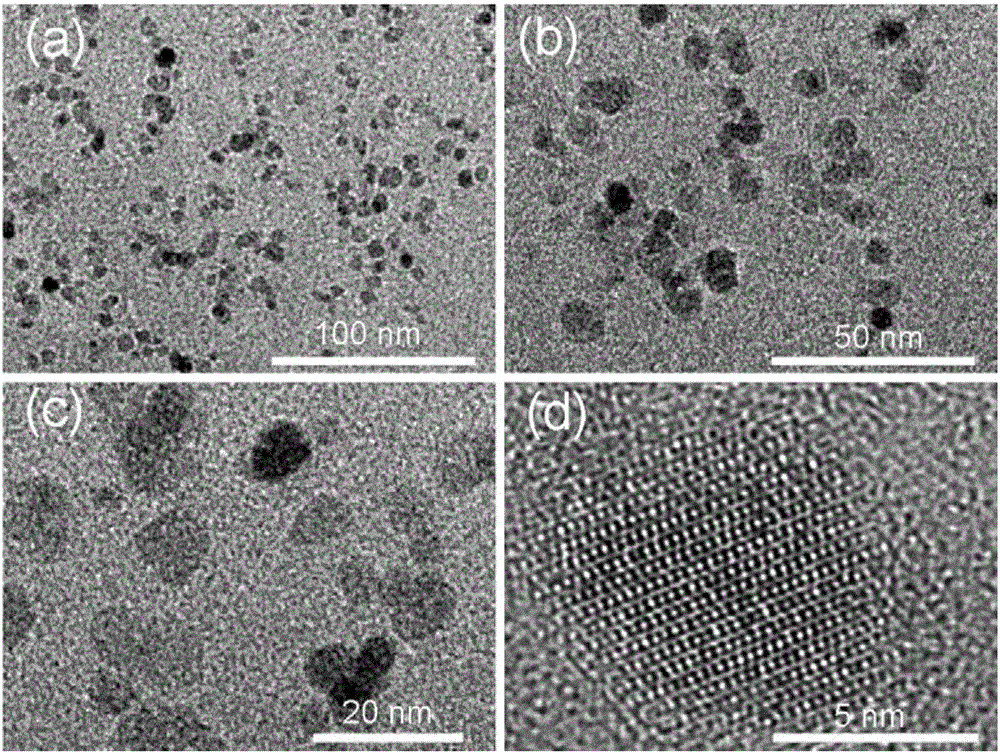

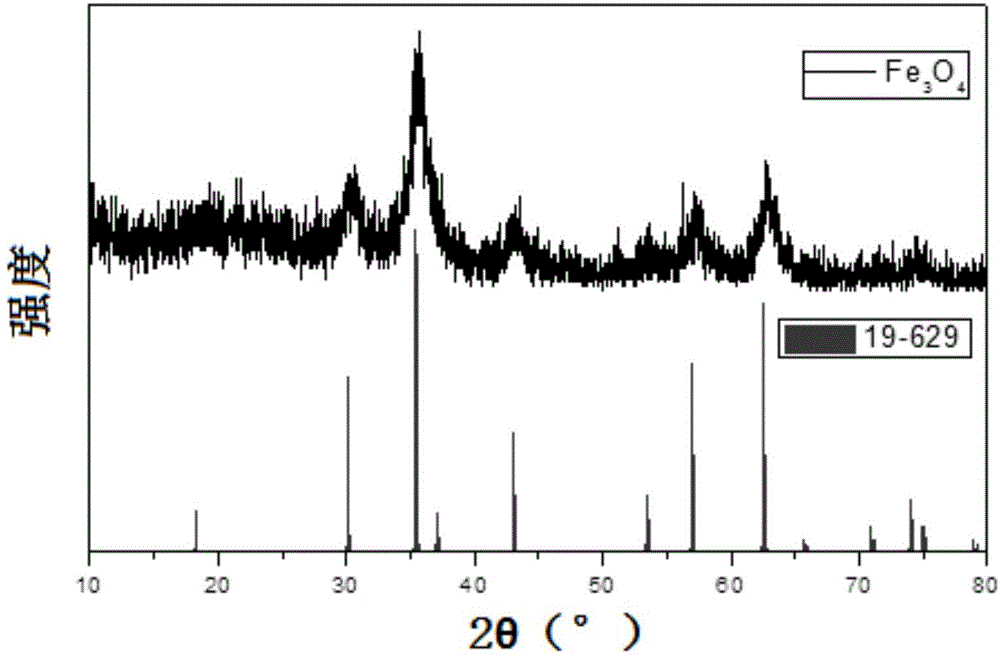

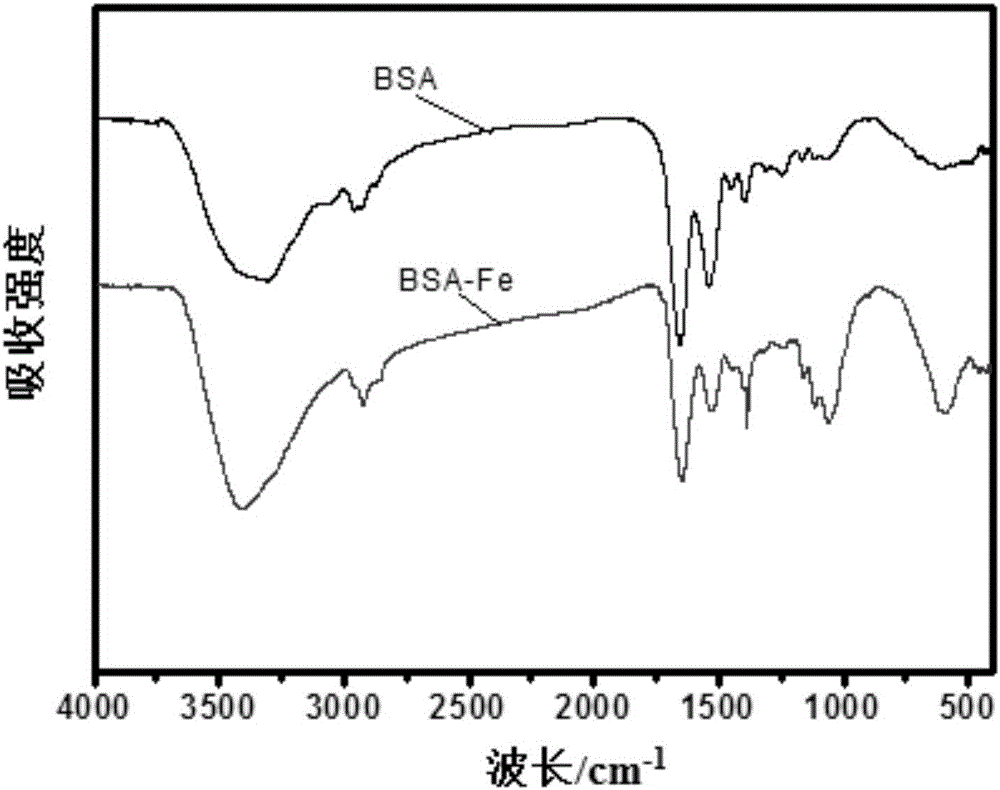

Bovine serum albumin coated ferriferrous oxide nano-particle T1-MRI (Magnetic Resonance Imaging) contrast medium and preparation method thereof

InactiveCN106075475AGood biocompatibilityLow toxicityEmulsion deliveryIn-vivo testing preparationsMRI contrast agentFerrous salts

The invention relates to a bovine serum albumin coated ferriferrous oxide nano-particle T1-MRI (Magnetic Resonance Imaging) contrast medium and a preparation method thereof. The method specifically comprises the following steps: (1) dissolving bovine serum albumin into secondary water A; ultrasonically dissolving to prepare a bovine serum albumin solution; (2) adding soluble ferric iron salts and soluble ferrous salts into secondary water B and dissolving to prepare an iron source solution; (3) putting the bovine serum albumin solution into an inert atmosphere and heating and stirring; adding the iron source solution into the bovine serum albumin solution to prepare a BSA-Fe precursor; and (4) raising the temperature to 50-100 DEG C and rapidly adding concentrated ammonia water, and reacting at a constant temperature for 5min-30min to prepare the bovine serum albumin coated ferriferrous oxide nano-particle T1-MRI contrast medium. Compared with the prior art, the preparation method is simple and the controllability is good; and obtained bovine serum albumin coated ferriferrous oxide nano-particles have the characteristics of good biocompatibility, easiness of being discharged out of a body, small toxicity and good T1 imaging effect.

Owner:SHANGHAI NORMAL UNIVERSITY

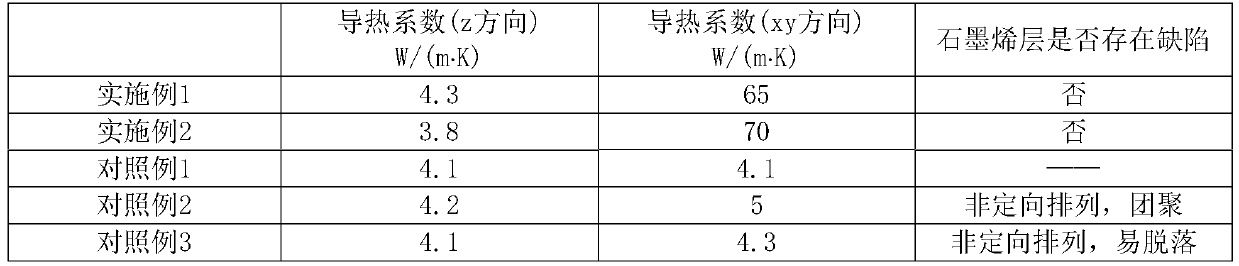

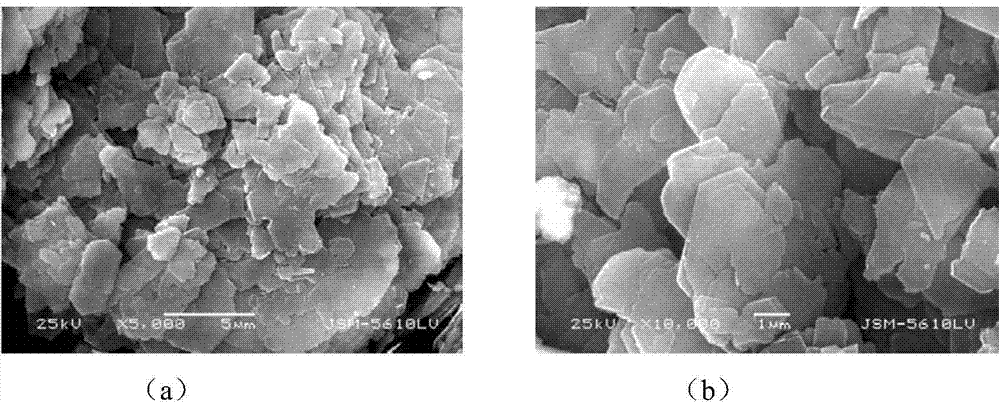

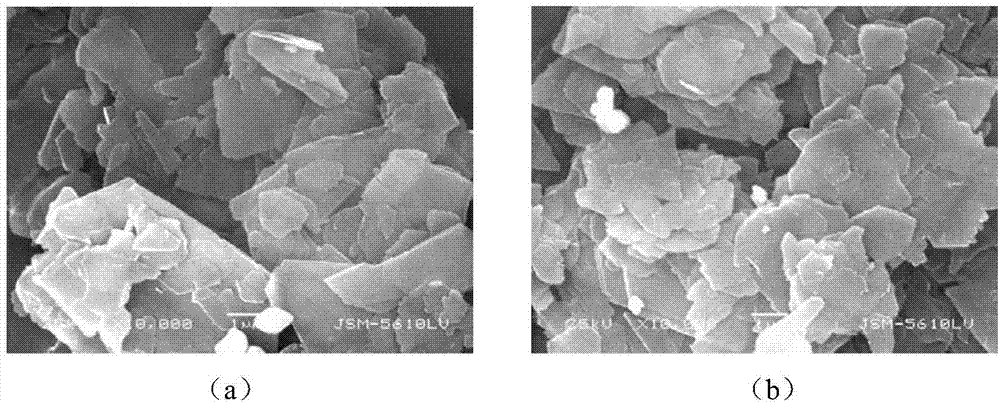

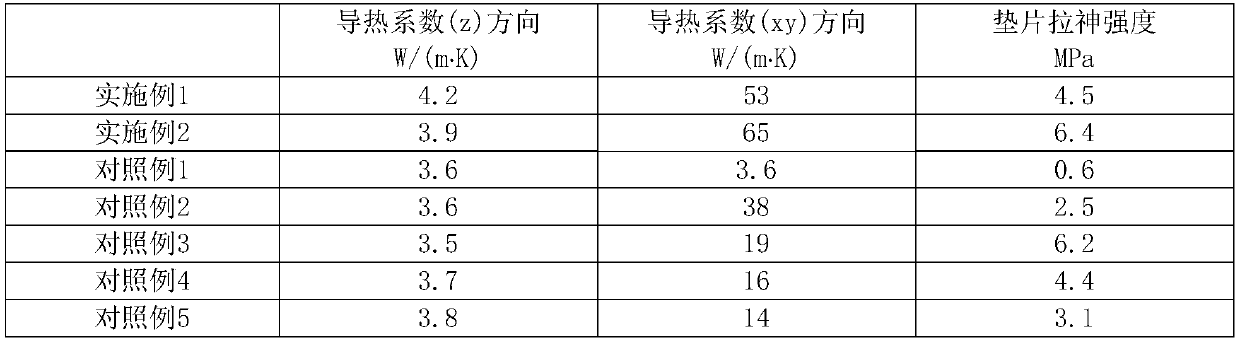

Graphene material directional arrangement and silica gel pad composite molding method and product

ActiveCN110157196AImprove thermal conductivityAvoid defects such as falling offVulcanizationHydrogen

The invention provides a graphene material directional arrangement and silica gel pad composite molding method and a thermally conductive silica gel pad product. A graphene powder material is wetted and dispersed and surface modified by adopting an organic volatilizable dilution solvent and a coupling agent. The obtained graphene dispersion liquid is added to the upper surface of a substrate pad in a spraying or coating mode. With volatilization of the organic dilution solvent, graphene can realize good directional arrangement, and excellent thermal conductivity and soaking performance of thethermally conductive pad are realized. Meanwhile, in a high-temperature vulcanization process, the coupling agent containing unsaturated groups adsorbed on the surface of graphene can generate crosslinking reaction with hydrogen-containing silicone oil and vinyl on the surface of the pad, thereby realizing firm connection between the graphene material and the raphene material directional arrangement and silica gel pad composite molding method and pad and solving the problems of defects such as insufficient strength, easy occurrence of falling off and the like in the bonding process of the graphene and the thermally conductive silica gel pad in the prior art.

Owner:中科热科技江苏有限公司

Polyvinyl chloride function modifier and its prepn process

The present invention discloses one kind of polyvinyl chloride function modifier and its preparation process. The modifier is prepared with polyhydric alcohol borate ester, polyhydric alcohol salicylate ester and acrylate as processing assistant, and oxide homopolymer or oxidized polyethylene wax. The modifier has the functions of coupling agent, dispersant, internal and external lubricant, processing assistant, etc. and has unique PVC / CaCO3 stuffing system modifying effects, including promoting plasticization, raising dispersivity, improving antiageing and machining performance, realizing high stuffing, etc.

Owner:NANJING CONCORD FERTILIZER CHEM

Catalytic ion reduction and anaerobic hydrolytic acidification cooperated industrial wastewater pretreatment method

InactiveCN101348314AImprove efficiencyAccelerated corrosionTreatment with anaerobic digestion processesMultistage water/sewage treatmentIonChemistry

The invention belongs to a wastewater treatment technology, relating to a method for coordinated pretreatment of nondegradable industrial wastewater by means of catalyzed iron reduction and anaerobic hydrolysis acidification. The method comprises the following steps: step 1, a catalytic iron filter material is prepared and pressed into a unitized catalytic iron filter material; step 2, a common anaerobic hydrolysis-acidification reaction tank is arranged; step 3, the catalytic iron filter material is put in the anaerobic hydrolysis-acidification reaction tank; and step 4, sewage is fed into the anaerobic hydrolysis-acidification reaction tank, flows through the catalytic iron filter material and is discharged, and the hydraulic residence time is between 3 and 8 hours for anaerobic hydrolysis-acidification reaction. The method not only removes poisonous functional group of poisonous contaminant so as to reduce the toxic action on anaerobe generated by the poisonous contaminant, but also hydrolyzes nonbiodegradable contaminant into easily biodegradable small molecular substance; therefore, the method improves the comprehensive biodegradability of wastewater, and has the advantages of high treatment efficiency and excellent treatment effect.

Owner:ZHENJIANG WATER IND CORP +1

Easy-to-disperse sericite for cosmetics and preparation method thereof

InactiveCN104761932AStrong compatibilityImprove the effect of surface modificationPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPolymethylhydrosiloxaneSurface finishing

The invention relates to the technical field of nonmetal ore mineral materials and organic surface treatment. Easy-to-disperse sericite for cosmetics is characterized in that the sericite for cosmetics is used as a raw material, surface modification is firstly performed on sericite powder at a low temperature by using a surface treating agent and then high-temperature ageing modification is performed to obtain easy-to-disperse sericite for cosmetics, wherein the surface treating agent is obtained by mixing a modifying agent and a dispersing agent in a mass ratio of 1 to (1-10), the modifying agent is a mixture of any two or three of N-octyl triethoxysilane, polymethylhydrosiloxane and polydimethyl siloxane; the dispersing agent is isopropanol. The easy-to-disperse sericite for cosmetics prepared by the method is good in dispersion, excellent in glossiness, refreshing in skin feel and good in ductility, is in good fit with skin, can meet special needs of high-grade cosmetics and can be used as body pigments for being widely applied to various cosmetics fields.

Owner:WUHAN UNIV OF TECH +1

Curable composition containing silicon-containing highly-branched polymer

InactiveUS20150299500A1Fine particle-like behaviorImprove solubilityRadiation applicationsSynthetic resin layered productsSpray coatingLipophilicity

There is provided a hard coat layer-forming composition that can form a surface excellent in smoothness and lipophilicity (fingerprint resistance) and that enables the formation of a smooth surface maintaining lipophilicity even by spray coating and having no uneven coating. A curable composition including: 0.01 to 10 parts by mass of a specific lipophilic highly branched polymer (a); 0.0001 to 1 part by mass of a specific silicon-containing highly branched polymer (b); 100 parts by mass of an active energy ray curable polyfunctional monomer (c); and 0.1 to 25 parts by mass of a polymerization initiator that generates radicals by an active energy ray (d). A cured film obtained from the composition. A laminate obtained by use of the composition.

Owner:NISSAN CHEM IND LTD

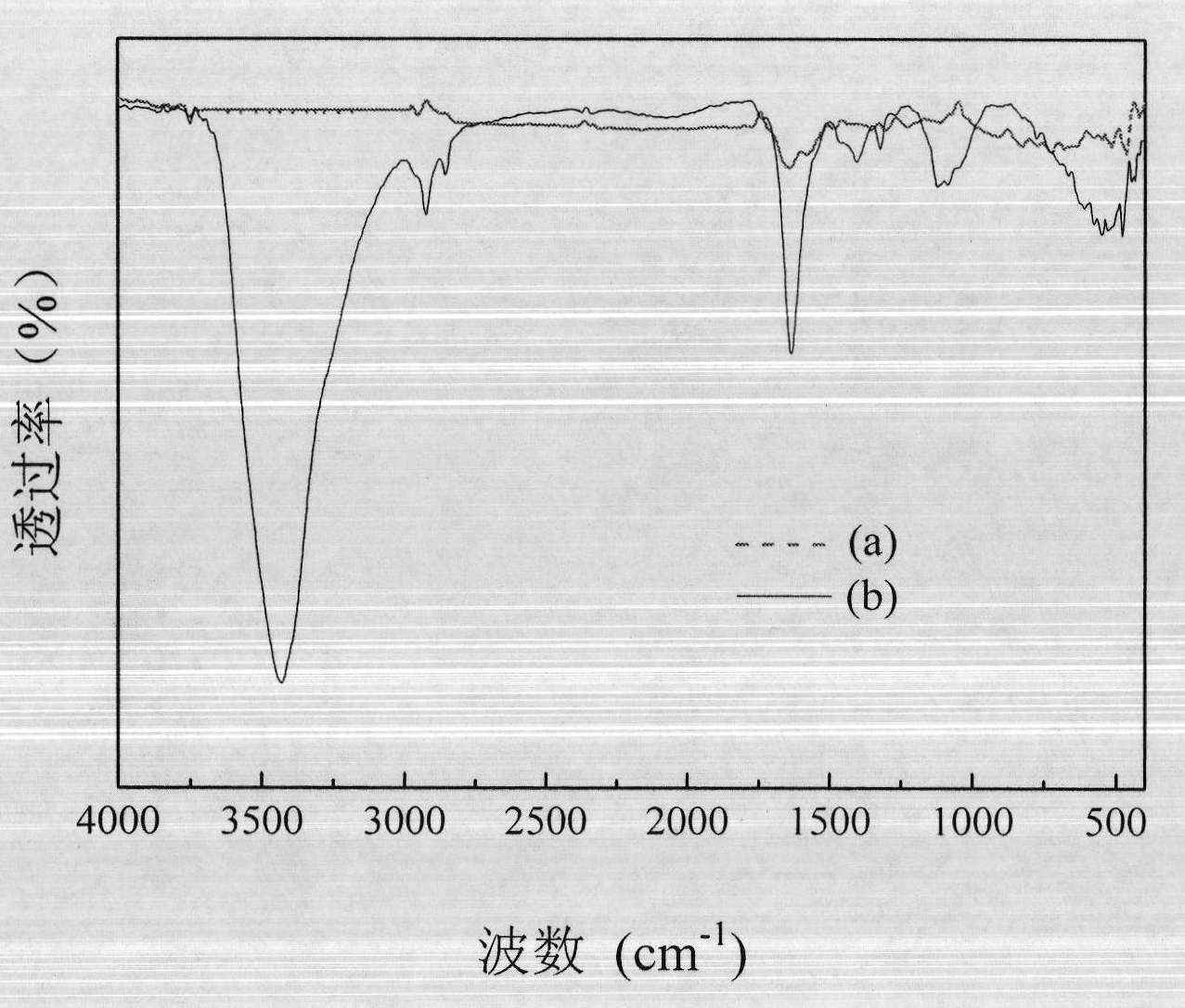

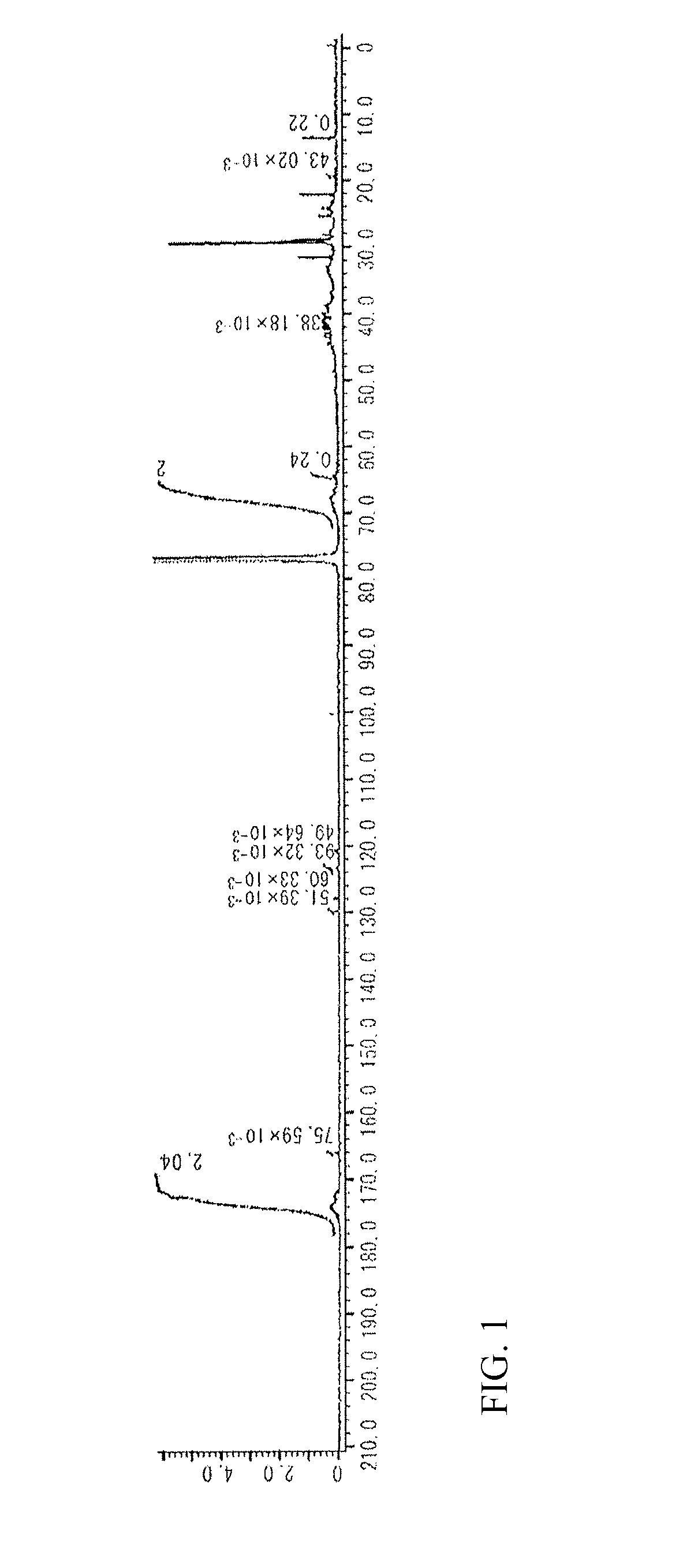

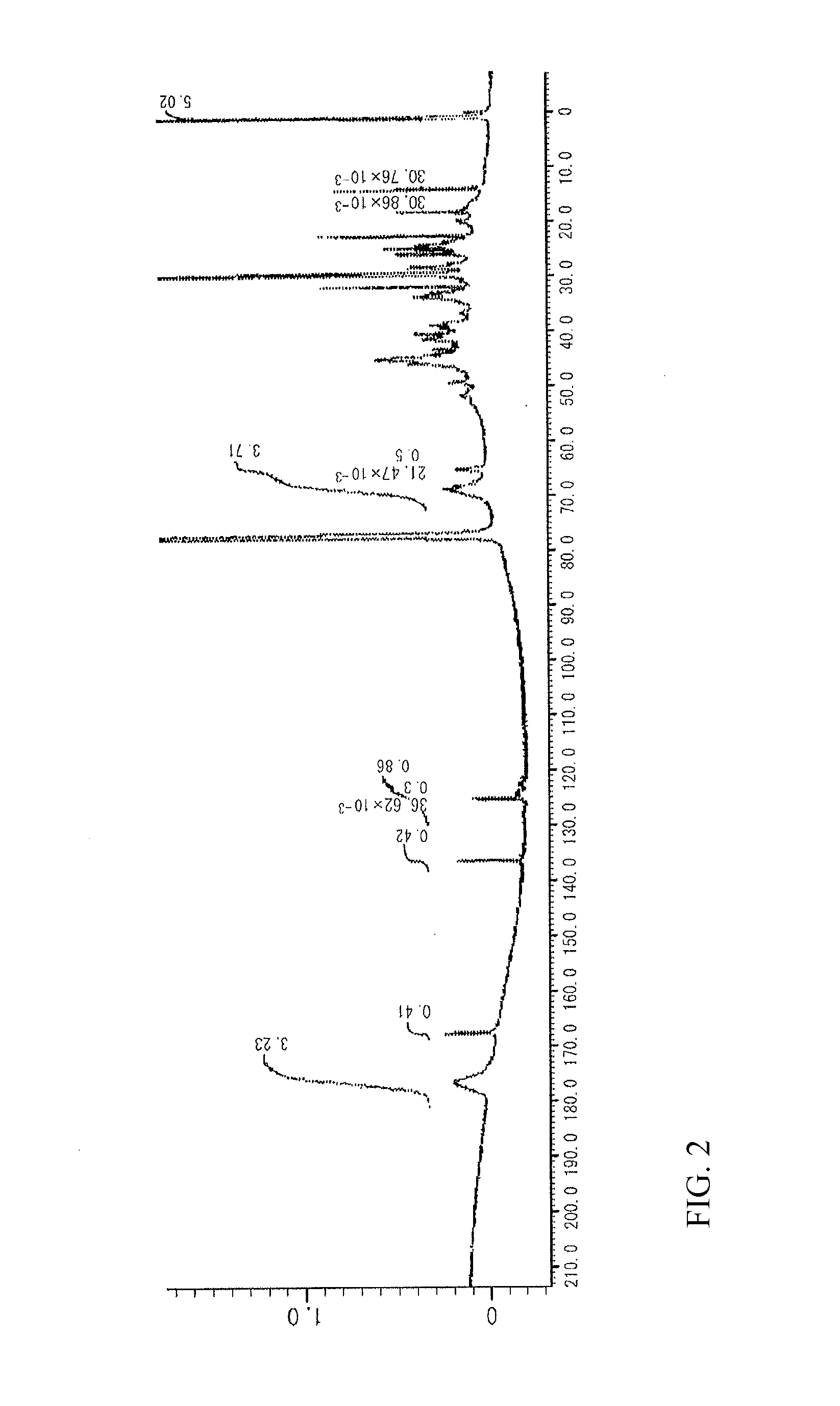

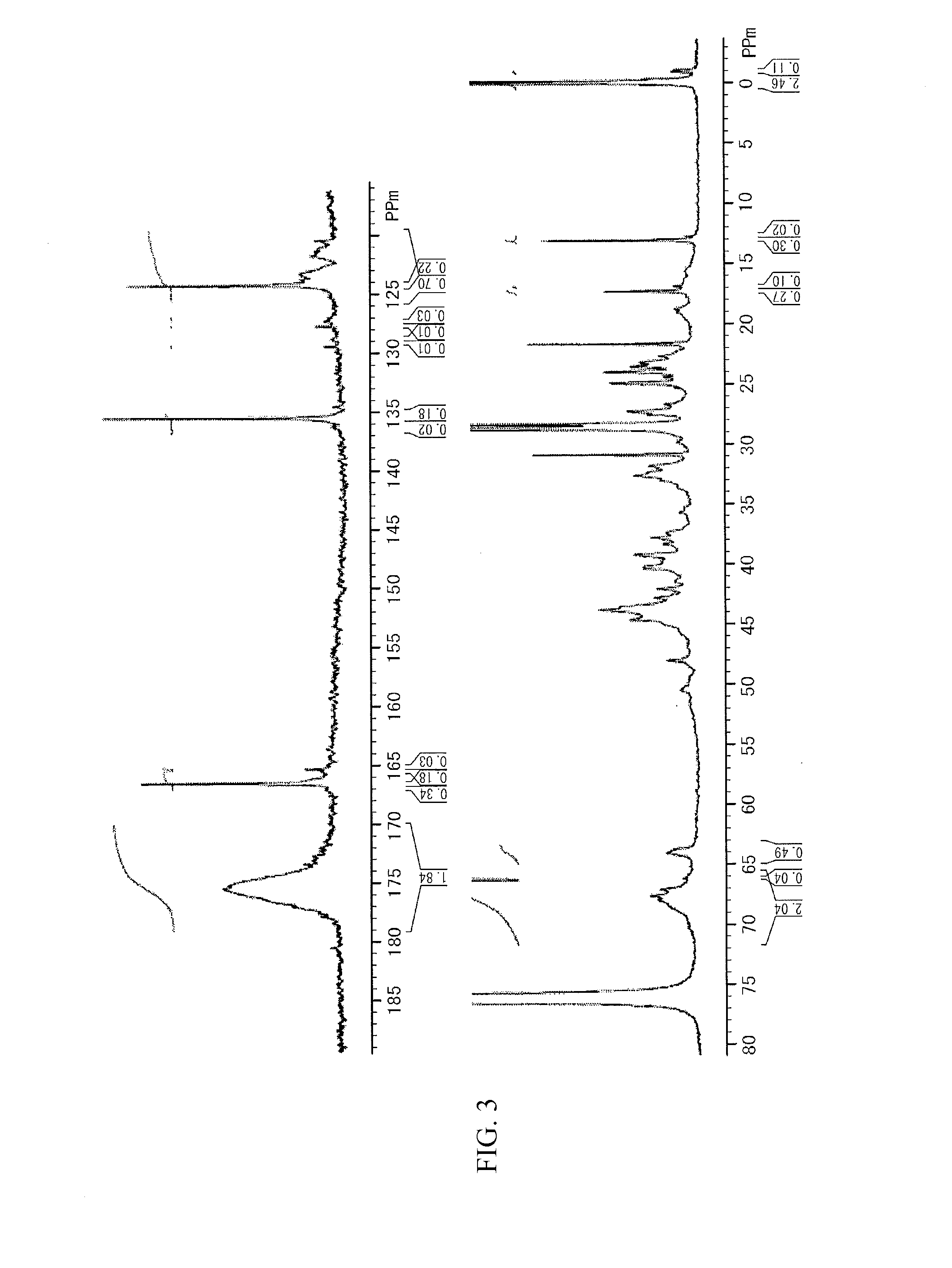

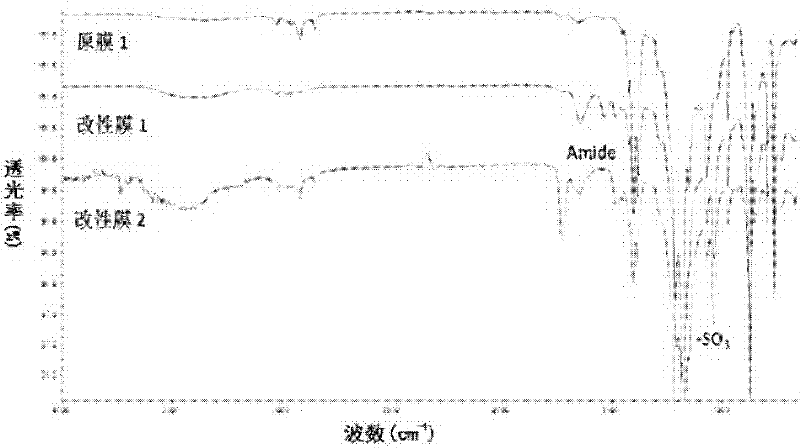

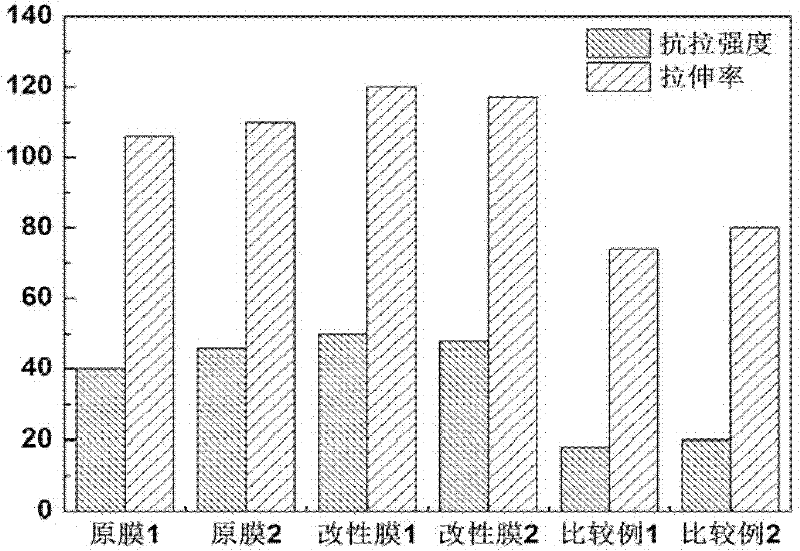

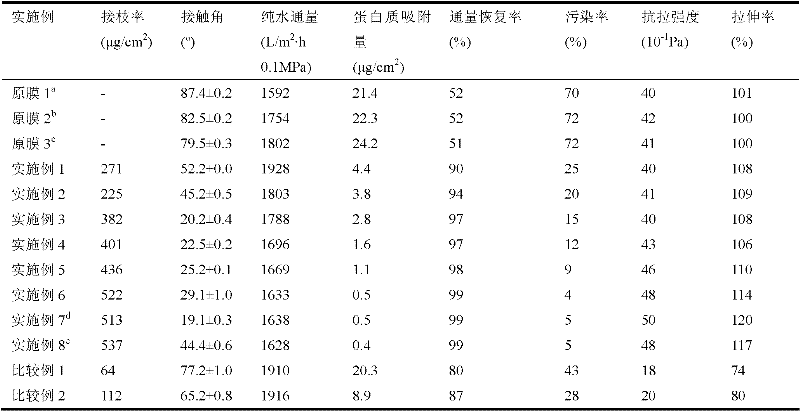

Method for modifying polyvinylidene fluoride microporous film to be protein contamination resistant

ActiveCN102516584AGood effectSignificant technological progressFibre typesProtein solutionFiltration

The invention relates to a method for modifying a polyvinylidene fluoride microporous film to be protein contamination resistant, which forms a zwitter ion copolymer layer on polyvinylidene fluoride surface through two-stage polymerization grafting method. The method specifically comprises allowing atom free radical polymerization of olefine acid hydroxyl ester compounds on the surface of a polyvinylidene fluoride microporous film, placing the film in a mixed solution containing zwitter ions, and allowing alkali metal ion-induced copolymerization, so as to obtain the polyvinylidene fluoride microporous film with protein contamination resistance. The modified polyvinylidene fluoride microporous film obtained by the method of the invention has enhanced hydrophilicity and strength, and the flux recovery rate after protein solution filtration is over 97%.

Owner:TSINGHUA UNIV

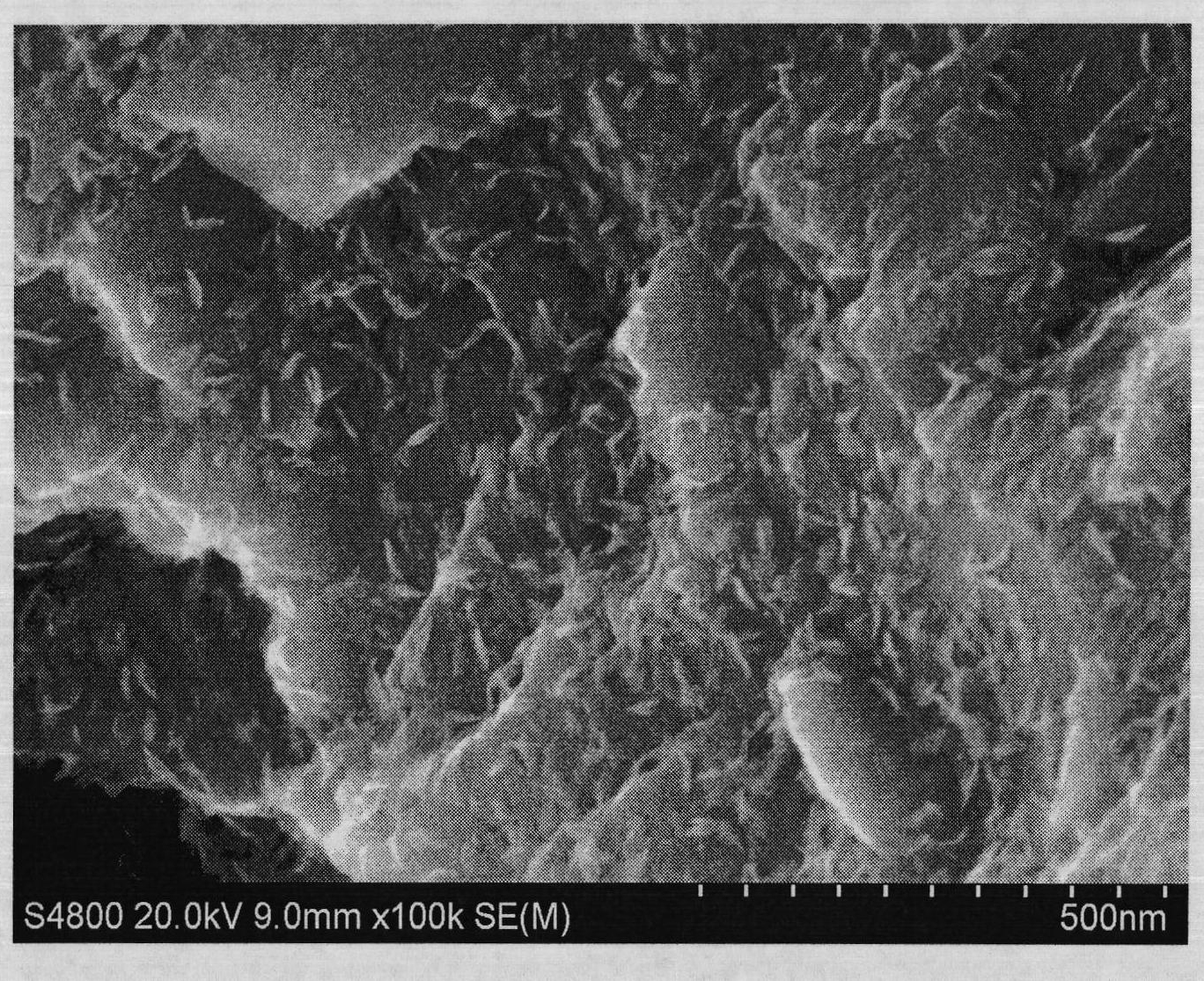

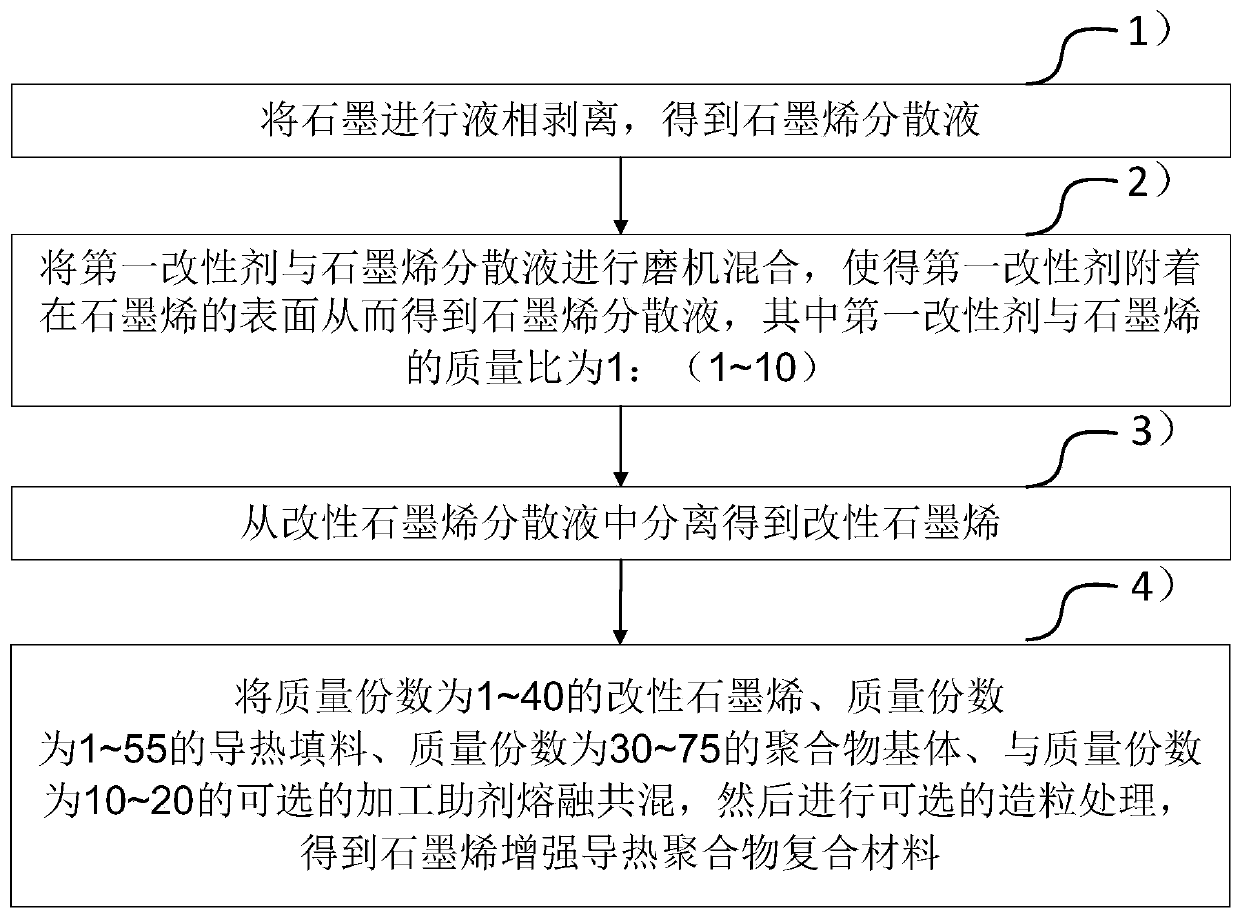

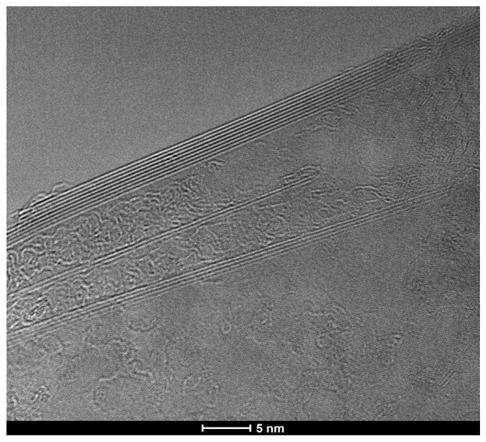

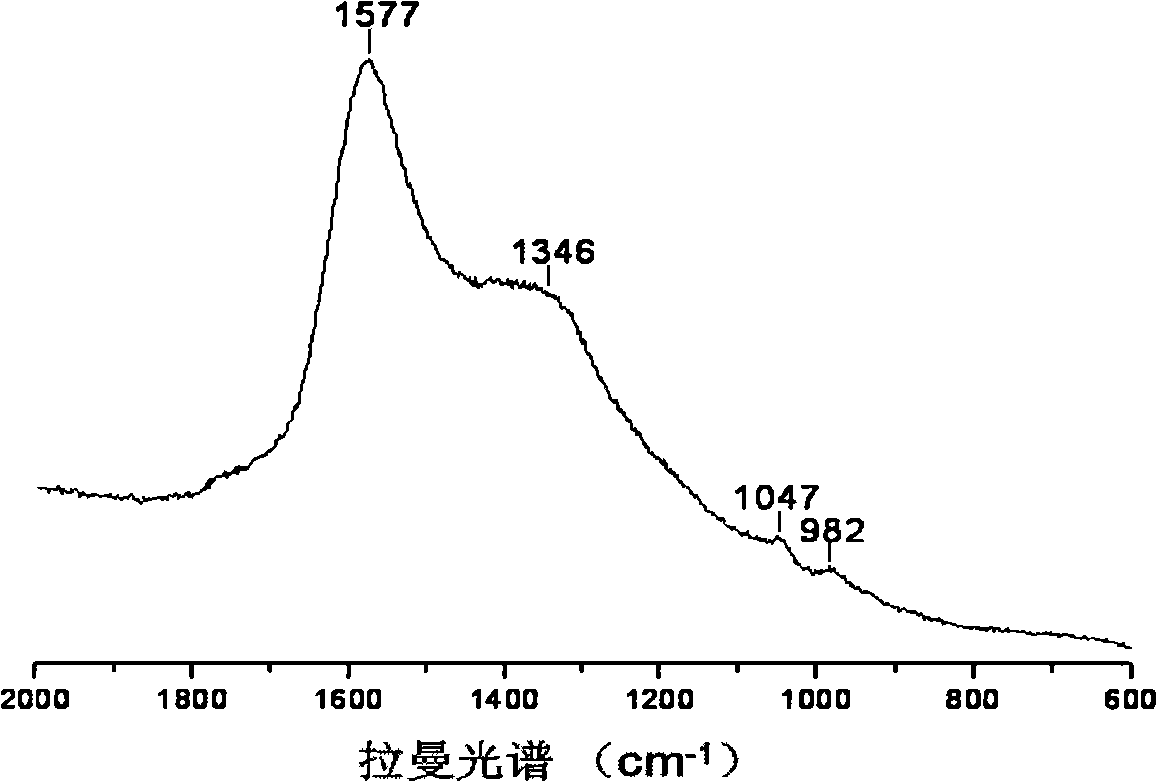

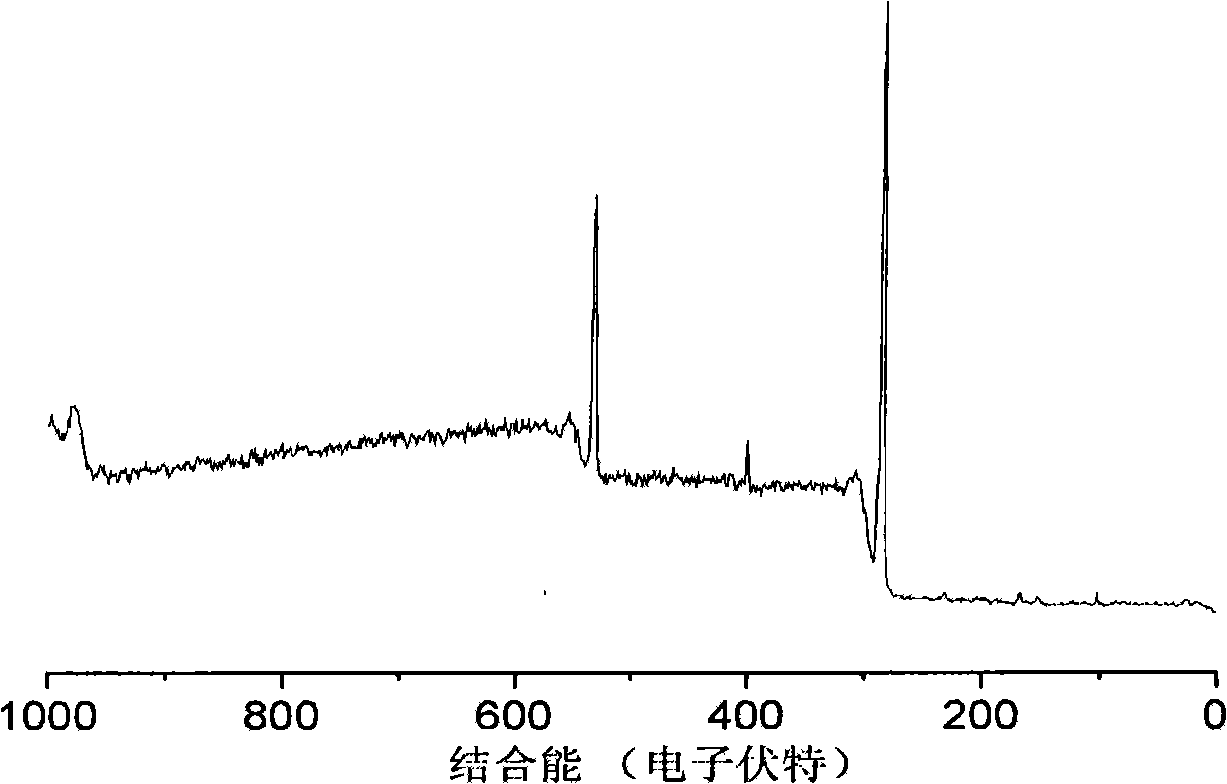

Graphene-reinforced heat-conducting polymer composite material and preparation method thereof and heat-conducting product

ActiveCN111205558AEvenly dispersedSave scattered timeHeat-exchange elementsPolymer compositesGraphene

The invention discloses a graphene-reinforced heat-conducting polymer composite material and a preparation method thereof and a heat-conducting product, relates to the technical field of heat-conducting materials, and is used for improving the dispersity of graphene in the graphene-reinforced heat-conducting polymer composite material, so that the graphene composite material has relatively good heat-conducting property. The preparation method of the graphene reinforced heat-conducting polymer composite material comprises the following steps: carrying out liquid-phase stripping on graphite to obtain a graphene dispersion liquid; mixing the first modifier with the graphene dispersion liquid by a mill to obtain modified graphene dispersion liquid; separating from the modified graphene dispersion liquid to obtain modified graphene; and carrying out melt blending on the modified graphene, a heat-conducting filler, a polymer matrix and a processing aid to obtain the graphene reinforced heat-conducting polymer composite material. The graphene-reinforced heat-conducting polymer composite material is prepared by the preparation method of the graphene-reinforced heat-conducting polymer composite material. The heat conduction material comprises the graphene reinforced heat conduction polymer composite material.

Owner:内蒙古信敏惠纳米科技有限公司

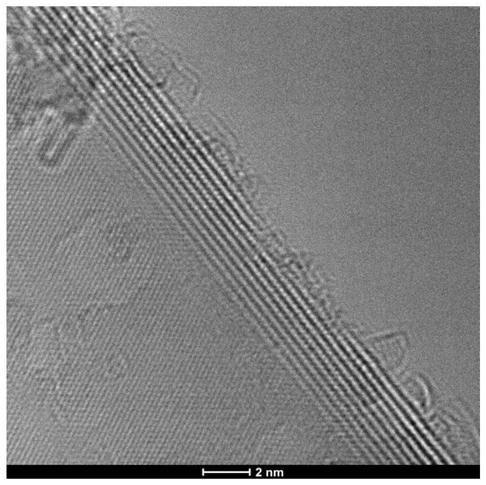

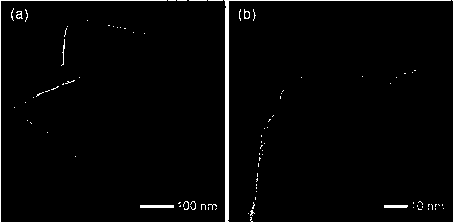

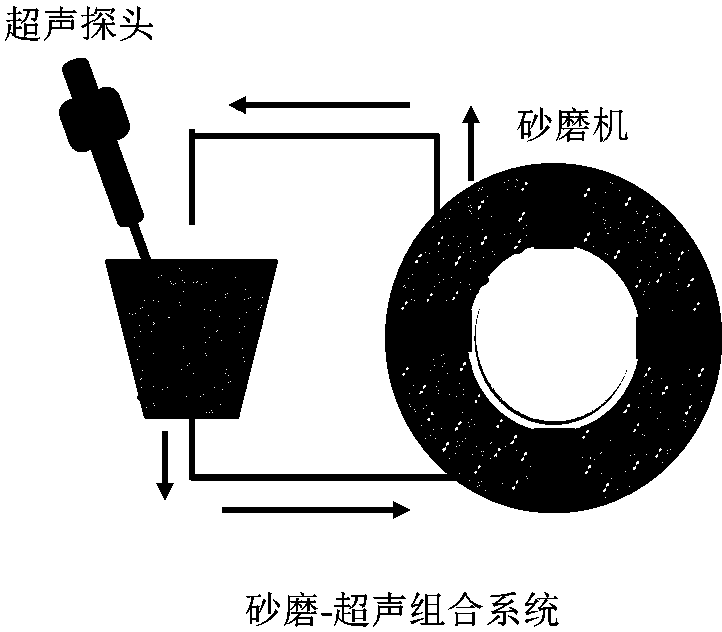

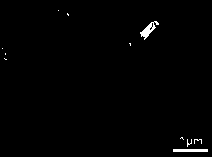

Preparation method of biomass-graded porous carbon material

ActiveCN108455600AImprove the effect of ultra-fine processingImprove the effect of surface modificationCarbon compoundsOther chemical processesSolid carbonPorous carbon

The invention particularly relates to a preparation method of a biomass-graded porous carbon material. The preparation method comprises the following steps that after pyrolytic carbonization, biomassmaterials are ground and sieved to obtain carbon-containing solid powder; after mixing the carbon-containing solid powder and a solvent, adopting ultrasonic-grinding coupling to carry out ultrafine treatment in the solvent to obtain ultrafine carbon powder; carrying out alkaline boiling, washing and drying on the ultrafine carbon powder to obtain high-purity solid carbon powder; heating and activating the high-purity solid carbon powder under the protective atmosphere to obtain an activated material; carrying out washing, acid boiling, washing and drying on the activated material to obtain thebiomass-graded porous carbon material. The preparation method has the beneficial effects that the process is simple and environment-friendly, the mass production is easy, the mesoporous / microporous structure can be accurately controlled, the adaptability in the aspect of developing biomass materials is wide, and the technical scheme is provided for comprehensive utilization of agricultural wastes.

Owner:ZHENGZHOU UNIV

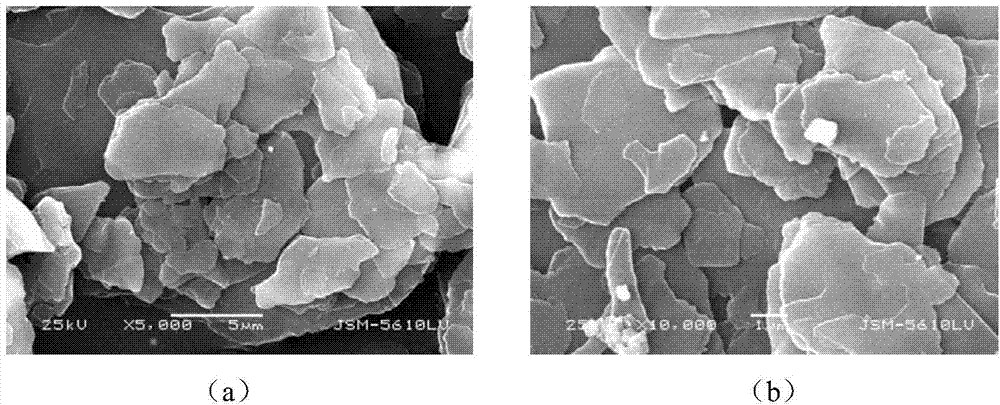

High-strength heat-conducting silica gel gasket and preparation method thereof

ActiveCN110157389AImprove thermal conductivityGood soaking functionSecondary cellsHeat-exchange elementsSolventHigh intensity

The invention discloses a high-strength heat-conducting silica gel gasket and a preparation method thereof, and the high-strength heat-conducting silica gel gasket is suitable for the fields of heat dissipation of new energy lithium batteries and the like. A carbon fiber powder material is wetted and dispersed and surface modified by adopting an organic volatilizable dilution solvent and a coupling agent. A carbon fiber dispersion liquid is brushed on the upper surface of a substrate gasket. With the volatilization of the organic dilution solvent, carbon fibers can be arranged parallel to theplane of the heat-conducting gasket, so that the high heat-conducting performance of the carbon fiber material along the fiber axial direction is exerted, and the gasket has a good heat equalizing function in the plane direction of the gasket. The directionally arranged carbon fiber material can play a role similar to skeleton strengthening and greatly improve the etching and tearing and other mechanical properties of the gasket. In the high-temperature vulcanization process, the coupling agent which contains unsaturated groups and is bonded on the surface of the carbon fibers by chemical bonds can generate crosslinking reaction with hydrogen-containing silicone oil and vinyl on the surface of the gasket, thereby realizing firm connection between the carbon fiber material layer and the gasket and facilitating subsequent calendaring processing.

Owner:中科热科技江苏有限公司

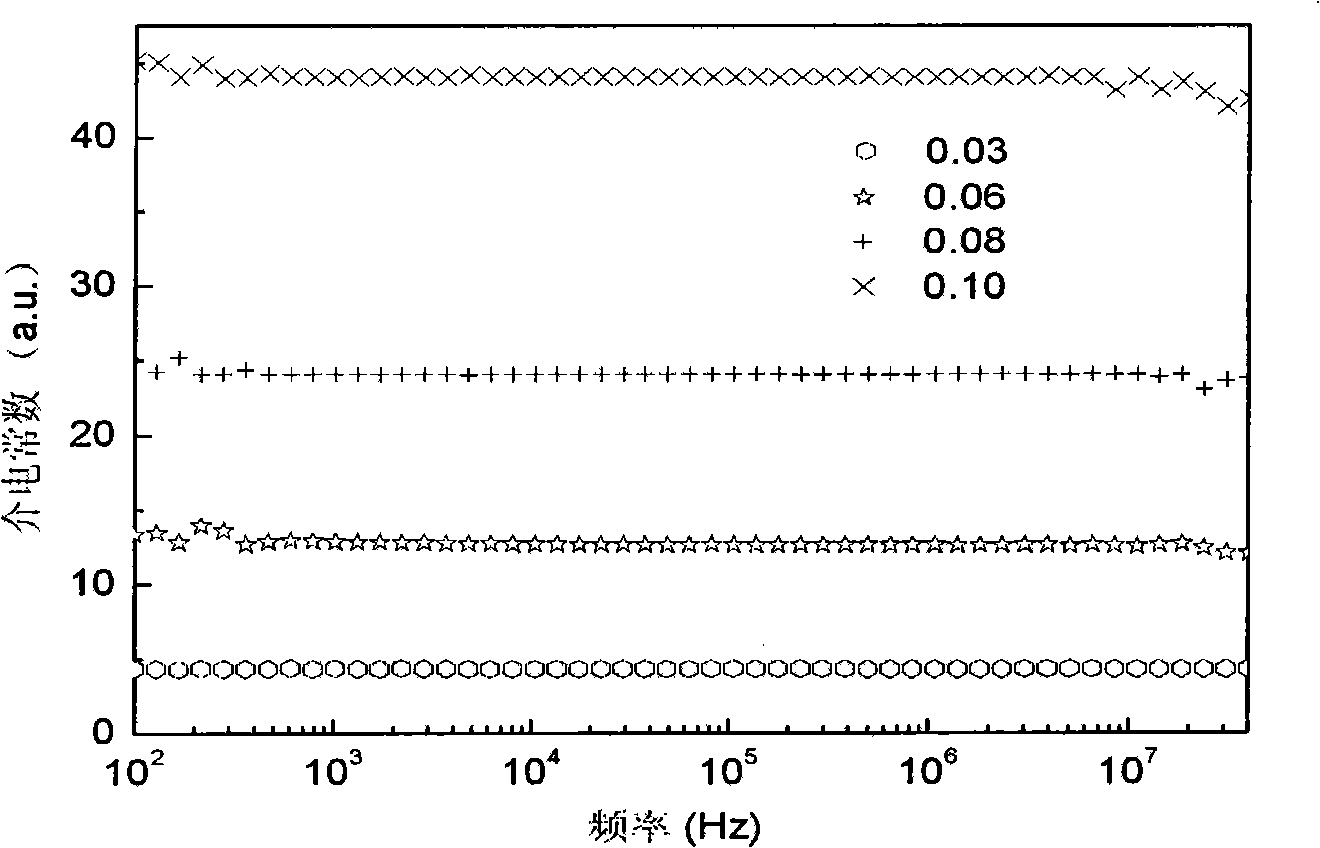

Polymer-based high energy storage density material and preparing method thereof

InactiveCN101323692AHigh energy storage densityLow energy storage densityFixed capacitor dielectricHigh energyPolystyrene

The invention discloses a polymer-based material with high density of energy storage and a preparation method thereof, pertaining to the technical field of the preparation of dielectric materials and energy storage materials. The polymer-based material with high density of energy storage comprises carbon nanotube materials and polymer matrix materials which are modified with organics by a chemical method in the proportions of 3 wt percent to 10 wt percent, and has the effects of good compatibility with the matrix, reduction in the leakage current density of the materials and dielectric loss and improvement of the dielectric constant and the breakdown field strength of the materials. The matrix material is polystyrene which is dissolved with ethyl acetate and then blended with modified carbon nanotube solution; the solution is then cast into a mould and the mould is formed by hot pressing and shaped by cold pressing. The polymer-based material with high density of energy storage of the invention is characterized by good insulation, low density, excellent toughness, low cost and easy processing, and can be applied to dielectric materials of electronic devices of information technologies, dielectric projects, electrostatic storage and capacitors.

Owner:TSINGHUA UNIV

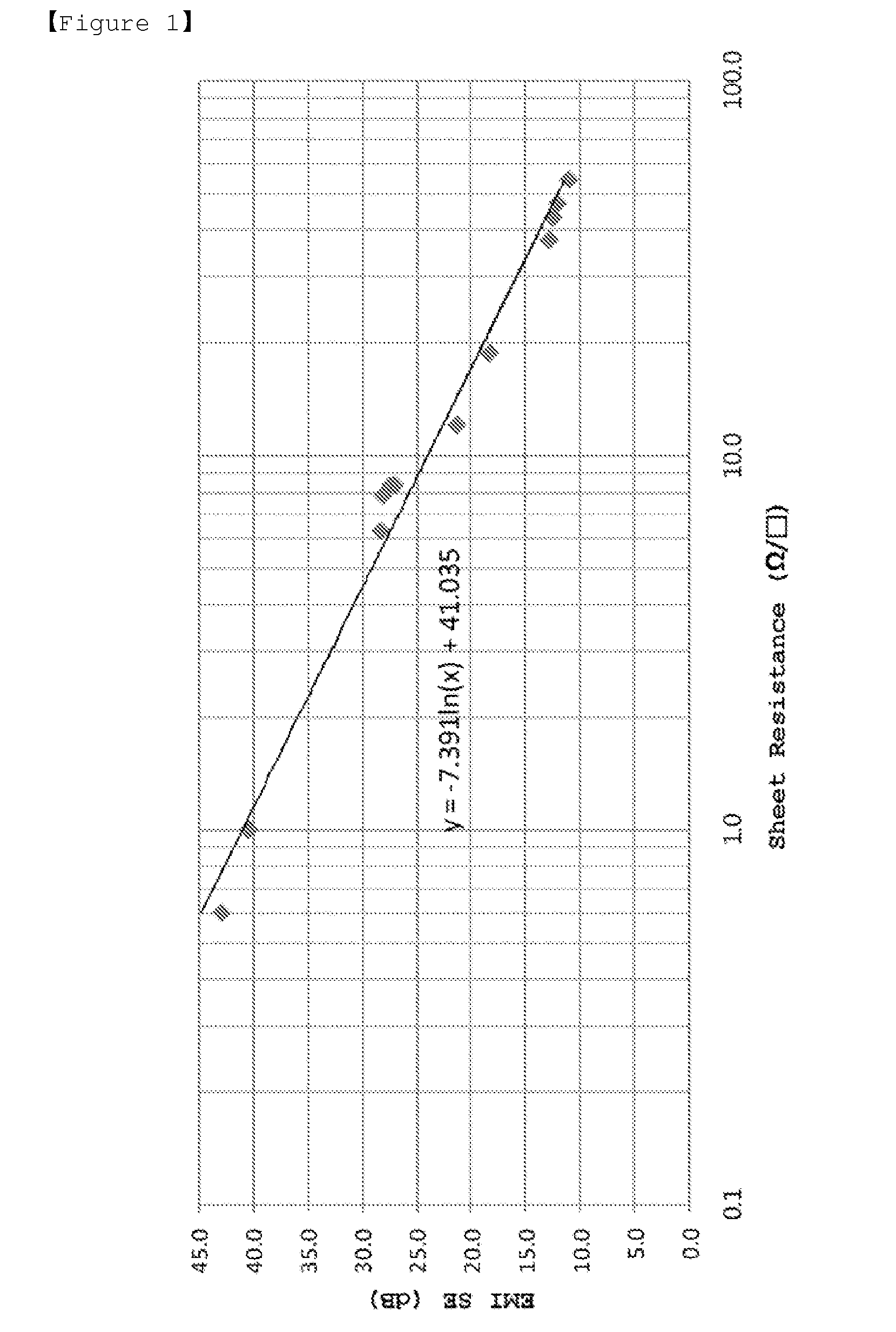

Resin composition for EMI shielding, comprising carbon hydride composite

ActiveUS20150005411A1Good dispersibilityExcellent impact relaxationNanotechShielding materialsCarbon nanotubeElectromagnetic interference shielding

Provided is a resin composition for electromagnetic interference shielding. More particularly, provided is a resin composition having superior dispersibility and impact relaxation and high conductivity, the resin comprising: (a) 100 parts by weight of a resin; based on 100 parts by weight of the resin, (b) 0.1 to 15 parts by weight of a carbon nanotube surface-modified in a condition of the absence of oxidant; and (c) 1 to 40 parts by weight of a carbon compound, a metal, a metal compound, or a mixture thereof. The resin composition for electromagnetic interference shielding, comprising a carbon hydride composite, is specifically useful in an electronic control unit material for weight reduction of car, and thus can be replaced with a high-priced heavy metal material.

Owner:HANWHA CHEMICAL CORPORATION

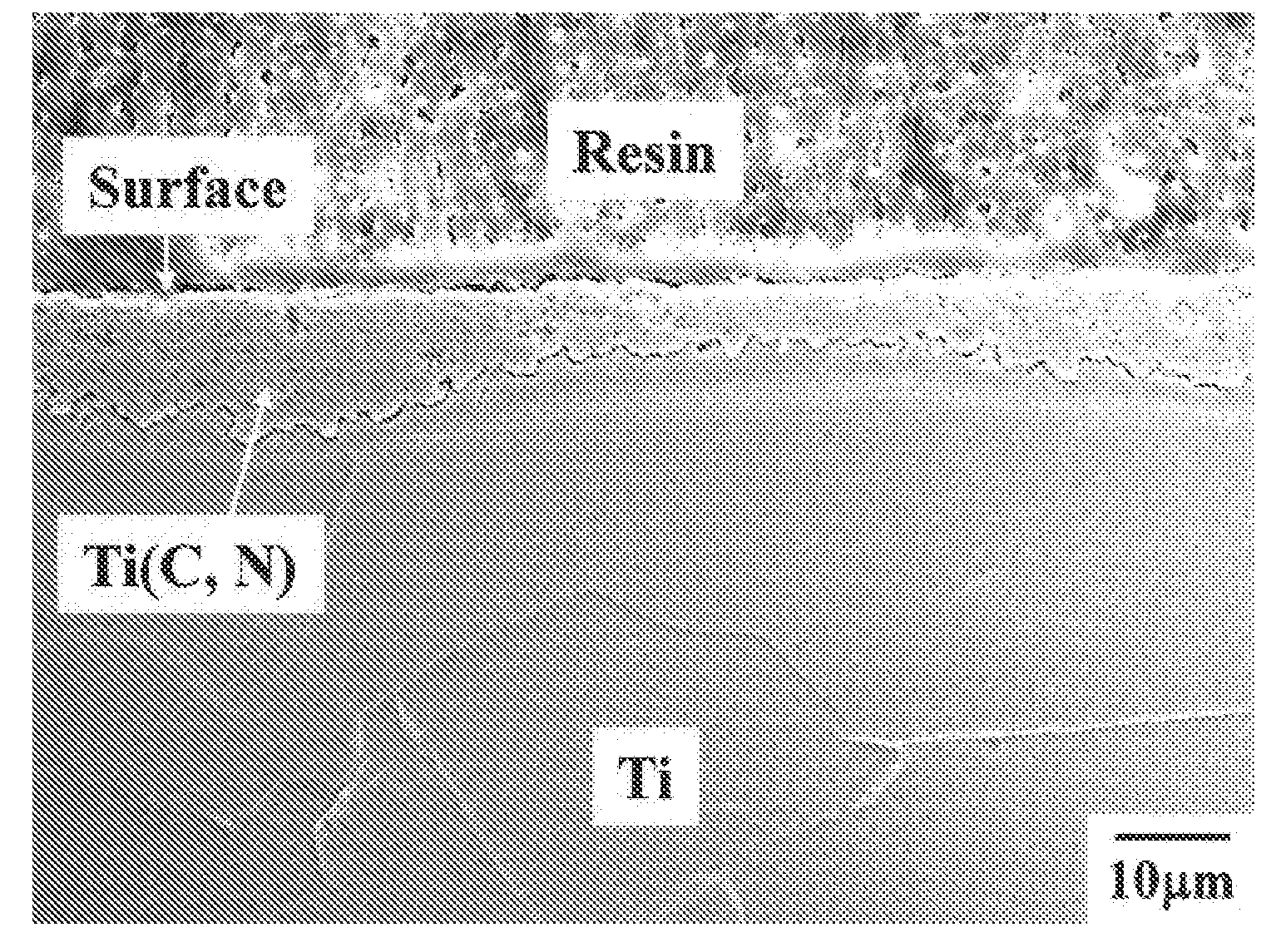

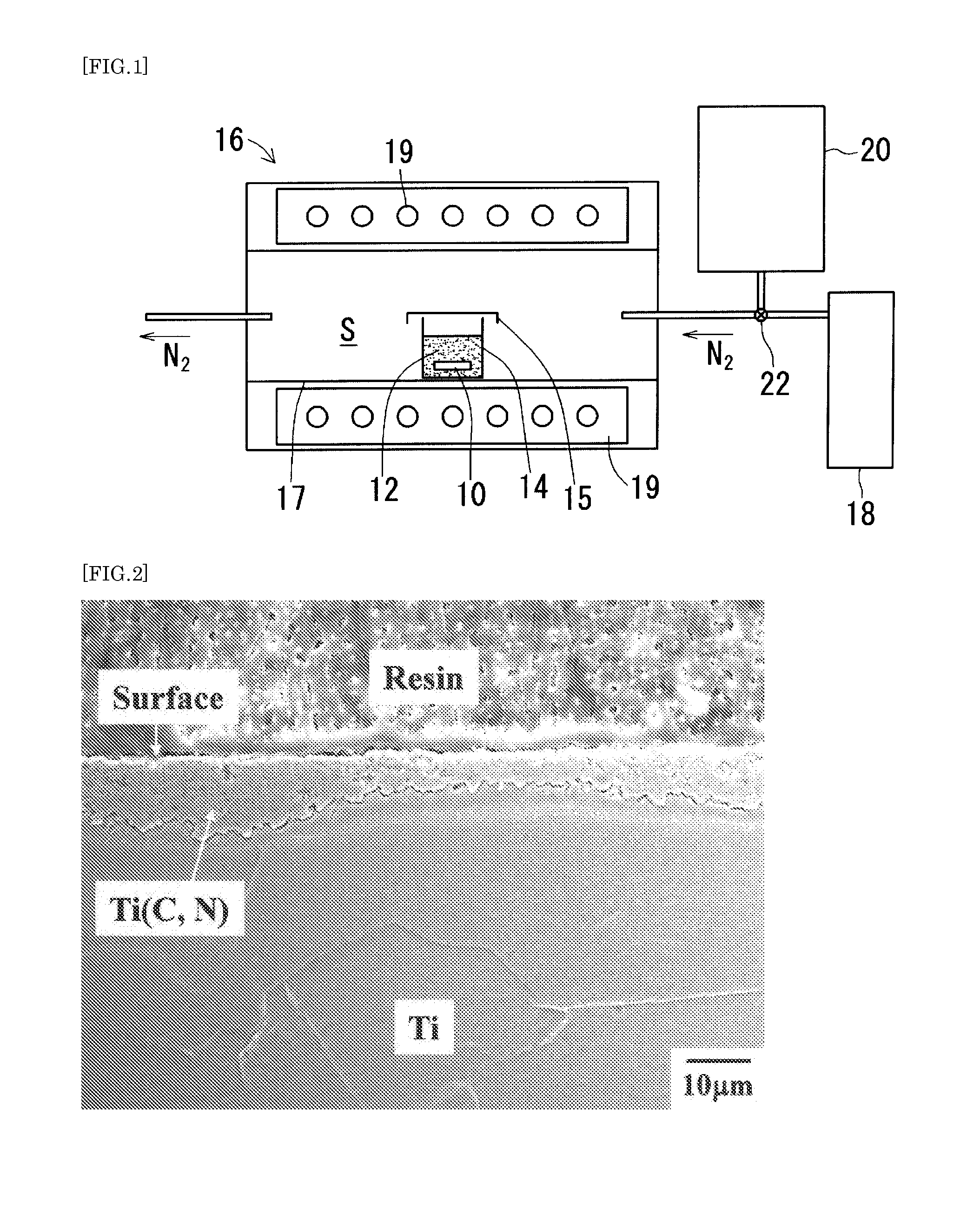

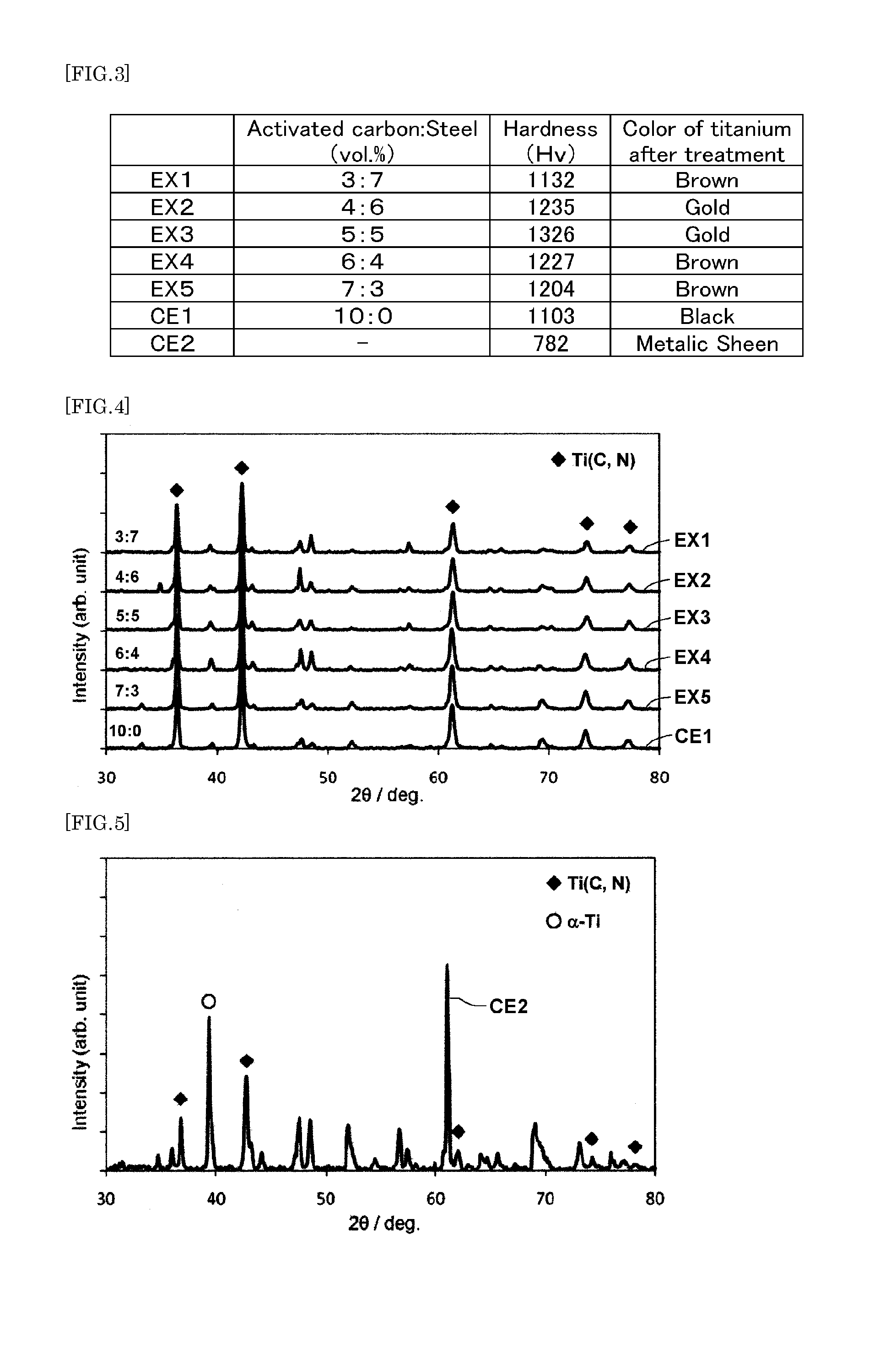

Method for treatment of metal surface, and surface-modified metal product

InactiveUS20120325373A1Improve surface propertiesLow costSolid state diffusion coatingMetal layered productsCarbon sourceNitrogen gas

Provided is a method of treating a metal surface, which can improve surface properties of a target metal, such as surface hardness and wear resistance in a simple manner and at low cost using very simple equipment alone, and which can prevent the deterioration of the metal to create high added value. The present invention is comprised of a method of treating a metal surface, characterized in that: heat-treating a target metal (10) to be surface-modified in nitrogen gas atmosphere (S), in such a state where the target metal (10) is buried in a carbon source powder (12) comprising a carbon powder and a powder of iron or an iron alloy mainly comprising iron and containing carbon, whereby the surface of the target metal (10) is at least nitrided or nitrogen-absorbed to modify the surface.

Owner:NAT UNIV CORP KUMAMOTO UNIV

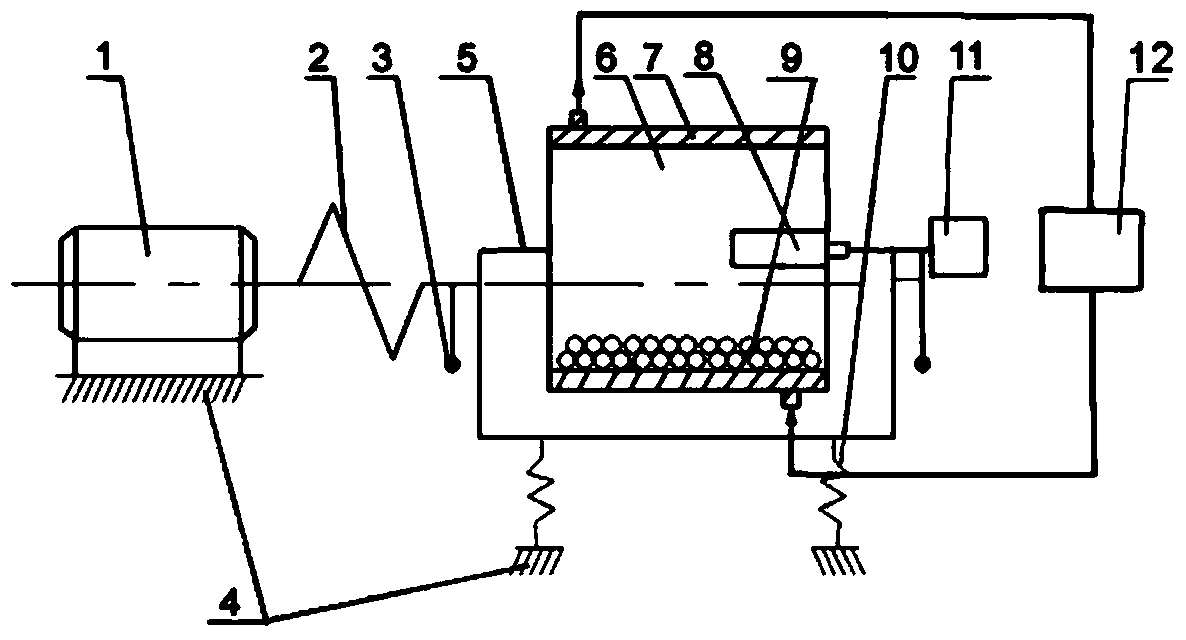

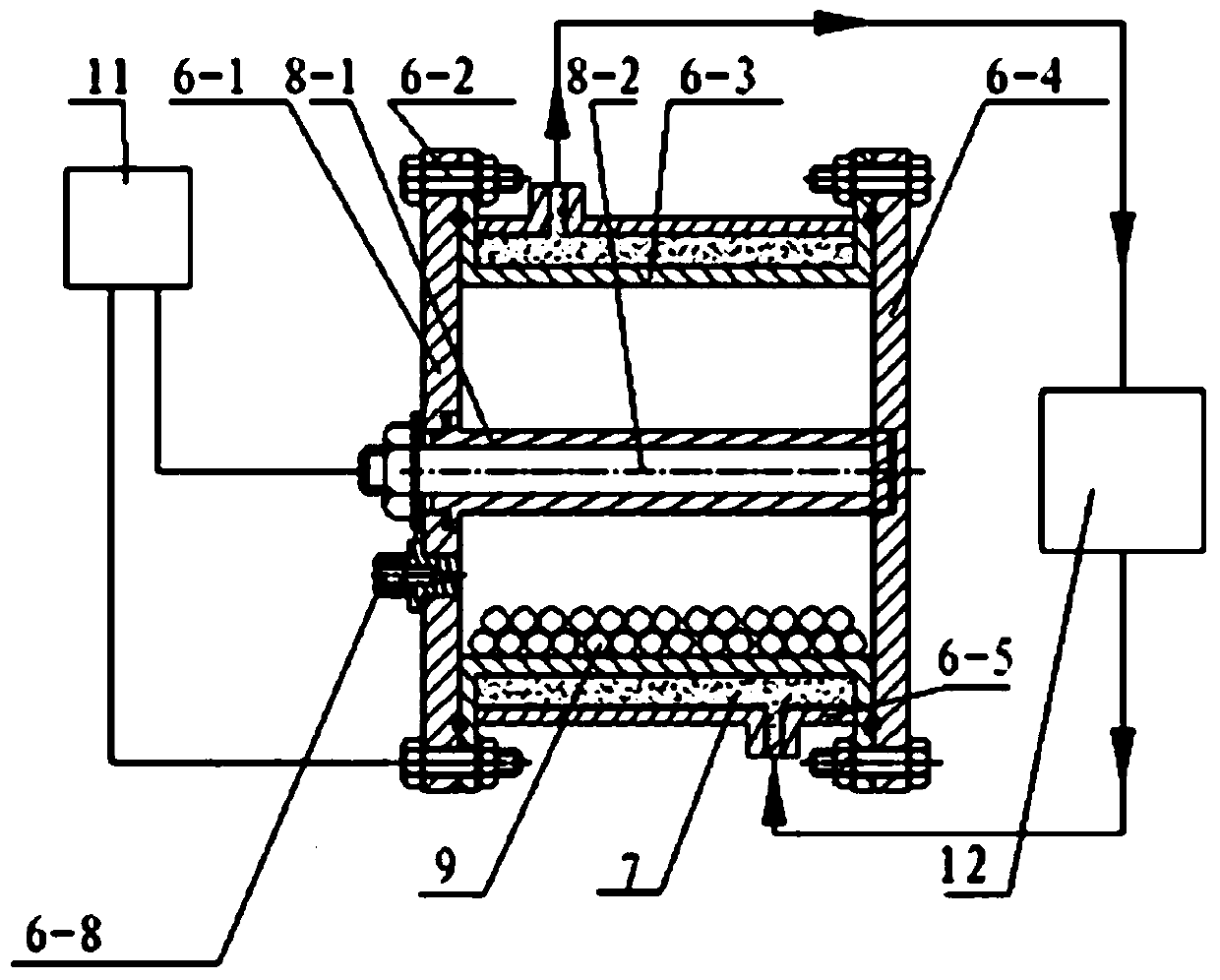

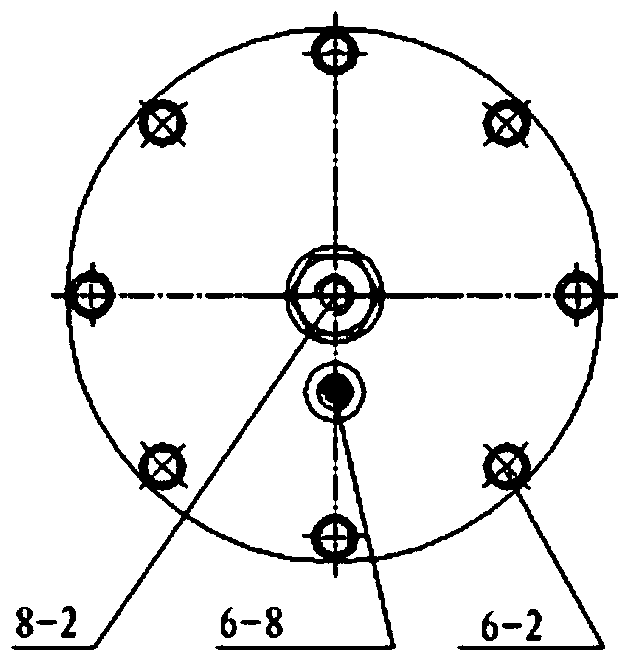

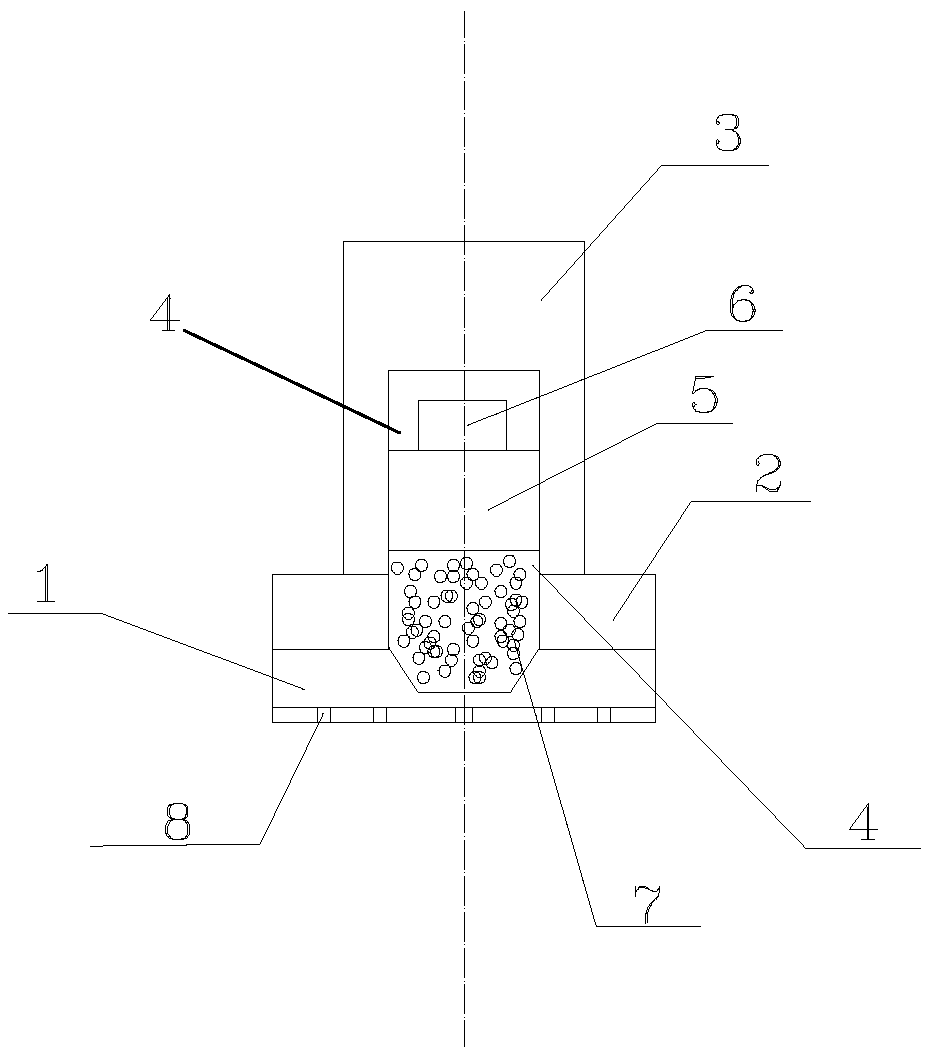

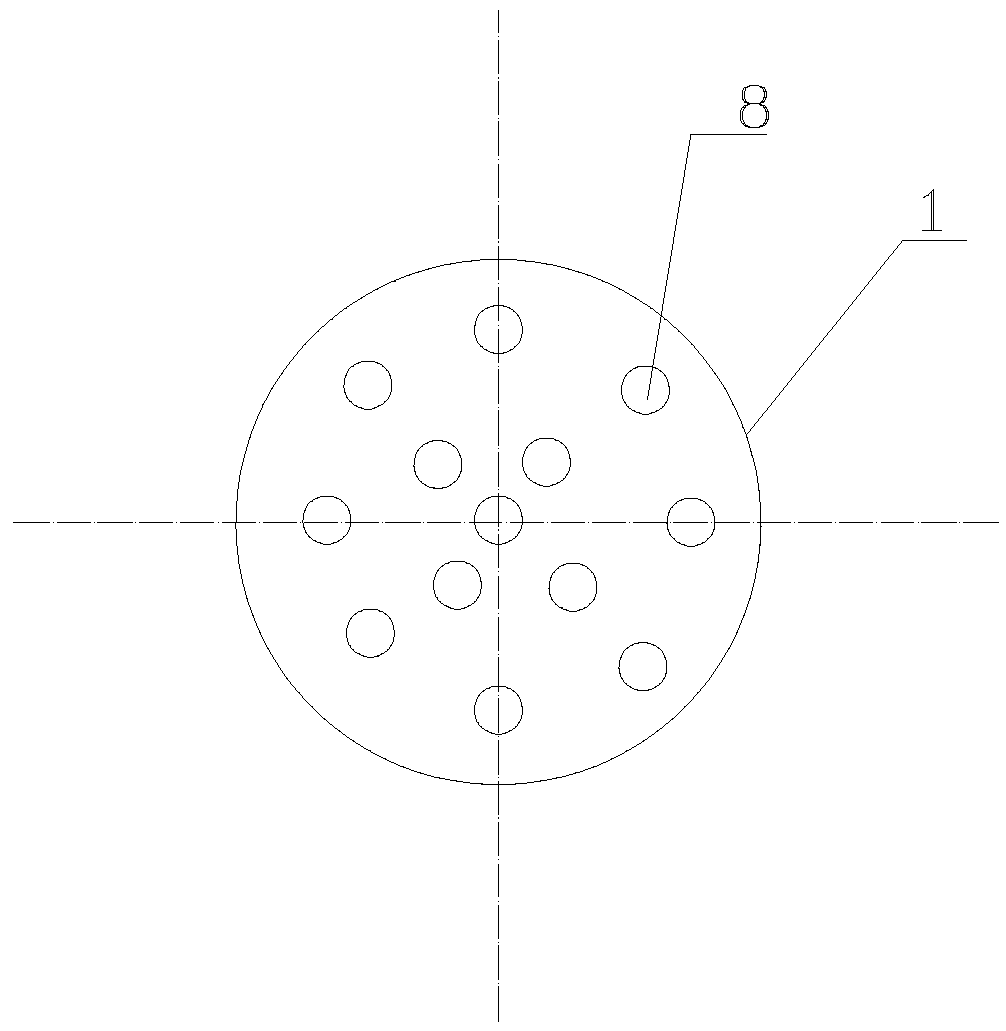

Stirring head for processing modification of stirring friction surface of surface layer of metal material

InactiveCN108406085AImprove efficiencyGood effectNon-electric welding apparatusSurface layerMetallic materials

The invention provides a stirring head for processing modification of a stirring friction surface of a surface layer of a metal material. The stirring head mainly comprises a lower shaft shoulder (1)and an upper shaft shoulder (2), wherein the lower shaft shoulder (1) and the upper shaft shoulder (2) are connected. The stirring head is characterized in that a cavity is formed inside the lower shaft shoulder (1), and small circular holes (8) are formed in the bottom of the lower shaft shoulder (1). The upper shaft shoulder (2) and a clamping handle (3) are integrated, a sliding hole (4) is formed inside the upper shaft shoulder (2), and a control component (6), a hydraulic device (5) and steel balls (7) are installed on the top of the sliding hole (4). The hole diameter of each small circular hole (8) is smaller than the diameter of the corresponding steel ball (7). By the adoption of the stirring head, the surface modification quality of the metal surface layer can be substantially improved, the modification efficiency is improved, and the modification cost is saved.

Owner:HUANGSHAN UNIV

Preparation method of high temperature resistance ultrafine active calcium carbonate

ActiveCN109943101AStable chemical anchoringRapid responseChemical industryPigment treatment with macromolecular organic compoundsMicrowaveFiltration

The invention provides a preparation method of high temperature resistance ultrafine active calcium carbonate, and relates to the technical field of preparation and processing of calcium carbonate powder. The preparation method comprises the following steps of S1, preparing an ultrafine calcium carbonate slurry; S2, adding a dispersing agent into the ultrafine calcium carbonate slurry prepared byS1, and aging for 24-144 hours to obtain an aged slurry; S3, adding a surface treatment agent to the aged slurry prepared by S2, carrying out an auxiliary catalytic reaction by microwave or / and high pressure, after the surface treatment is finished, dehydrating the slurry by pressure filtration, drying, and pulverizing to obtain the calcium carbonate. The surface treatment agent is surface-hydrophilically-treated fatty acid, and the surface treatment agent accounts for 3-5% the mass of the dry basis of the calcium carbonate. The ultrafine active calcium carbonate can maintain the activation degree at 350 DEG C, and do not volatilize and turn yellow. The ultrafine active calcium carbonate can be widely applied to products having a processing temperature of 270 DEG C or higher such as BOPP and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Nano-sheet lithium-rich cathode material and preparation method and application thereof

InactiveCN108288709AImprove efficiencyQuality improvementCell electrodesSecondary cellsCharge dischargeLithium-ion battery

The invention provides a nano-sheet lithium-rich cathode material and a preparation method and application of the nano-sheet lithium-rich cathode material. The nao-sheet lithium-rich cathode materialis prepared by combining a coprecipitation method and a solid-phase sintering method, and a used precipitate is hydroxide; the modified nanosheet lithium-rich cathode material of which the surface iscoated with metal oxides is obtained by coating transition metal oxides on the surface of the nanosheet lithium-rich cathode material by a hydrothermal method and a heat treatment method. The nano-sheet lithium-rich cathode material disclosed by the invention has small particle sizes, shortens a lithium-ion transmission channel and realizes rapid charge and discharge. The modified nano-sheet lithium-rich cathode material of which the surface is coated with the metal oxides provided by the invention has the advantages of good first-ring charge-discharge capacity, coulomb efficiency and cycle stability, excellent lithium storage performance and the like for a lithium-ion battery, and further is simple and practical in preparation method, low in cost and very good in application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

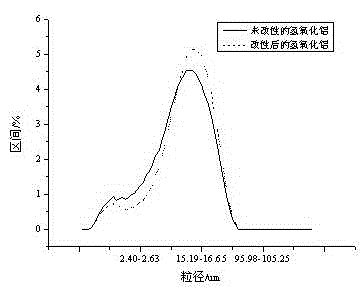

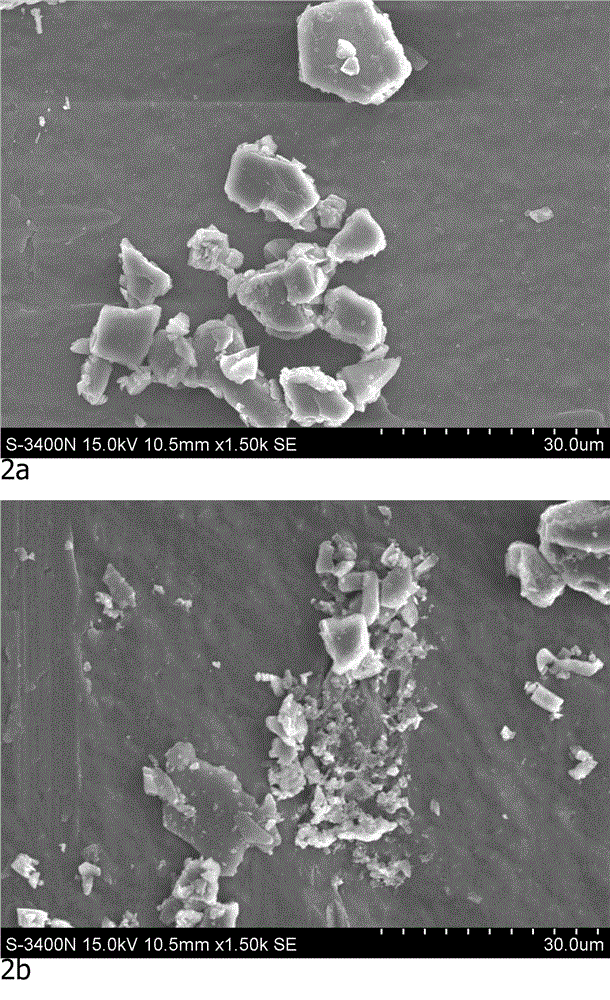

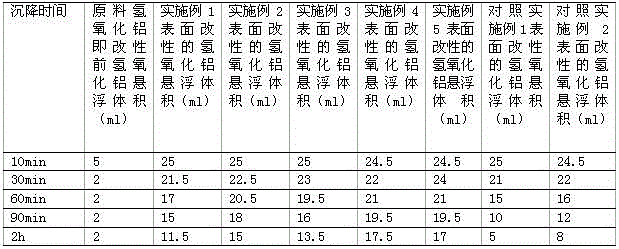

Modified aluminum hydroxide and preparation method thereof

InactiveCN104004226AReduce polarityImprove the effect of surface modificationPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSodium stearateFiltration

The invention discloses a surface-modified aluminum hydroxide and a preparation method thereof. The surface-modified aluminum hydroxide comprises, by mass, 30 parts of aluminum hydroxide and 0.3-1.2 parts of a modifier. The modifier is Span, a complex of Span and stearic acid, or a complex of Span and sodium stearate. The Span is Span 40, Span 60 or Span 85. The preparation method comprises the following steps of preparing an aluminum hydroxide aqueous suspension having a mass concentration of 10%, heating the aluminum hydroxide aqueous suspension to a temperature of 80-85 DEG C, preparing a modifier-ethanol solution having a modifier mass concentration of 1%, adding the modifier-ethanol solution into the aluminum hydroxide aqueous suspension, heating the mixed suspension to a temperature of 70-90 DEG C, keeping the temperature for 0.5-1.5h, and carrying out standing, suction filtration, washing, drying and grinding so that the surface-modified aluminum hydroxide which is conducive to uniform dispersion in a polymer base and improves base compatibility is obtained.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com